Engineering Consultancy for a pedestal for a robotic arm

About the project

The project is based on a mechanical and structural engineering synergy, with the top kinematic robotic arm designed, analyzed, and checked by a group of mechanical engineers. Principle engineer, Jakub Čech, is in charge of the steel team, where another five structural engineers performed the calculations.

Czech Republic

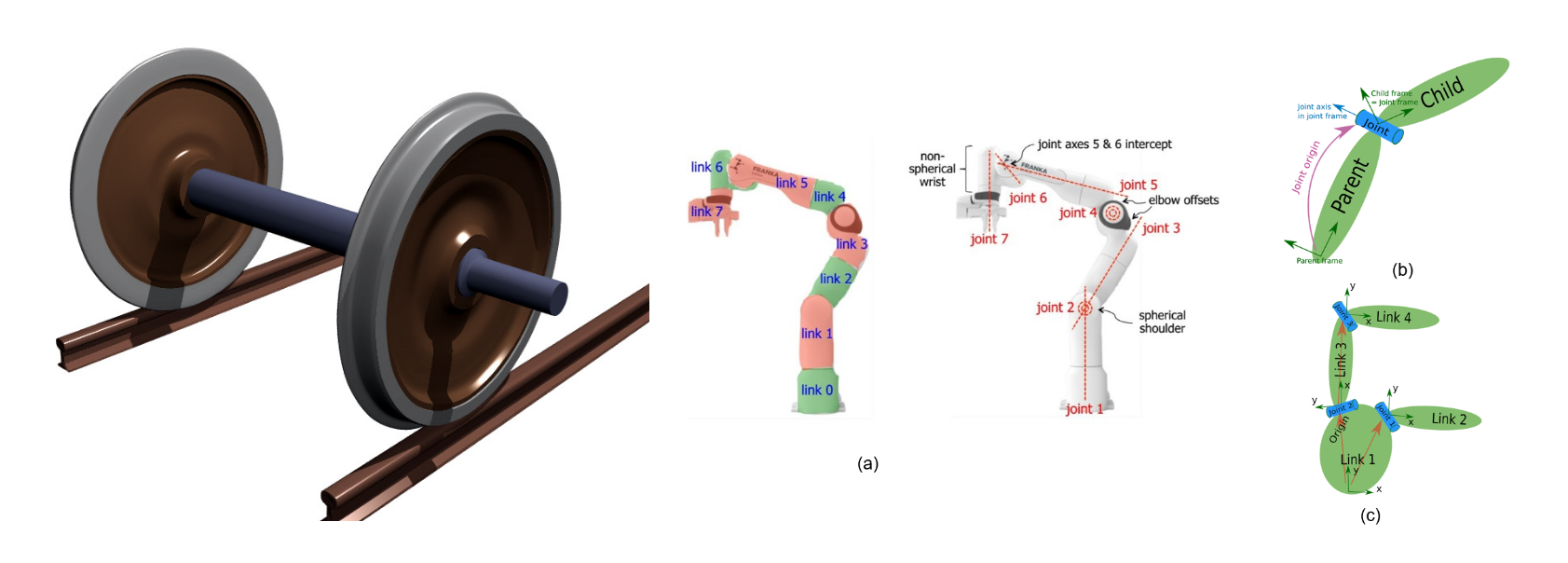

A robotic arm is a type of mechanical arm, usually programmable, with similar functions to a human arm. The arm may be the sum total of the mechanism or may be part of a more complex robot. The links of such a manipulator are connected by joints, allowing either rotational motion (such as in an articulated robot) or translational (linear) displacement.

Illustration figure: wheelset for trains and kinematics behind the motion of the robotic arm

Steel pedestal & IDEA StatiCa

The mechanical part of the model must be fixed to a rigid pedestal to minimize deformation for correct manipulation during assembly. It leads to the need for a precise design, analysis, and code-checking. All the components that together form the support of the mechanical parts, like plates, bolts, and welds, ensure the spatial stiffness of the substructure and its need to be analyzed precisely.

