CBFEM online book - Component-based finite element design of steel connections

Introduction

As computational tools become increasingly accessible and user-friendly, even for relatively inexperienced engineers, the need for critical evaluation of computational analyses has grown correspondingly. In the field of structural steel design, the finite element analysis (FEA) of structural connections represents the next rapidly advancing step. However, the reliability of such analyses can only be established through a systematic process of verification and validation (V&V). Without rigorous V&V, finite element results lack credibility and cannot serve as a basis for engineering decision-making.

The present article revisits selected chapters from Component-Based Finite Element Design of Steel Connections by František Wald et al., recalculated using the most recent release of IDEA StatiCa software. In addition, several chapters have been expanded through supplementary examples, thereby enhancing the robustness and accuracy of the verification process. This contribution aims to strengthen the methodological foundations of connection design and provide a more reliable reference for both academic research and engineering practice.

Theoretical background

You can find the description of the CBFEM method in two separate Theoretical background online documents:

IDEA StatiCa Connection – Structural design of steel connections - general introduction to the CBFEM method and analysis model inside the Connection app.

Check of steel connection components (EN) - description of the implementation of Eurocode (EN) regarding the required checks.

IDEA StatiCa Member – Member stability - general introduction to the stability, buckling, and geometrically nonlinear analysis with imperfections (GMNIA) calculation method inside the Member app.

Welded connections

Fillet weld in lap joint

Description

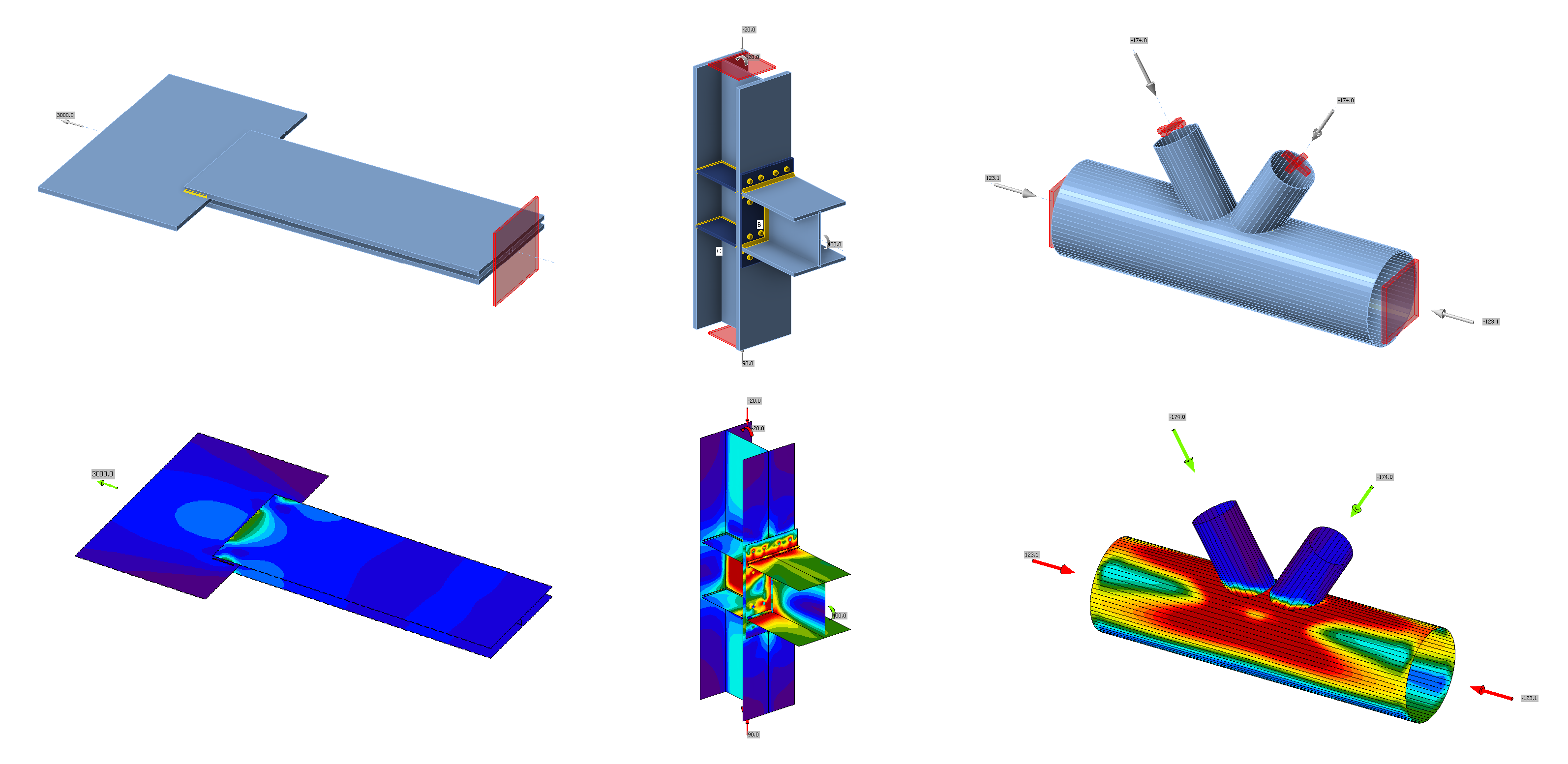

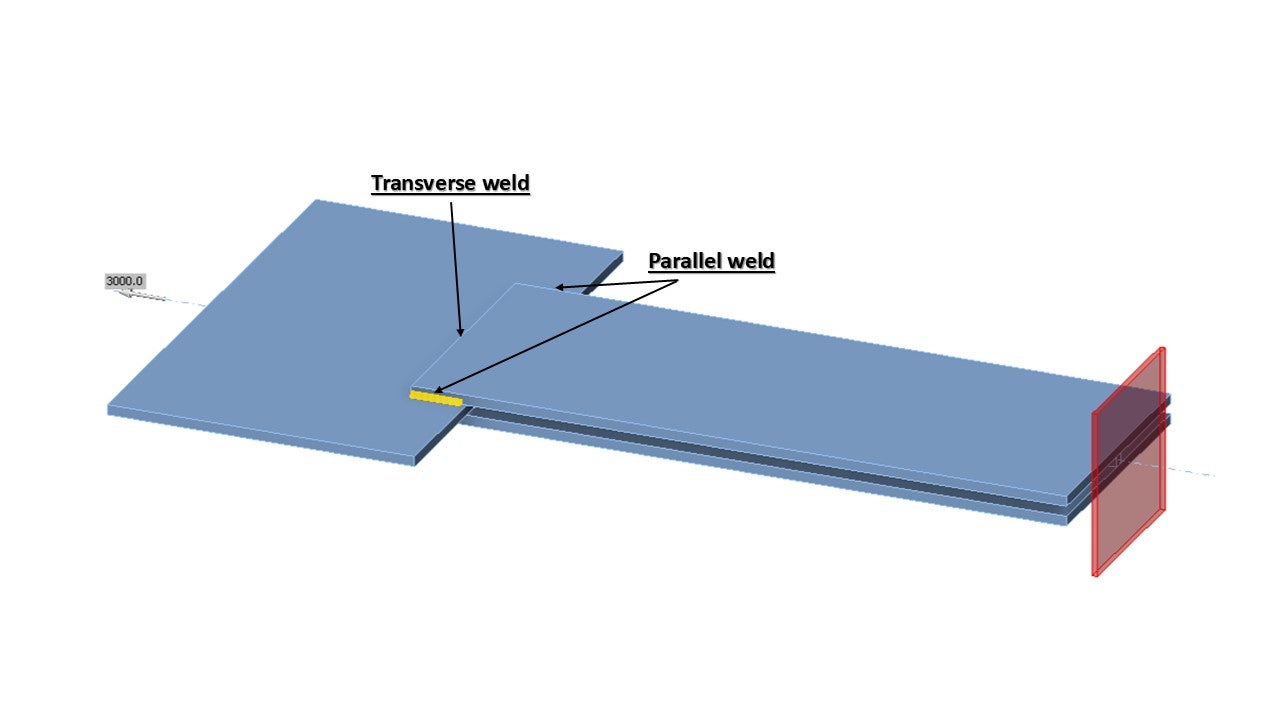

The objective of this chapter is the verification of the component-based finite element method (CBFEM) of a fillet weld in a lap joint with the component method (CM). Two plates are connected in three configurations, namely with a transverse weld, with a longitudinal weld, and a combination of transverse and longitudinal welds. The length and throat thickness of the weld are the varying parameters in the study. The study also covers long welds whose resistance is reduced due to stress concentration. The joint is loaded by a normal force.

Analytical model

The fillet weld is the only component examined in the study. The welds are designed to be the weakest component in the joint. The weld is designed according to EN 1993-1-8:2005. The design resistance of the fillet weld is determined using the Directional method given in Cl. 4.5.3.2 in EN 1993-1-8:2005. The available calculation methods for checking the strength of fillet welds are based upon the simplifying assumption that stresses are uniformly distributed within a throat section of a fillet weld, leading to the normal stresses and shear stresses shown in Fig. 4.1.1, as follows:

- σ⊥ is the normal stress perpendicular to the throat section;

- σ∥ is the normal stress parallel to the axis of the weld in its cross-section;

- τ⊥ is the shear stress (in the plane of the throat section) perpendicular to the axis of the weld;

- τ∥ is the shear stress (in the plane of the throat section) parallel to the axis of the weld.

The normal stress σ∥ parallel to the axis is not considered when verifying the design resistance of a weld.

\[ \textsf{\textit{\footnotesize{Fig. 4.1.1 Stresses in a throat section of a fillet weld}}}\]

The design resistance of the fillet weld will be sufficient if the following are both satisfied:

\[ \sqrt{\sigma_{\perp}^2 + 3 \cdot ( \tau_{\perp}^2 + \tau_{\perp}^2 )} \le \frac{f_\textrm{u}}{\beta_\textrm{w} \gamma_\textrm{M2}} \]

\[ \sigma_{\perp} \le \frac{0.9 f_\textrm{u}}{\gamma_\textrm{M2}} \]

In lap joints longer than \( 150 \cdot a \), the reduction factor \(\beta_{\mathrm{Lw,1}}\) is given by:

\( \beta_{\mathrm{Lw,1}} = 1.2 - \frac{0.2 L_\textrm{j}}{150 a} \) but \(\beta_{\mathrm{Lw,1}} \le 1.0 \)

Numerical model

The weld component in CBFEM is described in General theoretical background and EN theoretical background. Nonlinear elastic-plastic material is used for welds in this study. The limiting plastic strain is reached in the longer part of the weld, and stress peaks are redistributed.

