Avoid fire design hell: Ensure your project meets all safety requirements

With increasingly advanced methods, we now have many more ways of verifying a proposed design under conditions other than normal, such as in the case of fire. There is no longer a need to use simplified or table methods that used to produce inaccurate and overly conservative results. It is now possible to subject a design, including its details, to advanced analysis. IDEA StatiCa Connection offers you the calculation of fire resistance for standards, including fire calculation (EN/AISC).

What's more, it's not that complicated. Let's get some clarity on the topic.

How to approach fire design

When speaking of fire design, we have several methods we can use:

- Table Method

- Simplified Design (verification of single elements at normal temperature)

- Advanced Design (verification including numerical calculation of fire resistance for connections)

Until now, simplified methods have been used, either the Table Method or Simplified Design with an analytical or numerical approach, but only for individual members exposed to standard temperatures. The calculation of fire resistances for steel connections was not used at all. Simplified Design was used with the basic consideration that the connections have more material and heat up more slowly than the other elements. This has led to safety gaps and also economic inefficiencies.

How do we deal with that? There is an easy solution – to do a proper check. Advanced Design at increased temperatures can cover these weaknesses. That is essential, especially for buildings of greater importance, such as airports, stadiums, hospitals, etc. And what's more, we have the possibility to perform a numerical calculation for increased temperature, not only for the members but also for the connections!

Let's take a look at the calculation principle used in IDEA StatiCa and the procedure of designing steel connections in general.

The core of the calculation

The calculation of fire resistance is based on fire class (also known as fire rating) and fire curve.

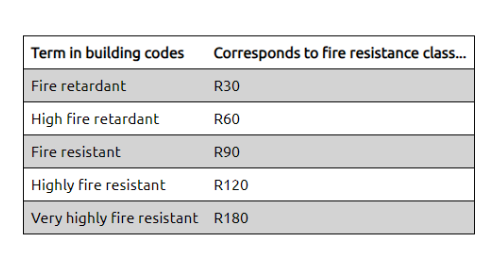

The first input is known from the project specification. Fire class is an output that is usually part of the fire documentation approved by the fire department. It indicates the length of time the structure must withstand for in order for everyone to exit the building safely before collapse. The time can vary from 15 to 240 minutes (R15 to R240) and will be affected by many parameters, such as building function and size, number of levels, location of exits, and much more. In practice, this means that you can design a building that will be more difficult to leave but must last up to four hours, or the structure may collapse after 15 minutes if it can be left quickly enough. But remember, it's not up to you, the structural engineer, it's up to the building and fire department.

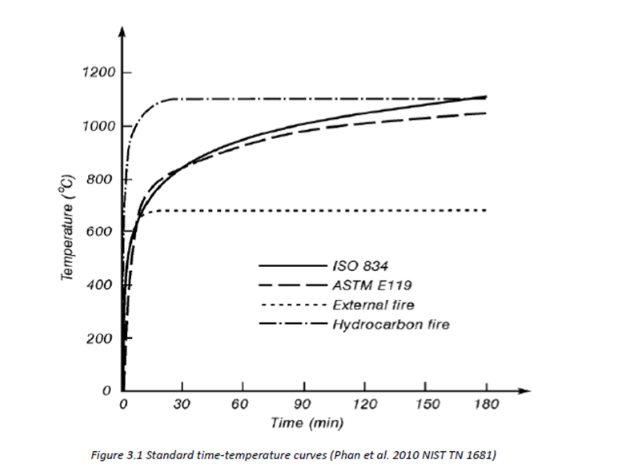

As the next parameter, you must choose a fire curve, which shows the burning process. In other words, the heating of the air over time. In reality, the curve would start to fall as soon as there is nothing left to burn. But for design purposes, an artificial curve was created based on tests and inflated to give conservative results. In IDEA StatiCa, you can choose from several curves according to Eurocode (ISO 834/standard fire) or AISC (ASTM E119) but also special curves for faster fire spread, like hydrocarbon used for oil platforms, ships, or industrial plants.

Based on the type of fire curve and other material parameters and dimensions, the software calculates the temperature of individual elements (plates) at a specific time, according to the fire class, using an incremental method. The temperature of bolts and welds is taken as per the hotter connected plate. The automatic calculation of the plate is taken according to valid standards, and it is possible to specify whether fire protection is used or not. At the same time, the possibility to enter the temperature of individual elements manually is also maintained.

