Circular hollow sections

Failure mode method

In this chapter, component-based finite element method (CBFEM) for design of uniplanar welded Circular Hollow Sections (CHS) is verified to Failure Mode Method (FMM): T, X, and K-joints. In CBFEM, the design resistance is limited by reaching 5 % of strain or a force corresponding to 3% d0 joint deformation, where d0 is chord diameter. The resistance in FMM is generally determined by peak load or 3% d0 deformation limit, see (Lu et al. 1994). FMM is based on the principle of identifying modes that may cause joint failure. From the practical experience and experiments accomplished during the 70s and 80s, two modes of failure were identified for the CHS joints: chord plastification and chord punching shear. This calculation method is always limited to a probed geometry of joints. This means that different formulas always apply for each geometry. In the following studies, the welds are designed according to EN 1993‑1‑8:2006 not to be the weakest components in the joint.

Chord plastification

The design resistance of a CHS chord face can be determined using the method given by FMM model in Ch. 9 of prEN 1993-1-8:2020; see Fig. 7.1.1. The method is also given in ISO/FDIS 14346 and is described in more detail in (Wardenier et al. 2010). The design resistance of the axially loaded welded CHS joint is:

- for T and Y joint

\[ N_{1,Rd} = C_f \frac{f_{y0} t_0^2}{\sin{\theta_1}} (2.6+17.7 \beta^2) \gamma^{0.2} Q_f / \gamma_{M5} \]

- X joint

\[ N_{1,Rd} = C_f \frac{f_{y0} t_0^2}{\sin{\theta_1}} \left ( \frac{2.6+2.6 \beta}{1-0.7 \beta} \right ) \gamma^{0.15} Q_f / \gamma_{M5} \]

- and for K gap joint

\[ N_{1,Rd} = C_f \frac{f_{y0} t_0^2}{\sin{\theta_1}} (1.65+13.2 \beta^{1.6}) \gamma^{0.3} \left [ 1+ \frac{1}{1.2+(g/t_0)^{0.8}} \right ] Q_f / \gamma_{M5} \]

where:

- di – an overall diameter of CHS member i (i = 0, 1, 2 or 3)

- fyi – yield strength of member i (i = 0, 1, 2 or 3)

- g – gap between braces of K joint

- ti – thickness of the wall of CHS member i (i = 0, 1, 2 or 3)

- \(\theta_i\) – included angle between brace member i and the chord (i =1, 2 or 3)

- \(\beta\) – ratio of the mean diameter or width of brace members, to that of the chord

- \(\gamma\) – ratio of a chord width or diameter to twice its wall thickness

- Qf – chord stress factor

- Cf – material factor

- \(\gamma_{M5}\) – partial safety factor for resistance of joints in hollow section lattice girders

- Ni,Rd – design resistance of a joint expressed in terms of the internal axial force in member i (i = 0, 1, 2 or 3)

\[ \textsf{\textit{\footnotesize{Fig. 7.1.1 Examined failure mode – chord plastification}}}\]

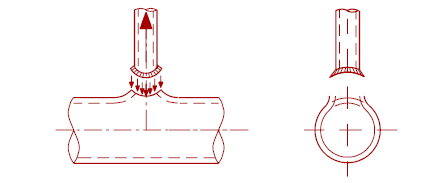

Chord punching shear

(for \(d_i \le d_0 - 2 t_0\))

The design resistance of the axially loaded T, Y, X, and K joint of welded circular hollow sections for chord punching shear (Fig. 7.1.2) is:

\[ N_{1,Rd} = C_f \frac{f_{y0}}{\sqrt{3}} t_0 \pi d_i \frac{1+\sin{\theta_1}}{2 \sin^2{\theta_1}} / \gamma_{M5} \]

where:

- di – overall diameter of CHS member i (i = 0,1,2 or 3)

- ti – thickness of the wall of CHS member i (i = 0,1,2 or 3)

- fy,i – yield strength of member i (i = 0,1,2 or 3)

- \(\theta_i\) – included angle between brace member i and the chord (i = 1,2 or 3)

- Cf – material factor

- Ni,Rd – design resistance of a joint expressed in terms of the internal axial force in member i (i = 0, 1, 2 or 3)

\[ \textsf{\textit{\footnotesize{Fig. 7.1.2 Examined failure mode – chord punching shear}}}\]

Chord shear

(for X joints, only if \(\cos{\theta_1} > \beta\))

The design resistance of the axially loaded X joint of welded circular hollow sections for chord shear, see Fig. 7.1.3, is:

\[ N_{1,Rd} = \frac{f_{y0}}{\sqrt{3}} \frac{(2/\pi A_0)}{\sin{\theta_1}} / \gamma_{M5} \]

where:

- Ai – area of cross-section i (i = 0,1,2 or 3)

- fy,i – yield strength of member i (i = 0,1,2 or 3)

- \(\theta_i\) – included angle between brace member i and the chord (i = 1,2 or 3)

- Ni,Rd – design resistance of a joint expressed in terms of the internal axial force in member i (i = 0, 1, 2 or 3)

\[ \textsf{\textit{\footnotesize{Fig. 7.1.3 Examined failure mode - Chord shear}}}\]

Range of validity

CBFEM was verified for typical joints of the welded circular hollow sections. Range of validity for these joints is defined in Table 7.1.8 of prEN 1993-1-8:2020; see Tab 7.1.2. The same range of validity is applied to CBFEM model. Outside the range of validity of FMM, an experiment should be prepared for validation or verification performed for verification according to a validated research model.

Tab. 7.1.2 Range of validity for method of failure modes

| General | \(0.2 \le \frac{d_i}{d_0} \le 1.0 \) | \( \theta_i \ge 30^{\circ} \) | \(-0.55 \le \frac{e}{d_0} \le 0.25 \) |

| \(g \ge t_1+t_2 \) | \(f_{yi} \le f_{y0} \) | \( t_i \le t_0 \) |

| Chord | Compression | Class 1 or 2 and \(10 \le d_0 / t_0 \le 50 \) (but for X joints: \( d_0/t_0 \le 40 \)) |

| Tension | \(10 \le d_0 / t_0 \le 50 \) (but for X joints: \( d_0/t_0 \le 40 \)) | |

| CHS braces | Compression | Class 1 or 2 and \(d_i / t_i \le 50\) |

| Tension | \(d_i / t_i \le 50 \) |

Uniplanar T and Y-CHS joint

Overview of the considered examples in the study is given in Tab. 7.1.3. Selected cases cover a wide range of joint geometric ratios. Geometry of the joints with dimensions is shown in Fig. 7.1.2. In the selected cases, the joints failed according to the FMM by the chord plastification or punching shear.

\[ \textsf{\textit{\footnotesize{Fig. 7.1.4 Dimensions of T/Y joint}}}\]

