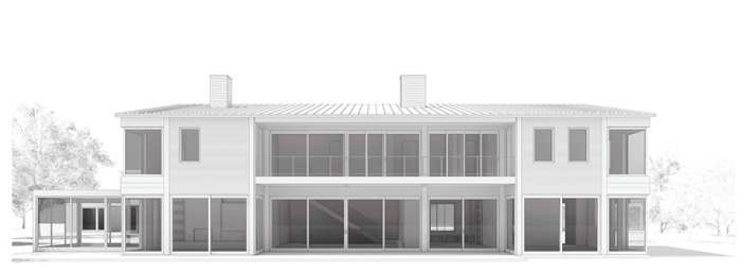

Family home in Massachusetts

About the project

Using REVIT for all drafting, exhaustive CAD file sharing, and workflow management, CRAFT could leverage the tool (and its integration with RFEM) to configure their structure model based on the structural analysis.

They had also wanted to do their connection design in RFEM, but it wasn’t supported for such a highly complex joint design. So they turned to IDEA StatiCa.

United States

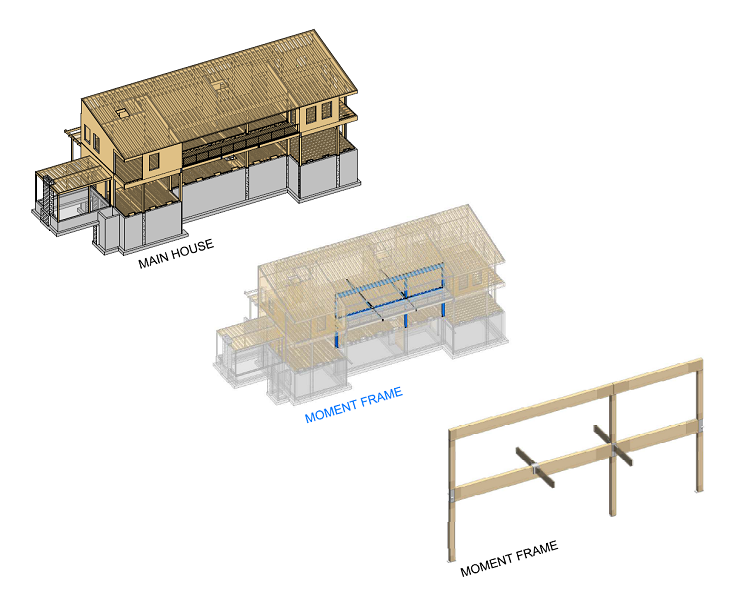

With an average floor height of 10 ft (3 m), the two-story moment frame consists of two spans of 21 ft (6.4 m) and 14 ft (4.3 m).

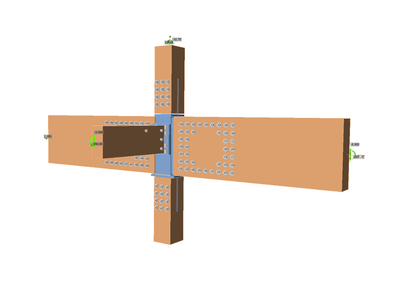

The architect-designed a soft-story structure in order to leave a completely open space for the balcony area without obvious structural braces or support. So, the team had to design thermally broken un-propped balcony framing, for which they chose to combine a moment frame with deep multi-LVL timber girders intersected with orthogonal flitch beams to form the cantilevers and back spans.