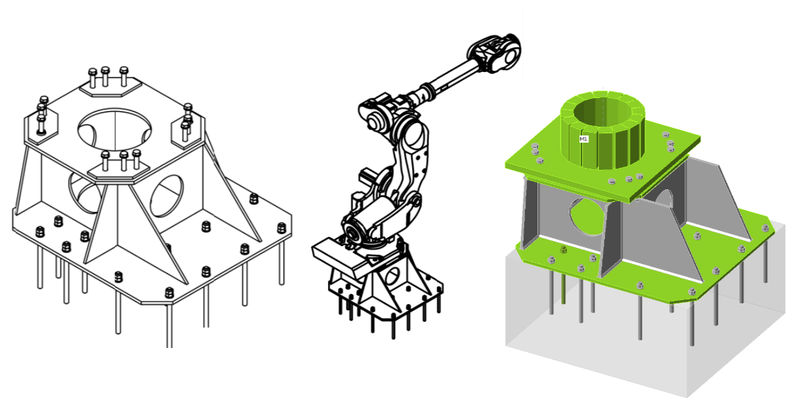

A drawing of the pedestal for the robotic arm

Due to its manipulation (pick up/drop off) of goods, craft, packages, etc., the forces change over time. The centrifugal/ inertial forces were also included, except for the static forces. These forces are strictly dependent on the angular velocity of the motion. The design and code–checking of the pedestal consider the critical combinations of the forces. The forces are derived from a simulation of rigid body dynamics.