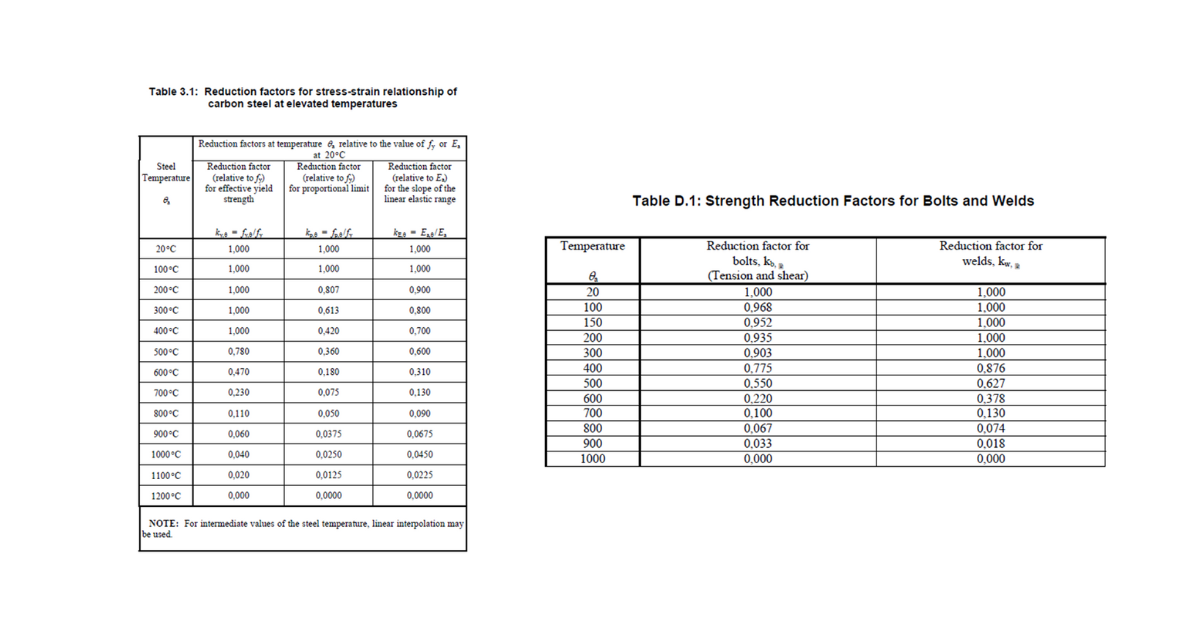

According to the temperature of the components, the degradation of the material and, therefore, the coefficient that reduces the material properties are then determined. The code checks of plates, bolts, and welds are then the same as for the classical stress and strain analysis but use reduced values.

