Walking Columns: A Solution to Structural and Architectural Complexity

When floor layouts change, like a parking garage beneath a lobby or offices below apartments, it often requires shifting column grids to meet both architectural and functional needs. This is when a walking column provides a smart, practical alternative to bulky transfer beams or visually intrusive raking columns.

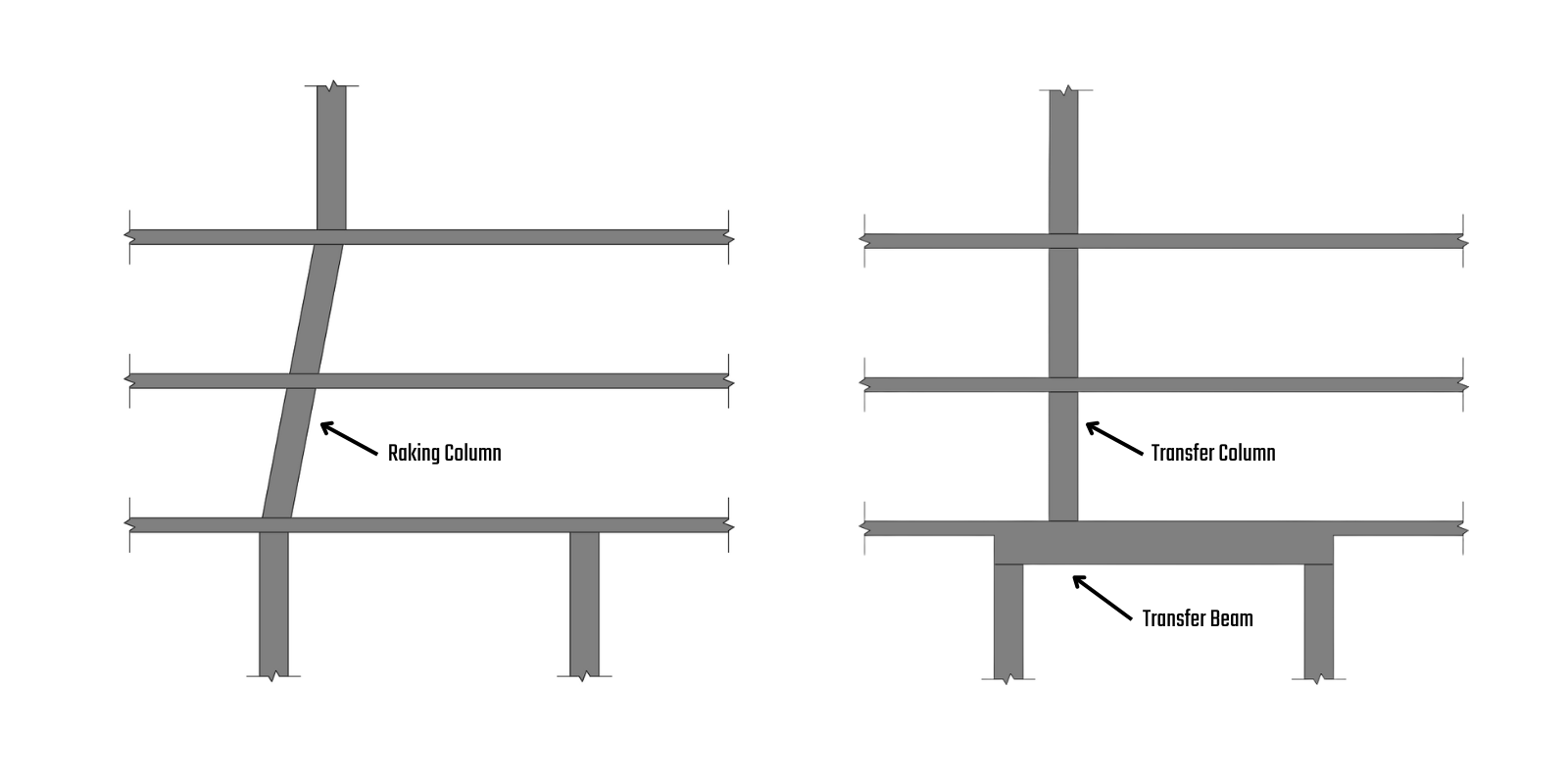

a) Raking column arrangement, and b) Transfer column and transfer beam arrangement