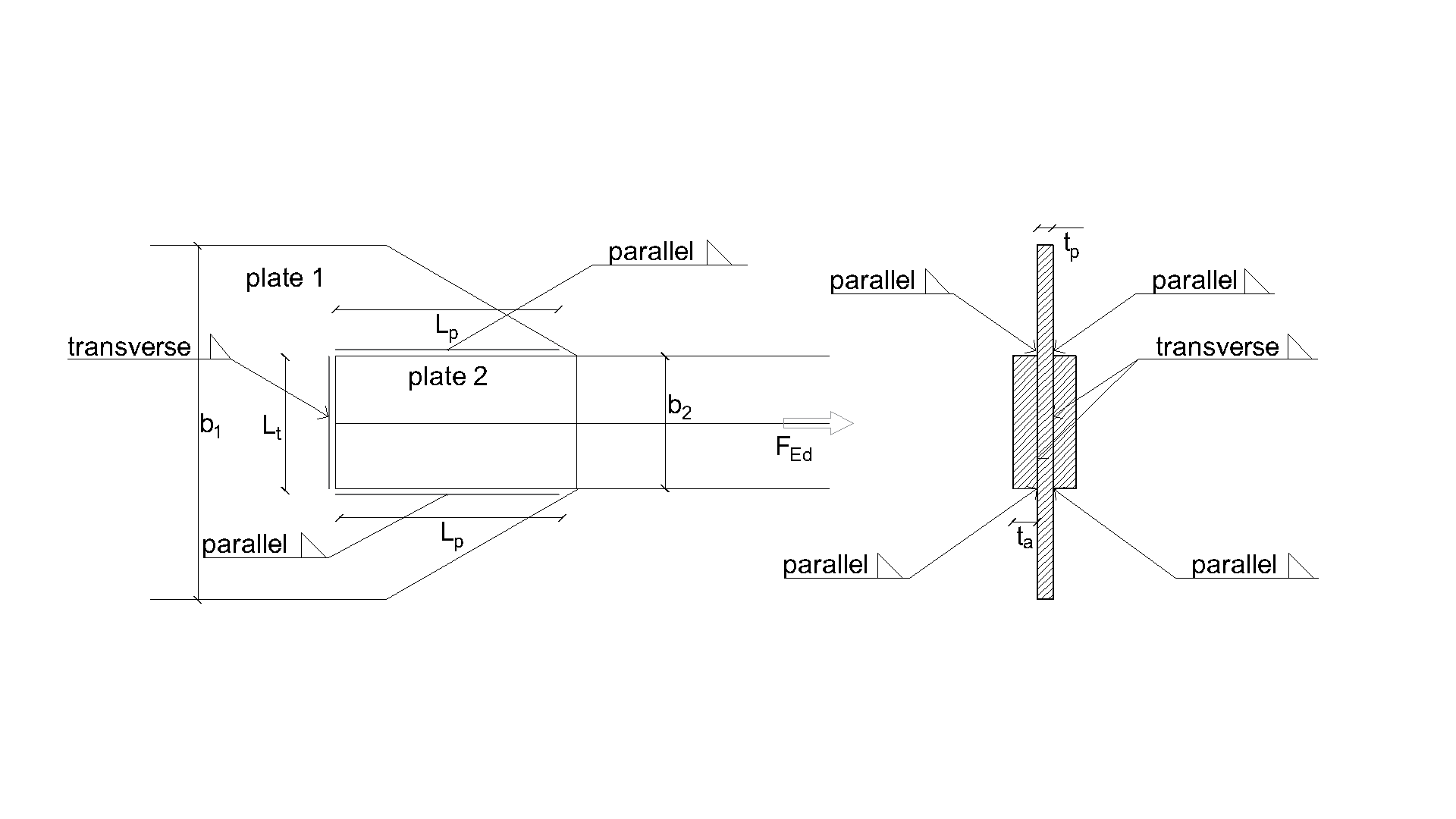

Verification of resistance

An overview of the considered examples and the material properties is provided in Tab. 4.1.1. The weld configurations are T for transverse, P for parallel weld, and TP for a combination of both; see the geometry in Fig. 4.1.2. The steel grade was S235 (fy = 235 MPa, fu = 360 MPa, E = 210 GPa, βw = 0,8). Partial safety factors were γM0 = 1.0, γM2 = 1.25. The geometry of the model is shown in Fig. 4.1.2. The plates have a thickness of 20 mm. The connection is symmetrical, and the plate is pulled out of the welded splice connection. The length and width of the plates are adjusted according to the length of the parallel and transverse weld. The weld resistance is always the governing failure mode. The weld throat thickness is 3 mm. The lengths of the transverse and parallel welds vary in this parametric study.

\[ \textsf{\textit{\footnotesize{Drawing 4.1 Joint geometry with dimensions}}}\]

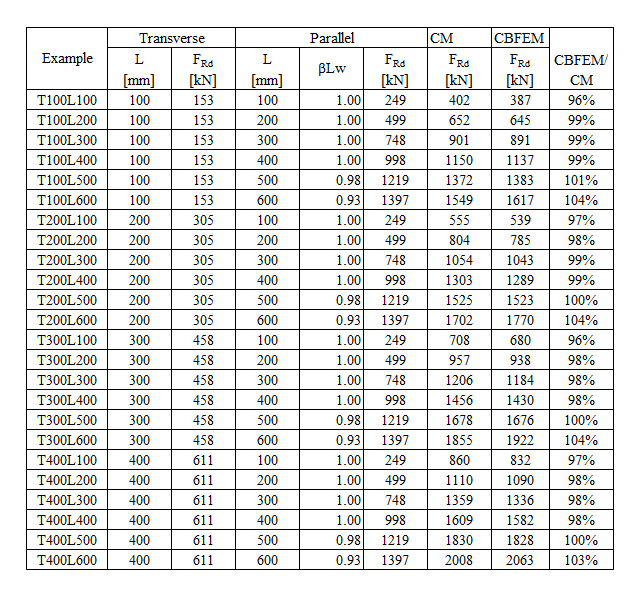

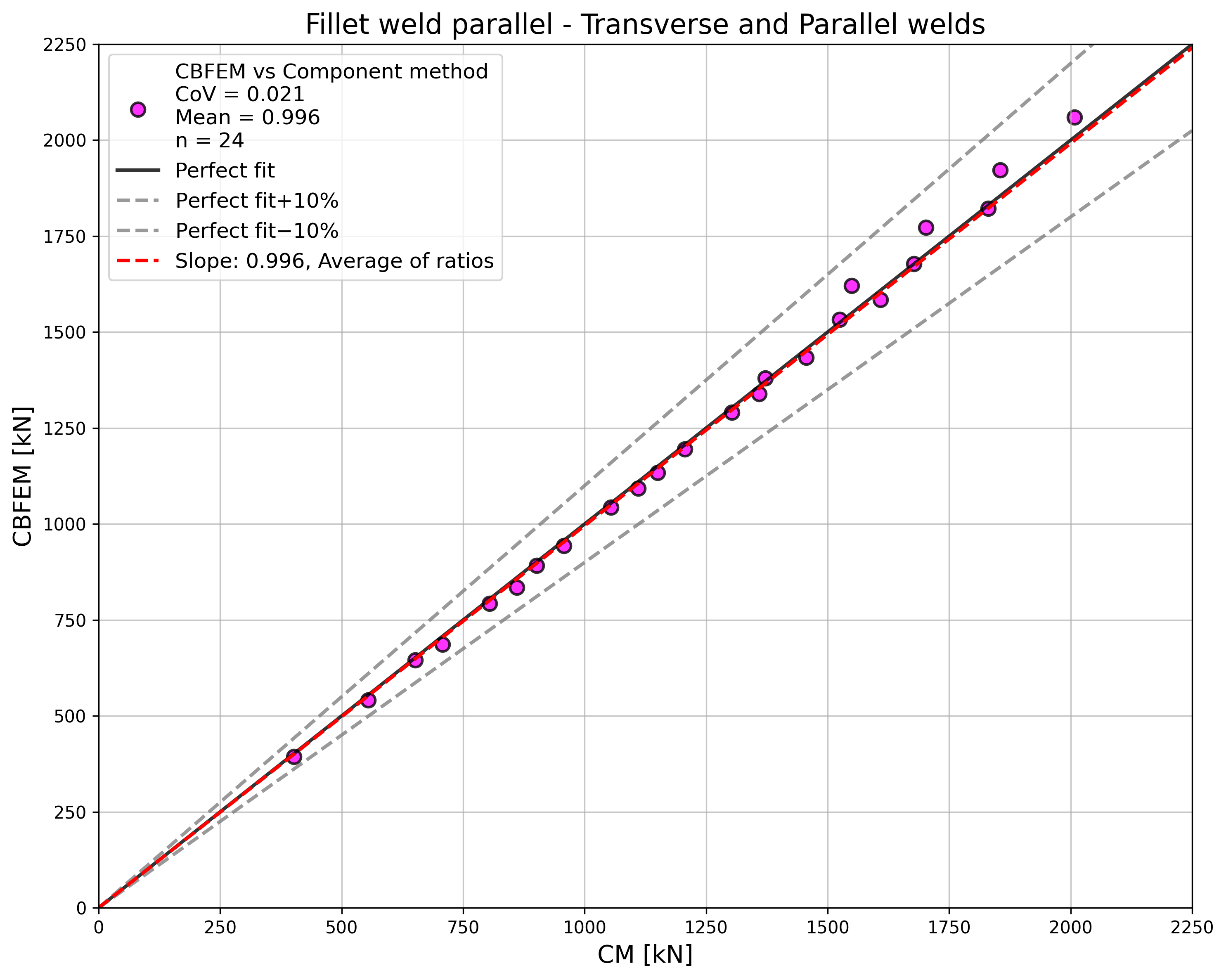

Design weld resistance calculated by CBFEM is compared with the results of CM. The results are presented in Tab. 4.1.1 – 4.1.3 and Fig. 4.1.3 – 4.1.5.

