Modern construction vs. openings in beams

These ducts and pipes are usually placed underneath the soffit of the beam and, for aesthetic reasons, are covered by a suspended ceiling, thus creating a dead space. On each floor, the height of this dead space adds to the overall height of the building depending on the number and depth of ducts.

Therefore, the web openings enable the designer to reduce the height of the structure, especially with regard to tall building construction. In other words, leading to an effective economical design.

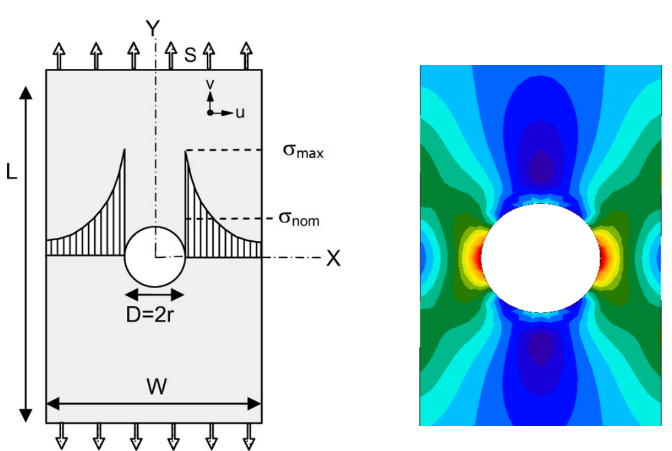

Stress concentration

The stress concentration is observed in the vicinity of the geometrical irregularities as an abrupt change of the section or the openings. It’s called generally notches. The notches create the local increase of nominal stress. The result is an unequal stress flow along the cross-section. The ratio between the maximal and the nominal stress is called the stress concentration factor. The factor is dependant on the position of the load and the geometry of the notch. The values used to be found out from the experiments. Nowadays, we are using FEA to find out the stress concentration factor.

Small vs. big openings in beams

Small openings

Openings are classified as small or big (large) and the best position of the opening is decided based on its size. Web openings may take various shapes such as circular, rectangular, diamond, triangular, trapezoidal, and even irregular shapes. However, circular and rectangular openings are the most common ones.

Openings might be considered as big when their diameter exceeds 0.25 times the depth of the web. When the opening is small enough to maintain the beam-type behavior (in other words, if the usual beam theory applies), then the opening may be termed as small.

If the load-carrying mechanism for pure bending of the beam is not changed due to opening, the flexure at the ultimate limit is not influenced.

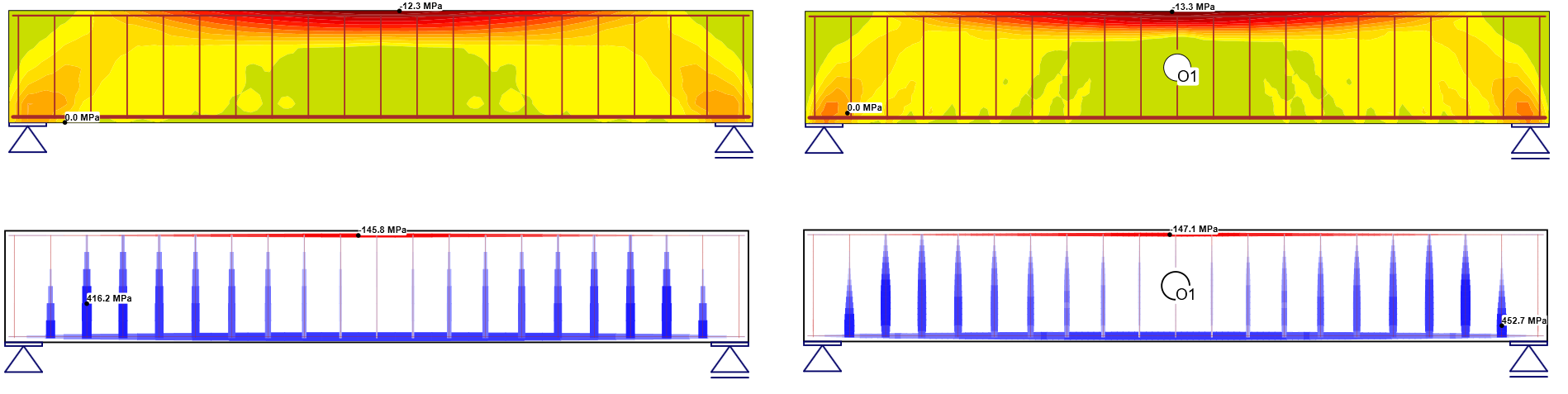

Principal stress in concrete and stress in rebars for one opening in the middle of the span

