Concrete - Strength

The concrete model implemented for strength calculations in CSFM is based on the parabolic-plastic stress-strain curve. The tensile strength is neglected, as it is in classic reinforced concrete design.

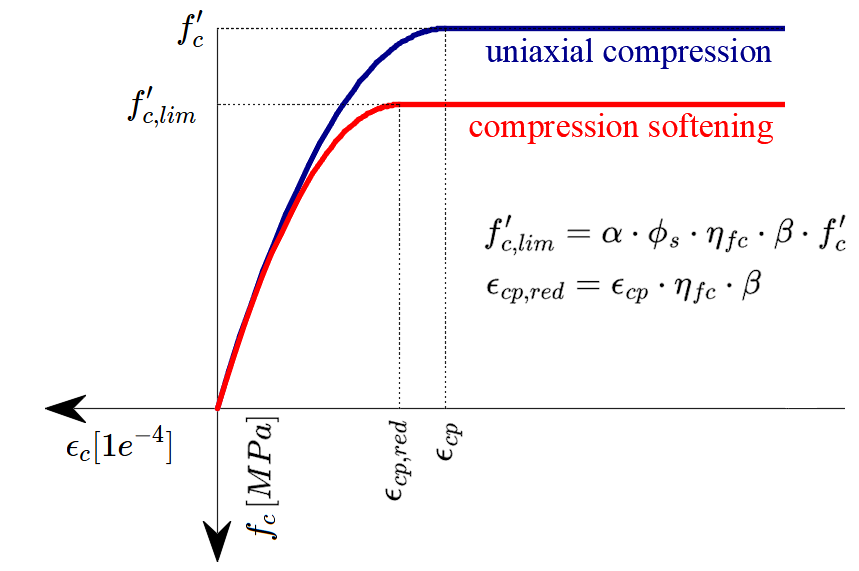

\[ \textsf{\textit{\footnotesize{Fig. 57\qquad The stress-strain diagram of concrete for Strength analysis}}}\]

The implementation of CSFM in IDEA StatiCa Detail does not consider an explicit failure criterion in terms of strains for concrete in compression (i.e., after the peak stress is reached, it considers a plastic branch with εc0 in maximum value 5%, while AS 3600 Cl. 8.3.1 assumes ultimate strain of less than 0.3%). This simplification does not allow the deformation capacity of structures failing in compression to be verified. However, the strength is properly predicted when, in addition to the factor of cracked concrete (kc2 defined in (Fig. 58)), the increase in the brittleness of concrete as its strength rises is considered by means of the \(\eta_{fc}\) reduction factor defined in fib Model Code 2010 as follows:

\[f'_{c,lim}=\alpha_{2}\cdot\phi_{s}\cdot \beta \cdot \eta_{fc}\cdot f'_{c}\]

\[{\eta _{fc}} = {\left( {\frac{{30}}{{{f'_{c}}}}} \right)^{\frac{1}{3}}} \le 1\]

where:

α2 is the reduction factor of concrete compressive strength defined in AS 3600 Cl. 8.3.1

When using a parabola-rectangle stress-strain diagram, it is necessary to reduce the maximum compressive stress by this factor. This averages the stress distribution in the compression zone in such a way that the resulting compressive strength is less than or equal to the compressive strength calculated using a stress-strain diagram with a decreasing plastic branch. An analogous approach is defined for the Rectangular stress block in Chapter 8.1.3.

Φs is the stress reduction factor for concrete. The default value is set according to AS 3600 Table 2.2.3.

β is the reduction factor due to the presence of transverse cracking (also referred to as kc2 in this text)

f'c is the concrete cylinder strength (in MPa for the definition of \( \eta_{fc} \)).

\[ \textsf{\textit{\footnotesize{Fig. 58\qquad The compression softening law.}}}\]

β is a reduction factor based on the same principles as an effective compressive strength factor defined in Chapter 2.2.3. The literature against which this factor is determined can be found (including the context of the AS3600 standard) in AS3600:2018 Sup 1:2022 CL. C2.2.3.