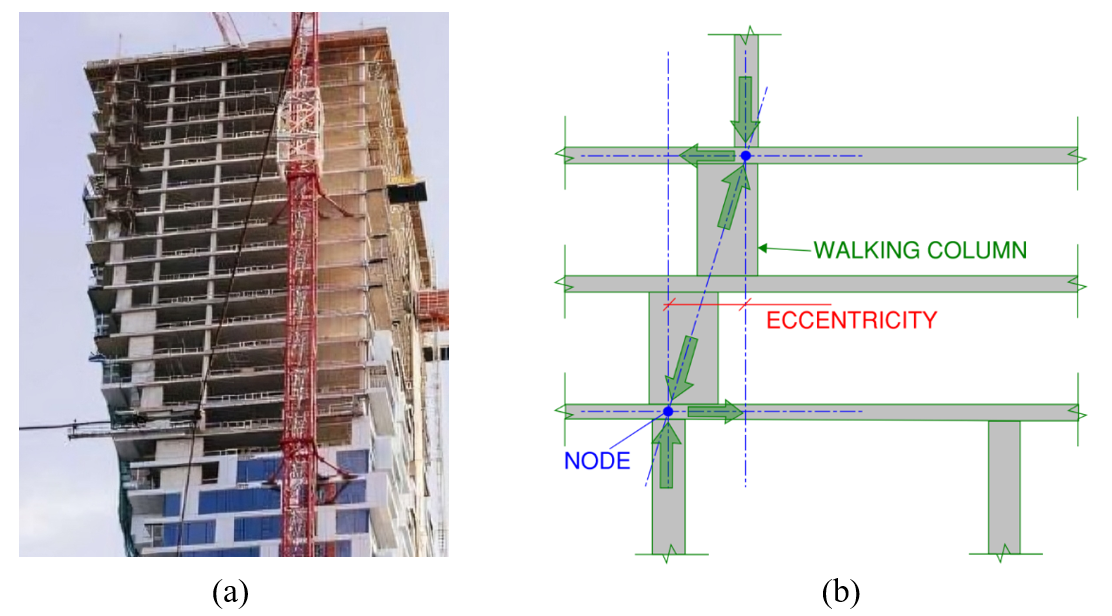

A walking column is a structural column that steps or "walks" horizontally between floors, allowing the column's plan location to gradually shift without abrupt load transfers. Unlike sloped or raking columns, walking columns are composed of vertically stacked segments offset at each floor level. This makes them easier to build and integrate into conventional formwork systems while maintaining a relatively direct load path, which is a key principle in efficient structural design.

a) Walking column in real building, and b) Load transfer mechanism of walking column (SheerForce Engineering, 2021).

You can find a detailed description of different structural systems, including their methods of load transfer along with their respective benefits and drawbacks, on the following SheerForce Engineering web page.

Problems that arise

Though walking columns can be an advantage in certain structural layouts, they also bring unique design challenges that go beyond the scope of conventional codes such as ACI 318 or Eurocode. These elements typically exhibit low span-to-depth ratios, ranging from 1:9 to 1:4, making them fundamentally different from deep beams. For ratios below 1:4, deep beams are generally favored due to their enhanced resistance to overturning, supported on two opposite faces. In contrast, walking columns' slender geometry can inhibit the formation of diagonal strut-like compression fields that are characteristic of deep beam behavior.

As a result, their design requires careful consideration of diaphragm strut action, complex node reinforcement, and reliance on mechanics-based approaches like the strut-and-tie method (STM). Whether STM remains effective and efficient across all aspect ratios, particularly in slender cases, necessitates further evaluation through scientifically oriented FEM tools, ensuring both structural safety and material optimization. However using such software for concrete column design can be very time-consuming due to their iterative nature..

IDEA StatiCa Detail helps engineers find a solution that provides sufficiently realistic analysis based on input data (not just estimation), while at the same time avoiding the need to spend hours or even days on modeling. Using Detail, you can perform FEM analysis by applying the CSFM method, as well as model using the entities available in the application. This replaces the need to manually define all the interactions between reinforcement and concrete, boundary conditions, or meshing as the software handles these aspects automatically.