\[ \textsf{\textit{\footnotesize{Fig. 4.1.2 Specimen geometry}}}\]

Transverse welds resistance calculation

\[\sqrt{ \sigma_{\perp}^2 + 3 \cdot \left( \tau_{\perp}^2 + \tau_{\parallel}^2\right)} \leq \frac{f_\textrm{u}}{\beta_{\textrm{w}} \cdot \gamma_{\textrm{M2}}}\]

\[\sigma_{\perp} = \tau_{\perp} = \frac{\sigma_\textrm{N}}{\sqrt{2}} = \frac{N}{L_{\textrm{t}} \cdot a}\cdot \frac{1}{\sqrt{2}} \]

\[ \tau_{\parallel} = 0\]

\[ \sqrt{ \left( \frac{\sigma_\textrm{N}}{\sqrt{2}} \right)^2 + 3 \cdot \left( \frac{\sigma_\textrm{N}}{\sqrt{2}} \right)^2} \leq \frac{f_\textrm{u}}{\beta_{\textrm{w}} \cdot \gamma_{\textrm{M2}}}\]

\[ \sqrt{ \left( \frac{N}{L_{\textrm{t}}\cdot a}\cdot \frac{1}{\sqrt{2}} \right)^2 + 3 \cdot \left( \frac{N}{L_{\textrm{t}}\cdot a}\cdot \frac{1}{\sqrt{2}} \right)^2} \leq \frac{f_\textrm{u}}{\beta_{\textrm{w}} \cdot \gamma_{\textrm{M2}}}\]

\[ N \leq \frac{f_\textrm{u} \cdot L_{\textrm{t}}\cdot a }{\beta_{\textrm{w}} \cdot \gamma_{\textrm{M2}} \cdot \sqrt{2}} \]

\[ \sigma_{\perp}= \frac{N}{L_{\textrm{t}} \cdot a}\cdot \frac{1}{\sqrt{2}} \leq \frac{f_\textrm{u} \cdot 0.9}{ \gamma_{\textrm{M2}}} \]

\[ N \leq \frac{f_{u} \cdot L_{\textrm{t}}\cdot a \cdot 0.9 \cdot \sqrt{2}}{ \gamma_{\textrm{M2}} } \]

Where:

\(a\) - weld throat thickness

\(N\) - the normal force acting on the beam

\(L_{\textrm{t}}\) - total transverse weld length

\(\beta_{\mathrm{w}}\) - correlation factor taken from EN 1993-1-8 Table 4.1

\(f_\textrm{u}\) - nominal ultimate tensile strength of the weaker part joined

\(\gamma_{\mathrm{M2}}\) - partial safety factor for welds

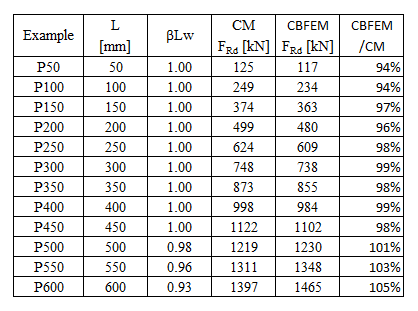

Parallel weld resistance calculation

\[\sqrt{ \sigma_{\perp}^2 + 3 \cdot \left( \tau_{\perp}^2 + \tau_{\parallel}^2\right)} \leq \frac{f_\textrm{u}}{\beta_{\mathrm{w}} \cdot \gamma_{\mathrm{M2}}}\]

\[\sigma_{\perp} = \tau_{\perp} = 0 \]

\[ \tau_{\parallel} = \frac{V}{L_{\textrm{p}} \cdot a}\]

\[ \sqrt{ 3 \cdot \left( \tau_{\parallel} \right)^2} \leq \frac{f_\textrm{u}}{\beta_{\mathrm{w}} \cdot \gamma_{\mathrm{M2}}}\]

\[ \sqrt{ 3 \cdot \left( \frac{V}{L_{\textrm{p}} \cdot a}\right)^2} \leq \frac{f_\textrm{u}}{\beta_{\mathrm{w}} \cdot \gamma_{\mathrm{M2}}}\]

\[ V = \frac{f_\textrm{u} \cdot L_{\textrm{p}} \cdot a \cdot \beta_{\mathrm{Lw1}}}{\beta_{\mathrm{w}} \cdot \gamma_{\mathrm{M2}} \cdot \sqrt{3}} \]

Where:

\(a\) - weld throat thickness

\(V\) - shear force acting on beam

\(L_{\textrm{t}}\) - total parallel welds length

\(\beta_{\mathrm{w}}\) - correlation factor taken from EN 1993-1-8 Table 4.1

\(\beta_{\mathrm{Lw1}}\) - long weld reduction factor, EN 1993-1-8 Equation 4.9

\(f_\textrm{u}\) - nominal ultimate tensile strength of the weaker part joined

\(\gamma_{\mathrm{M2}}\) - partial safety factor for welds

Transverse and parallel calculation

The resistance calculated by hand for a transverse and parallel weld combination is simply the sum of the transverse and parallel resistances derived from the equations above.

Results Presentation

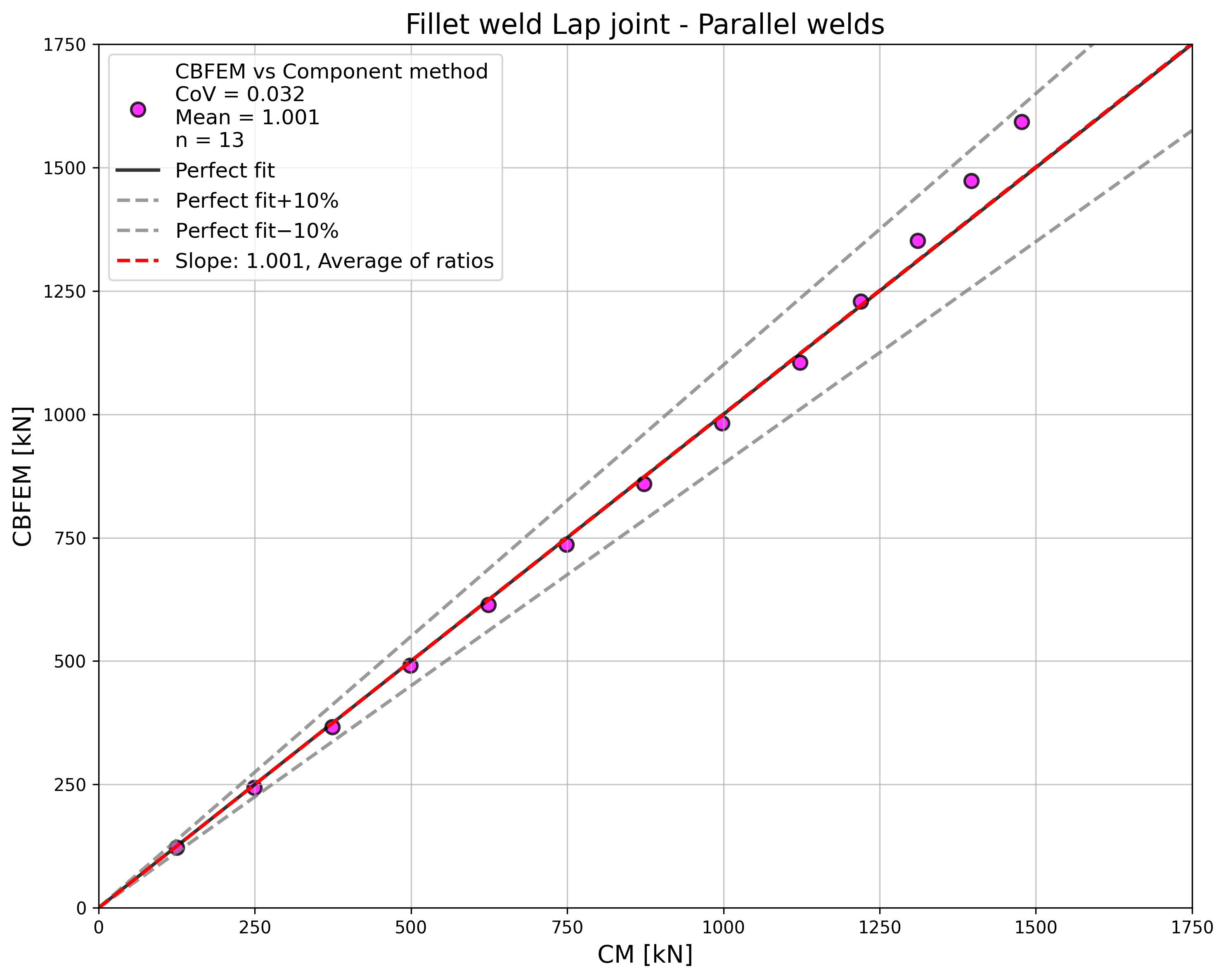

\[ \textsf{\textit{\footnotesize{Tab. 4.1.1 Parallel welds results}}}\]

\[ \textsf{\textit{\footnotesize{Fig. 4.1.3 Comparison of load resistances of parallel welds}}}\]

