Prefabricated concrete structure of a residential complex in Tallinn

About the project

Kalaranna District is a modern residential area on six hectares comprised of 12 residential buildings with restaurants and commercial spaces, all linked by an underground parking lot. The third stage of the giant project, including four five-story buildings, was assigned to the structural company Innopolis Insenerid OÜ. Innopolis is a full-service architecture and engineering firm specializing in comprehensive digital construction design solutions across the Nordic and Baltic regions.

The structure is designed as reinforced concrete. The vertical load-bearing system is composed of prefabricated concrete walls with general shapes, while the horizontal load-bearing systems consist of hollow core slabs supported by prefabricated concrete elements or steel elements. Several buildings face the street, requiring code checks for potential car crashes and their impact on structural integrity.

\[ \textsf{\textit{\footnotesize{Architectural visualization of the Kalaranna District}}}\]

Engineering challenges

The investor required the entire structure to be designed using prefabricated elements, with minimal in-situ concrete work to maintain safety on the construction site and save time and money. The whole designing process was difficult, not only because of the complexity of the shapes of concrete elements but also because of intense pressure on the engineering team to complete all designs on schedule. Moreover, the detailed design period overlapped with the construction phase, demanding real-time adjustments without altering the approved architectural plans which were locked with no exceptions.

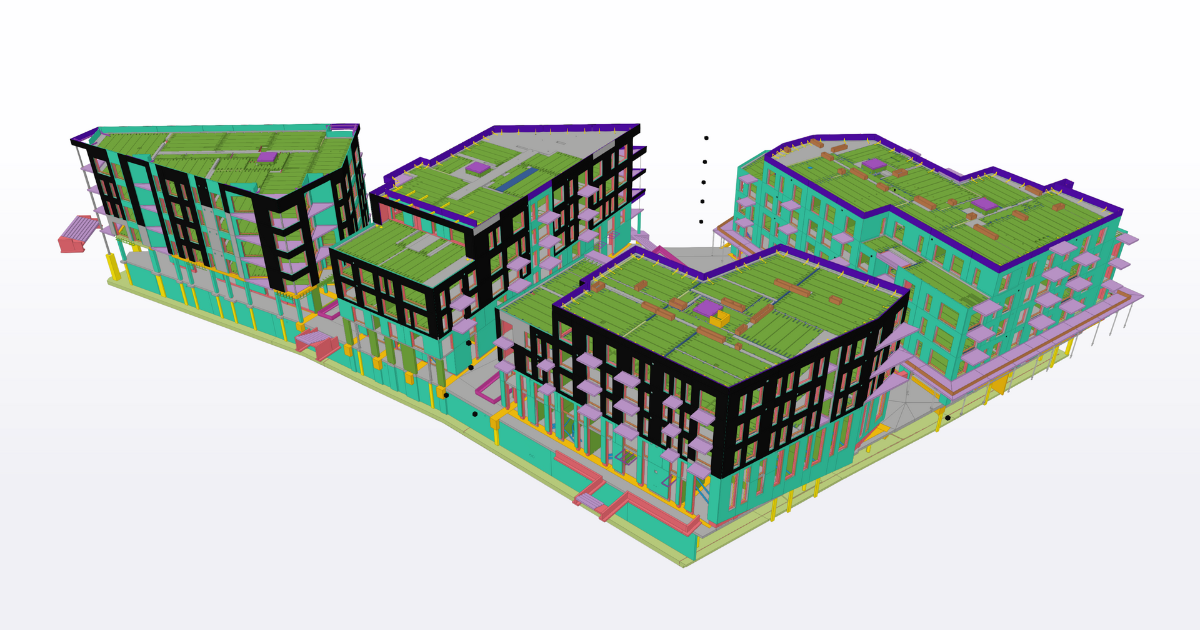

\[ \textsf{\textit{\footnotesize{Model of the third stage of the project}}}\]