Concrete – Serviceability

The serviceability analysis contains certain simplifications of the constitutive models which are used for strength analysis. The plastic branch of the stress-strain curve of concrete in compression is disregarded, while the elastic branch is linear and infinite. Compression softening law is not considered. These simplifications enhance the numerical stability and calculation speed and do not reduce the generality of the solution as long as the resultant material stress limits at serviceability are clearly below their yielding points (as required by AS3600). Therefore, the simplified models used for serviceability are only valid if all verification requirements are fulfilled.

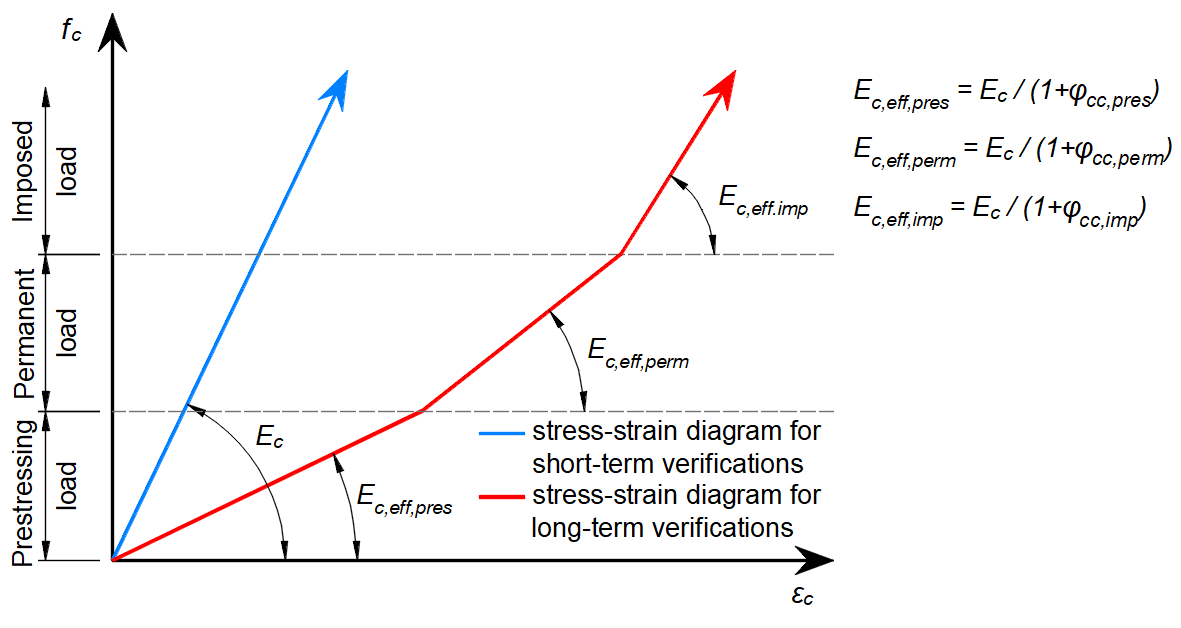

\[ \textsf{\textit{\footnotesize{Fig. 59\qquad Concrete stress-strain diagrams implemented for serviceability analysis: short- and long-term verifications.}}}\]