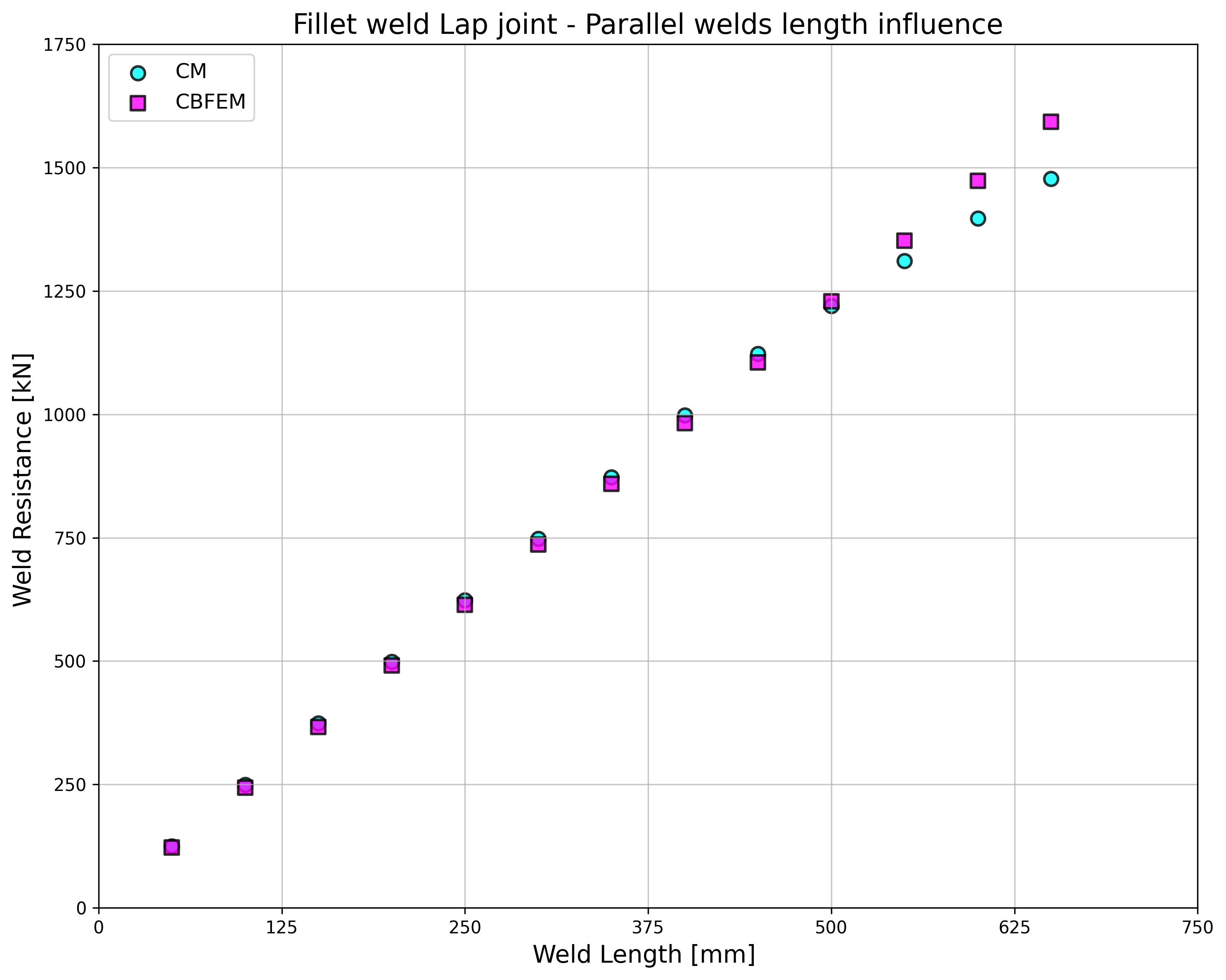

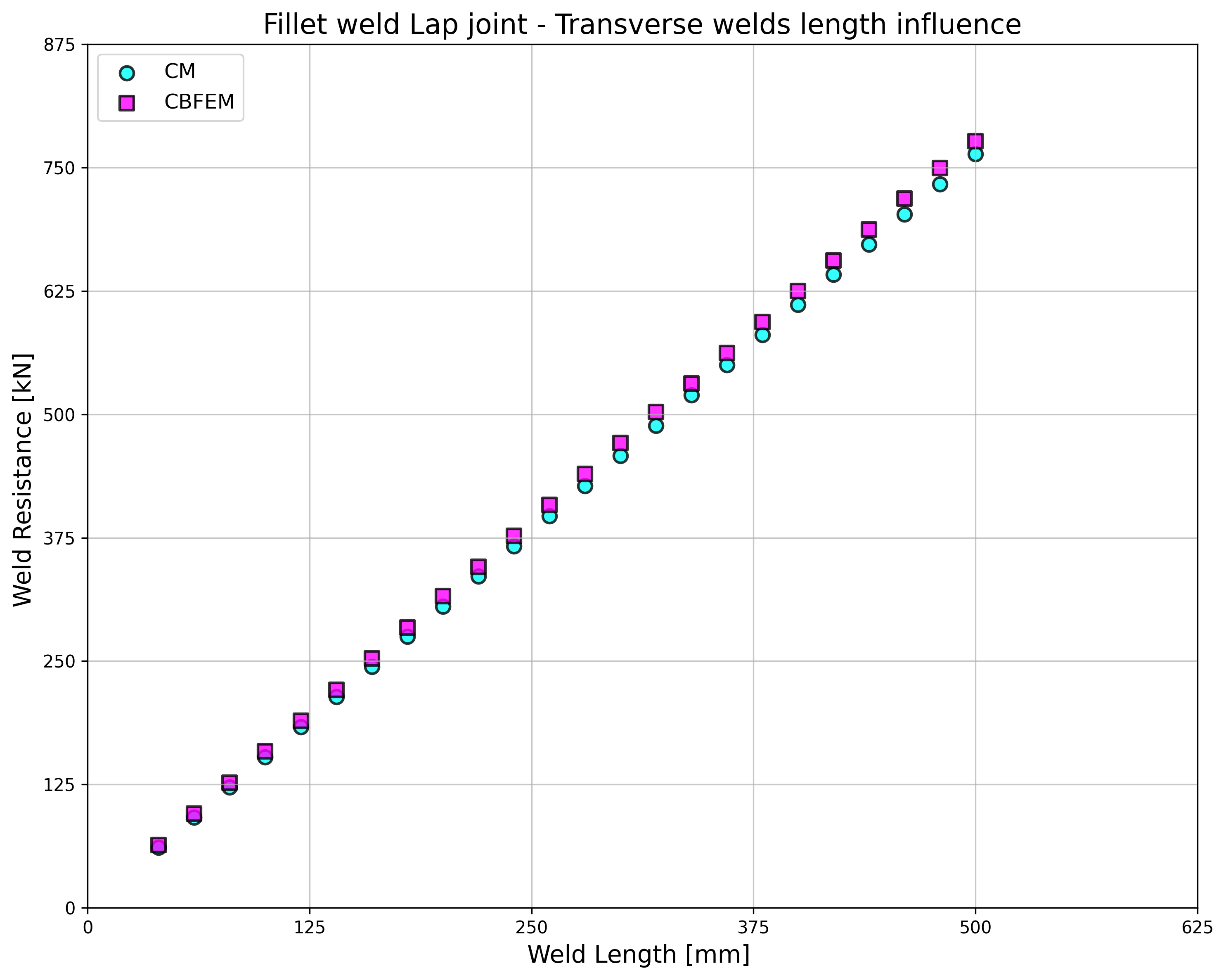

\[ \textsf{\textit{\footnotesize{Fig. 4.1.3.a Influence of weld length on resistance}}}\]

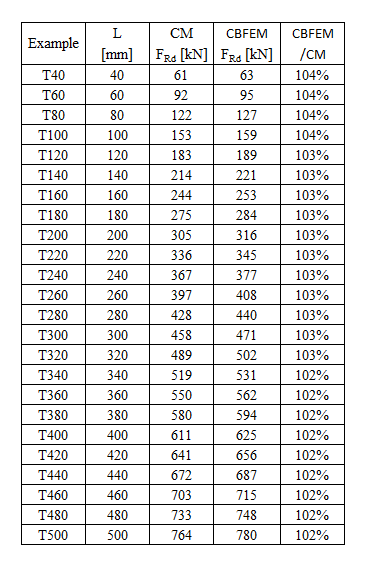

\[ \textsf{\textit{\footnotesize{Tab. 4.1.2 Transverse welds}}}\]

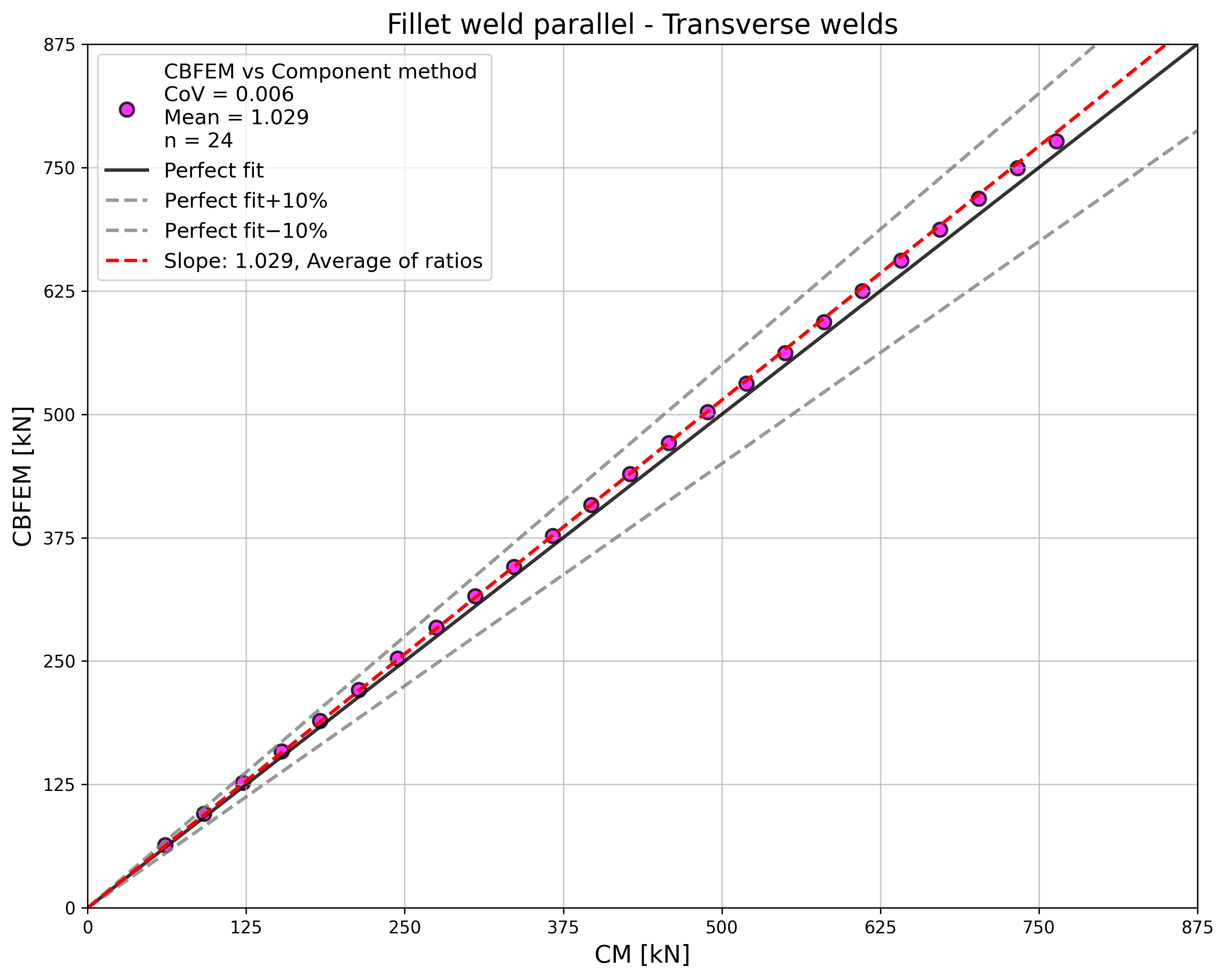

\[ \textsf{\textit{\footnotesize{Fig. 4.1.4 Comparison of load resistances of transverse welds}}}\]

\[ \textsf{\textit{\footnotesize{Fig. 4.1.4.a Influence of weld length on resistance}}}\]

\[ \textsf{\textit{\footnotesize{Tab. 4.1.3 Grouped welds}}}\]

\[ \textsf{\textit{\footnotesize{Fig. 4.1.5 Comparison of load resistances of group}}}\]