Tab. 7.1.3 Examples overview

| Example | Chord | Brace | Angles | Material | ||

| Section | Section | \(\theta\) | fy | fu | E | |

| [°] | [MPa] | [MPa] | [GPa] | |||

| 1 | CHS219.1/5.0 | CHS48.3/5.0 | 90 | 355 | 490 | 210 |

| 2 | CHS219.1/5.0 | CHS114.3/6.3 | 90 | 355 | 490 | 210 |

| 3 | CHS219.1/6.3 | CHS114.3/6.3 | 90 | 355 | 490 | 210 |

| 4 | CHS219.1/10.0 | CHS60.3/5.0 | 90 | 355 | 490 | 210 |

| 5 | CHS219.1/12.5 | CHS168.3/10.0 | 90 | 355 | 490 | 210 |

| 6 | CHS219.1/8.0 | CHS48.3/5.0 | 90 | 355 | 490 | 210 |

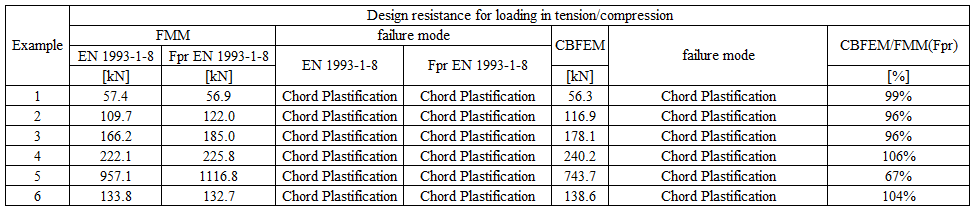

Verification of resistance

The results of the method based on FMM are compared with the results of CBFEM. The comparison is focused on the resistance and design failure mode. The results are presented in Tab. 7.1.4.