Long-term effects

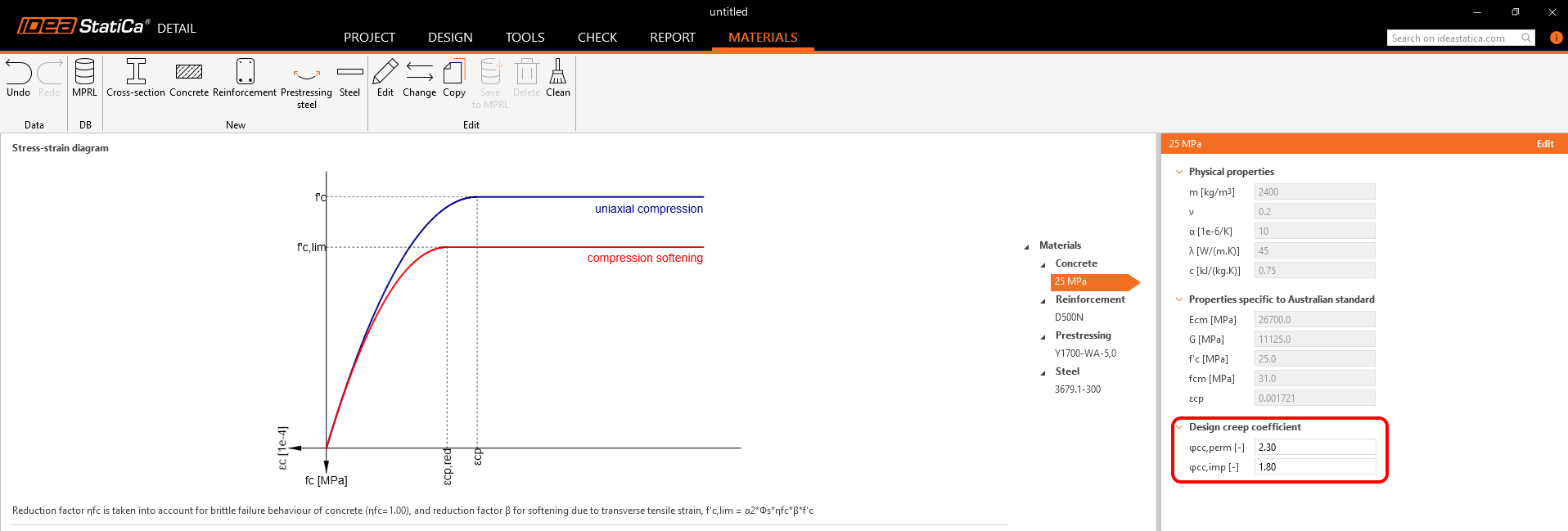

In serviceability analysis, the long-term effects of concrete are considered using the Design creep coefficient according to AS 3600 CL 3.1.8 (φcc, taken as a value of 2.5 by default), which modifies the secant modulus of elasticity of concrete (Ec) as follows:

\[E_{c,eff} = \frac{E_{c}}{1+\varphi_{cc}}\]

Load increments are sequentially calculated in the order: Prestressing - Permanent - Imposed, using the appropriate effective modulus of elasticity for each increment as shown in Fig. 59. Creep factors are defined by the user in material properties and shall be calculated according to AS 3600 CL 3.1.8.3

\[ \textsf{\textit{\footnotesize{Fig. 60\qquad Definition of the design creep factor}}}\]

Short-term effects

To conduct short-term verifications, another calculation is performed in which all loads are calculated without the time-dependent factor for sustained loads. Both calculations for long and short-term verifications are depicted in Fig. 59.