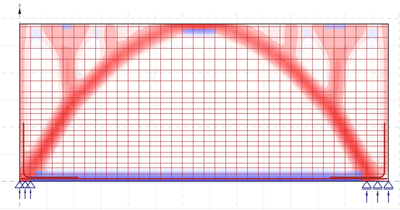

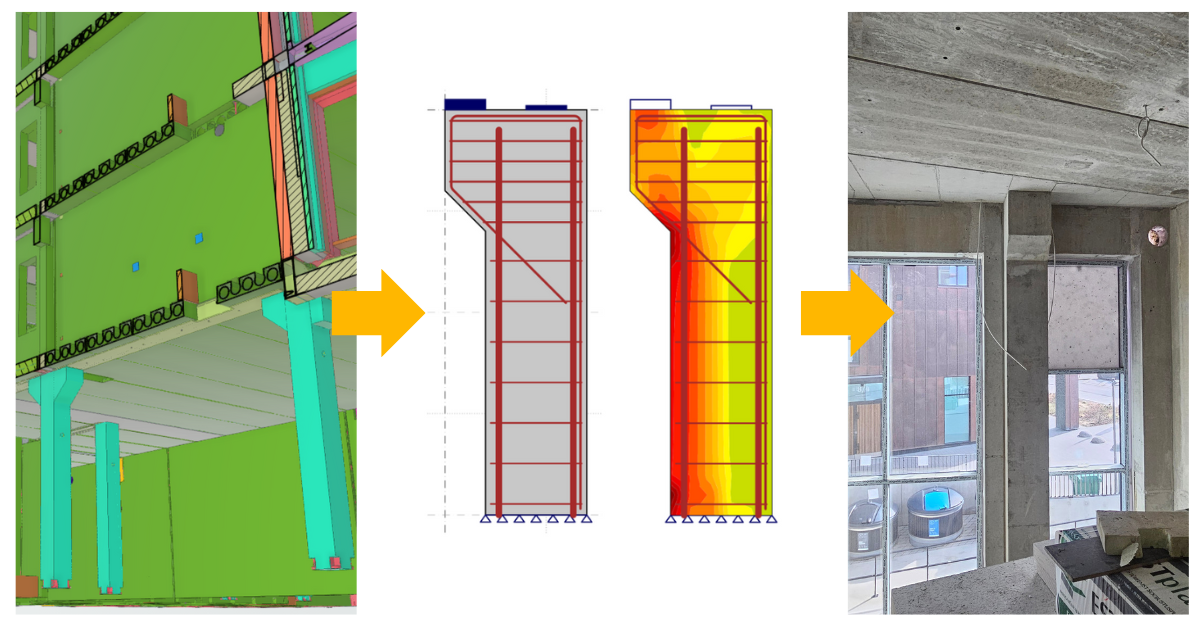

One of the main engineering challenges associated with the design was managing discontinuity regions, particularly openings for HVAC systems, creating weak points in the elements. The project also included unusually tall, 8-meter-high precast walls with large openings for windows. Another significant challenge was the varied shapes of the walls on different floors, which complicated how forces were transferred to the lower levels. This required detailed analysis to ensure the load paths were properly managed.

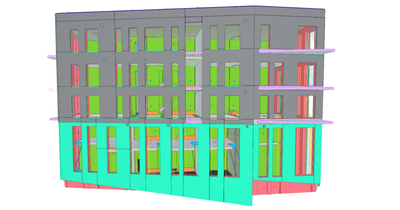

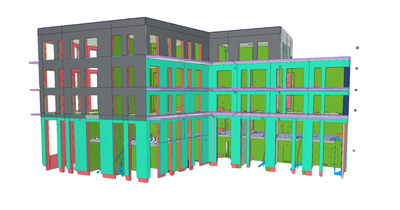

\[ \textsf{\textit{\footnotesize{8-meter-high precast walls }}}\]