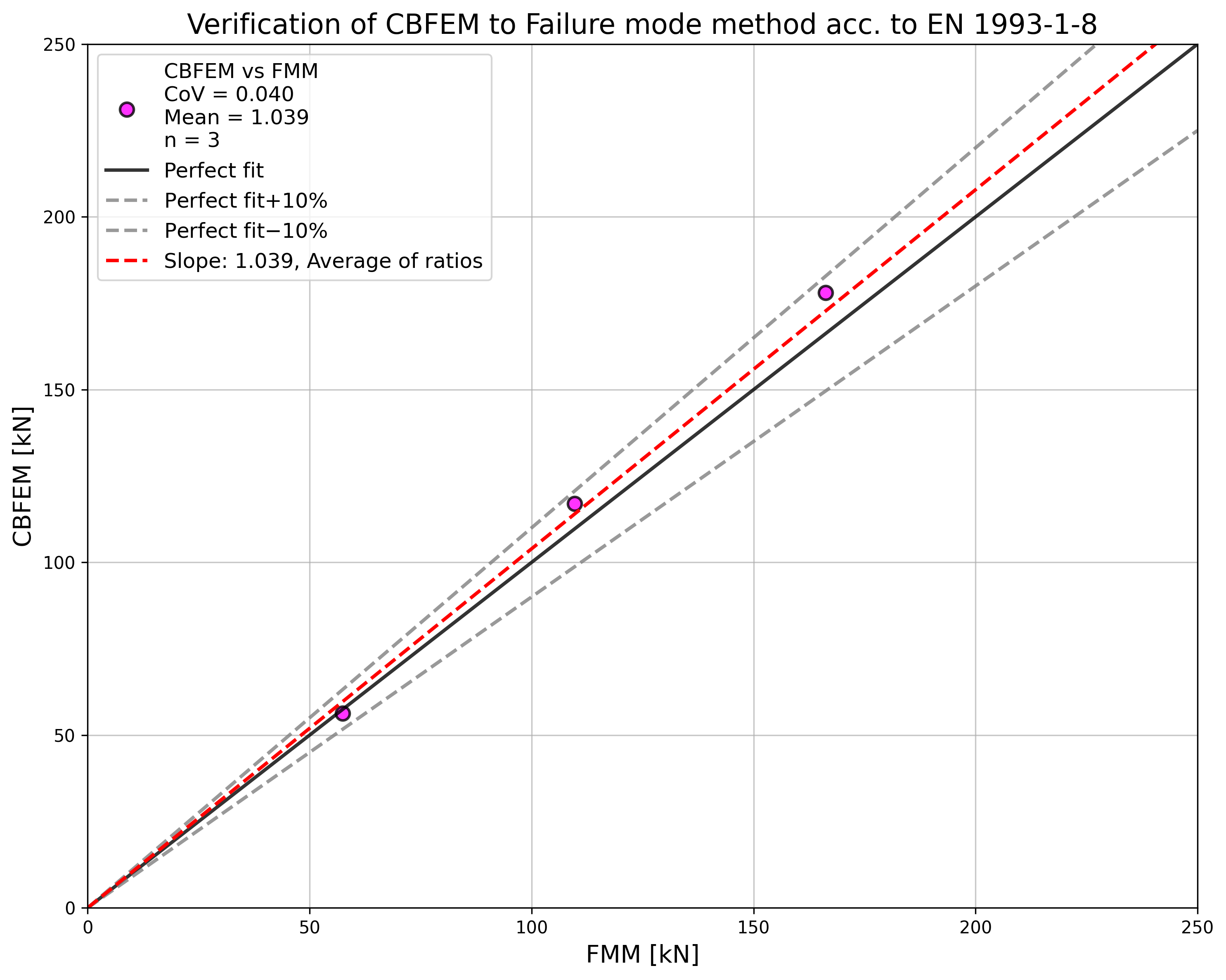

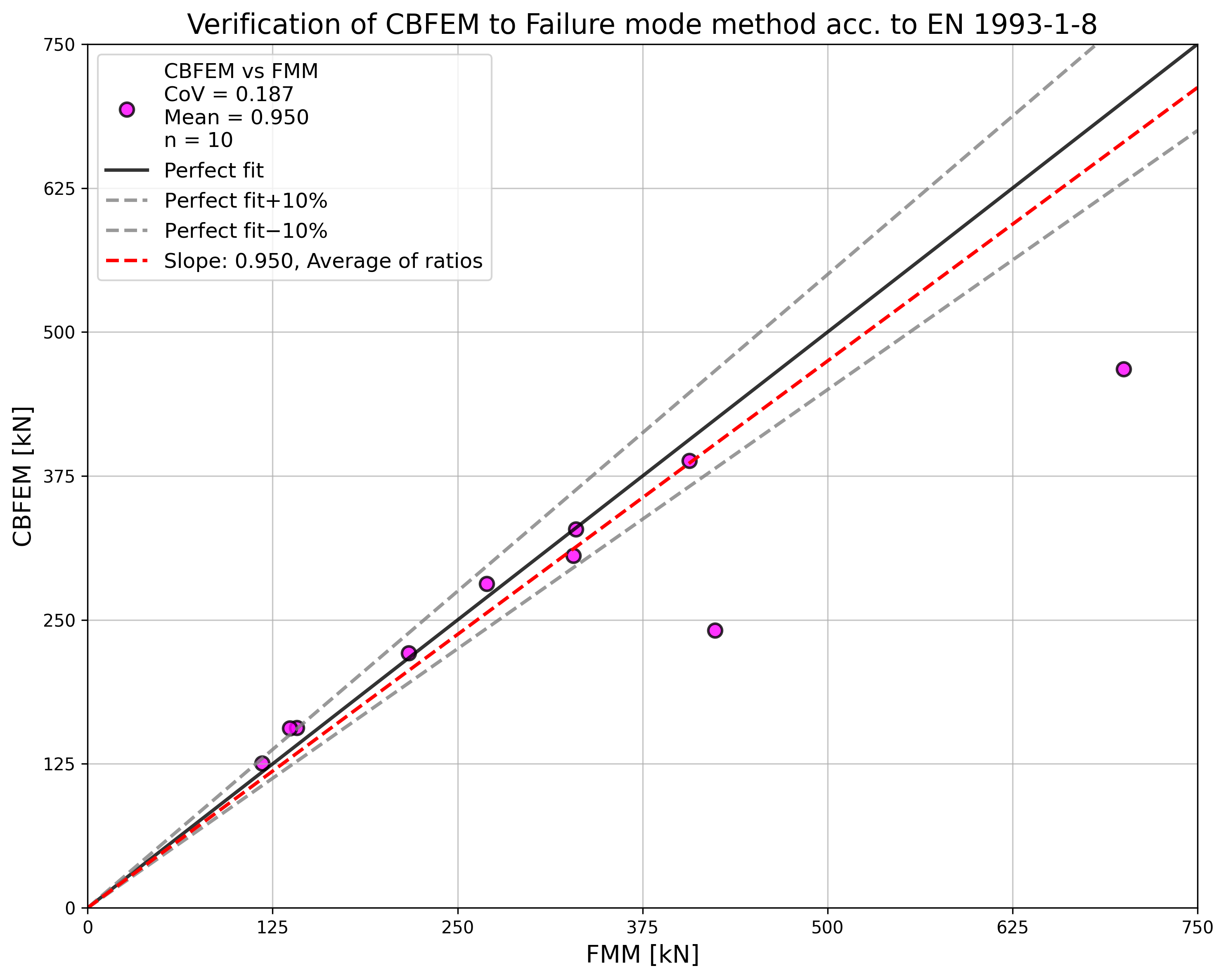

The study shows a good agreement for the applied load cases. The results are summarized in a diagram comparing CBFEM’s and FMM’s design resistances; see Fig. 7.1.5. The results show that the difference between the two calculation methods is in all cases less than 14%.

Tab. 7.1.4 Comparison of design resistances for loading in tension/compression: prediction by CBFEM and FMM

\[ \textsf{\textit{\footnotesize{Fig. 7.1.5 Verification of CBFEM to EN 1993-1-8 for the uniplanar CHS T and Y-joint}}}\]

\[ \textsf{\textit{\footnotesize{Fig. 7.1.6 Verification of CBFEM to Fpr EN 1993-1-8 for the uniplanar CHS T and Y-joint}}}\]

Benchmark example

Inputs

Chord

- Steel S355

- Section CHS219.1/5.0

Brace

- Steel S355

- Sections CHS48.3/5.0

- Angle between the brace member and the chord 90°

Weld

- Butt weld around the brace

Loaded

- By force to brace in compression

Mesh size

- 64 elements along surface of the circular hollow member

Outputs

- The design resistance in compression is NRd = 56.3 kN

- The design failure mode is chord plastification

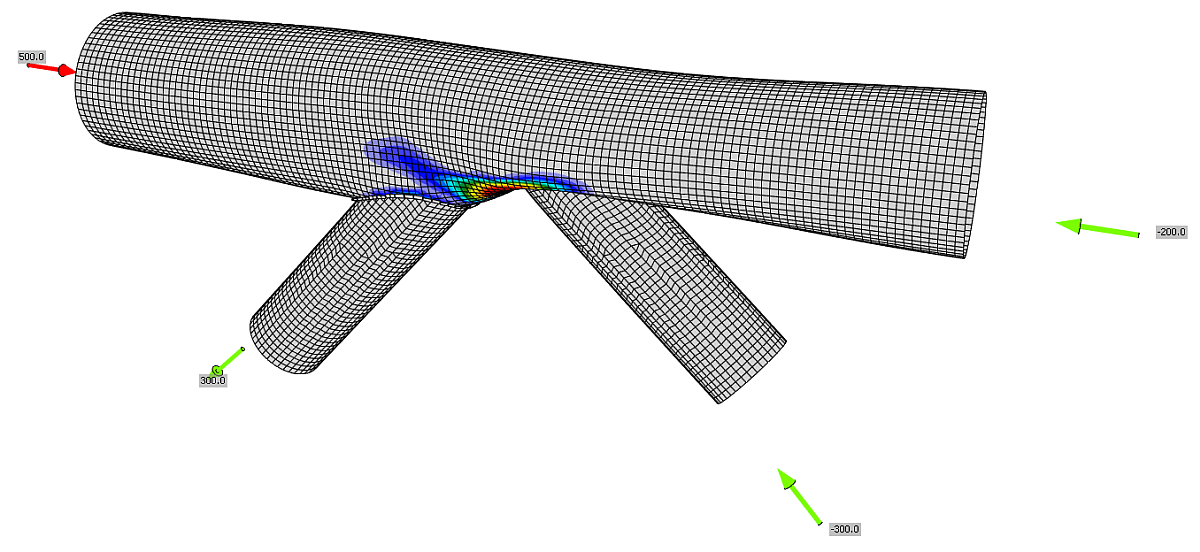

\[ \textsf{\textit{\footnotesize{Fig. 7.1.6a Boundary conditions for the uniplanar CHS T and Y-joint}}}\]

Uniplanar X-CHS joint

Overview of the considered examples in the study is given in Tab. 7.1.5. Selected cases cover a wide range of joint geometric ratios. Geometry of the joints with dimensions is shown in Fig. 7.1.6. In the selected cases, the joints failed according to the FMM by the chord plastification or punching shear.

\[ \textsf{\textit{\footnotesize{Fig. 7.1.7 Dimensions of X joint}}}\]

