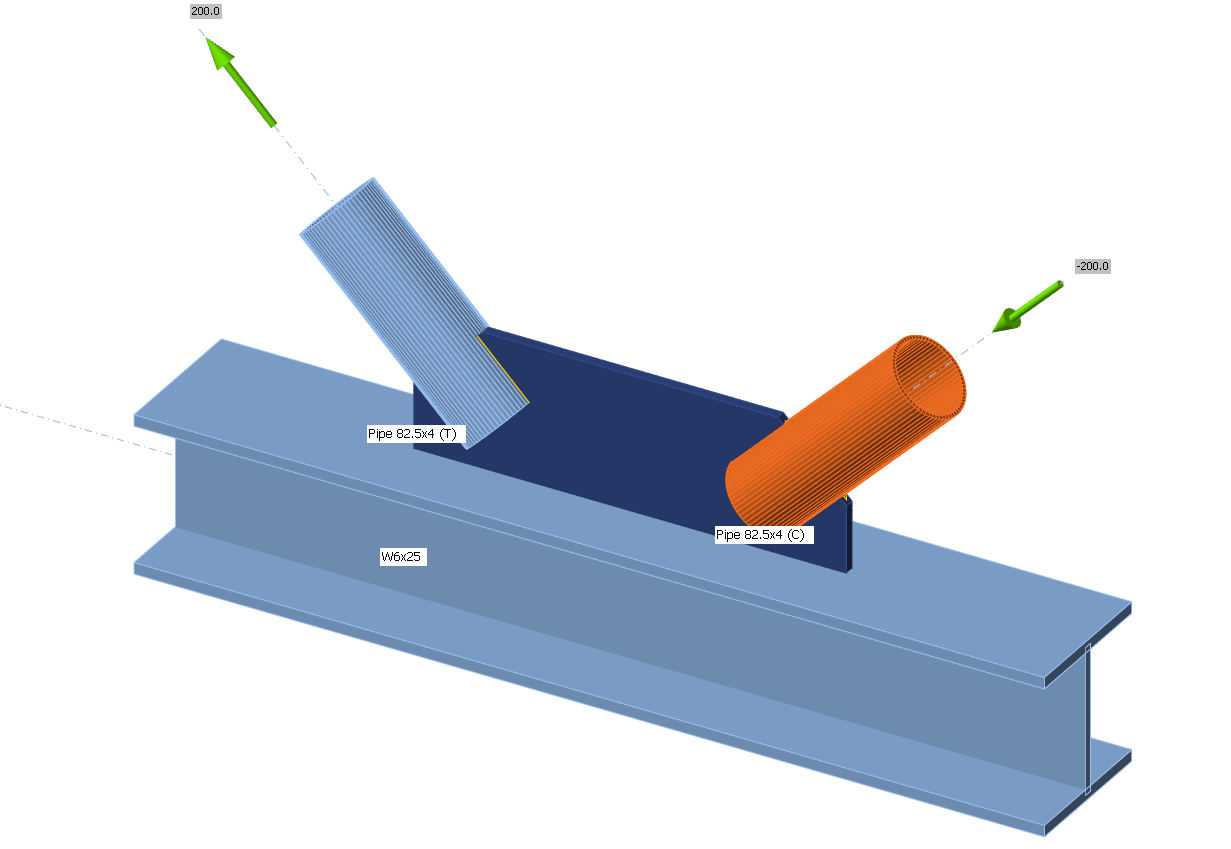

Type of connection: Pipe – Shear lag connection in bracing

Unit system: Metric

Designed acc. to: AISC 360-10

Investigated: Shear lag of pipe, welds

Materials: Steel A36, Weld E70XX

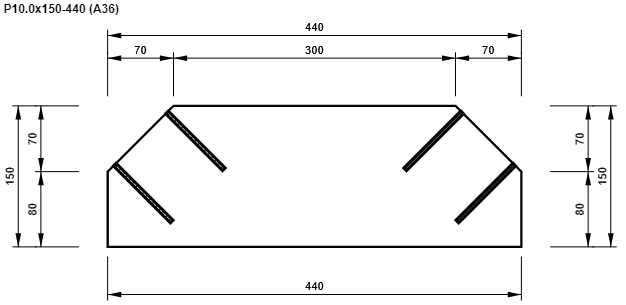

Geometry:

Length of embedded part of pipe tp = 85 mm

Weld leg size: 5 mm

Applied forces:

N = 200 kN (in tension and compression per pipe)

AISC 360-10 and Steel construction manual – results

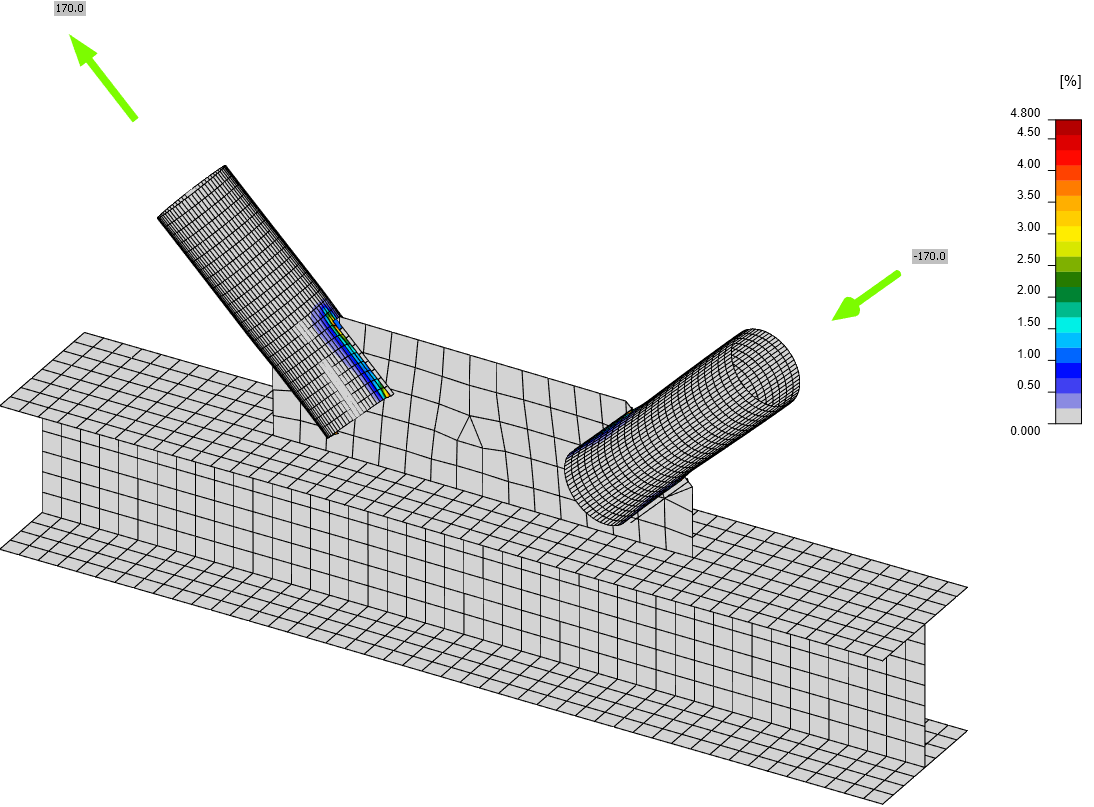

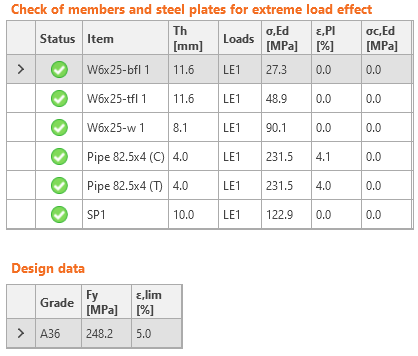

IDEA StatiCa Connection – results

Analysis: 84.8 %

Plates: 3.7 % < 5.0 %

Welds: 83.5 % < 100 %

The analysis stopped at 84.8 % when the plastic limit strain was reached. The resulting resistance is 170 kN. The results shown below are at the load resistance – 170 kN.

Comparison:

Shear Lag: Check of the plastic strain in IDEA StatiCa clearly shows the shear lag effect. The capacity is exhausted at 170 kN when the limit plastic strain of 5 %is reached. The computation acc. part D of AISC 360 shows that the connection is beyond the limit by 19%, and predicts the rupture at 168 kN. Both results are very close to each other with a difference of 1 %.

Weld: Weld checks are passing according to both methods with sufficient reserve.