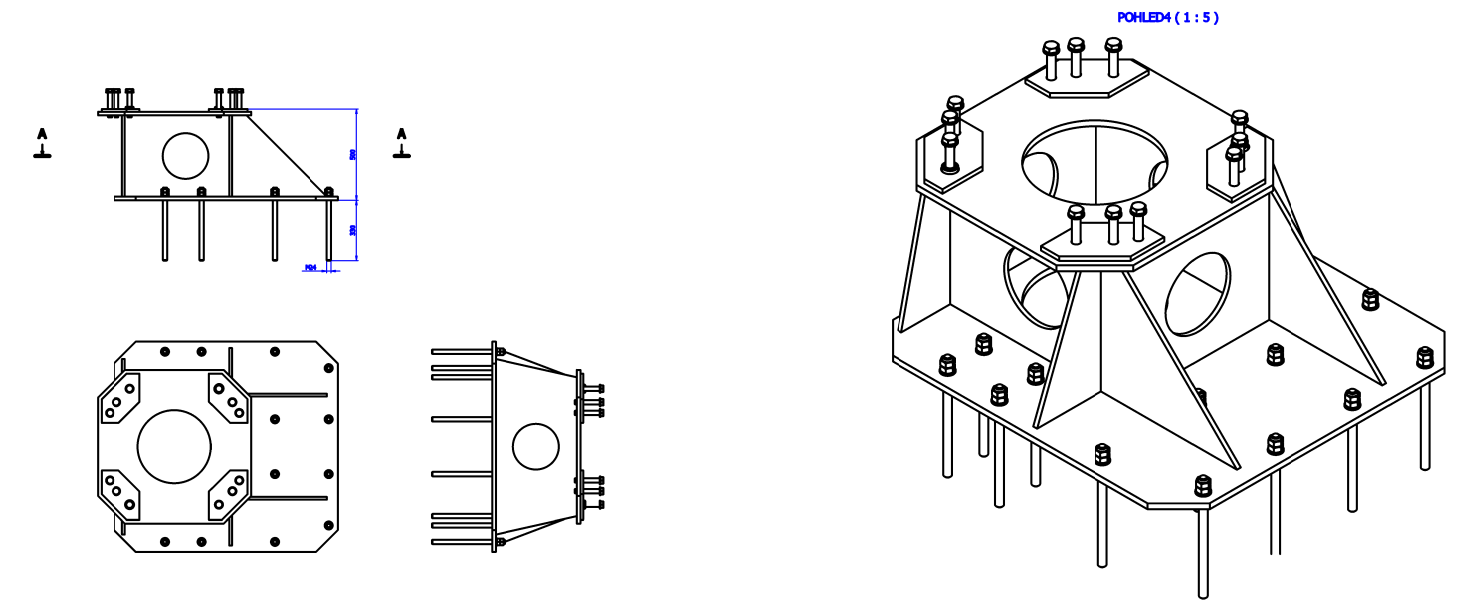

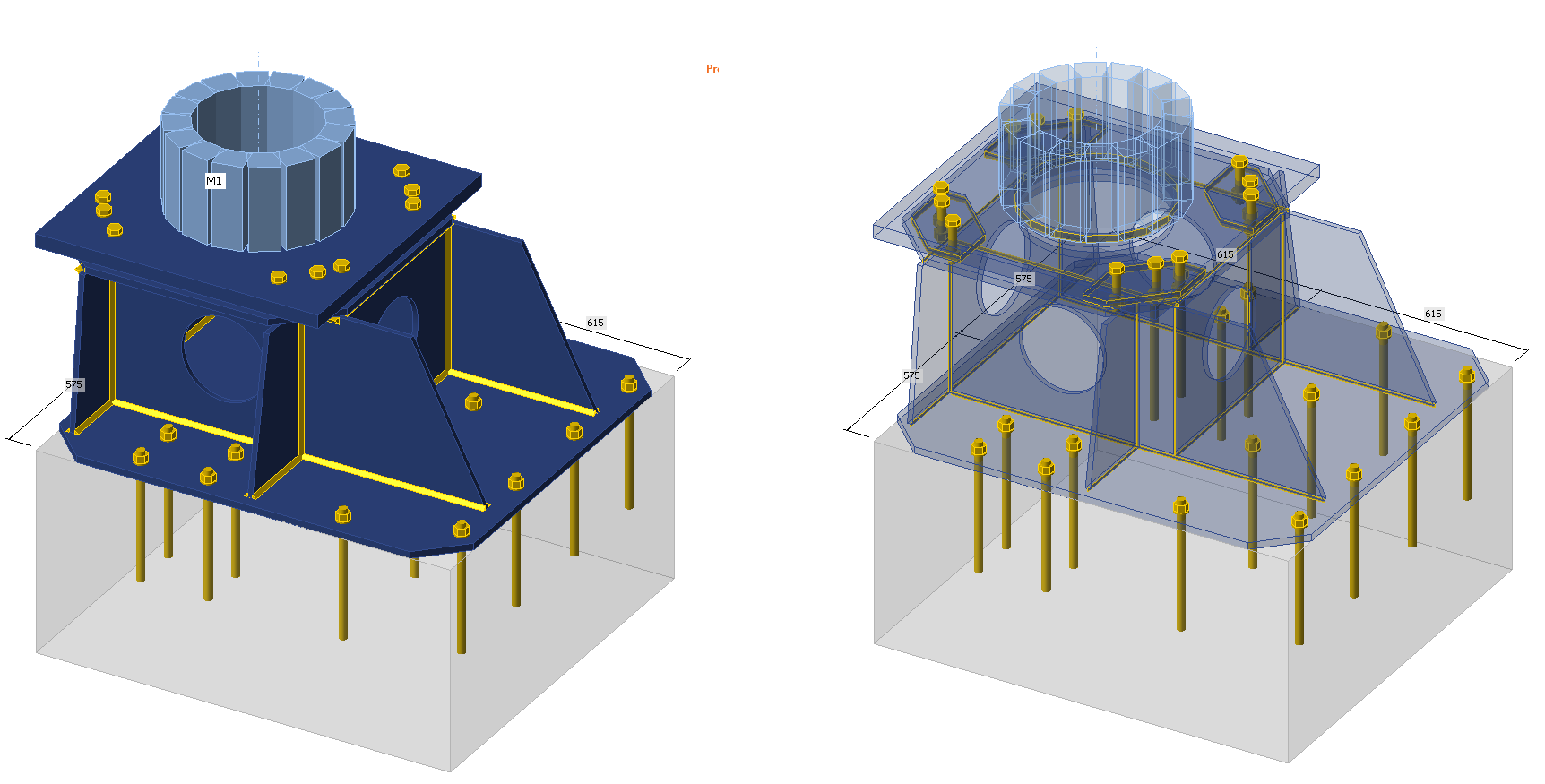

The model is assembled from a base plate anchored to a concrete block. The pedestal box with openings is stiffened using welded stiffeners. The model ensures spatial stability and rigidity. The complexity of the anchoring model can be seen in both a solid and transparent view.