Tab. 7.1.5 Examples overview

| Example | Chord | Brace | Angles | Material | ||

| Section | Section | \(\theta\) | fy | fu | E | |

| [°] | [MPa] | [MPa] | [GPa] | |||

| 1 | CHS219.1/6.3 | CHS60.3/5.0 | 90 | 355 | 490 | 210 |

| 2 | CHS219.1/8.0 | CHS76.1/5.0 | 90 | 355 | 490 | 210 |

| 3 | CHS219.1/10.0 | CHS139.7/10.0 | 90 | 355 | 490 | 210 |

| 4 | CHS219.1/12.5 | CHS114.3/6.3 | 90 | 355 | 490 | 210 |

| 5 | CHS219.1/10.0 | CHS76.1/5.0 | 90 | 355 | 490 | 210 |

| 6 | CHS219.1/8.0 | CHS114.3/6.3 | 90 | 355 | 490 | 210 |

| 7 | CHS219.1/6.3 | CHS48.3/5.0 | 60 | 355 | 490 | 210 |

| 8 | CHS219.1/6.3 | CHS114.3/6.3 | 60 | 355 | 490 | 210 |

| 9 | CHS219.1/8.0 | CHS60.3/5.0 | 60 | 355 | 490 | 210 |

| 10 | CHS219.1/10.0 | CHS114.3/6.3 | 60 | 355 | 490 | 210 |

| 11 | CHS219.1/12.5 | CHS139.7/10.0 | 60 | 355 | 490 | 210 |

| 12 | CHS219.1/8.0 | CHS139.7/10.0 | 60 | 355 | 490 | 210 |

| 13 | CHS219.1/6.3 | CHS48.3/5.0 | 30 | 355 | 490 | 210 |

| 14 | CHS219.1/6.3 | CHS193.7/12.5 | 30 | 355 | 490 | 210 |

| 15 | CHS219.1/6.3 | CHS219.1/12.5 | 30 | 355 | 490 | 210 |

| 16 | CHS219.1/8.0 | CHS76.1/5.0 | 30 | 355 | 490 | 210 |

| 17 | CHS219.1/8.0 | CHS168.3/10 | 30 | 355 | 490 | 210 |

| 18 | CHS219.1/12.5 | CHS168.3/10 | 30 | 355 | 490 | 210 |

Verification of resistance

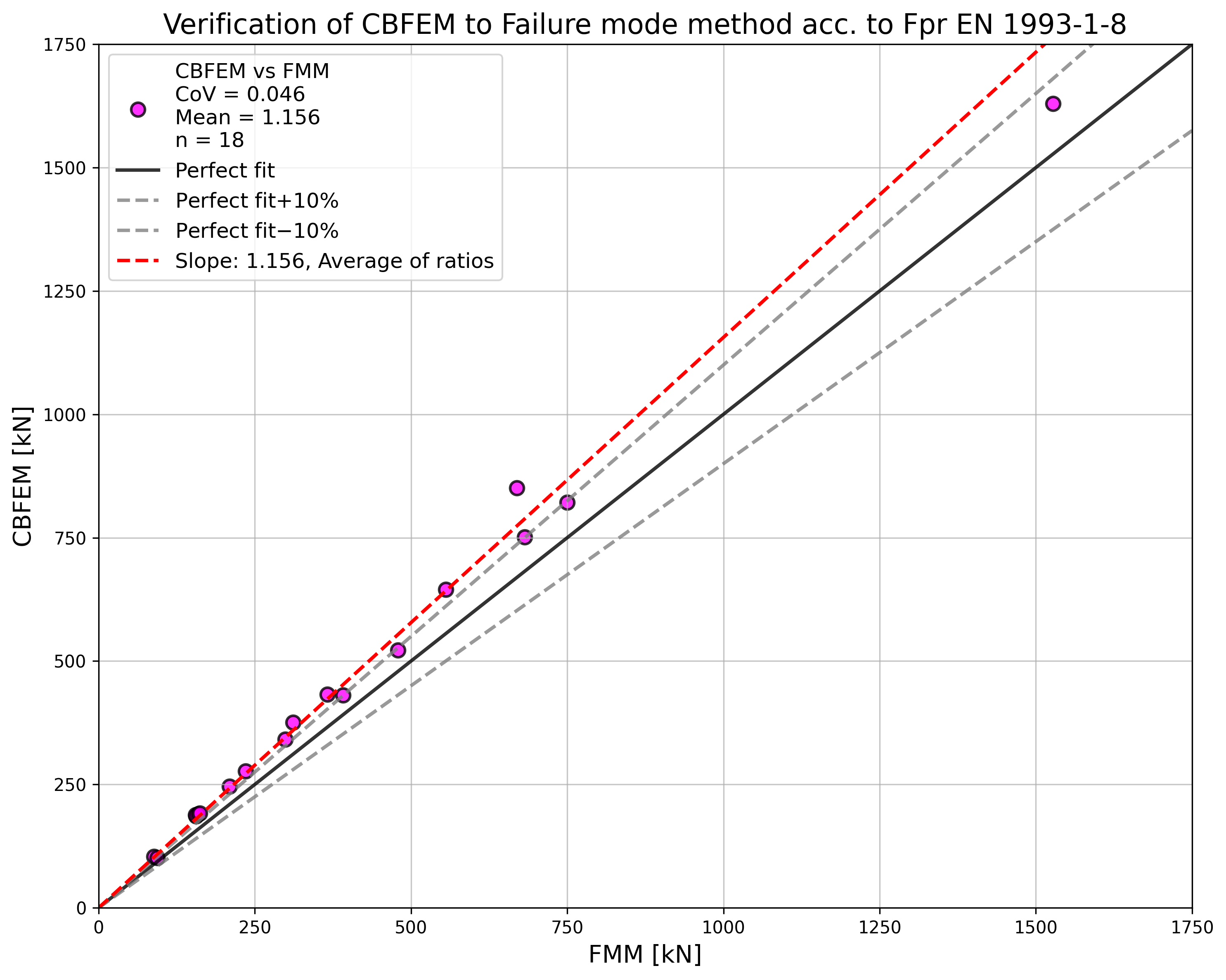

The results of CBFEM are compared with the results of FMM. The comparison is focused on the resistance and design failure mode. The results are presented in Tab. 7.1.6.