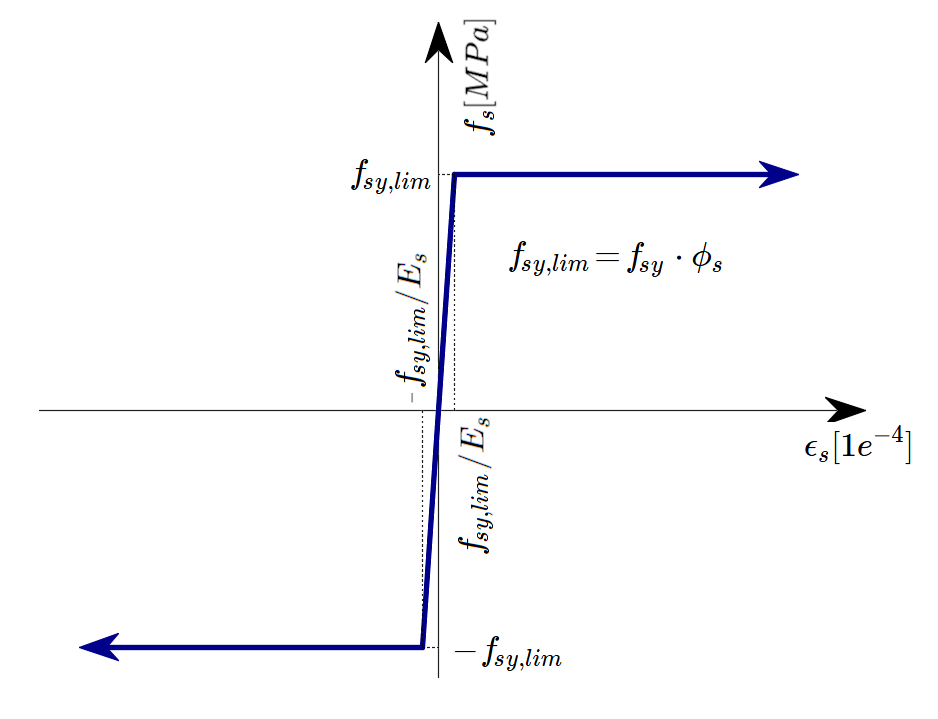

Reinforcement

A perfectly elasto-plastic stress-strain diagram with a defined yield point for the non-prestresses reinforcement is considered, see AS 3600 Section 3.2. The definition of this diagram only requires the basic properties of the reinforcement to be known – the strength and modulus of elasticity.

The reinforcement stress-strain diagram can be also defined by the user, but in this case, it is impossible to assume the tension stiffening effect (it is impossible to calculate crack width).

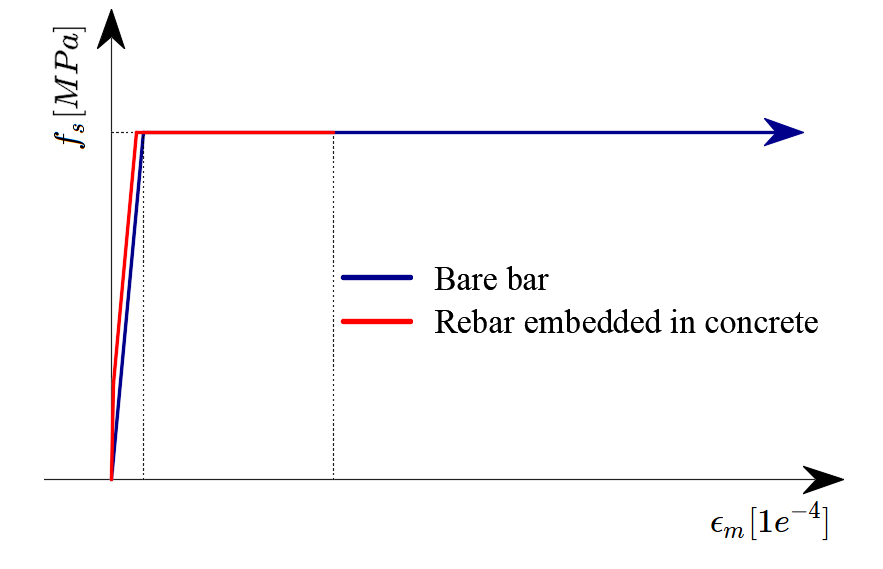

\[ \textsf{\textit{\footnotesize{Fig. 61 \qquad Stress-strain diagram of reinforcement}}}\]

where:

Φs is the strength reduction factor for reinforcement. Where the default value is set according to AS 3600 Table 2.2.3.

fy is the yield strength of reinforcement

Es modulus of elasticity of reinforcement

Tension stiffening (Fig. 62) is accounted for automatically by modifying the input stress-strain relationship of the bare reinforcing bar in order to capture the average stiffness of the bars embedded in the concrete (εm).

\[ \textsf{\textit{\footnotesize{Fig. 62\qquad Scheme of tension stiffening.}}}\]