Precast concrete purlin of logistic hall CTPark Blučina

About the project

The high-capacity hall BLU3 is part of the CTPark Blučina logistics hub. The building has a footprint of 264.0 x 192.0 meters. The load-bearing structure of the hall is made as a prefabricated assembly of atypical reinforced concrete elements. In the longitudinal direction, the building consists of 11 aisles, with a modular span of the main tapered roof beams being 24.0 meters. In the transverse direction, the distance between the frames is 12 meters. Perpendicular to the main tapered roof beams are prefabricated purlins, and the roof covering is made from trapezoidal sheets. The structure is founded on wide-profile drilled piles with pile caps, where collars have been formed.

The investor of the logistics park construction is the company CTP Invest, spol. s r.o., and CTPark Blučina is part of an extensive network of business parks across Europe, from the North Sea to the Black Sea.

Engineering Challenges

Although the basic static system of the load-bearing structure generally represents a fairly traditional solution, it was necessary to address a number of technical challenges. A standard requirement in today's world is the maximization of usable space, which leads to very slender vertical structures and large spans of horizontal load-bearing elements in the roof structure. Designers of prefabricated constructions are also under pressure to achieve maximum optimization of material consumption. Additionally, from the perspective of transporting individual prefabricated elements, it is necessary to design slender and as lightweight as possible roof beams, purlins, etc. All of this, of course, while maintaining high load-bearing capacity and long-term durability of the structure. Therefore, modern computational tools must be used for the design and assessment of these slender and optimized elements, which describe the response of the structure more accurately than was previously possible.

What role did IDEA StatiCa play?