Tab. 7.1.6 Comparison of results of prediction by CBFEM and FMM

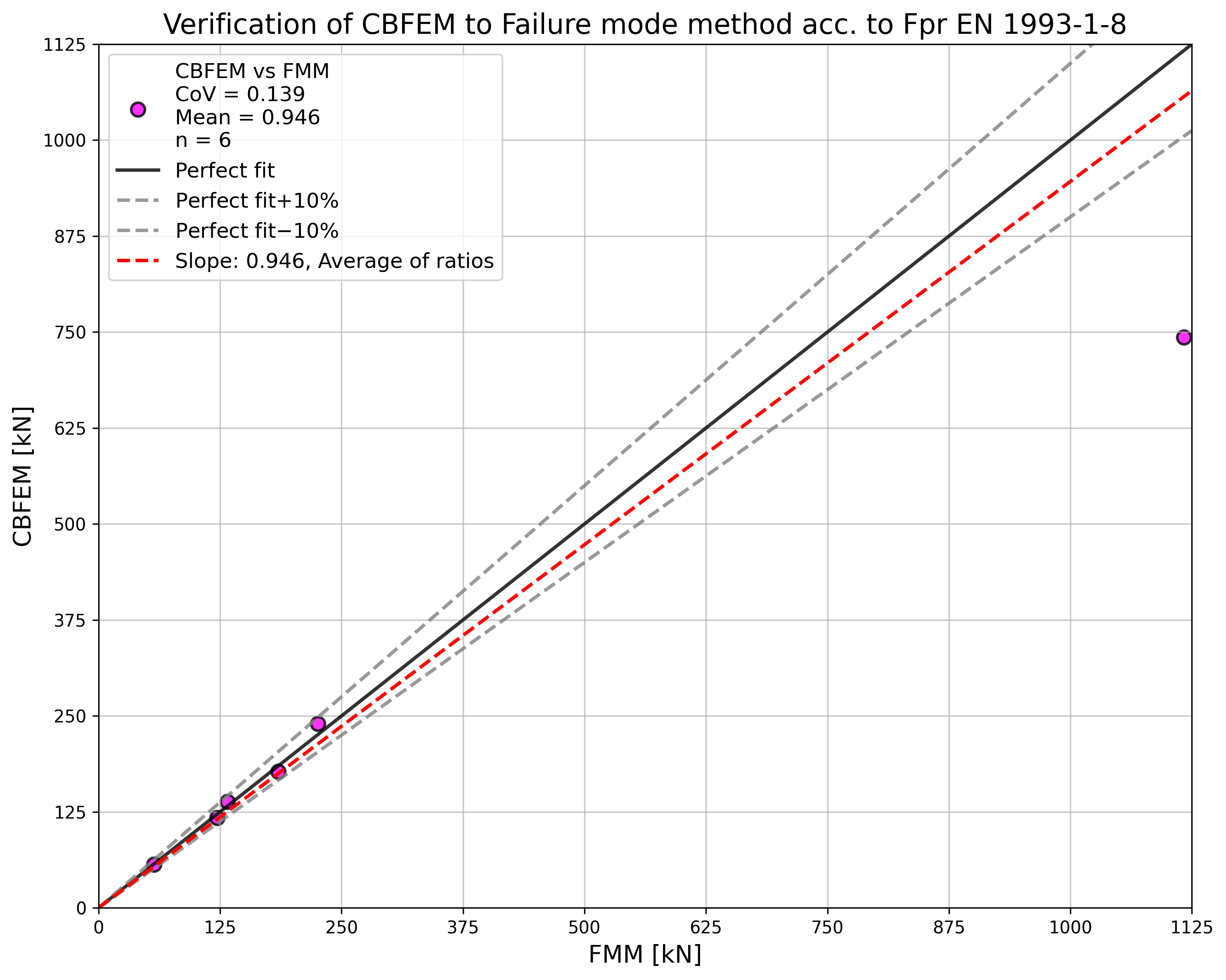

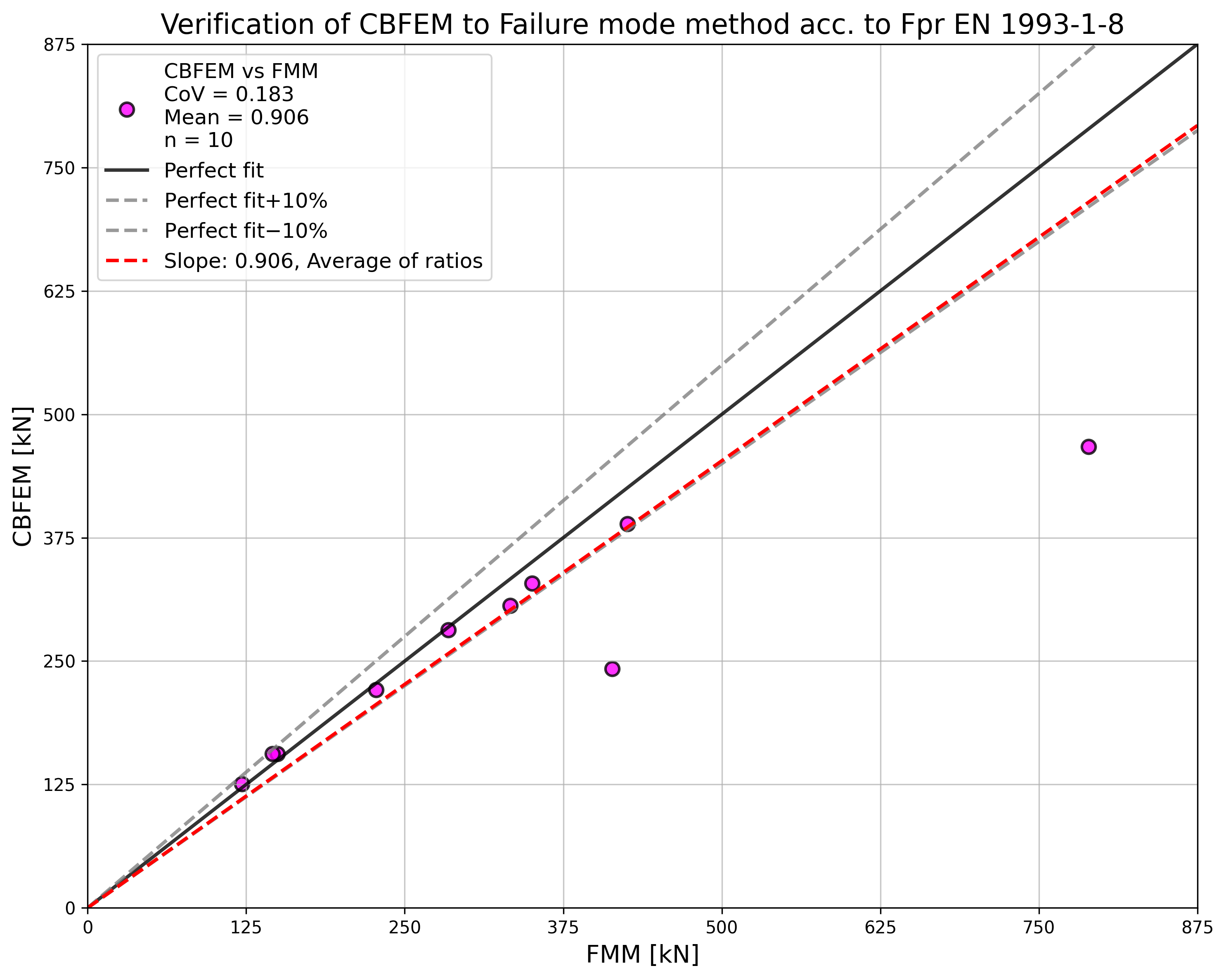

The study shows a good agreement for most of the applied load cases. The results are summarized in a diagram comparing CBFEM’s and FMM’s design resistances; see Fig. 7.1.7. The results show that the difference between the two calculation methods is in most cases less than 13%.

\[ \textsf{\textit{\footnotesize{Fig. 7.1.8 Verification of CBFEM to EN 1993-1-8 for the uniplanar CHS X- joint}}}\]

\[ \textsf{\textit{\footnotesize{Fig. 7.1.9 Verification of CBFEM to Fpr EN 1993-1-8 for the uniplanar CHS X-joint}}}\]