Structural safety above all

In the strut-and-tie method, we assume what the strut-and-tie model will look like and then design its individual components accordingly. Similarly, the ratios mentioned above are usually based on experience. But what if we need to design a slightly different type of structure? Can we be 100% sure that the structure still behaves exactly as assumed? FEM methods can provide you with that level of confidence.

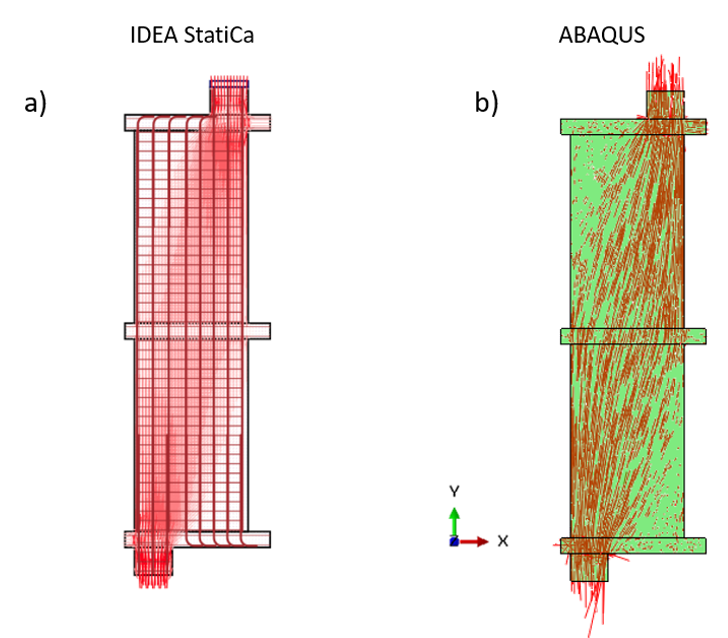

Ohio State University recently published a comparison of the use of SaT, CSFM (via IDEA StatiCa), and FEM (ABAQUS) to analyze several models, with the comparative analysis revealing clear trends. ABAQUS consistently predicted higher capacities, reflecting its strength in capturing complex material behavior and loading conditions. In contrast, STM and CSFM (with ϕ factors) yielded more conservative estimates. CSFM proved to be a reliable tool for evaluating walking columns, offering valuable insights into failure mechanisms and structural performance. You can read the full study here.

Comparison of the direction of principal stresses calculated using the IDEA StatiCa and ABAQUS models