The resistance of parallel welds, transverse welds, and multi-oriented weld groups is nearly identical according to CM and CBFEM. The biggest difference in this study is 6% in load resistance.

The CBFEM results of parallel welds are slightly conservative but start to diverge for long welds. The reduction of resistance due to long welds is not captured by CBFEM, but it is not expected that welds longer than 200×throat thickness could appear in any connection, and up to this length, the results are still very close.

For transverse welds, CBFEM provides very consistent results with 2–4% higher resistance.

Benchmark example

Inputs

Member 1 – Iw60x500

• Welded from plates with thickness t = 20 mm

• Width b = 500 mm

• Web is removed by Opening manufacturing operation

• Steel S235

Member 2 – Plate 20x1000

• Thickness t = 20 mm

• Width b = 1000 mm

• Steel S235

• Offset ex = –90 mm

Transverse fillet weld at both sides of Member 2

• Throat thickness a = 3 mm

• Weld length Lt = 100 mm

Parallel fillet weld at both sides of Member 2

• Throat thickness a = 3 mm

• Weld length Lp = 100 mm

Output

• Design resistance in tension FRd = 387 kN (It should be noted that the resistance was calculated using the "Stop at limit strain" function. Consequently, the actual CBFEM resistance may be marginally higher.)

Fillet weld in angle plate joint

Description

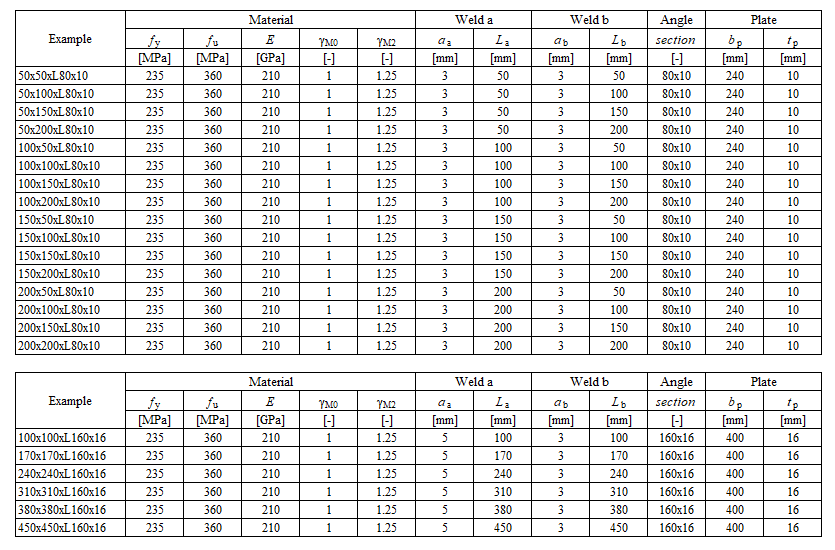

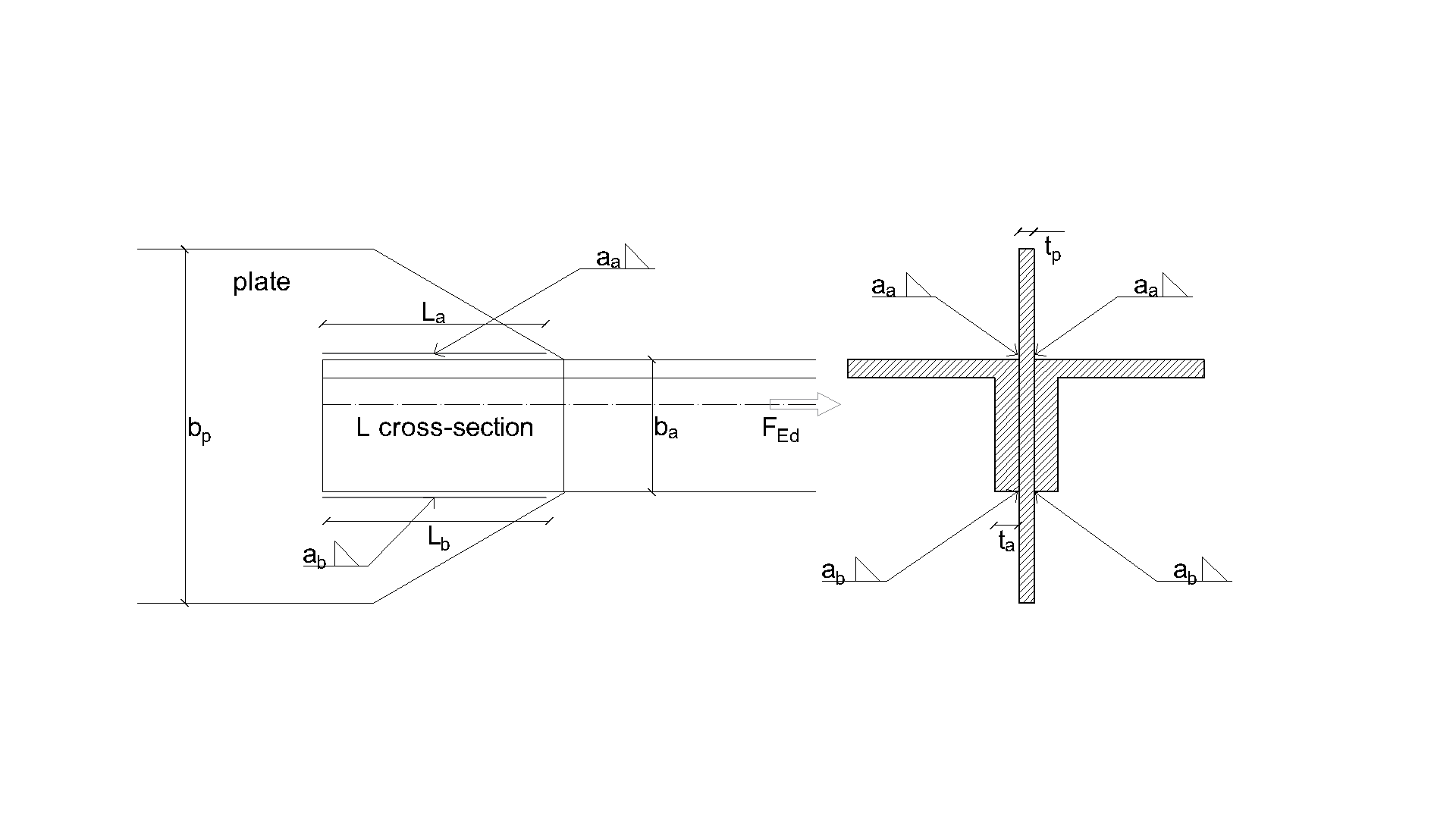

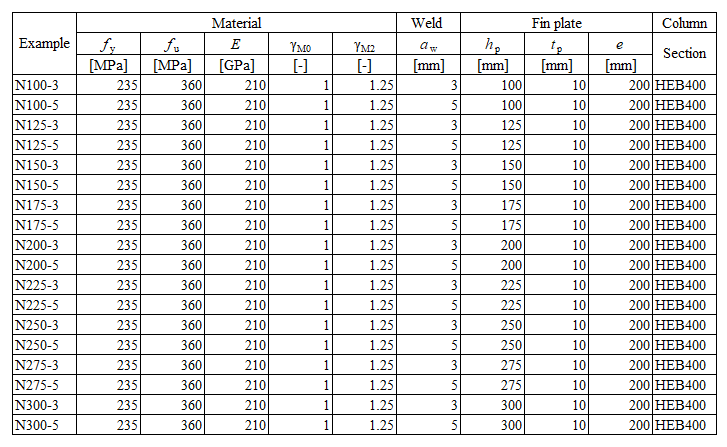

In this chapter, the model of the fillet weld in angle plate joint calculated by component-based finite element method (CBFEM) is verified on component method (CM). An angle is welded to a plate and loaded by normal force. The angle size and the length of the weld are studied in a sensitivity study.

Analytical model

The fillet weld is the only component examined in the study. The welds are designed according to Chapter 4 in EN 1993-1-8:2005 to be the weakest component in the joint. The design resistance of the fillet weld is described in Section 4.1. Overview of considered examples and material is given in Tab. 4.2.1. The geometry of the joints with dimensions is shown in Fig. 4.2.1.

