Surface - all around cutting method

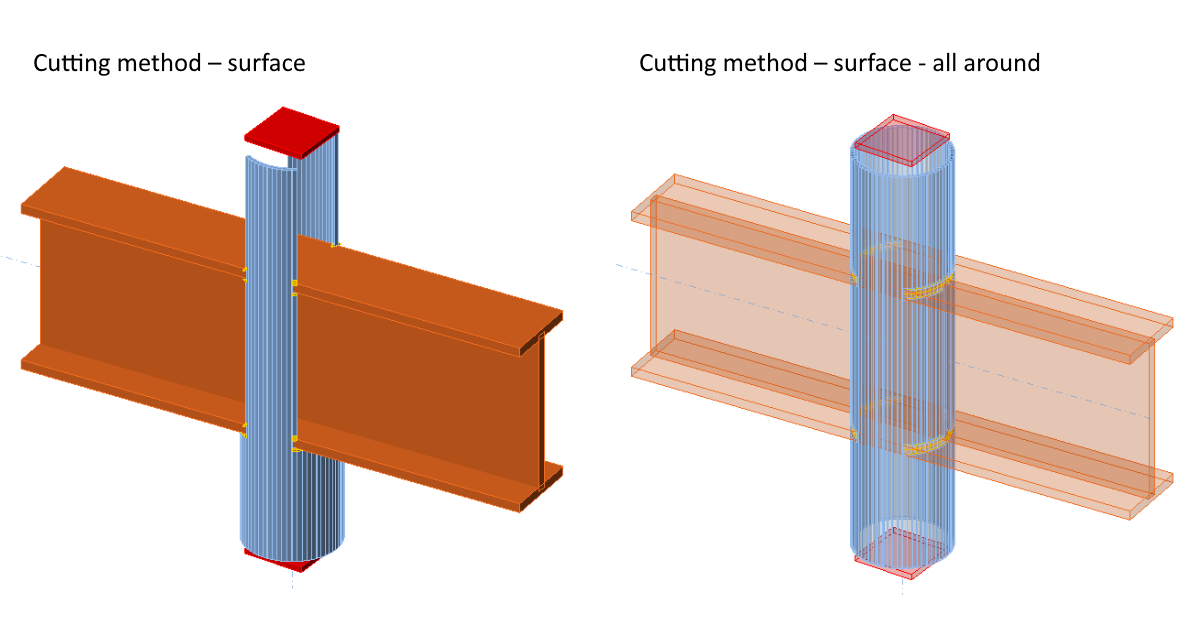

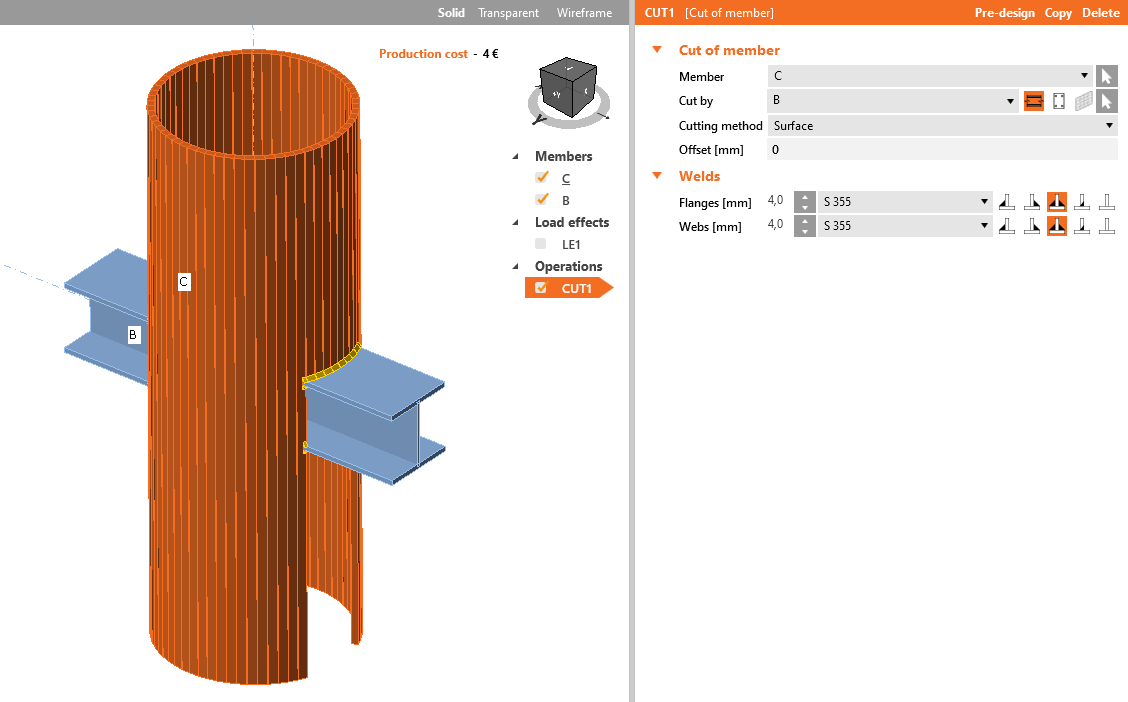

Curved hollow sections in IDEA StatiCa (e.g. CHS) are represented by a polygon of multiple plates composing the shell of the member. When a hollow section is cut by the cutting method Surface, the cut plates are divided into two parts and only one part remains, while the other one is cut off. There is no workaround to cover this issue with this cutting method.

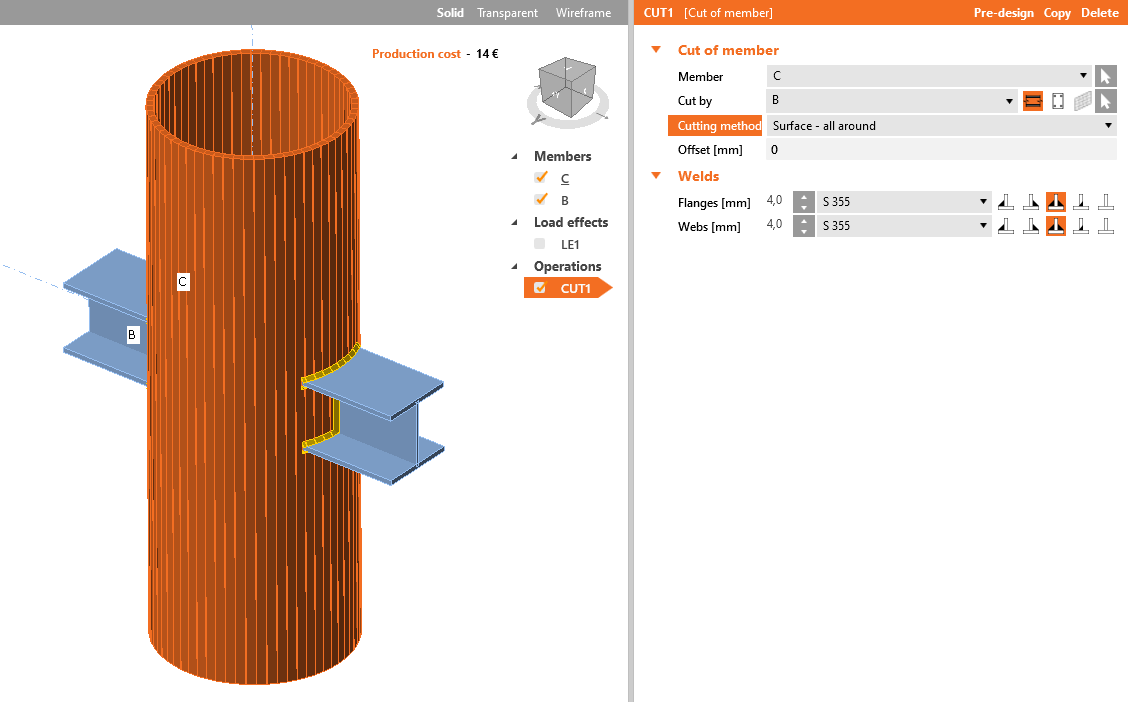

For such cases, there is an updated cutting method Surface - all around, which doesn't cut off any part of the member shell except the shape that goes through it.

Note that cutting methods Surface and Surface - all around may lead to slightly different weld geometries. Especially for CHS cross-sections, where the Surface method is specifically modified to avoid bad mesh with very small triangle lengths.

Also, the position of one-sided fillet welds is changed compared to the surface method, which is immediately visible in the 3D model.

This update has been available since the 21.1.2 patch.

Available in both Expert and Enhanced editions of IDEA StatiCa Steel.