From theory to practice

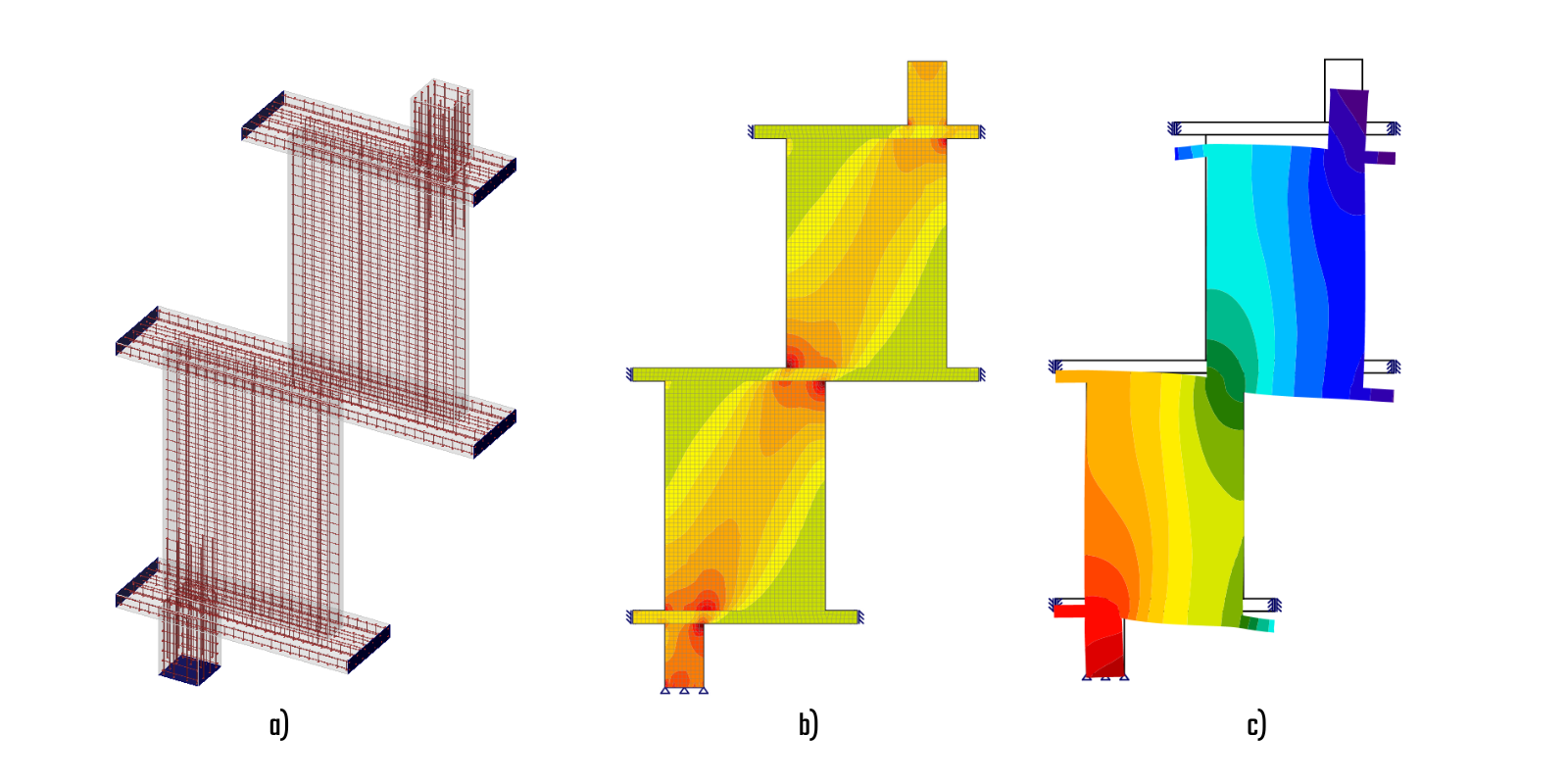

In practice, ideal cases matching theoretical models are not always available. A key benefit of IDEA StatiCa Detail (CSFM) is its ability to model and analyze any geometry, regardless of complexity, offering engineers a high degree of flexibility. The results include stress and strain fields, crack widths, load paths, and utilization ratios, which provide the user with a very clear understanding of what is happening within the structure and how the load is being applied. It is possible to carry out these assessments in both ACI and EN as the application includes material libraries and coefficients for both codes. A complete report can be generated from the results, including the export of the bill of materials and reinforcement layout.

For a better understanding of the modeling process, results, and application itself, take a look at the step-by-step tutorial or this webinar* dedicated to the topic.

*While the application interface has slightly changed since the version mentioned in the webinar, the method and modeling principles remain the same.

a) Reinforced model of walking column in IDEA StatiCa, b) Results - concrete stress fields, and c) Results - deflection