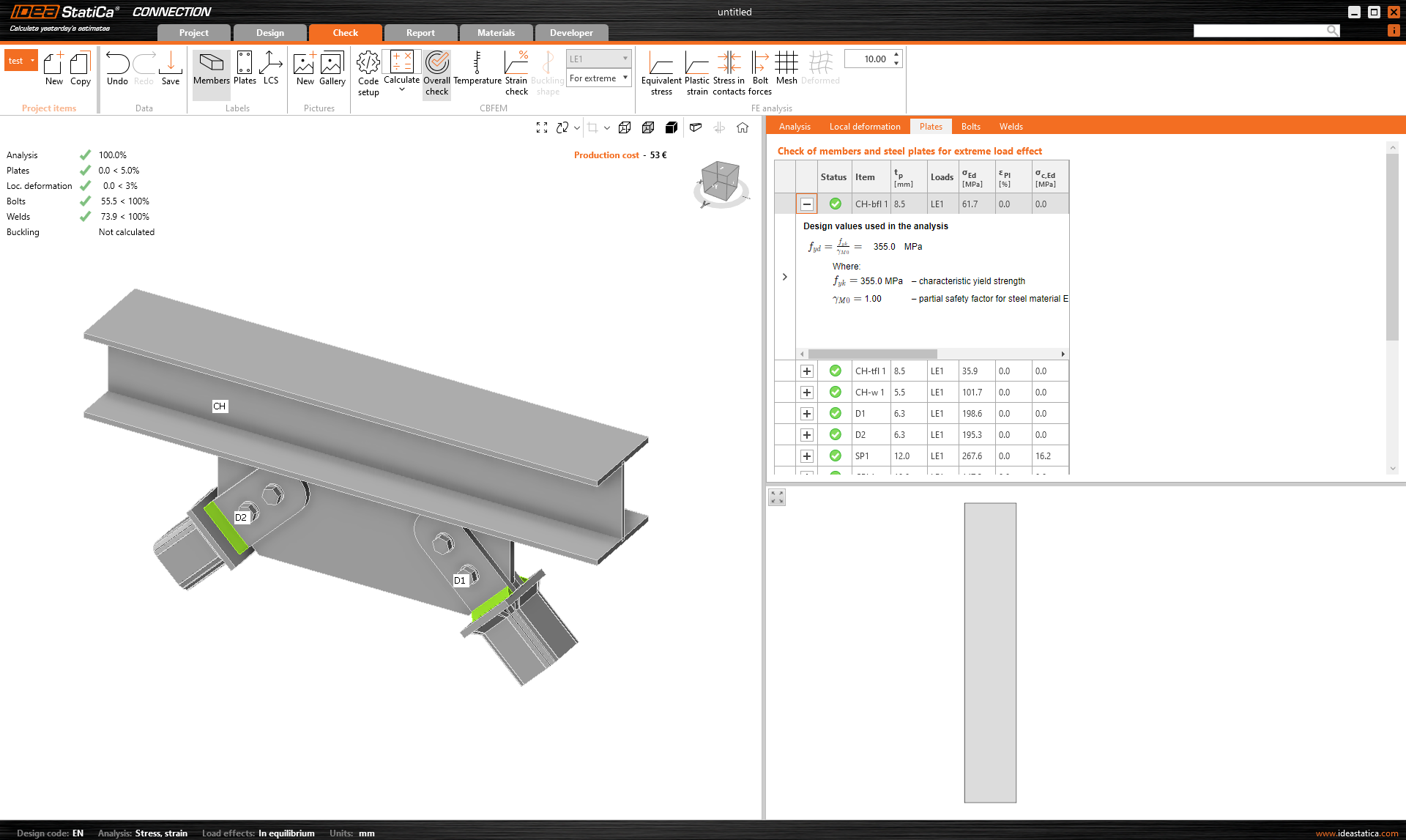

Look what you get

Take a look at the following short demonstration of the results of the fire resistance analysis in IDEA StatiCa Connection to get an idea of how the connection behaves under different conditions and how the theory is applied.

First, I will check with a stress and strain analysis to see if the joint passes.

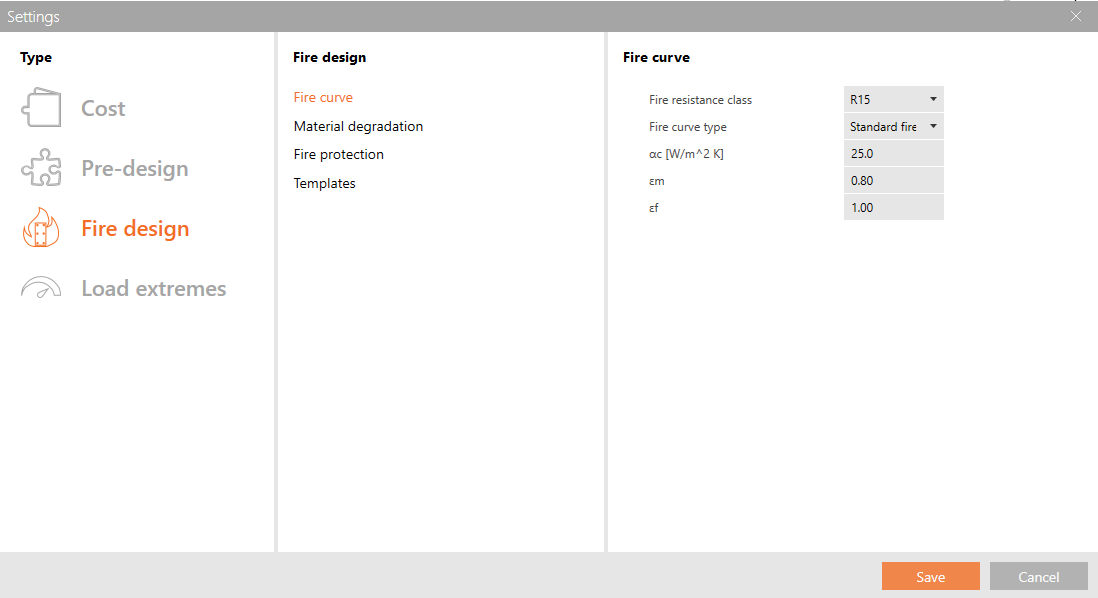

Then, I create a copy and set up a fire resistance analysis. In the settings, I choose the lowest fire class, R15, and a standard fire curve according to the Eurocode. I will, on purpose, set up a joint without fire protection.

