-

2020-03-18T00:00:00.0000000Z(in your local time, 24-hour format)

Webinar date:

Join the webinar and learn about

- How to model a joint in effective way

- Fit in-situ operations to the analytical model of a joint

- Reinforcing parts of I-section beam with doubler plates

- Maintaining a member length

- One bolt bracing connections

Speakers

IDEA StatiCa UK

IDEA StatiCa UK

IDEA StatiCa has been used in The Thames Tideway Tunnel – the biggest infrastructure project ever undertaken by the UK water industry. The 25 kilometers tunnel will run under Thames river and is due for completion in 2024, involving 24 construction sites in London.

Starting in Acton, west London, the tunnel will travel through the heart of London at depths of between 30 and 60 meters and will intercept, store and ultimately transfer sewage waste away from the River Thames, using gravity to transfer waste eastwards.

The route of Tideway Thames Tunnel with all the construction sites

The service tower is required in the shaft to support the services associated with the tunneling activities and provide access for their inspection and maintenance. The integrity of all main and secondary steelwork connections of the 60m high tower structure has been verified using IDEA StatiCa.

About the project

Our customer Wentworth House Partnership (WHP) – a leading Temporary Works and Geotechnical Design Consultancy in the UK – has been involved in this project and used IDEA StatiCa within the framework of a CATIII check of a shaft service tower for one of the project locations.

Webinar content

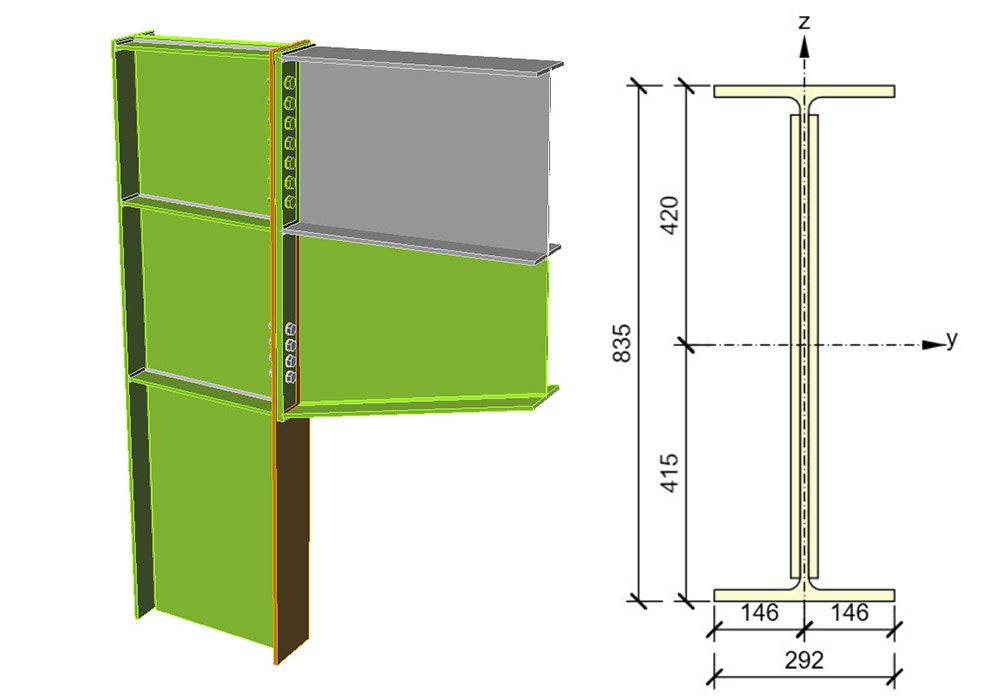

During the webinar, we will present the workflow of code-checking of a joint between a tower column and three beams at a typical bracing level. The beam-to-column joints are simple bolted connections utilizing fin plates. One plan and two vertical braces are also included in the connection. These are EA sections bolted to stiffening plates that are welded directly on the main members involved. The example illustrates the capability of the software to model the exact geometry that the steelworks designer envisaged using the various operation types available.

Helpdesk Highlights

In addition, we will go through one “HelpDesk highlight” – that can provide a nice solution for reinforcing the web of a wide column with doubler plates while maintaining the default length of the column.