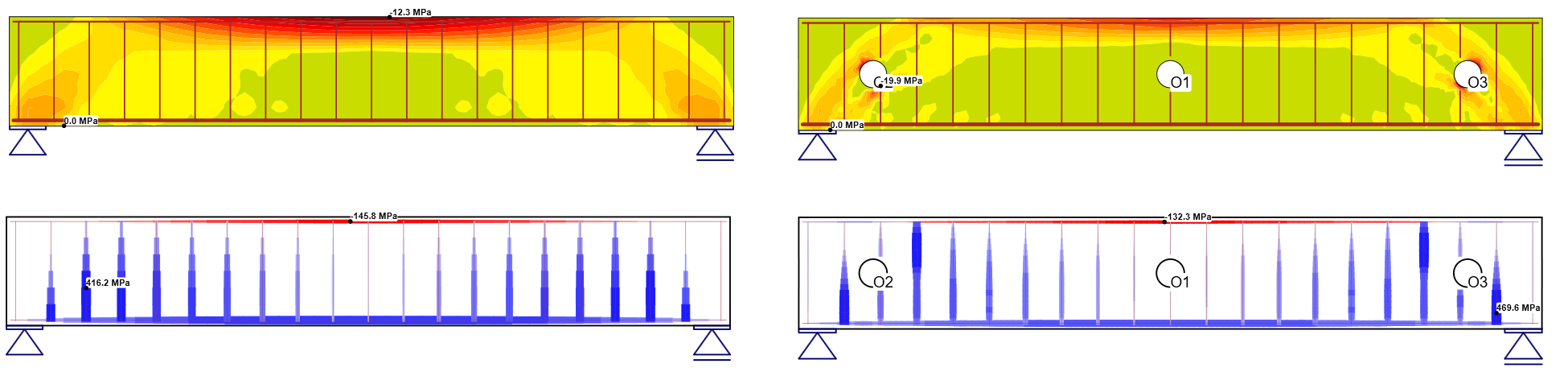

Based on the theory of elasticity, the maximal shear stress is reached around the center of the cross-section. Due to the nonlinear solution, CSFM (Compatible stress field method) can be observed in the redistribution of the stress to the zone where sufficient energy for transferring the load is persisted. It means that the openings in the vicinity of the support affect the bearing capacity more than the openings in the middle of the span where the maximal bending moment is acting.

Principal stress in concrete and stress in rebars for three openings in the critical sections for bending and shear

Big openings

The presence of big/large openings in reinforced concrete beams requires special attention in the analysis and design phase because of the reduction in both strength and stiffness of the beam and excessive cracking at the opening due to high-stress concentration. In practice, openings are located near the supports where shear is predominant.

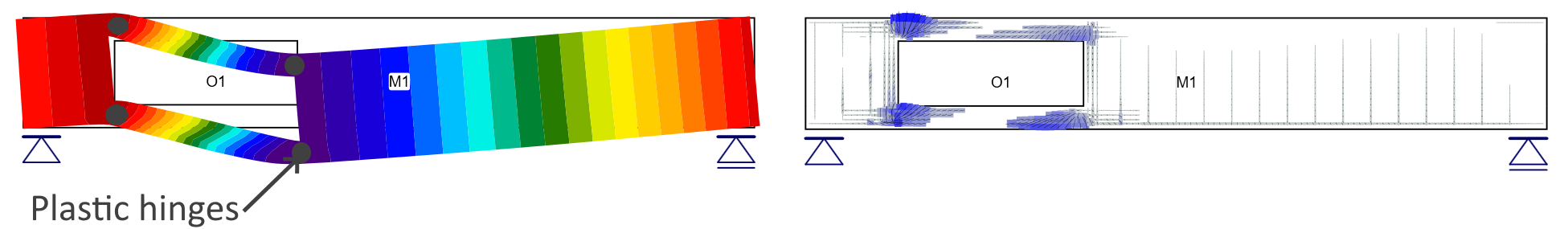

Experiments have shown that a beam with insufficient reinforcement and improper detailing around the opening region fails prematurely in a brittle manner. Clearly, the failure mechanism consists of four hinges, one at each end of the top and bottom chords.