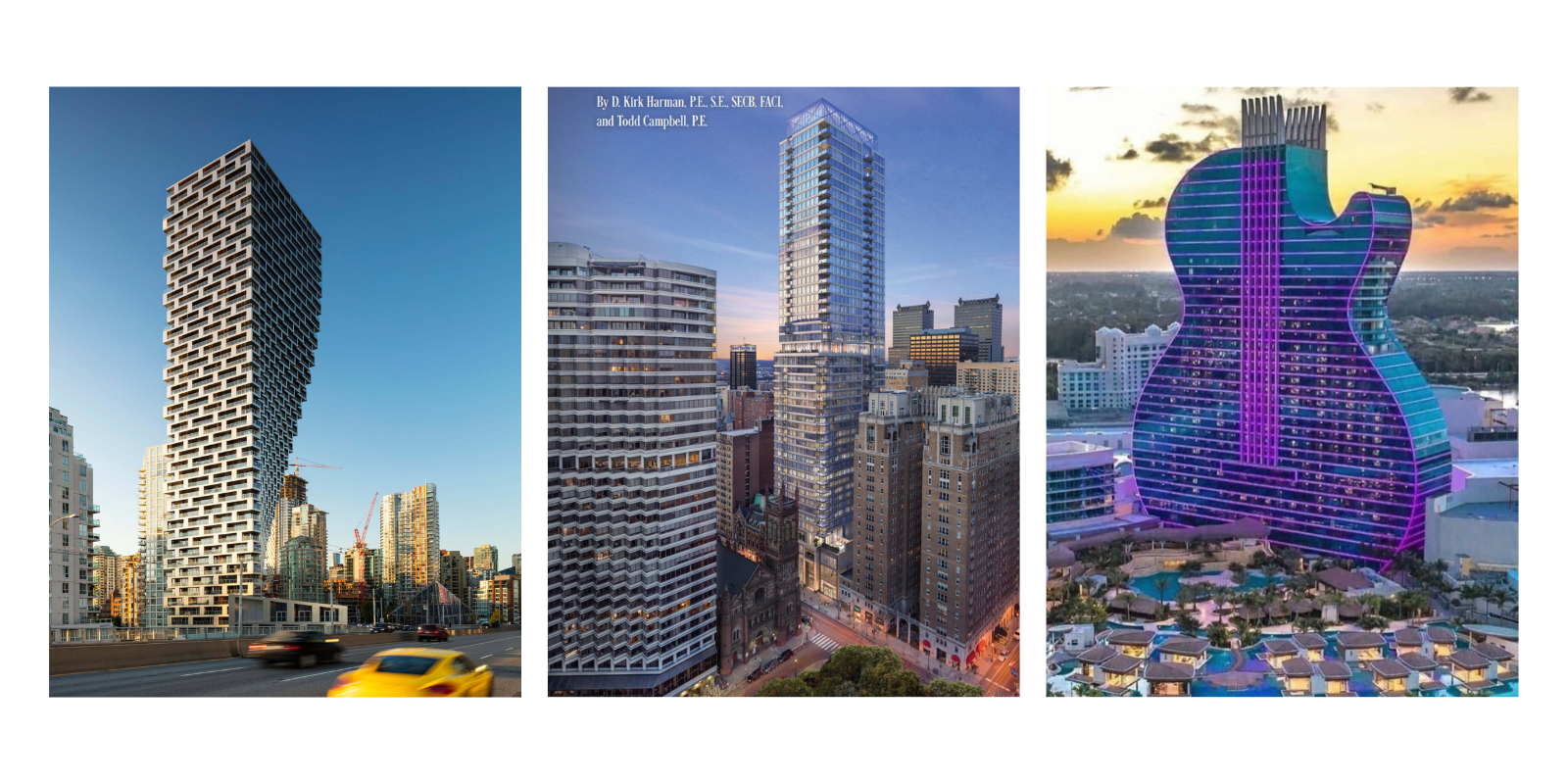

CSFM is not a new concept, it is an established method that has been in use for several years, and has been validated both in academic research and real-world applications. A notable example is IMEG, a pioneer in the field of walking columns, which now uses IDEA StatiCa Detail to verify strut-and-tie models for critical structural elements. One of the projects where IDEA was used to verify critical details is Laurel Rittenhouse Square Project, shown in the center of the image below.

Examples using walking columns - Vancouver House, The Laurel Rittenhouse Square, Seminole Hard Rock Hotel and Casino by IMEG

Conclusion

Walking columns offer a smart and practical structural solution for shifting column grids in complex building layouts, avoiding the need for bulky transfer beams or visually intrusive raking columns. Their unique geometry, however, introduces several design challenges not fully addressed by conventional codes, requiring advanced analysis methods.

The combined use of the Strut-and-Tie Method (STM) and FEM, particularly through tools like IDEA StatiCa Detail, provides engineers with a reliable and efficient means to model and evaluate walking columns. With support for both ACI and EN standards, integrated material libraries, and full reporting features, IDEA StatiCa Detail lets you bridge the gap between theoretical concepts and practical implementation.