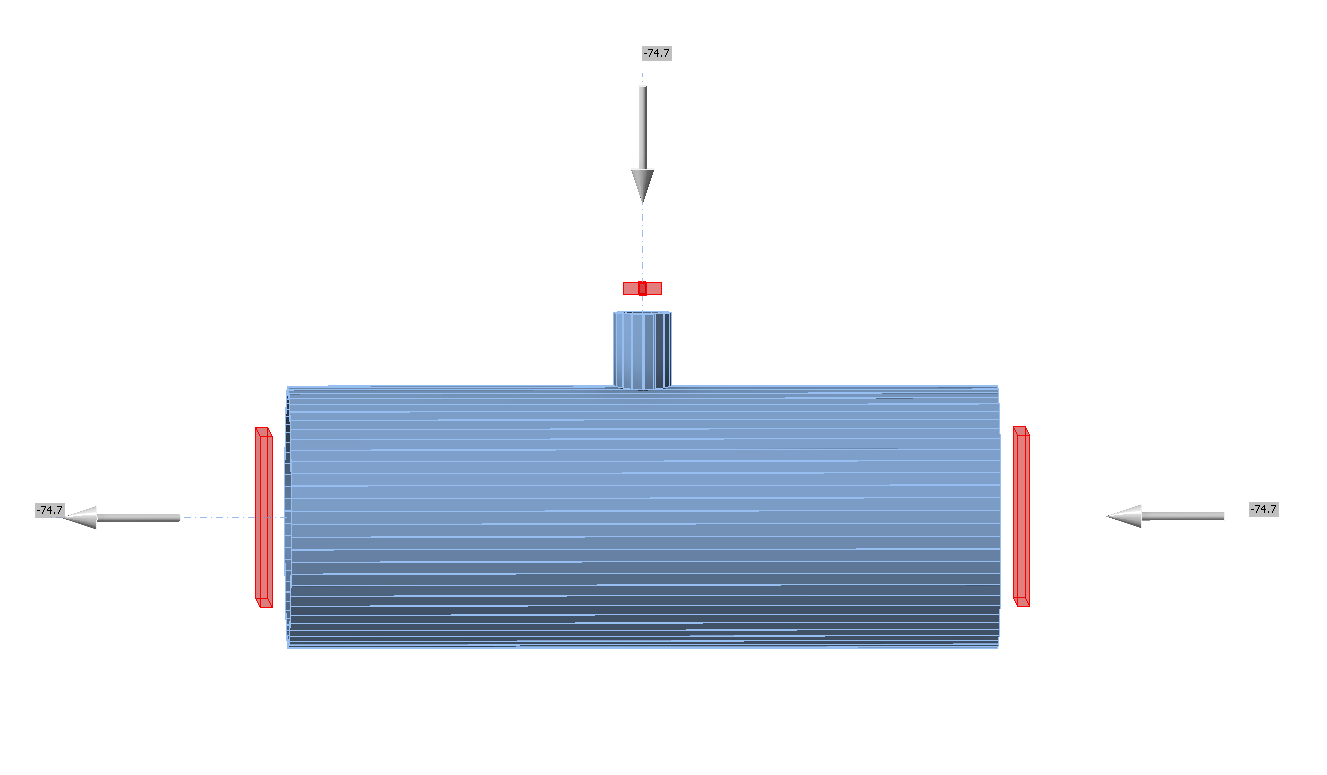

Benchmark example

Inputs

Chord

- Steel S355

- Section CHS219.1/6,3

Brace

- Steel S355

- Sections CHS60,3/5,0

- Angle between the brace member and the chord 90°

Weld

- Butt weld around the brace

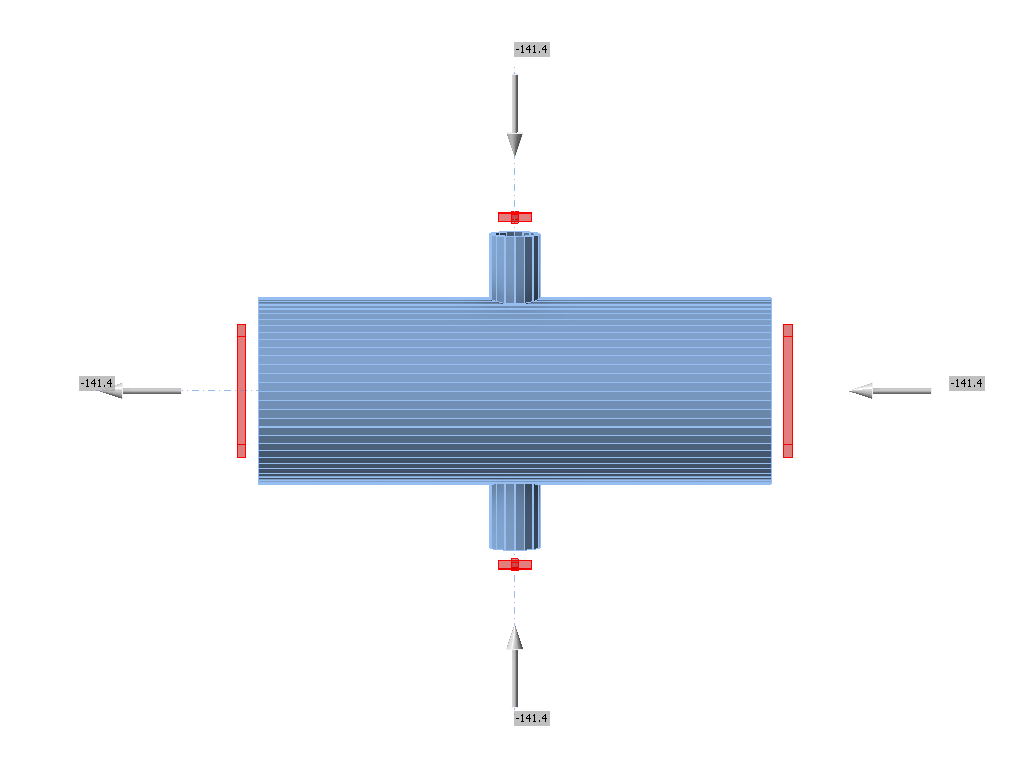

Loaded

- By force to brace in compression

Mesh size

- 64 elements along surface of the circular hollow member

Outputs

- The design resistance in compression is NRd = 103.9 kN

- The design failure mode is chord plastification

\[ \textsf{\textit{\footnotesize{Fig. 7.1.9a Boundary conditions for the uniplanar CHS X-joint}}}\]