Solid and transparent views of the model and each components

Czech Republic

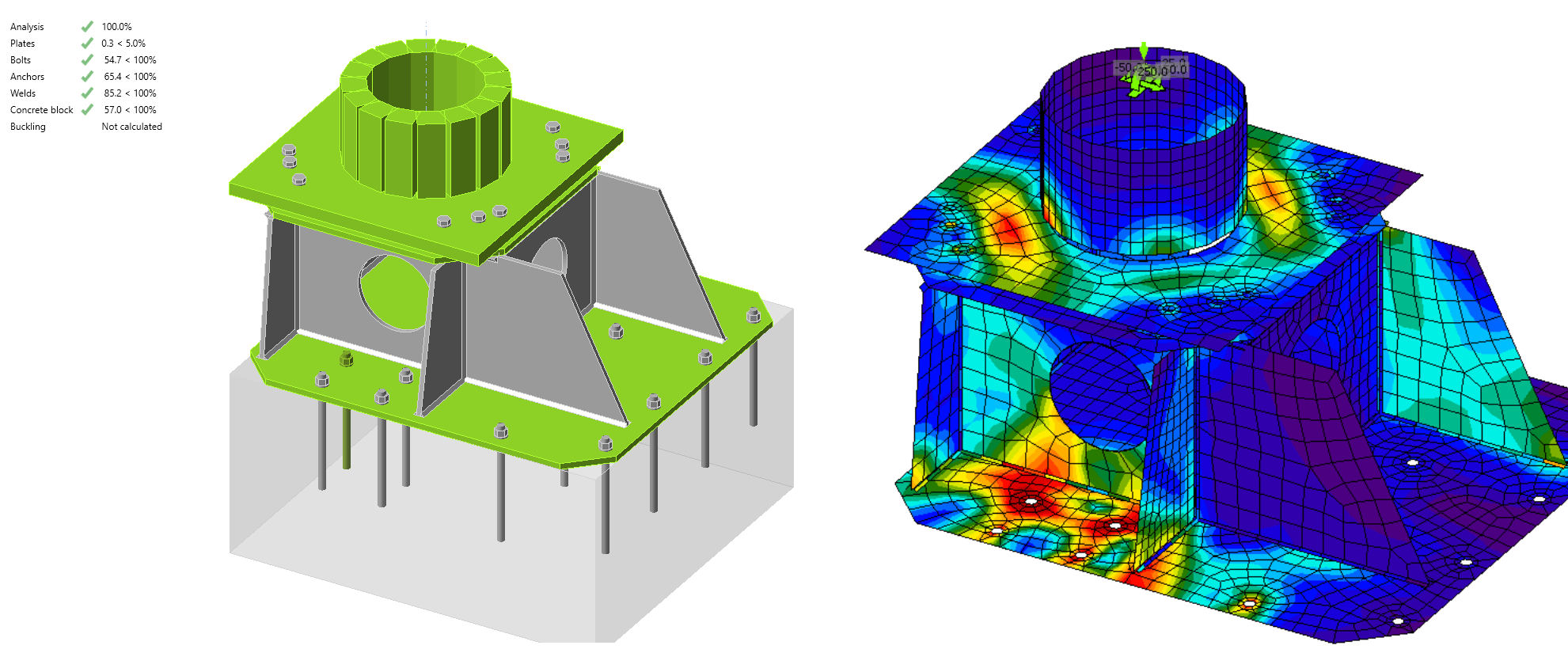

Thanks to advanced modeling techniques and the power solver engine behind IDEA StatiCa Connection, we analyzed the stress–strain on the model using materially nonlinear analysis.

Results and code-check

The design and code-checking fulfill all requirements of the Eurocode.