Component method calculation

This hand calculation neglects the additional moment of the weld, which is developed due to force redistribution to the L cross-section parts acc. to EN 1993-1-8 (4.13).

\[\sqrt{ \sigma_{\perp}^2 + 3 \cdot \left( \tau_{\perp}^2 + \tau_{\parallel}^2\right)} \leq \frac{f_u}{\beta_{\mathrm{w}} \cdot \gamma_{\mathrm{M2}}}\]

\[\sigma_{\perp} = \tau_{\perp} = 0 \]

\[ \tau_{\parallel} = \frac{V}{l \cdot a}\]

\[ \sqrt{ 3 \cdot \left( \tau_{\parallel} \right)^2} \leq \frac{f_u}{\beta_{\mathrm{w}} \cdot \gamma_{\mathrm{M2}}}\]

\[ \sqrt{ 3 \cdot \left( \frac{V}{l \cdot a}\right)^2} \leq \frac{f_u}{\beta_{\mathrm{w}} \cdot \gamma_{\mathrm{M2}}}\]

\[ V = \frac{f_u \cdot l \cdot a \cdot \beta_{\mathrm{Lw1}}}{\beta_{\mathrm{w}} \cdot \gamma_{\mathrm{M2}} \cdot \sqrt{3}} \]

Total resistance calculated as sum of top and bottom weld resistances

\[ V = V_\mathrm{top} + V_\mathrm{bottom} \]

Where:

\(a\) - weld throat thickness

\(V\) - shear force acting on beam

\(l = 2 \cdot L_\mathrm{\dots}\) - parallel welds length

\(\beta_{\mathrm{w}}\) - correlation factor taken from EN 1993-1-8 Table 4.1

\(\beta_{\mathrm{Lw1}}\) - long weld reduction factor, EN 1993-1-8 Equation 4.9

\(f_u\) - nominal ultimate tensile strength of the weaker part joined

\(\gamma_{\mathrm{M2}}\) - partial safety factor for welds

\[ \textsf{\textit{\footnotesize{Tab. 4.2.1 Examples overview}}}\]

\[ \textsf{\textit{\footnotesize{Fig. 4.2.1 Joint geometry with dimensions}}}\]

Numerical model

The weld component in CBFEM is described in General theoretical background and EN theoretical background. The weld model has an elastic-plastic material diagram, and stress peaks are redistributed along the weld length.