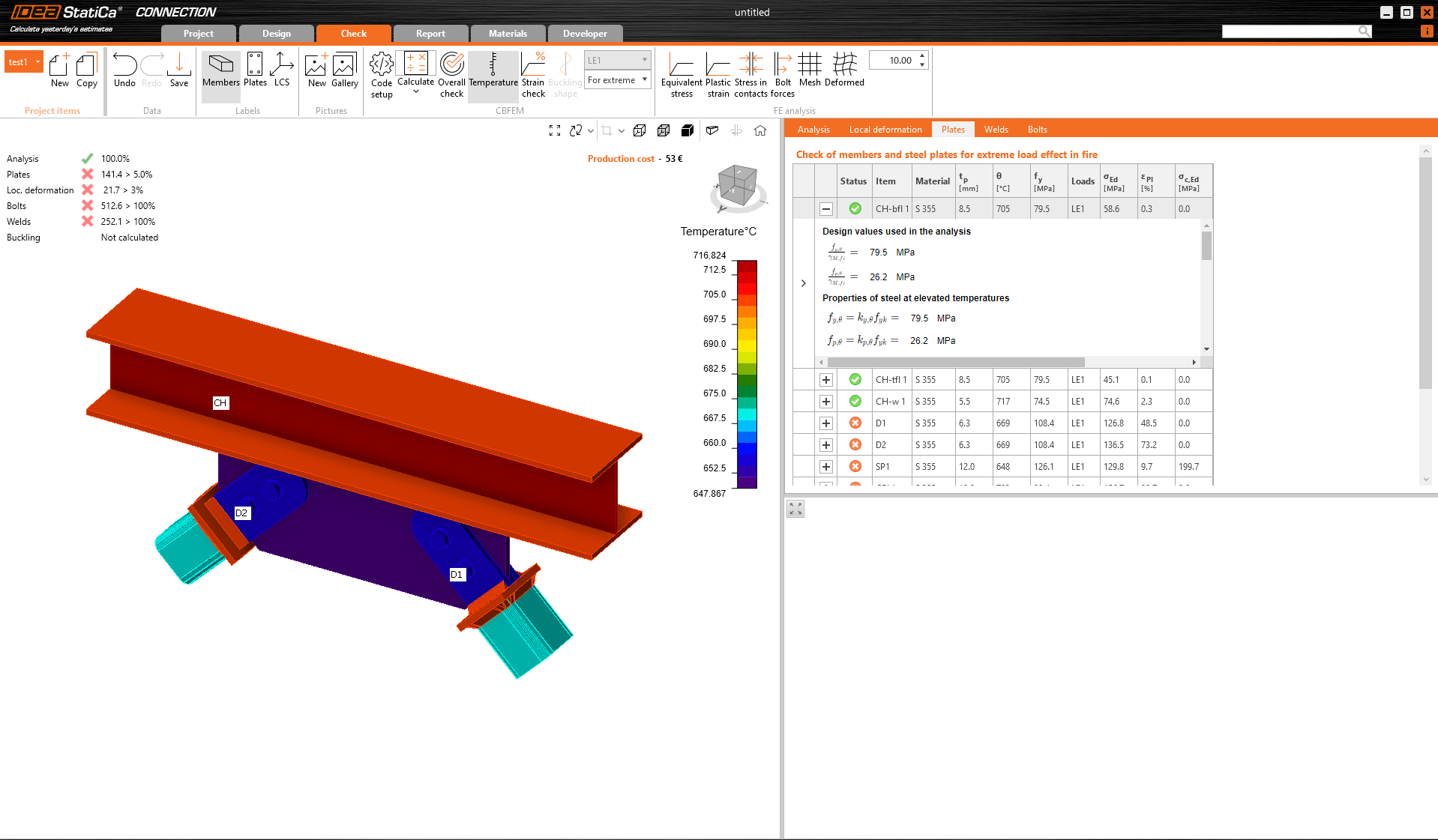

In the displayed results, we can see how the individual components will heat up without fire protection within 15 minutes and how this will affect the properties of the material and, thus, the bearing capacity of the tested joint. It can be seen that in just 15 minutes, it reached a temperature of over 700 °C at some components.

