The viaduct over the Mže River

About the project

This important transportation route circumvents the city in a length of 3.3 kilometers, reducing traffic congestion and enhancing the connectivity of the region. The bypass, which was put into service in February 2023, features a stunning viaduct over the inundation area of the Mže River that incorporates a balanced cantilever bridge, which is a key highlight of the entire infrastructure.

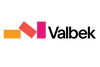

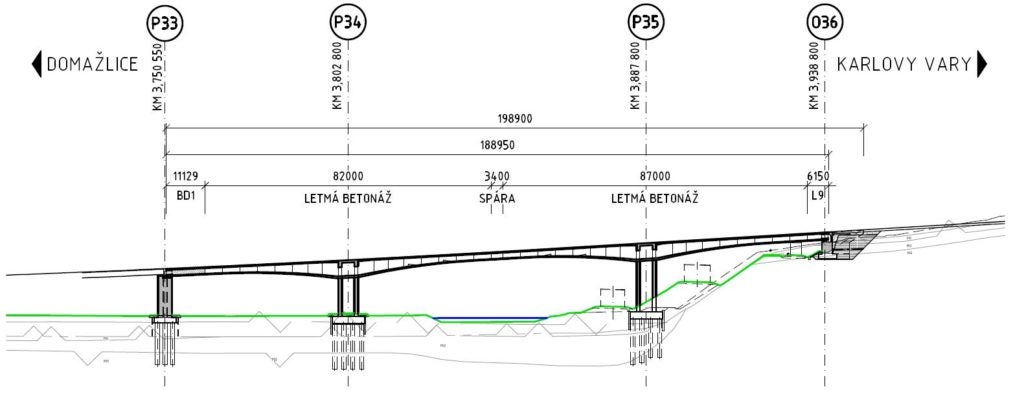

The viaduct is divided into three expansion sections carried by a total of 36 supports. The initial two sections, spanning approximately 510 meters each, were constructed using the incremental launching method. The third section, commencing at support P33, was built using the balanced cantilever method. This bridge was designed with three theoretical spans of 52.543 meters, 85.416 meters, and 51.106 meters. The Mže River flows beneath the second span, flanked by two adjacent country roads. The substructure comprises three pillars, one of which includes a dilatation joint and an abutment.

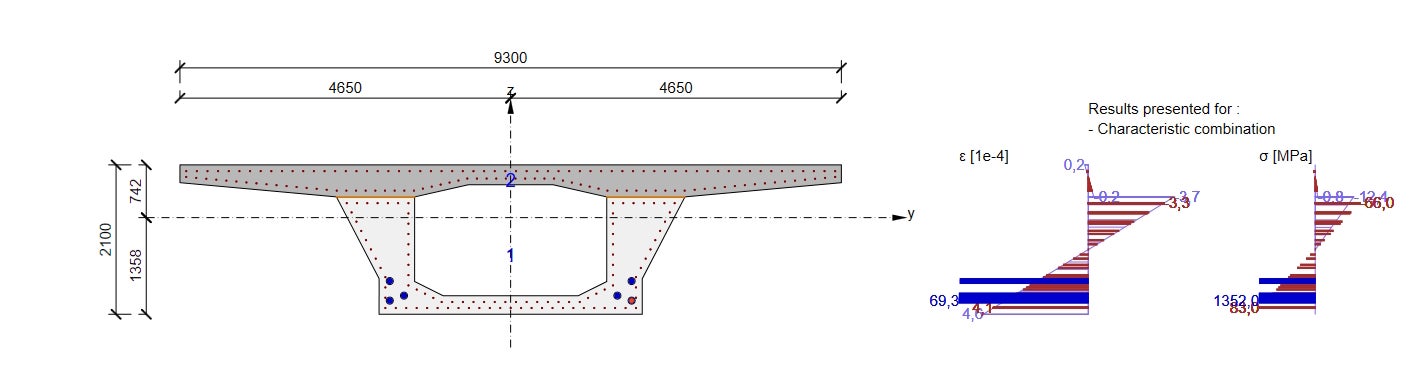

The construction of the superstructure began at pier P34. Initially, the pier table was erected, and two formwork travelers for cast-in-situ segments were assembled. Subsequently, 5-meter segments were constructed symmetrically using these travelers. To erect each segment, two 19-wire tendons made of Y1860S7-15.7 prestressing steel, which were provided by the fabricator VSL, were utilized. The cross-sectional height of each segment tapers from 5 meters toward the center of the span to a height of 2.1 meters. Once the balanced pair of segments was completed at P34, a similar pair was constructed on pier P35 using the same method. Finally, each section of the substructure was connected by closure segments placed in the middle of the spans.