Verification of resistance

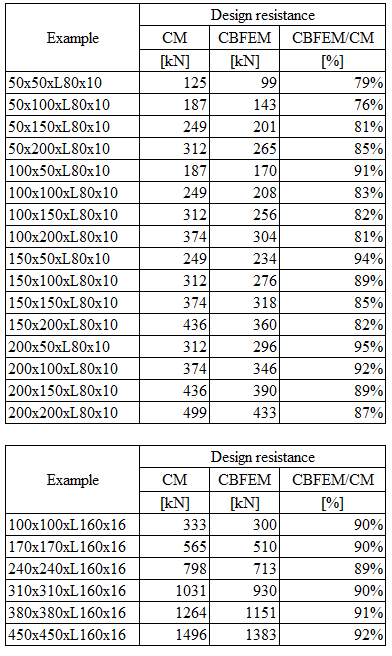

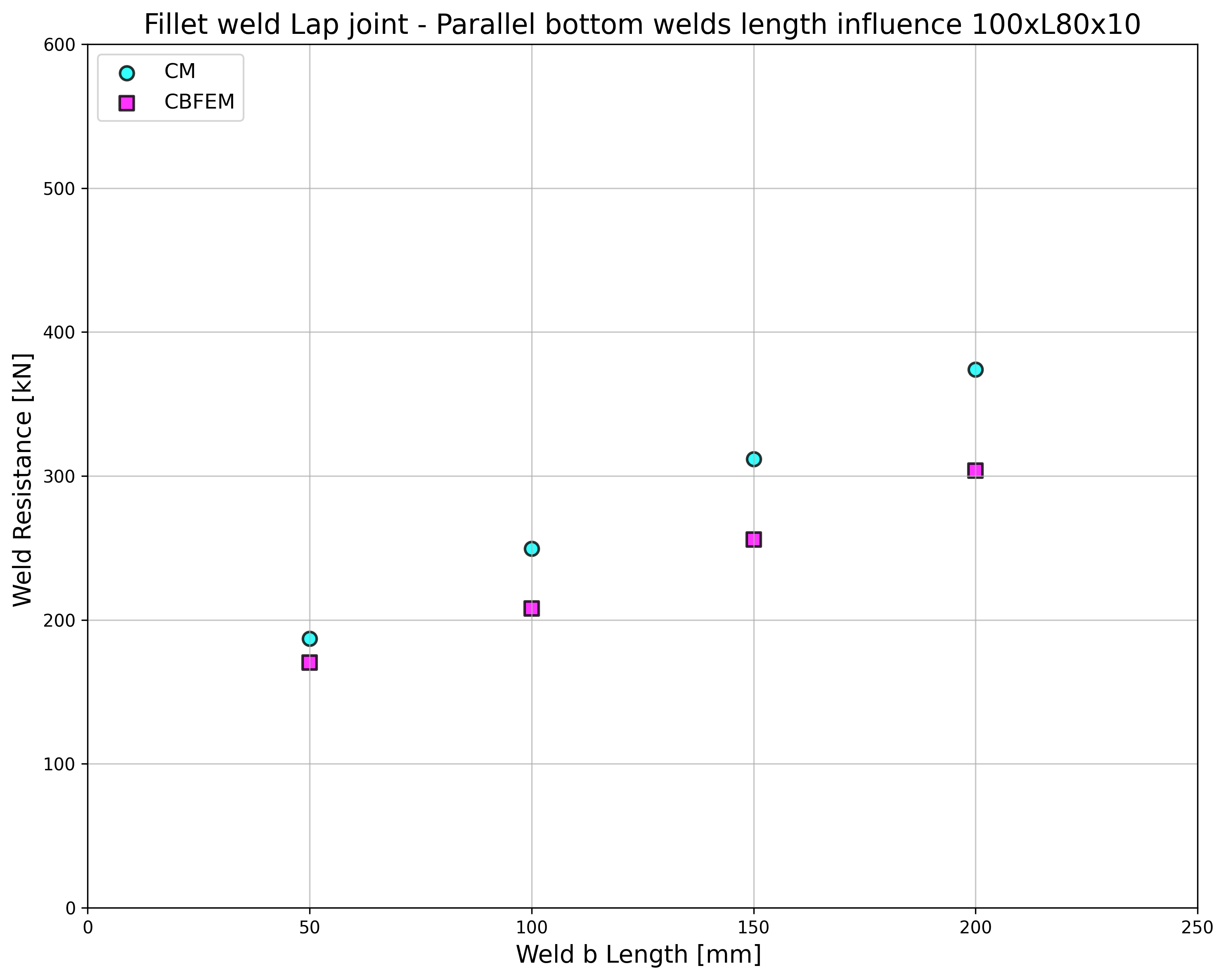

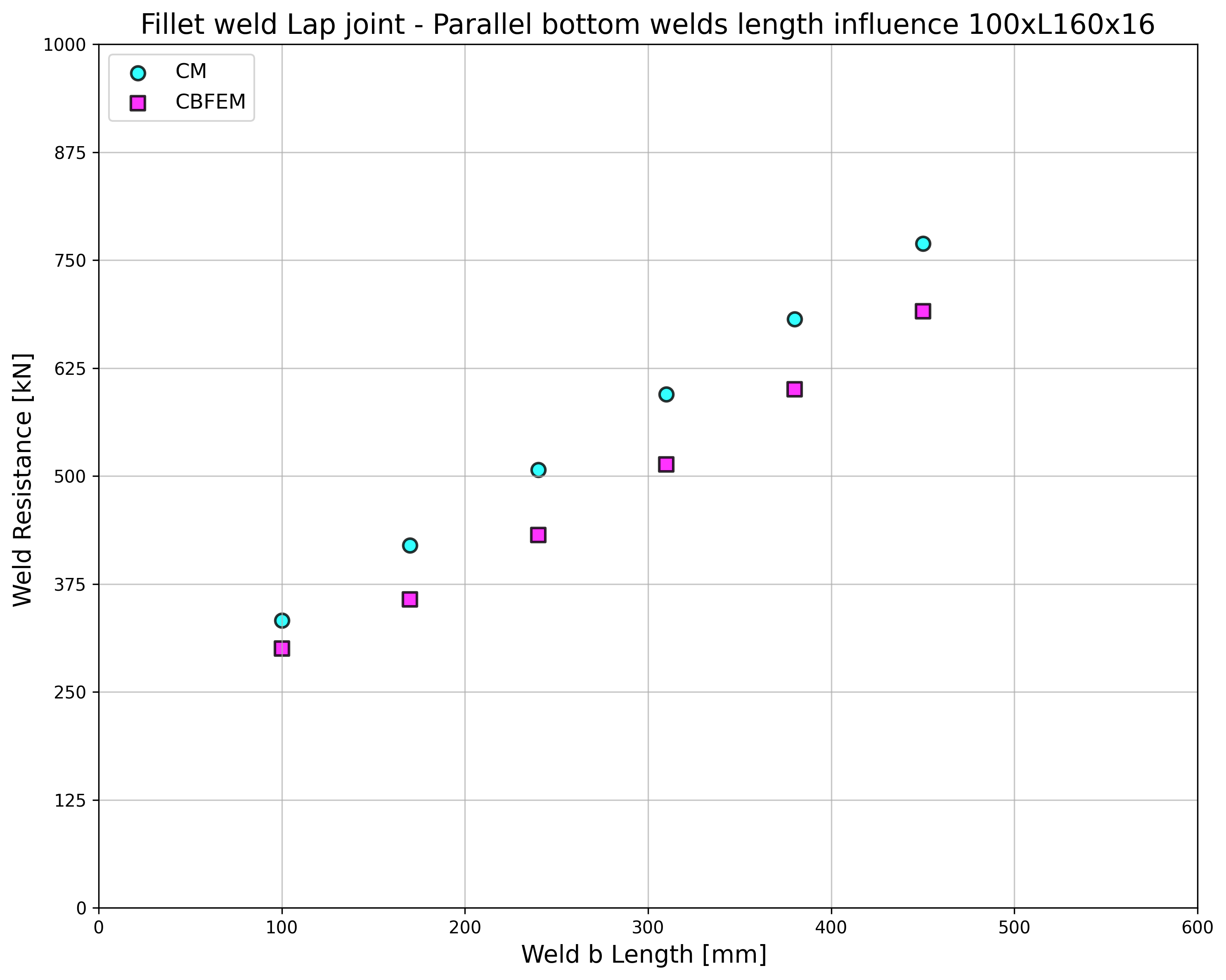

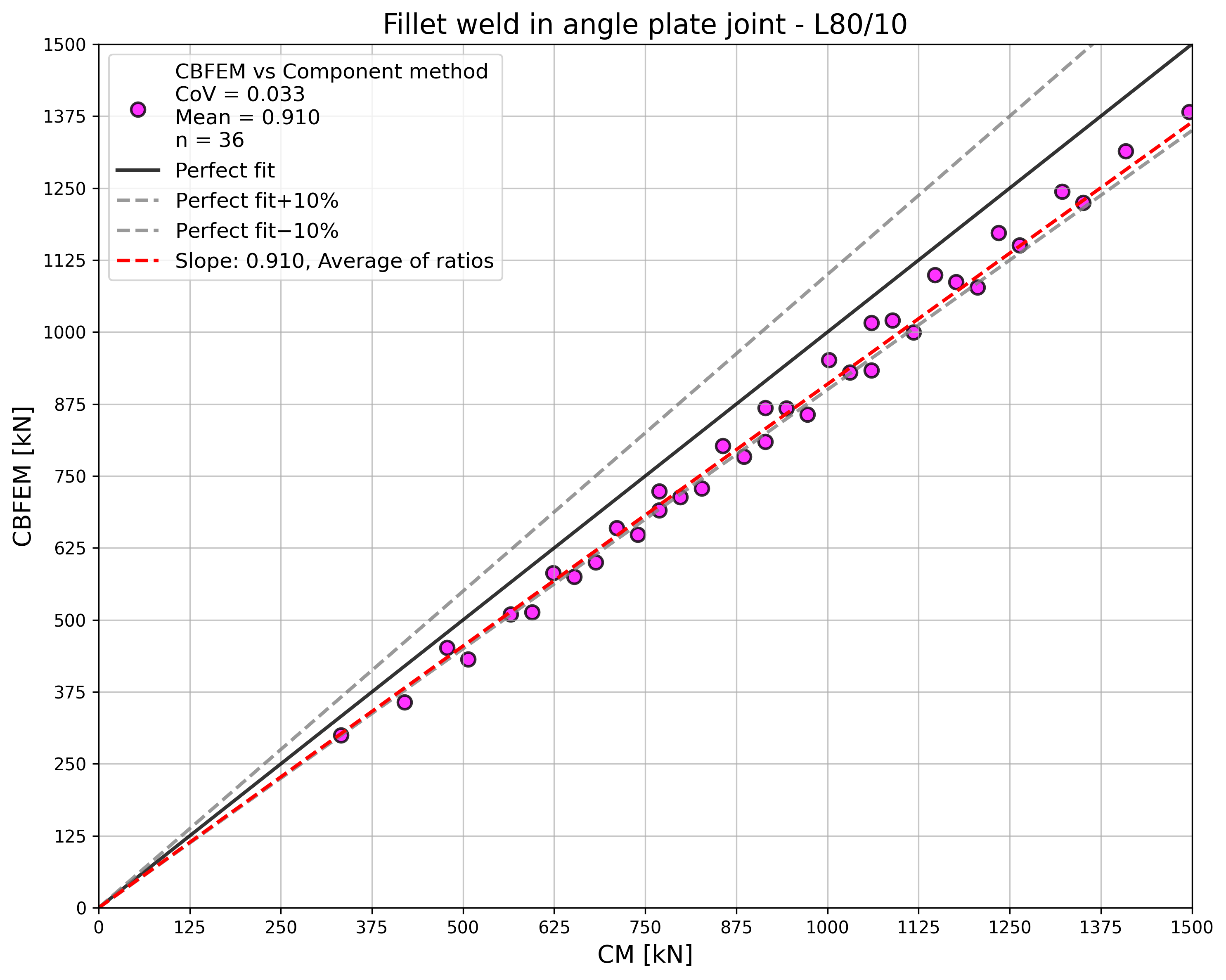

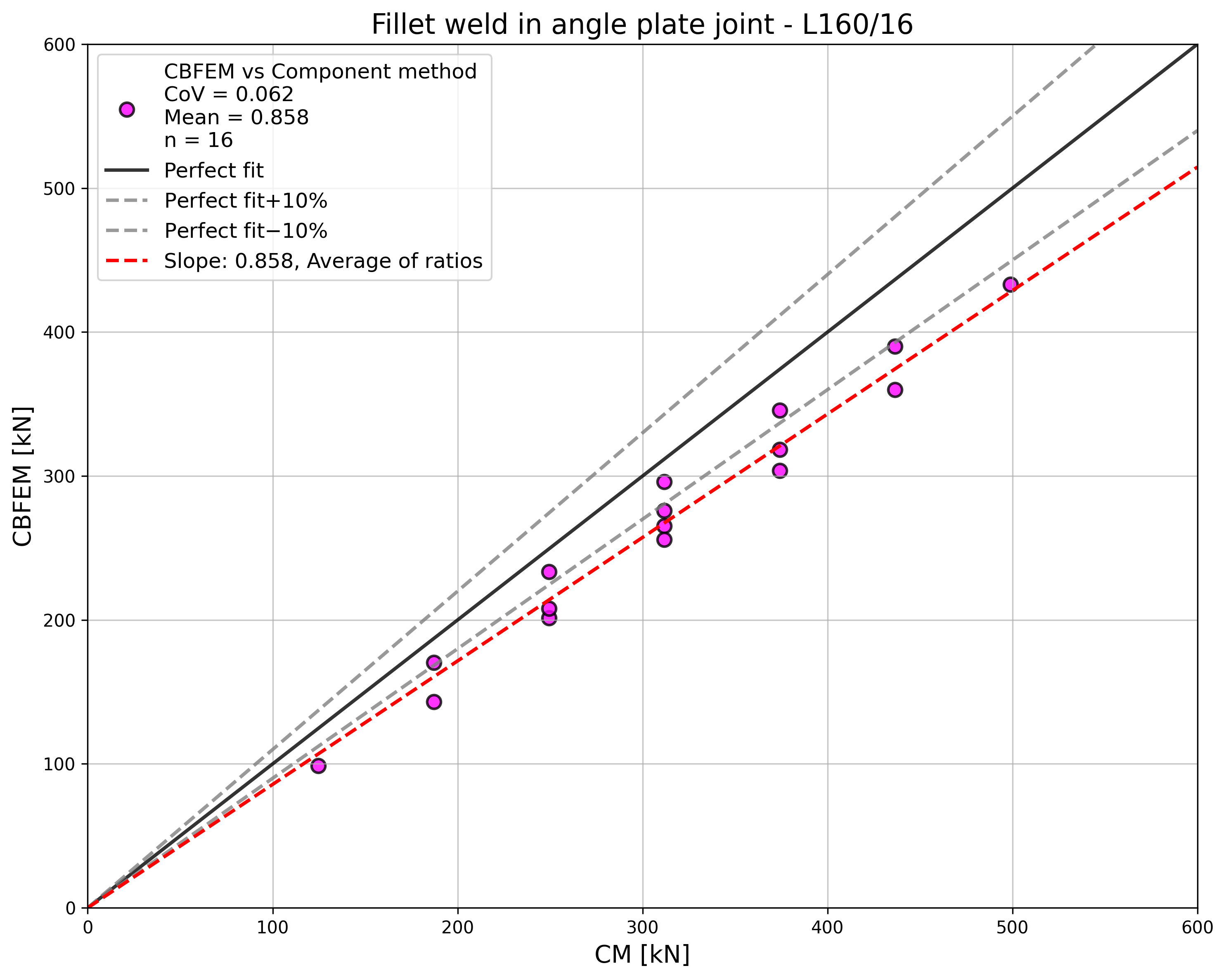

The weld design resistances calculated by CBFEM are compared with the results of CM; see Tab. 4.2.2. Two parameters are studied: the length of the weld and the angle section. Fig 4.2.2 shows the sensitivity study of bottom weld length. The length of the top weld a in the study is La=100mm.

\[ \textsf{\textit{\footnotesize{Tab. 4.2.2 Comparison of CBFEM and CM}}}\]

\[ \textsf{\textit{\footnotesize{a}}}\]

\[ \textsf{\textit{\footnotesize{b}}}\]

\[ \textsf{\textit{\footnotesize{a) Angle cleat 80×10 b) Angle cleat 160×16}}}\]

\[ \textsf{\textit{\footnotesize{Fig. 4.2.2 Sensitivity study of bottom weld b length}}}\]

Results of CBFEM and CM are compared, and the sensitivity study is presented. The influence of weld length on the design resistance of a welded angle joint is shown in Fig. 4.2.2. The study shows good agreement for all weld configurations. To illustrate the accuracy of the CBFEM model, the results of the study are summarized in a diagram comparing design resistances by CBFEM and CM; see Fig. 4.2.3. The results show that all the predictions of CBFEM are safe-sided compared to the CM, where eccentricity is neglected.

\[ \textsf{\textit{\footnotesize{Fig. 4.2.3 Verification of CBFEM to CM}}}\]

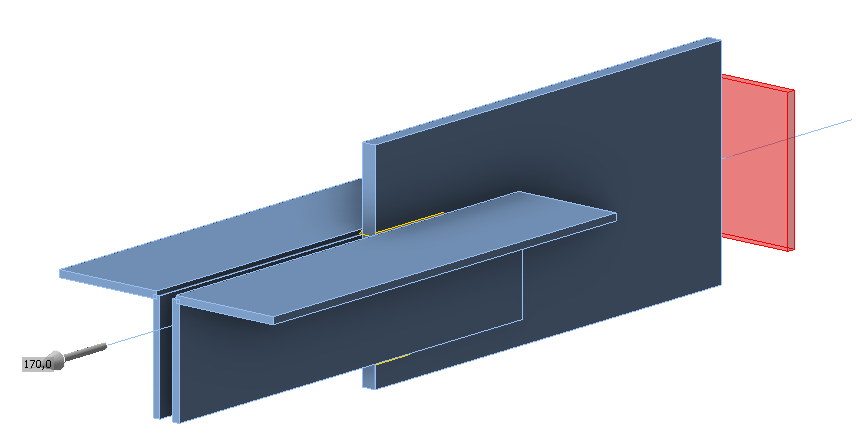

Benchmark example

Inputs

Angle

- Cross-section 2×L80×10

- Distance between angles 16 mm

Plate

- Thickness tp = 16 mm

- Width bp = 240 mm

Weld, parallel fillet welds, see Fig. 4.2.4

- Throat thickness aw = 3 mm

- Top weld length Lw,top = 100 mm

- Bottom weld length Lw,bottom = 50 mm

Outputs

- Design resistance in tension FRd = 170 kN (It should be noted that the resistance was calculated using the "Stop at limit strain" function. Consequently, the actual CBFEM resistance may be marginally higher.)