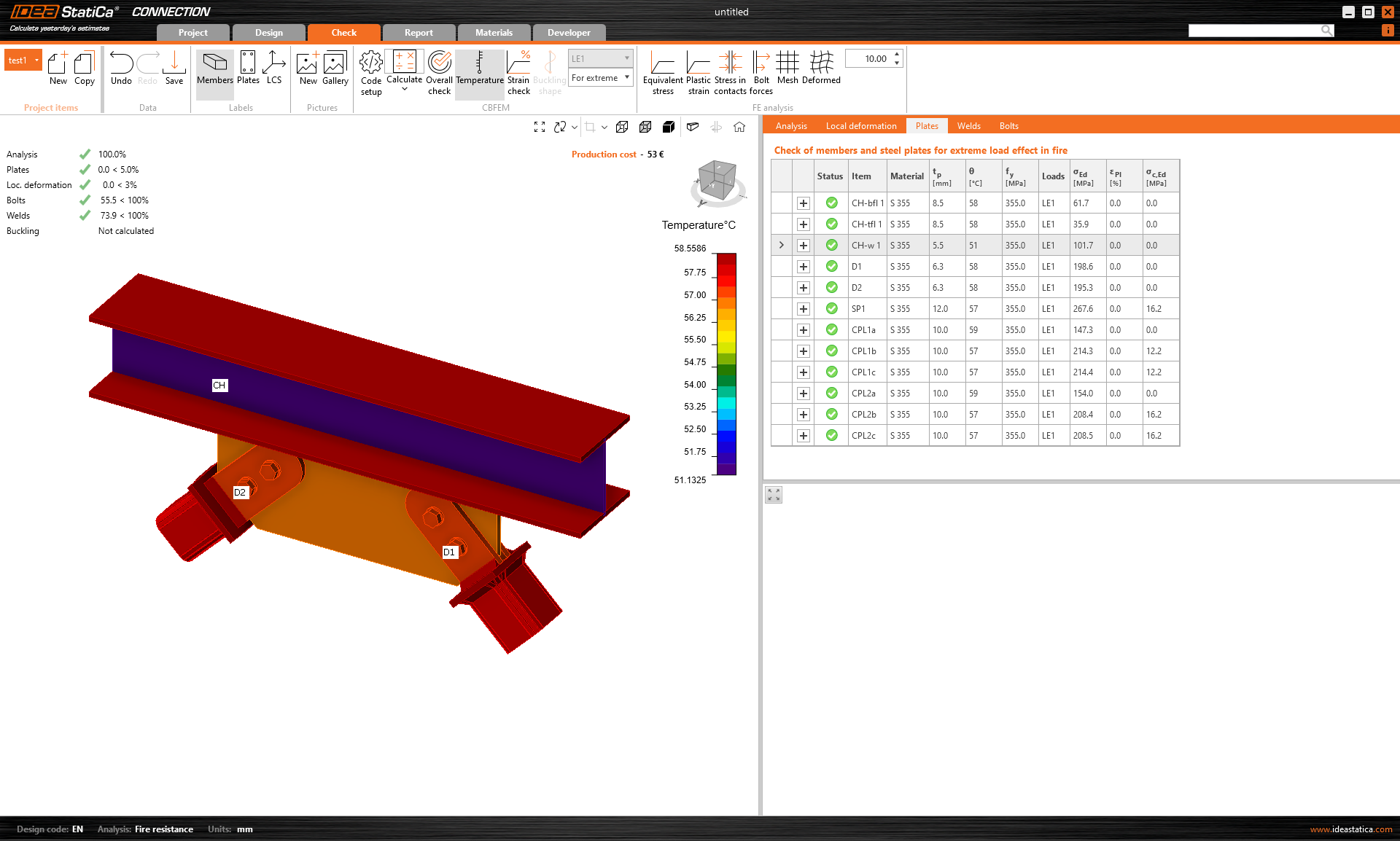

By adding fire protection, we immediately reach completely different values, especially for such a short time. The plates do not have time to heat up, and the degradation of the material is not an issue.