Engineering challenges

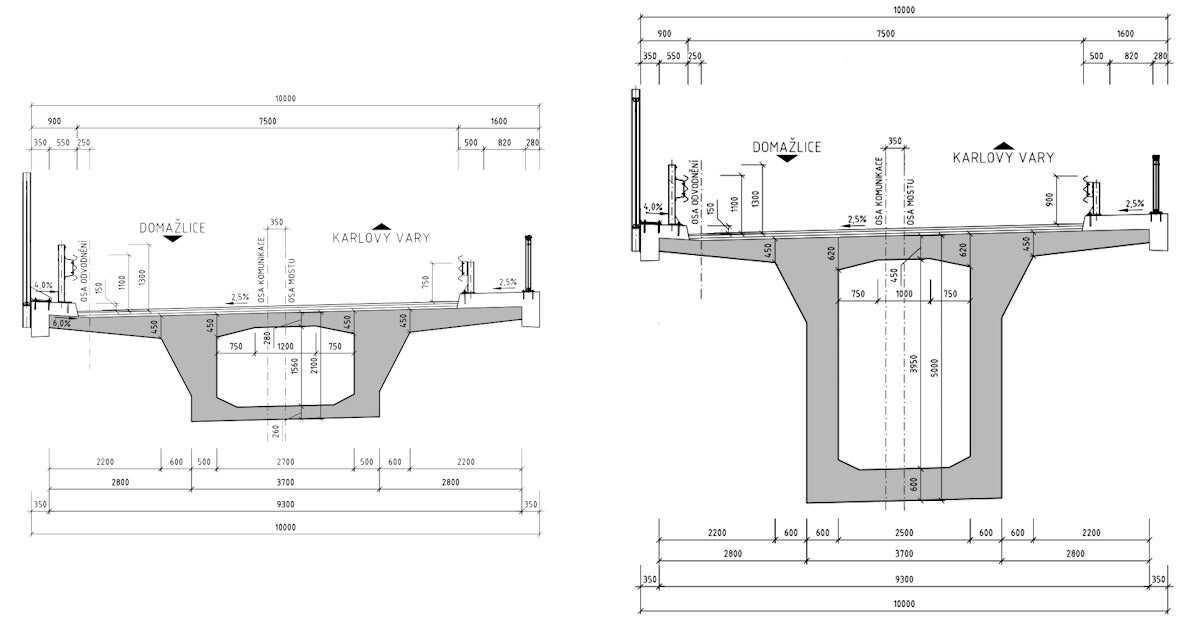

The balanced cantilever method involves a series of construction stages, with each segment requiring a distinct design. Furthermore, the design of each cross-section was carried out in two phases, first for the lower U-shaped portion and, subsequently, in conjunction with the upper deck. This intricate process is time-intensive and intricately connected to the time allocated for calculations. Nonetheless, this meticulous approach is a common feature, together with the camber configuration, of projects of this kind.

Moreover, the engineering team encountered various formidable challenges, encompassing code checks for different pier cross-sections and geometrically nonlinear calculations, tackling the second-order concerns associated with piers via linear buckling analysis, and executing nonlinear calculations to assess additional internal forces.

Solutions and results

The engineer in charge of the project, Ondřej Matoušek, was interviewed to explain how he manages his work on such a complex project.

First, a model is crafted of the entire bridge and analyzed with specialized FEA computer software Midas Civil.

To move the data from Midas Civil to IDEA StatiCa, he employs IDEA StatiCa BIM to replicate the model, including all cross-sections and tendon-related information. Since the model encompasses all construction stages, the data volume becomes overwhelming, resulting in nearly 200 extremes for a single section, which significantly slows the software's performance down.

To overcome this challenge, Ondřej Matousek has adopted a workaround by creating an RCS file for just one construction stage. Following this, he exclusively exports the information pertaining to the tendons and cross sections. This approach leads to significant time savings for him, enabling him to modify tendon-related details in Midas Civil and seamlessly transfer those changes to IDEA StatiCa via RCS with just a few clicks. This streamlined process provides him with effective control over the model.

Czech Republic

Ondřej Matousek has been using IDEA StatiCa at Valbek for several years and has mastered its full potential. In a notable project he worked on for his thesis, he went the extra mile by performing manual calculations and subsequently comparing them. Surprisingly, the results were a perfect match. The key distinction lies in the time required to obtain these results. Using IDEA StatiCa RCS, he achieves the results within a day, while the manual calculations consume several days and countless hours of effort.

About Valbek

Valbek, a company established in 1990, is an office that specializes in the design of linear structures. With over three decades of expertise in their field, they operate across 20 interconnected disciplines, providing their employees with a wide range of project design opportunities, spanning from small to large-scale endeavors or the chance to specialize in specific areas of their choosing. Valbek boasts a dedicated team of over 200 highly skilled structural engineers and 50 detailers. While their headquarters are located in Liberec, Czech Republic, they have also expanded their presence into Slovakia, demonstrating their commitment to delivering innovative and high-quality solutions in the realm of linear structure design.

Try IDEA StatiCa for free

OTHER CASE STUDIES