Utilization of each components and Von-Misses stress

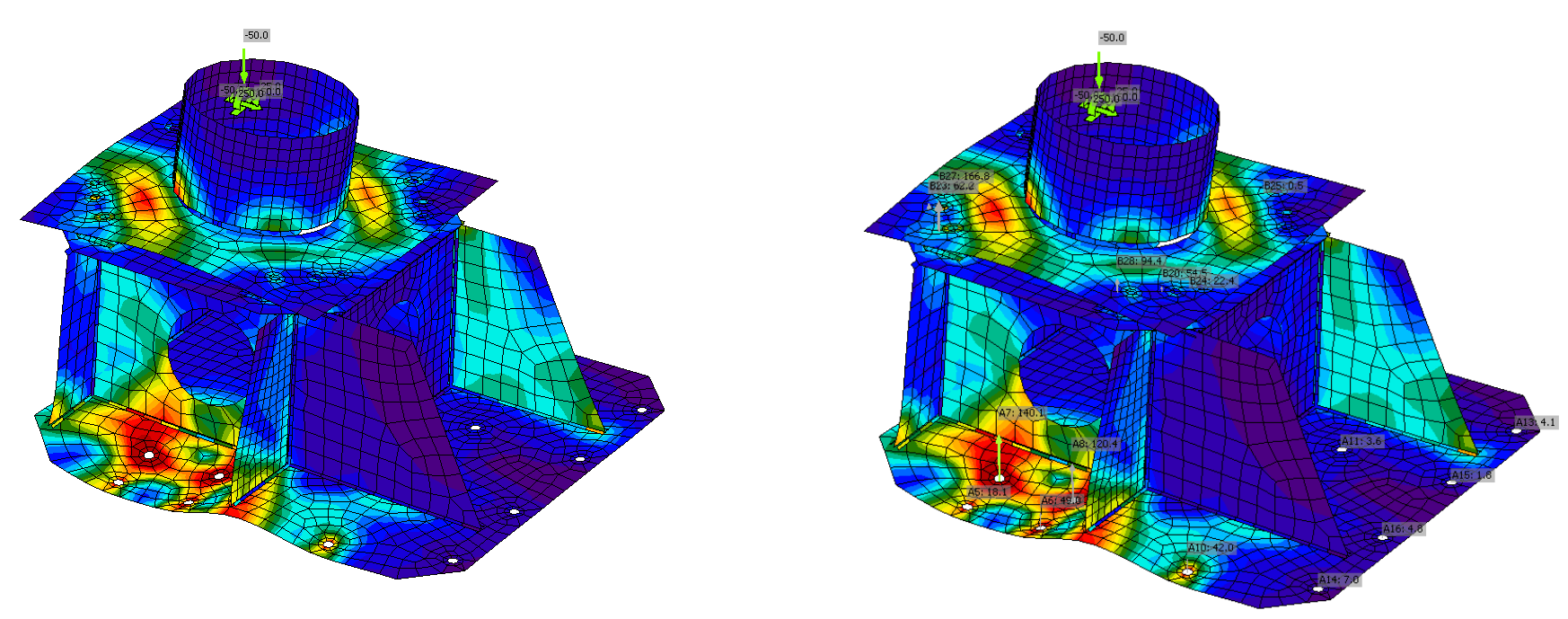

Scaling up the deformation and forces in the anchors

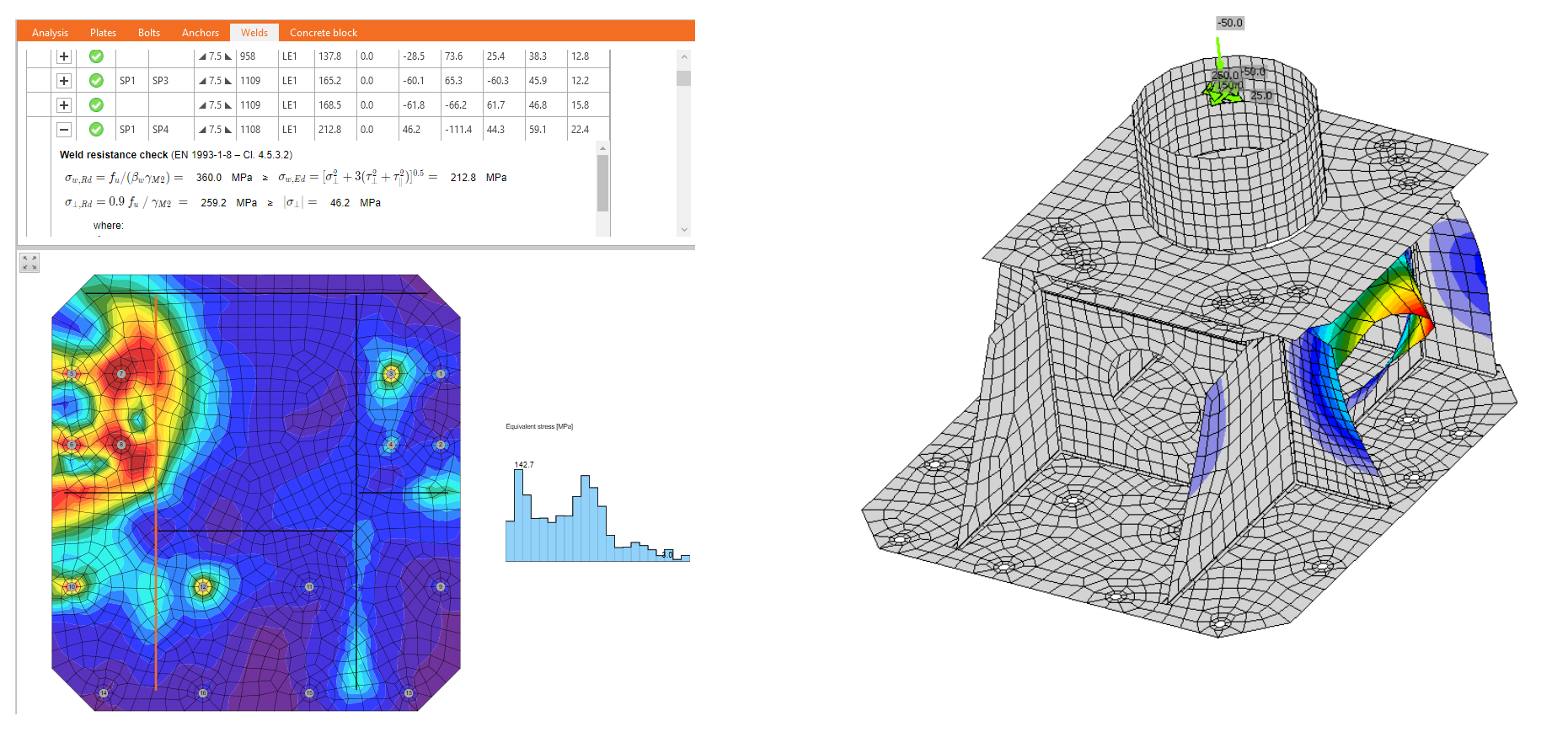

Stress in the welds and the first buckling shape

Conclusion

IDEA StatiCa, in close cooperation with BKB Metal, delivered the model with a detailed description of the modeling approach and its annotated results. IDEA StatiCa Engineering Consultancy provides necessary expertise and guidance to businesses on engineering projects and advises their clients on how best to meet their design and construction demands.

Czech Republic

The complex pedestal transfers all the critical combinations and fulfills the criteria according to the Eurocode. The model has undertaken a stress-strain and buckling analysis to validate all aspects of the design. The IDEA StatiCa Connection app also brings big potential for the mechanical engineering field, where it can assist as the software for the design and code-check of pedestals for mechanical robotic arms.

The feedback of Jakub Čech and his team has been extremely positive. This has resulted in both BKB Metal and IDEA StatiCa being satisfied with the outcome.

To find out more about IDEA StatiCa Engineering Consultancy, please contact your local reseller or IDEA StatiCa regional office.

Try IDEA StatiCa for free