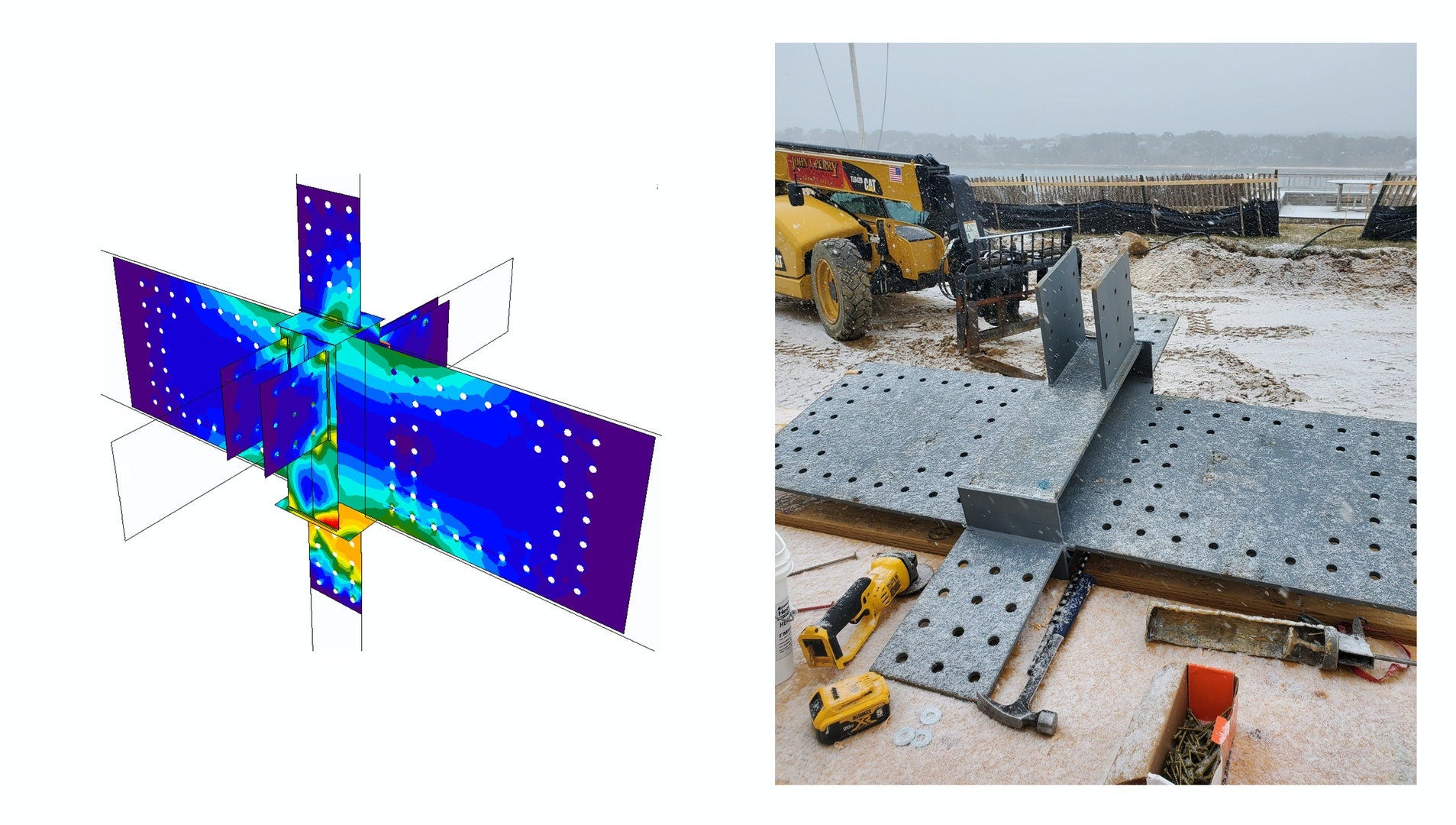

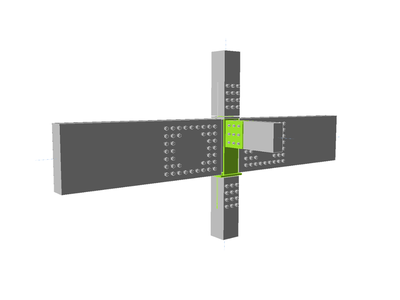

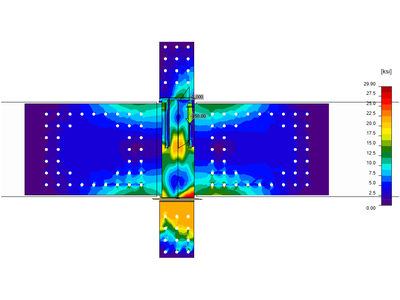

The resulting steel node joint was designed to resist forces and moments in the two orthogonal axes. Initially, they wanted to use a central hollow section hub but then found it to be incapable of resisting the high moments from the moment frame girder because of insufficient out-of-plane stiffness in the box section walls.