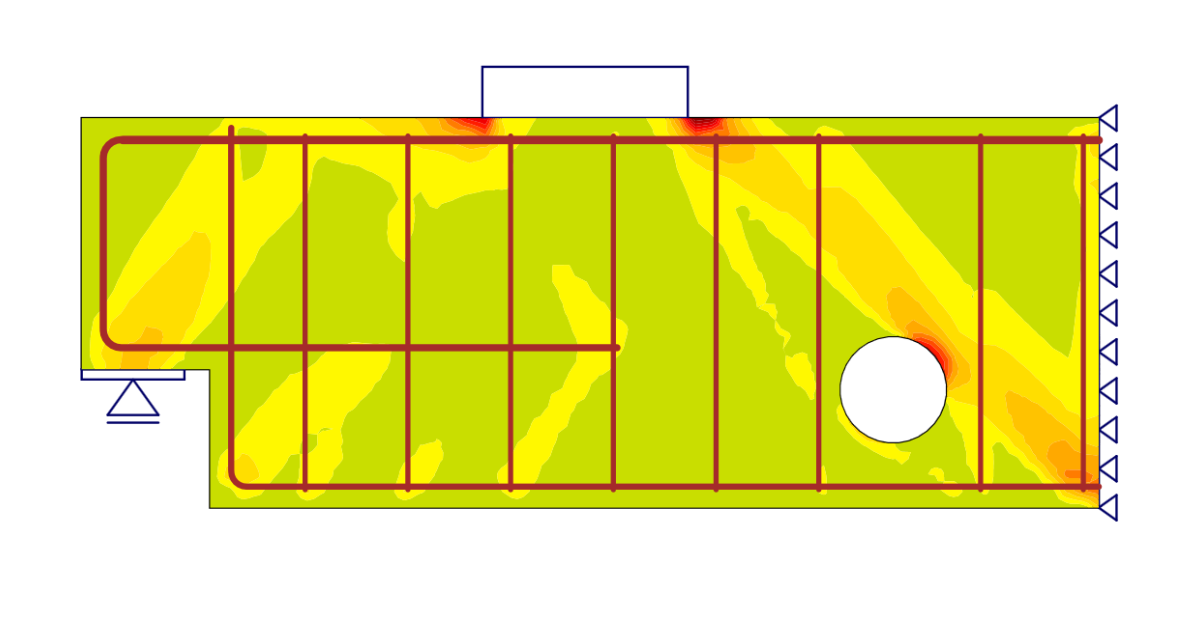

Another challenge appeared in the underground structure, where walls from the upper floors transferred their loads directly onto columns with no possibility of redesigning the load-bearing structure. This was because the structural layout had been locked in during the preliminary design stage, leaving little flexibility for changes during the detailed design phase. In one instance, engineers had to design custom steel box beams to support large openings, ensuring that the structural integrity of the walls was maintained despite the significant loads.