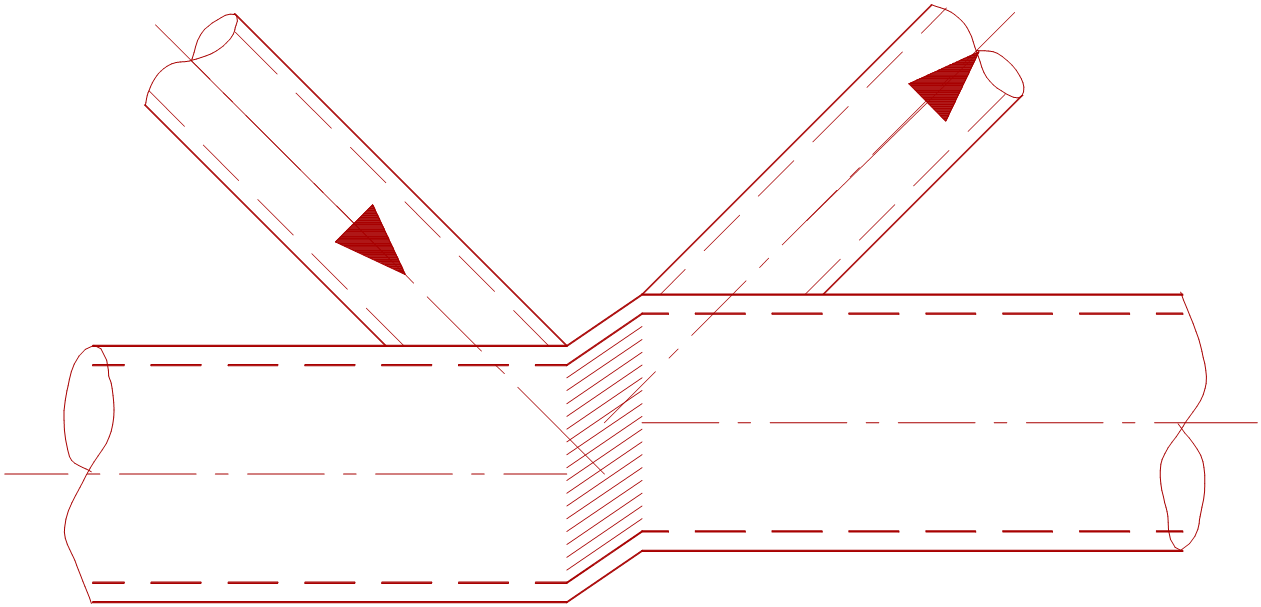

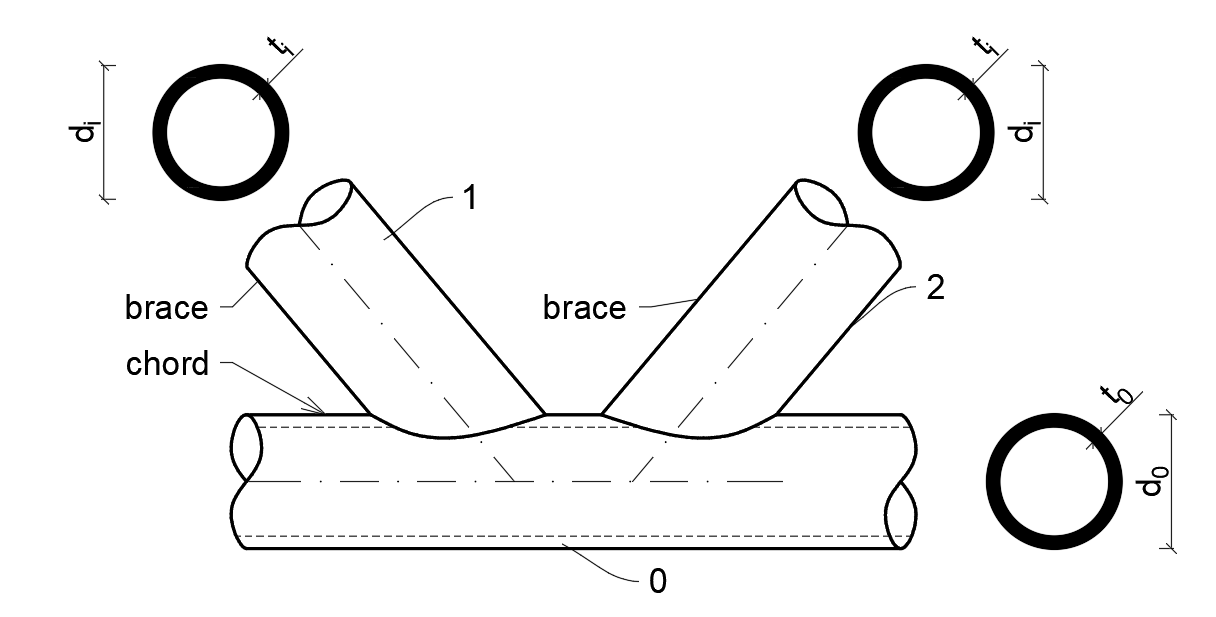

Uniplanar K-CHS joint

Overview of the considered examples in the study is given in Tab. 7.1.7. Selected cases cover a wide range of joint geometric ratios. Geometry of the joints with dimensions is shown in Fig. 7.1.8. In the selected cases, the joints failed according to the method based on the failure modes (FMM) by the chord plastification or punching shear.

Tab. 7.1.7 Examples overview

| Example | Chord | Brace | Gap | Angles | Material | ||

| Section | Section | g | \(\theta\) | fy | fu | E | |

| [mm] | [°] | [MPa] | [MPa] | [GPa] | |||

| 1 | CHS219,1/8,0 | CHS88,9/5,0 | 23.8 | 60 | 355 | 490 | 210 |

| 2 | CHS219,1/12,5 | CHS88,9/5,0 | 23.8 | 60 | 355 | 490 | 210 |

| 3 | CHS219,1/5,0 | CHS88,9/5,0 | 23.8 | 60 | 355 | 490 | 210 |

| 4 | CHS219,1/10,0 | CHS60,3/5,0 | 56.9 | 60 | 355 | 490 | 210 |

| 5 | CHS219,1/6,3 | CHS88,9/5,0 | 23.8 | 60 | 355 | 490 | 210 |

| 6 | CHS219,1/6,3 | CHS60,3/5,0 | 56.9 | 60 | 355 | 490 | 210 |

| 7 | CHS219,1/8,0 | CHS76,1/5,0 | 38.6 | 60 | 355 | 490 | 210 |

| 8 | CHS219,1/10,0 | CHS76,1/5,0 | 38.6 | 60 | 355 | 490 | 210 |

| 9 | CHS219,1/6.3 | CHS48,3/65,0 | 70.7 | 60 | 355 | 490 | 210 |

| 10 | CHS219,1/12,5 | CHS48,3/5,0 | 70.7 | 60 | 355 | 490 | 210 |

\[ \textsf{\textit{\footnotesize{Fig. 7.1.10 Dimensions of K joint}}}\]