United States

The steel joint was redesigned with a wide flange section to preserve continuity in both axes while also ensuring a more direct transmission of forces and moments to the center of the hub.

Additionally, the balcony members required steel to run continuously through the thermal line of the building, so the team included a thermal break pad (from a customized material) to reduce risks from heat loss and condensation.

They used Dlubal RFEM to analyze and design the framing members and IDEA StatiCa to design intricate connections in multiple materials.

United States

Engineering challenges

The challenges in this project were many.

As we’ve already learned, not only was the building atop a steep bluff and needed to be able to resist high winds without shear walls or braces but to make things more complicated, the thermally broken, unpropped balcony introduced a second orthogonal design direction to the main moment frame – meaning shear, axial and moment capacity needed to be resisted in 2 directions at the node points.

The original design was conceived as a steel system. So CRAFT was working with a steel-type building topology with the driver to do as much of it as possible in structural timber and wood.

Although timber connection designs were not supported by IDEA StatiCa, the tool was able to provide output forces at specific bolt positions. The team could then easily transfer these results to their in-house design spreadsheet (for wood-codified compliant bolt bearing checks) to verify the distribution of the force and then complete their structural design for the connection.

United States

Solutions and Results

Due to completion in 2022, the double-story single-family home in Martha’s Vineyard is a stunning example of superior architectural and structural design.

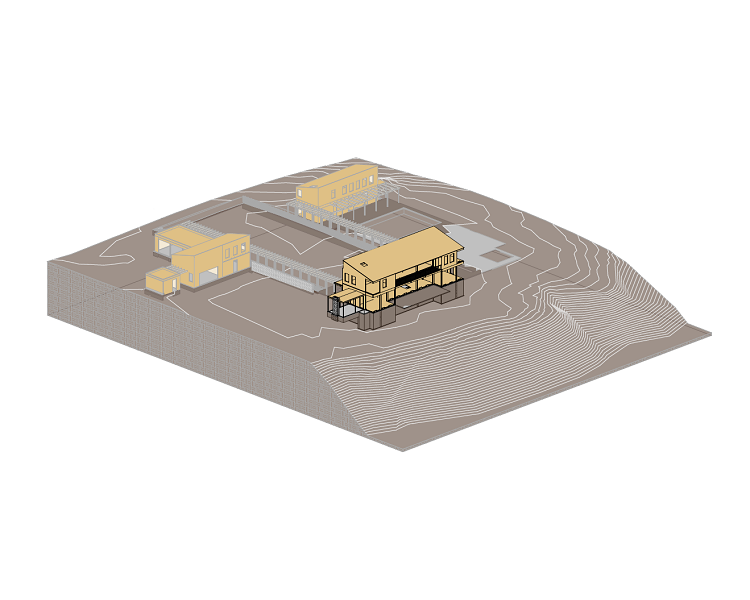

Through their use of IDEA StatiCa software and close collaboration with the architect, thermal consultant, and fabricator, CRAFT successfully evolved a full steel frame into a hybrid wood solution, reducing the amount of steel required and keeping the structure of the building in line with traditional local construction.

About Craft | Engineering Studio

Based in New York, CRAFT provides structural engineering consulting services in the construction of new (and the alteration of existing) residential, commercial and special projects in traditional and non-traditional materials.

A visionary structural engineering studio, the CRAFT team is passionate about the ongoing conversation between structural engineering and architecture. Blending their experience and open-mindedness with top computational and analytical tools, CRAFT is able to offer its clients efficient, practical, and innovative solutions to structural design – perfect for architects and designers looking for new approaches to structural engineering delivery.

As Project Engineer, Trevor Chou brings his experience in performing structural design and analysis for high-rise buildings and commercial housing (under US and Chinese building codes) and is passionate about integrating his knowledge of architecture and engineering.

Martyn Sheard is a Senior Project Engineer at the firm and has twelve years of experience in design and project management across a wide range of project types and scales, with a particular interest in engineering mass timber structures.

Martyn Sheard and Trevor Chou became winners of the Small scale structures category in IDEA StatiCa Excellence Award 2021, beating 100 other entrants in the small-scale structures category to win.

Learn what the engineers say about the project

OTHER CASE STUDIES