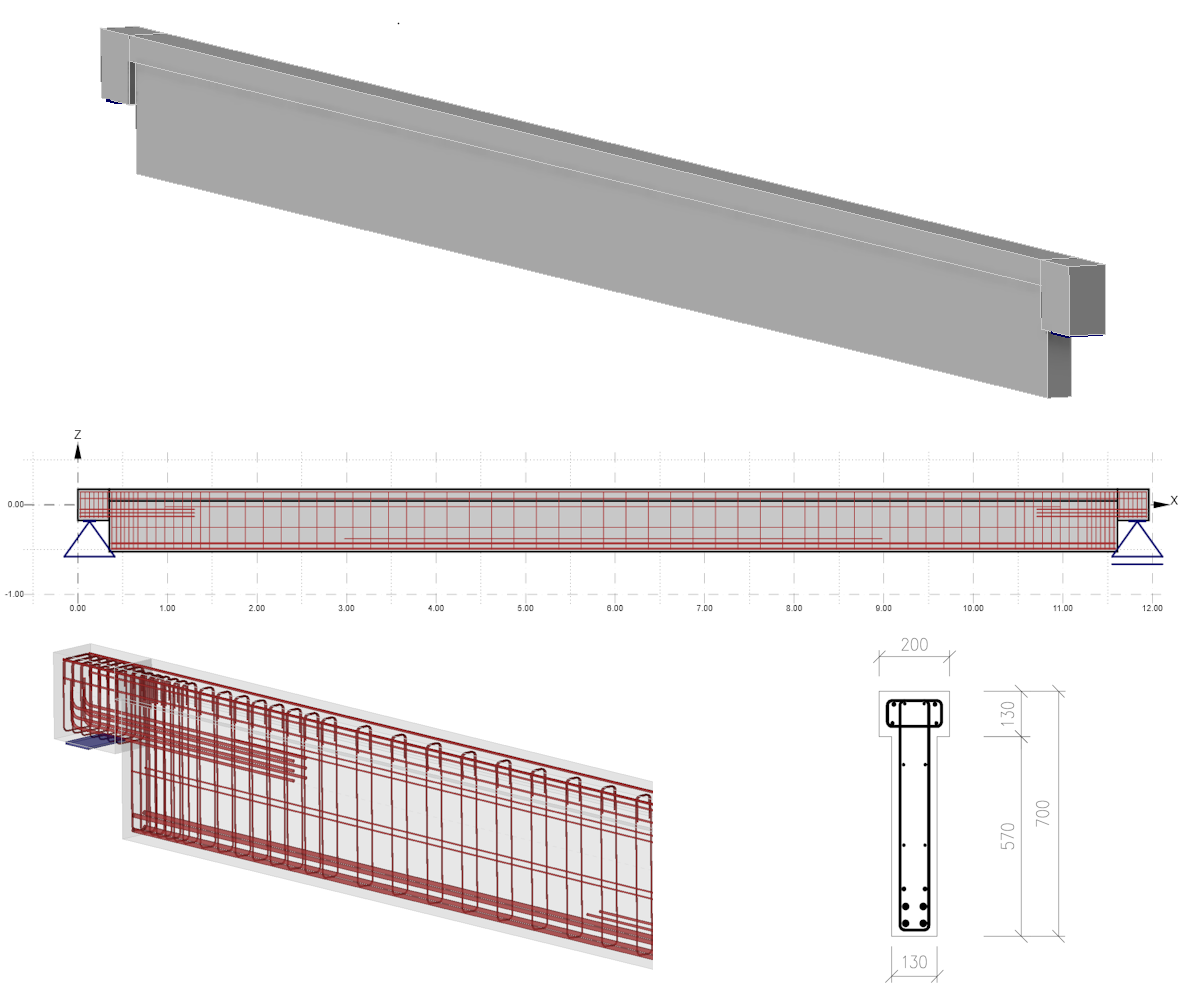

The modular spacing of the tapered roof beams is 12.0 meters. The purlins of this assembly length are supported on the upper flange of the beams using dapped end connection. The cross-section of the purlin is in the shape of a T with a wall thickness of only 130 mm. The dapped end of the purlin is a typical area of discontinuity (so-called D-region).

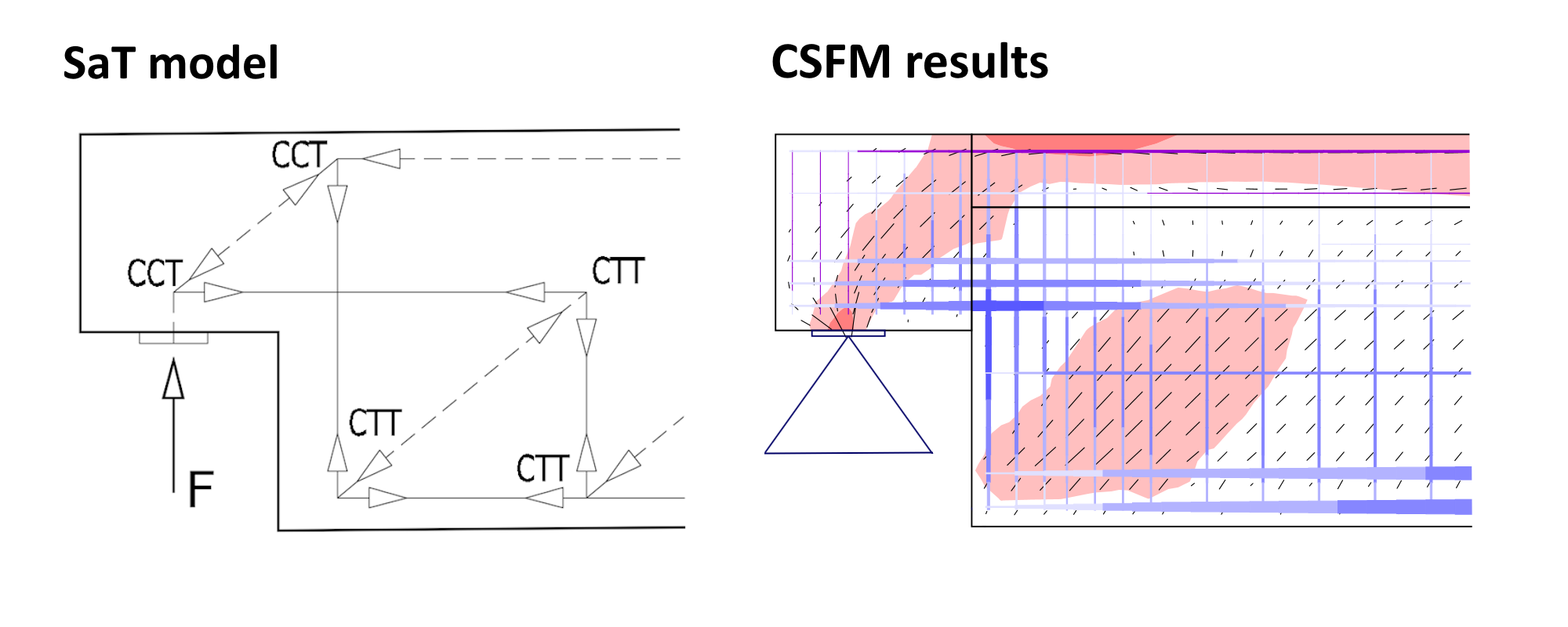

The dapped end can typically be analyzed using a Strut-and-Tie analogy, which is described in the literature for this D-region. However, a proper solution using the SaT model can be a lengthy iterative process. The exact geometry of the truss often needs to be determined through several iterations, depending on the actual reinforcement design. Additionally, assessing the anchorage of the reinforcement at the truss nodes is a complex task. Moreover, the SaT model is used solely for evaluating the ultimate limit state, not for serviceability limit state (cracks, deformations, stress limitations).