The experimental observations of the final mode of failure developed a method of analysis for predicting the ultimate strength of a beam with a large rectangular opening. It is based on the collapse load analysis in which the basic requirements of equilibrium, yield, and mechanism are satisfied simultaneously.

Plastic hinges and cracks in the vicinity of plastic hinges

Similar to a beam with small openings, the incorporation of a large opening in the pure bending zone of a beam will not affect its moment capacity provided that the depth of the ultimate compressive stress block is smaller than or equal to the depth of the compression chord and that instability failure of the compression chord is prevented by limiting the length of the opening which should be closely analyzed.

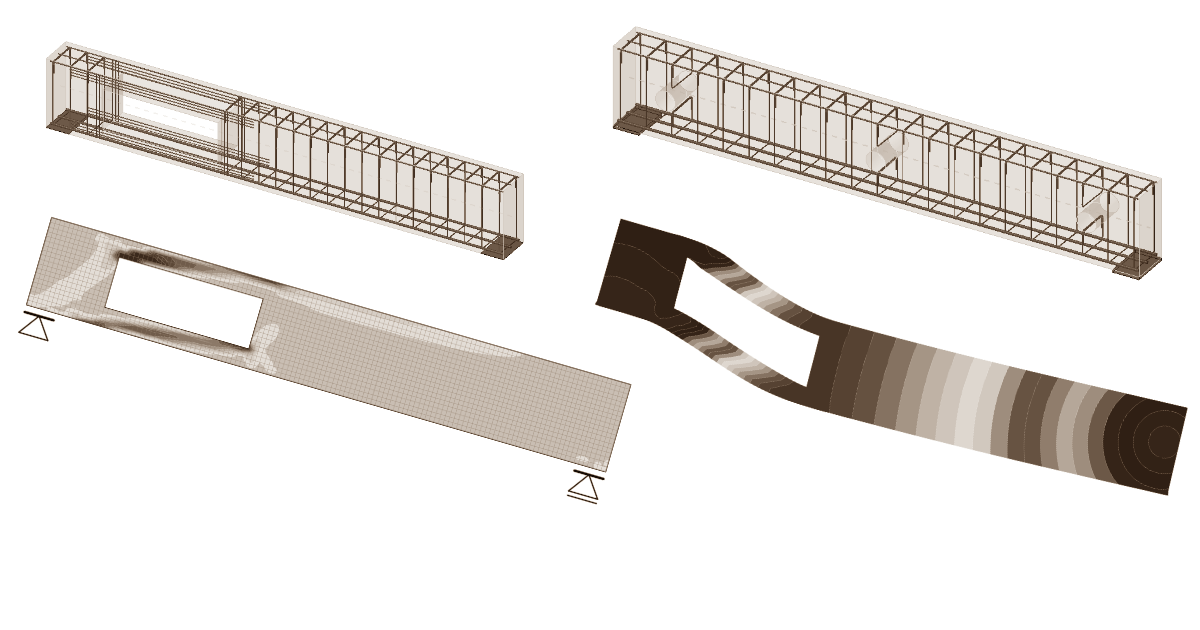

Buckling analysis, the first mode shape, and critical factor

Recap

The openings in beams, walls, plates are like the bread and butter of structural engineers. The modern world desires transparent, tall, and slender structures which bring benefits from economic but also an environmental point of view. A clear understanding of the mechanism of failure and prevention of it is the essence for the tall transparent and sexy structures. Besides that, it also saves the structural height for the ducts and pipes or other facilities.

The CSFM calculation method used to analyze these types of structures has been thoroughly tested and verified. Find out more about verifications of structural elements or take a deep dive into our Theoretical background for verification according to Eurocode

CSFM is a transparent method that provides the structural engineer with control over the behavior of the structure. To find out more about the method and its application look at our webinar about Reinforced concrete design via CSFM.

Try for FREE

Feel free to validate CSFM and its use for the calculation of cracks in concrete structures by yourself. Try out our latest version of IDEA StatiCa Concrete for 14 days absolutely for FREE. And for sure, let us know your feedback! We are always keen to hear about your experience.

Hope you have enjoyed the reading of the article.