Connection stiffness and its use in global analysis

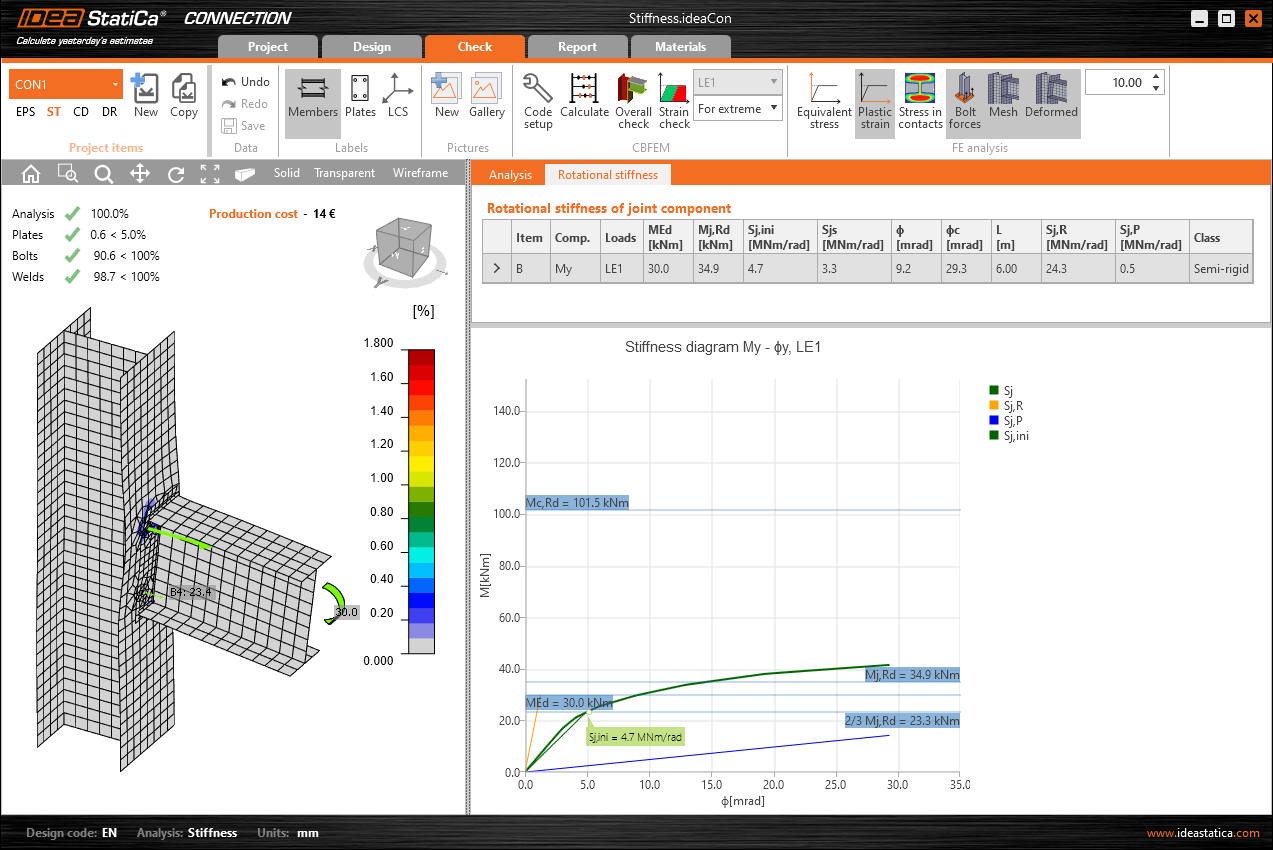

The moment-rotation diagram is one of the outputs of IDEA Connection application. It gives quite accurate behavior of a particular joint to particular static loading. But what happens if there are different types of loading? If this loading is exceeded and significant plastic deformations occur? If there are relatively high manufacturing tolerances?