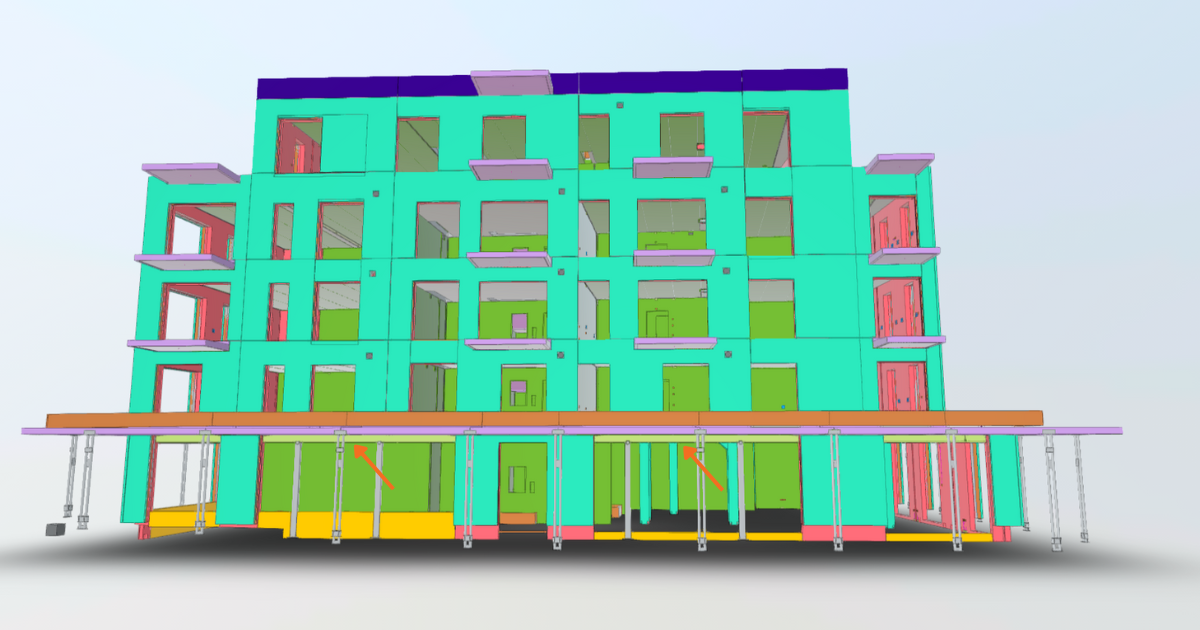

\[ \textsf{\textit{\footnotesize{Steel box beams supporting walls with large openings}}}\]

Solutions and results

To tackle the challenges of this kind of project, Innopolis Insenerid OÜ used IDEA StatiCa's software in their workflow to speed up the designing process to the maximum. Specifically, the IDEA StatiCa Detail application was used to model complex deep beams with discontinuities.

Estonia

Engineer Artur Andersalu utilized walls weakened by openings for doors and windows. He could easily determine boundary conditions, such as the steel column represented by the spring support acting in compression only and supporting walls represented by bearing plates for point supports. He also modeled the ceiling to account distribution of vertical loads from the upper floors to achieve more accurate stress flow according to the geometry and loads. Significant stresses occurred in the corners, which led to additional reinforcing to avoid wide cracks. Furthermore, he could determine and code-check deformation.

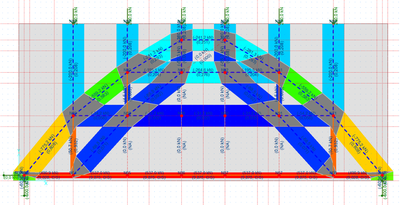

To ensure the accuracy of the design, the engineer also verified the results produced by IDEA StatiCa Detail using the strut-and-tie method. The comparison was conducted on a deep beam without opening to evaluate the distribution of forces. By cross-checking the results, the engineer confirmed the reliability of the software's analysis.

The design also included concrete beams with openings positioned close to the edge, which posed a challenge due to the high shear forces in these areas. To ensure the beams could handle these stresses, the engineering team used IDEA StatiCa to analyze the load distribution and optimize the reinforcement.

To address the concentrated loads from upper floors transferring directly onto columns in the underground structure, the engineering team designed columns with corbels. These corbels provided better stress distribution at wall element supports to avoid issues of controlling service limit stresses. By incorporating corbels, the engineers were able to maintain the structural integrity of the load paths without needing to alter the original architectural design, which was crucial for the project and did not allow any changes to the structure.

Conclusion

The construction of the residential complex in Tallinn, Estonia, was a demanding project that required careful coordination and advanced structural design. IDEA StatiCa Detail was an important tool in code-checking columns with corbels and deep beams with significant discontinuities, allowing the team to overcome challenges like irregular load paths and shear forces around openings.

Try IDEA StatiCa for free

OTHER CASE STUDIES