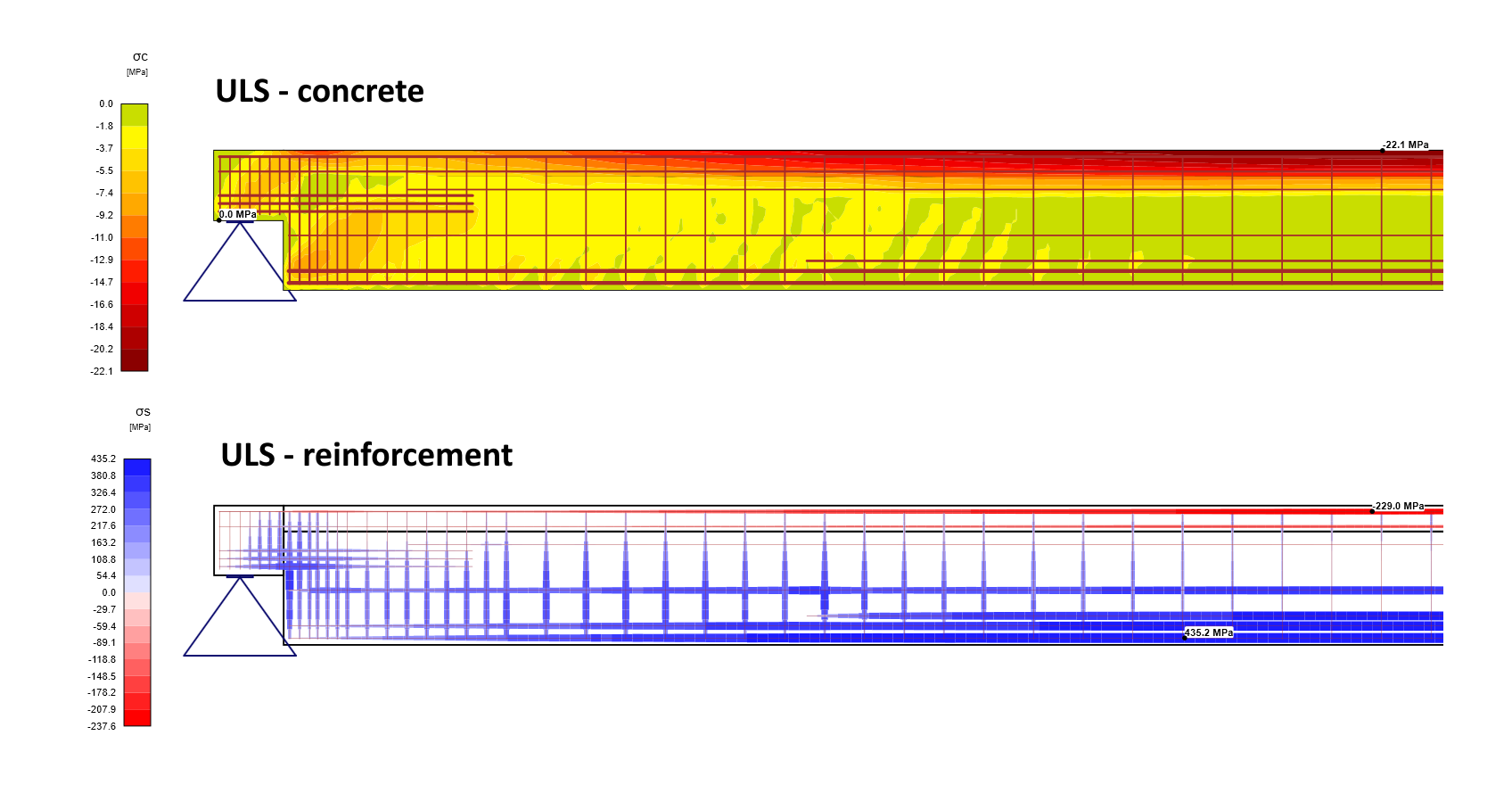

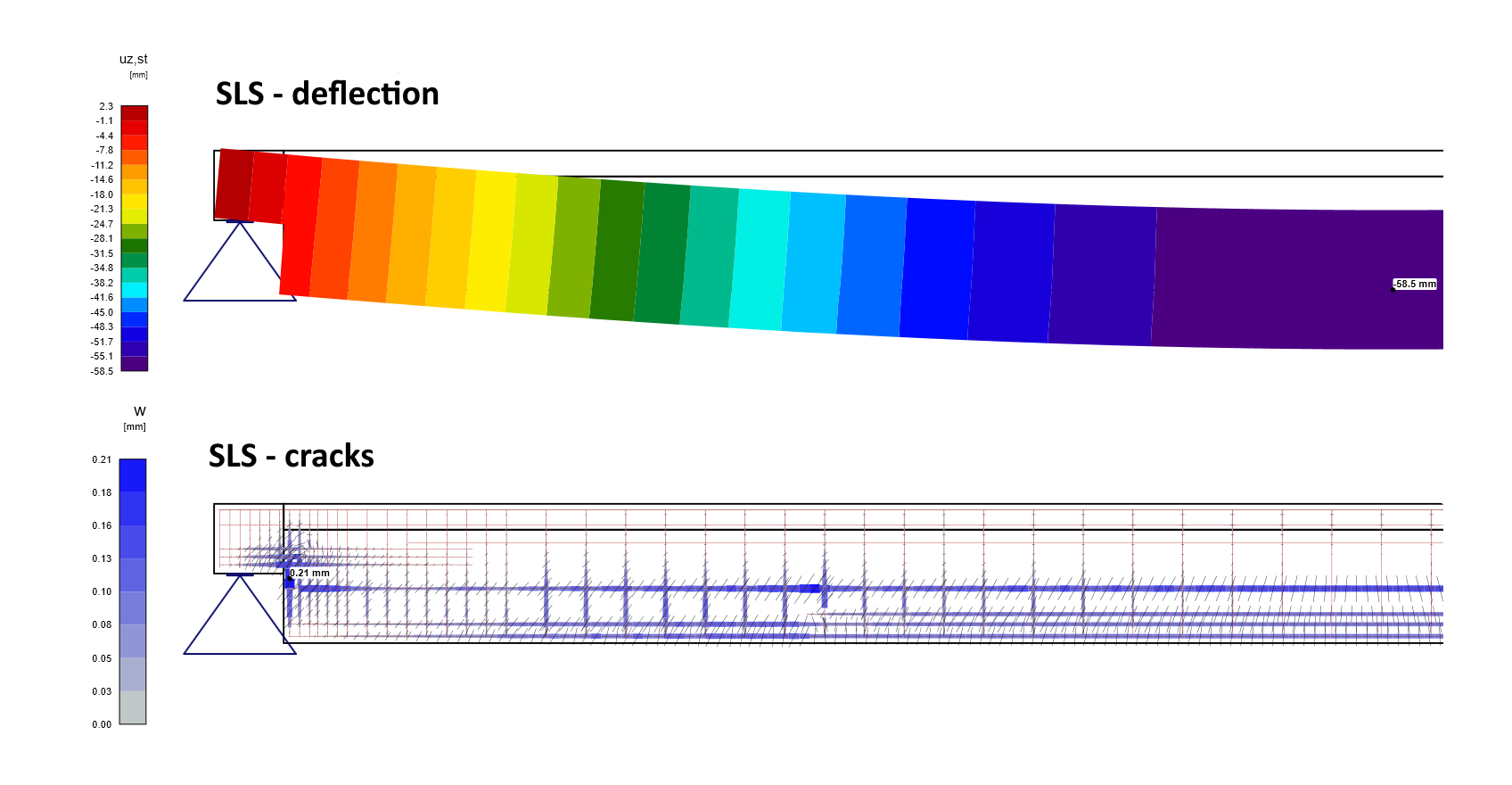

For a detailed assessment of the purlin support, the IDEA StatiCa Detail application was used, as it eliminates the aforementioned disadvantages of the SaT models. The CSFM method, implemented in the Detail application, is based on standard conservative assumptions for the design of reinforced concrete structures (concrete does not carry tension). It allows for the assessment not only of the ultimate limit state (including anchorage of reinforcement) but also of the serviceability limit state, including evaluation of crack widths and deformations in the D-region.

In the Detail application, it is possible to analyze details either as cut-out parts of the whole structure or, preferably, by assessing the entire element model. The engineers from DUPROCON decided to evaluate all limit states using a model of the complete purlin instead of a local model of the dapped end. This approach is particularly effective for elements where multiple D-regions occur simultaneously (dapped ends, openings in the web, haunches), and also in cases where material optimization is needed, especially for reinforcement.

About DUPROCON

The company DUPROCON, s.r.o., based in Zlín, is a structural design office specializing in the design of reinforced concrete structures for all types of buildings in civil engineering. It primarily focuses on precast structures, in which it has extensive experience. Currently, these are mainly buildings for manufacturing, logistics, and commerce.