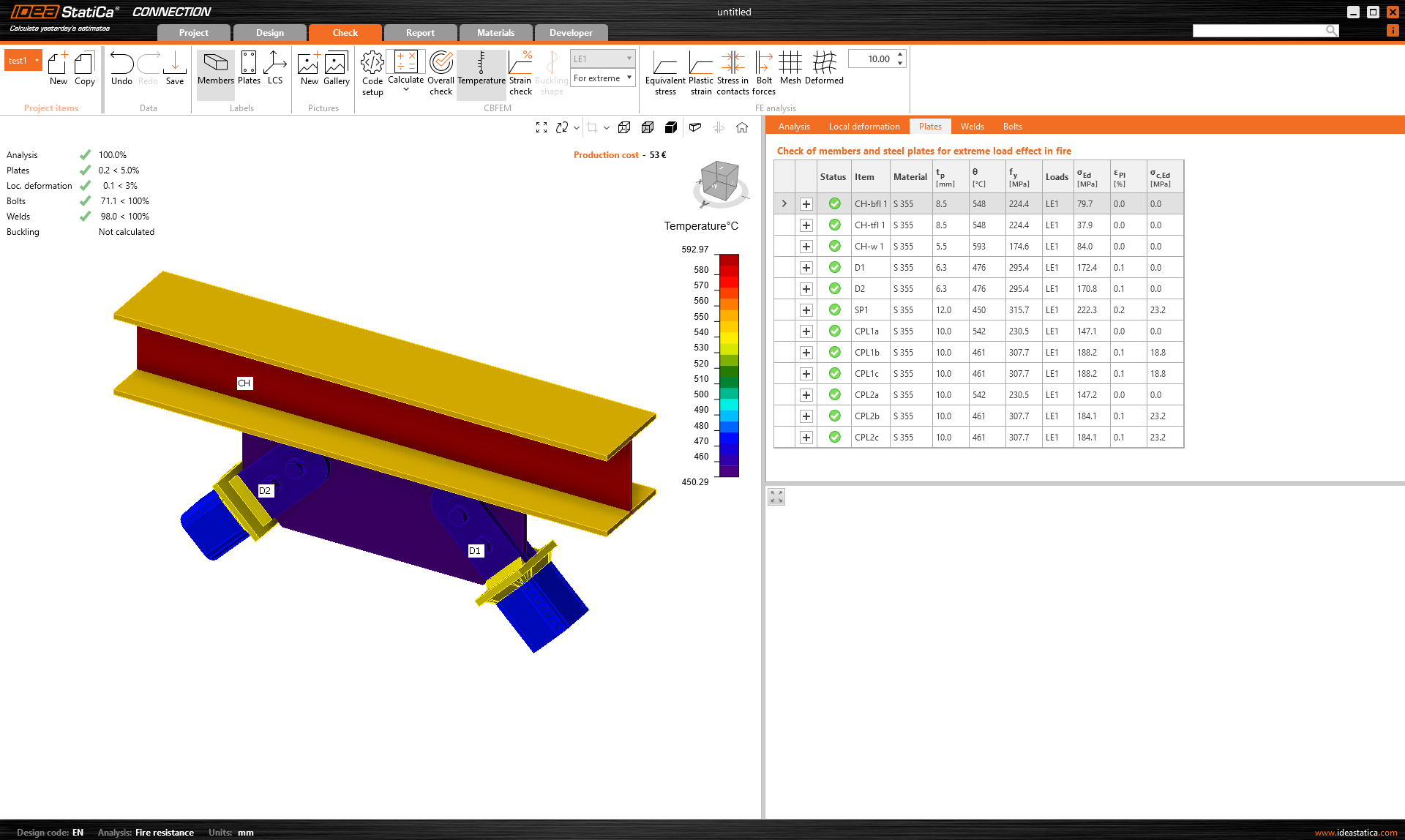

When the class is increased to R90, and, therefore, with the extension of the time during which the structure must withstand fire, we again reach temperatures around 700 °C. However, with fire protection, there is enough time for evacuation in the first case.

With the help of a numerical model, we were able to do this simple comparison of different cases in a few minutes. It is also easy to read from the results which component is likely to be the weakest point of the design.

Finally

As seen above, designing for the effects of fire doesn't need to be such a struggle. Idea StatiCa will help you design a structure that is safe for use and, at the same time, economical. There is no need to use outdated conservative methods or to avoid calculations completely.

In addition to fire resistance in IDEA StatiCa Connection, we also offer a solution for verifying all members in IDEA StatiCa Member.

For more theory, read the knowledge base article Fire Design or check the verification cases done by Professor Wald from CTU.