Classification

The most important is the effect on:

- Internal forces in the structure both in members and in joints (ultimate limit state)

- Deformations (serviceability limit state)

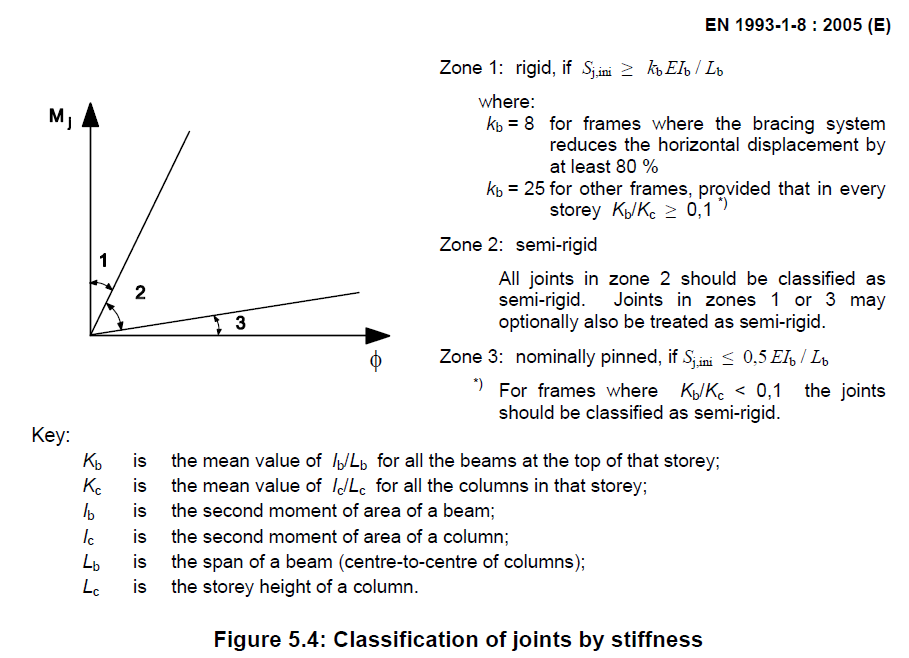

Eurocode EN 1993-1-8:2005 tackles this issue in Chapter 5. The beam-to-column joints are classified according to initial stiffness as:

- Pinned - joint does not transmit any bending moments

- Semi-rigid - joint transfers some bending moments and its behavior needs to be taken into account in global analysis

- Rigid - joint has no effect on the analysis, members are rigidly connected to each other

You may have noticed that the code does not mention cantilever joints. That is due to the fact that the classification is not important. The cantilever joint must always transfer the full bending moment.

Joints in global analysis

No joint is ideally pinned or rigid but the classification boundaries in Cl. 5.2.2.5 were devised to limit the error to:

- 5% for internal forces

- 20% for deformations

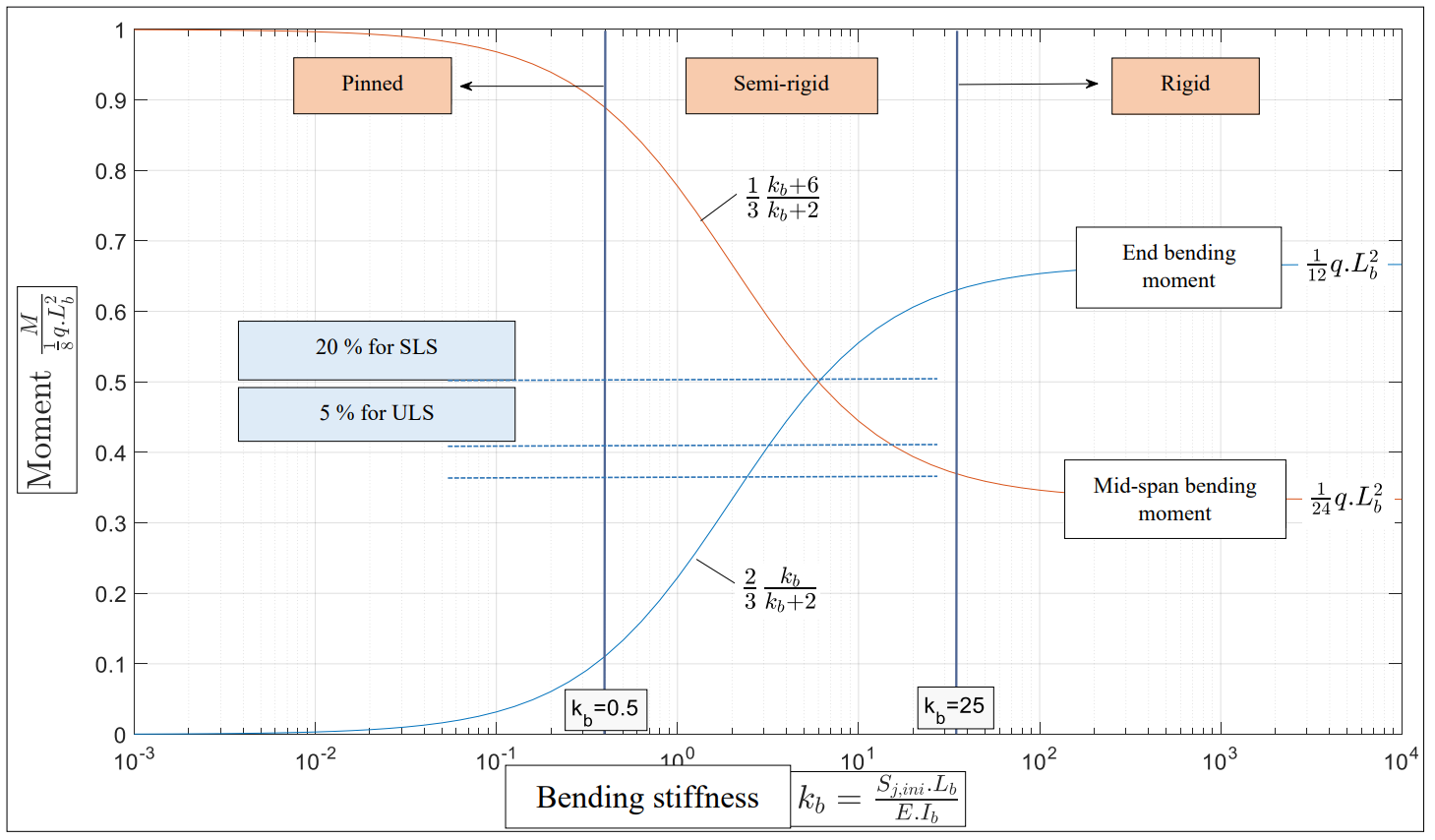

This possible error is displayed in the following picture with the example of a beam connected to a column on both ends. The blue curve shows the bending moment at the joints and the red curve bending moment in beam mid-span. The internal forces do not nearly change in pinned and rigid region but change rapidly in the semi-rigid region. Also notice the logarithmic scale for bending stiffness. It means that the stiffness may change even 100 times and it will have very small effect if the joint stays in rigid or pinned region.

That all means we can use rigid or pinned joint in global analysis and not care about its real stiffness.

But what to do for semi-rigid joints?

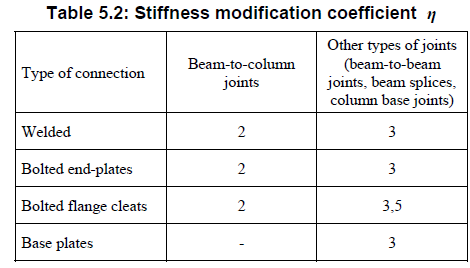

IDEA StatiCa shows the joint behavior as if it was brand new and loaded just one time with a particular load case. But there are a lot of uncertainties. The joint may have undergone some plastic deformations in the past, it may be rusty and workers may have used some nasty methods to assembly the joint together and get rid of manufacturing tolerances. For semi-rigid joints, the initial stiffness is used in global analysis only if Mj,Ed never exceeds 2/3 Mj,Rd in the whole life-time of the structure. That rarely happens but it can be the first step to determine the Mj,Ed. If the design bending moment exceeds 2/3 Mj,Rd in any load case, the initial stiffness reduced by factor \(\eta\) from Table 5.2 should be used in global analysis:

Summary

Mostly, the initial stiffness (not the secant stiffness) coming as an output from IDEA StatiCa Connection should be used in global analysis. The initial stiffness assumed at 2/3 Mj,Rd is used for joint classification.

- Rigid joints - keep the members merged in the node

- Pinned joints - add a perfect pin

- Semi-rigid joints:

- Mj,Ed < 2/3 Mj,Rd - use Sj,ini

- Mj,Ed > 2/3 Mj,Rd - use Sj,ini / \(\eta\)