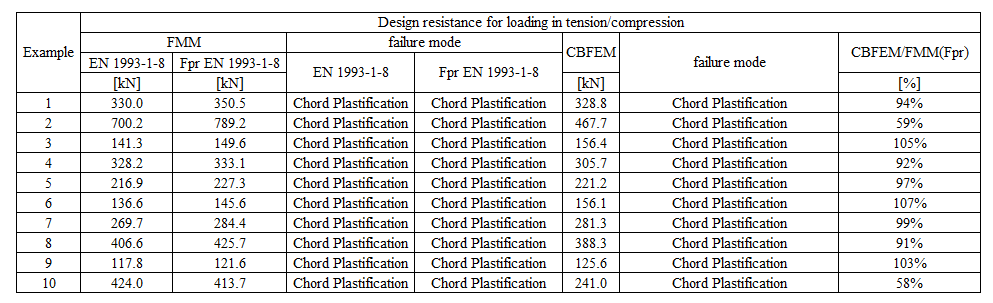

Verification of resistance

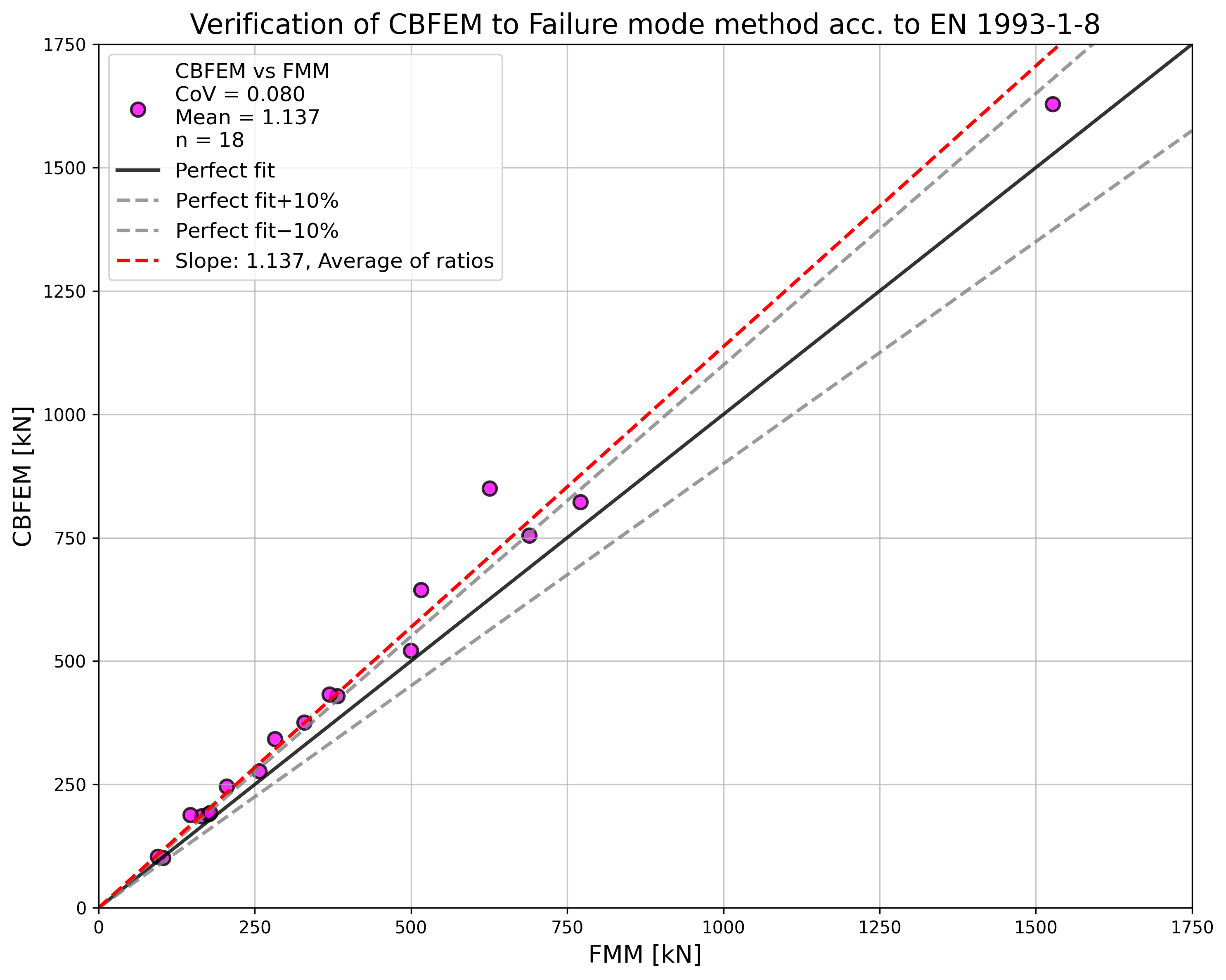

The results of the method based on failure modes (FMM) are compared with the results of CBFEM. The comparison is focused on the resistance and design failure mode. The results are presented in Tab. 7.1.8 and in Fig. 7.1.9.

Tab. 7.1.8 Comparison of results of design resistances by CBFEM and FMM

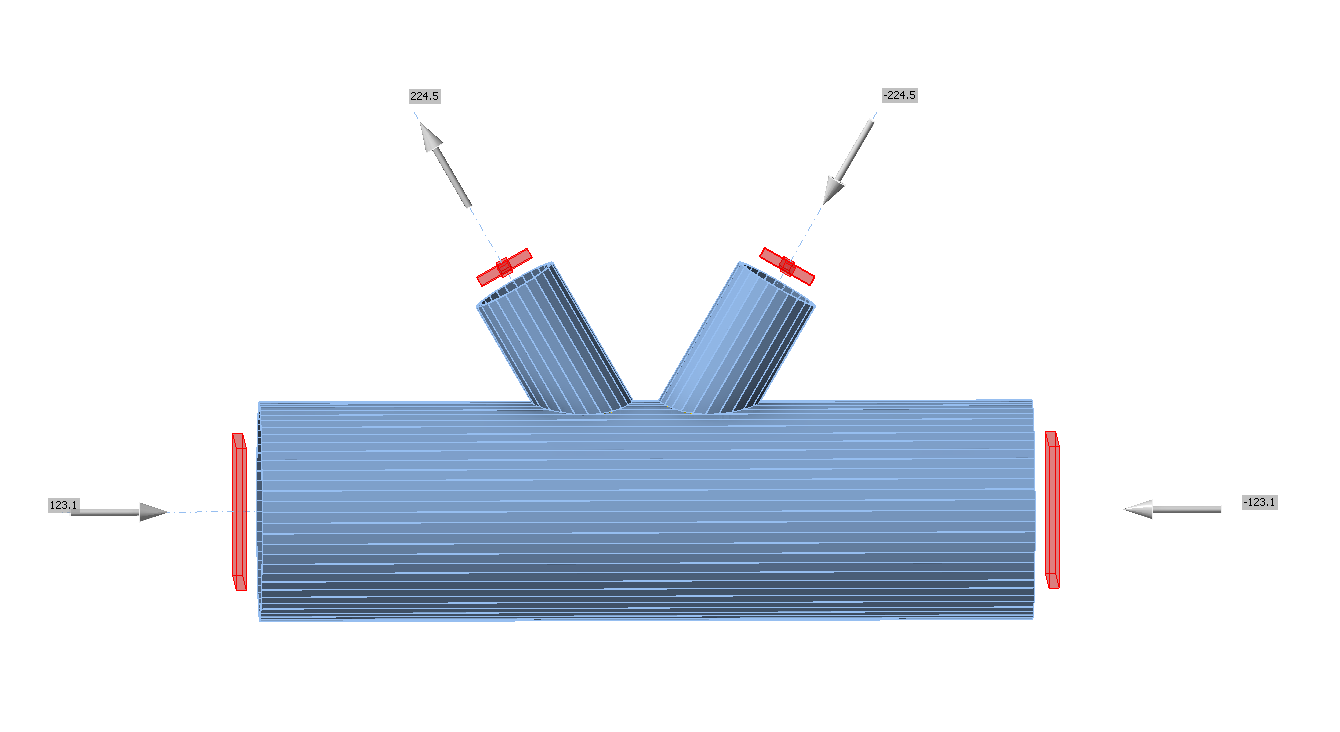

The study shows a good agreement for the applied load cases. The results are summarized in a diagram comparing CBFEM’s and FMM’s design resistances; see Fig. 7.1.6. The results show that the difference between the two calculation methods is in all cases less than 12 %.

\[ \textsf{\textit{\footnotesize{Fig. 7.1.11 Verification of CBFEM to EN 1993-1-8 for the uniplanar CHS K-joint}}}\]

\[ \textsf{\textit{\footnotesize{Fig. 7.1.12 Verification of CBFEM to Fpr EN 1993-1-8 for the uniplanar CHS K-joint}}}\]

Benchmark example

Inputs

Chord

- Steel S355

- Section CHS 219.1/8.0

Brace

- Steel S355

- Sections CHS 88.9/5.0

- Angle between the brace member and the chord 60°

- Gap between braces g = 23.8 mm

Weld

- Butt weld around the brace

Loaded

- By force to brace in compression

Mesh size

- 64 elements along surface of the circular hollow member

Outputs

- The design resistance in compression is NRd = 328.8 kN

- The design failure mode is chord plastification

\[ \textsf{\textit{\footnotesize{Fig. 7.1.6a Boundary conditions for the uniplanar CHS K-joint}}}\]