\[ \textsf{\textit{\footnotesize{Fig. 4.2.4 Benchmark example of the welded angle plate joint with parallel fillet welds}}}\]

Fillet weld in fin plate joint

Description

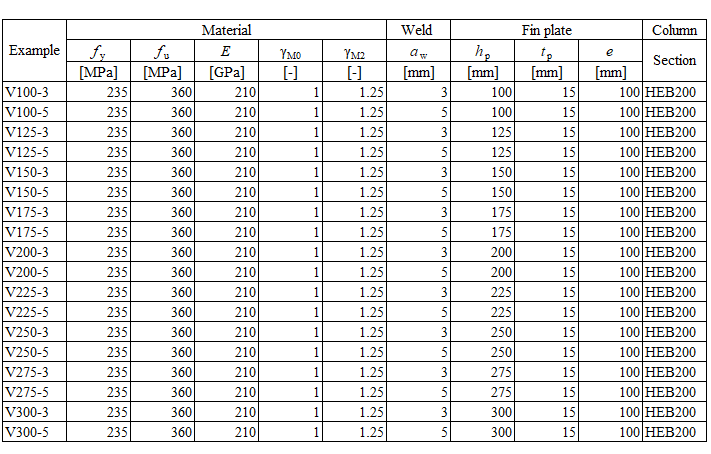

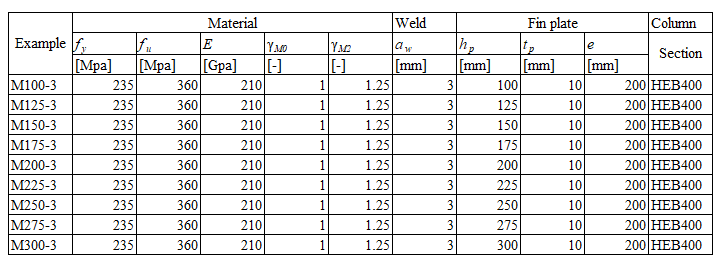

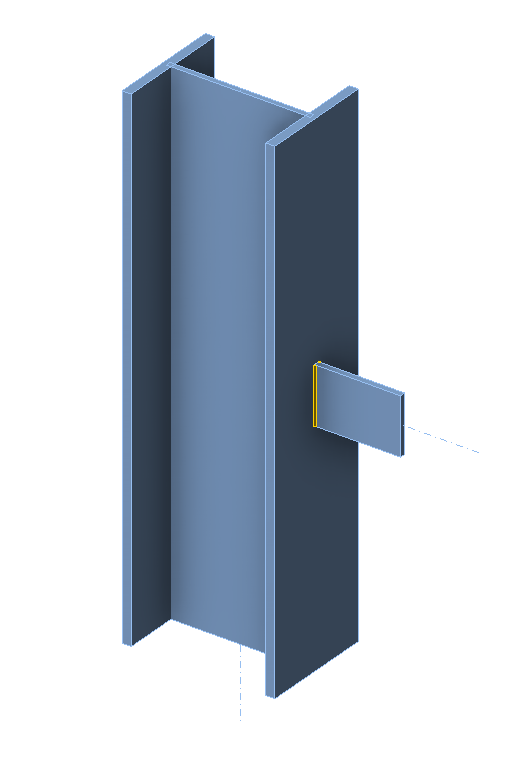

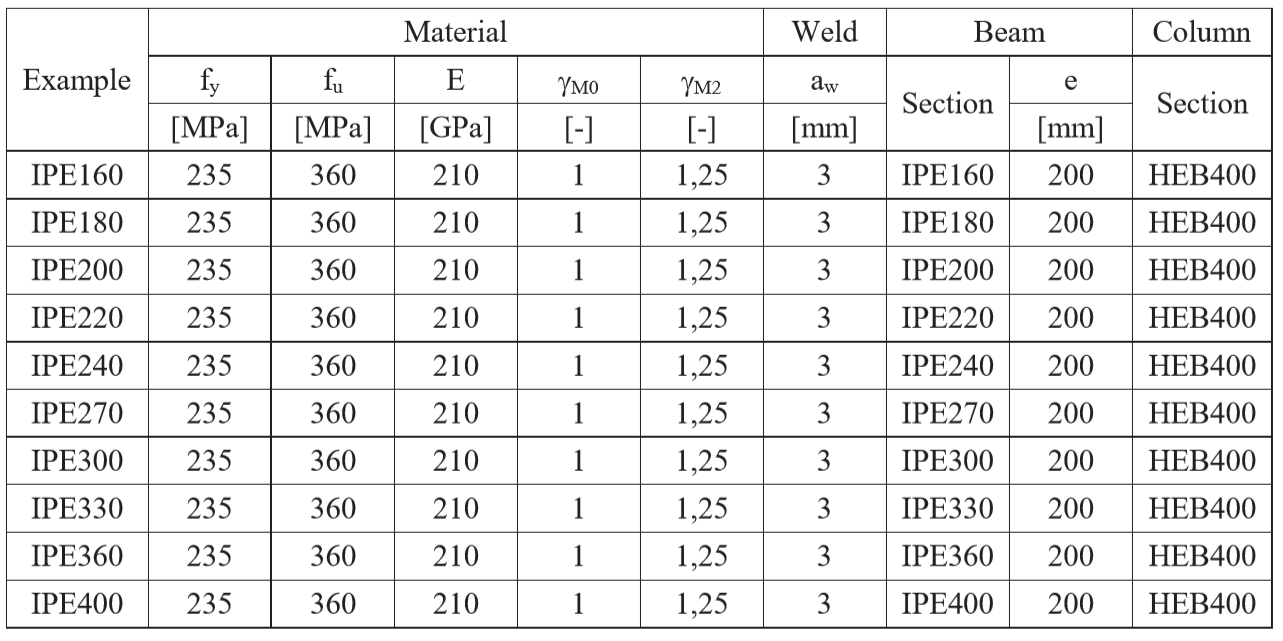

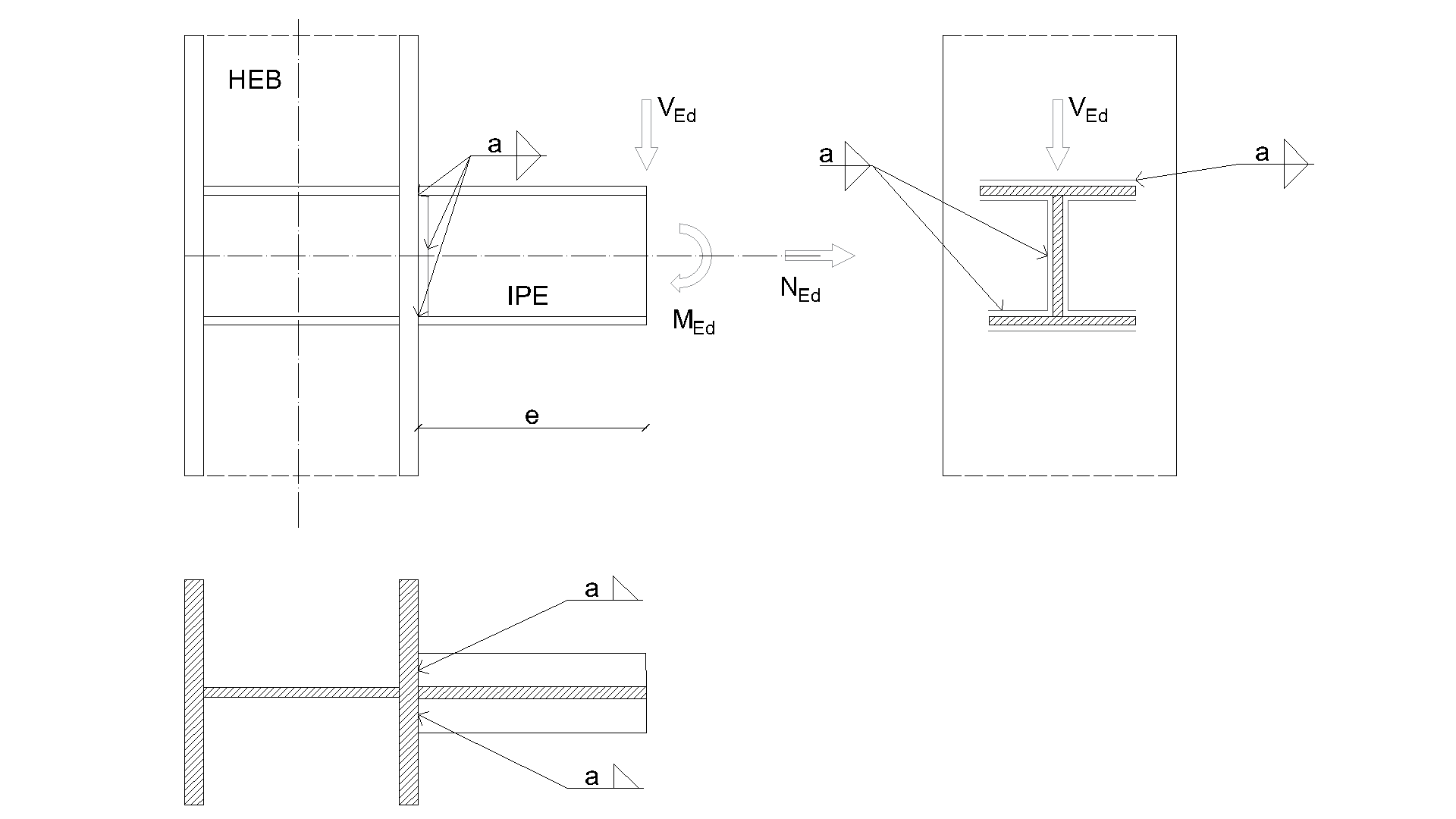

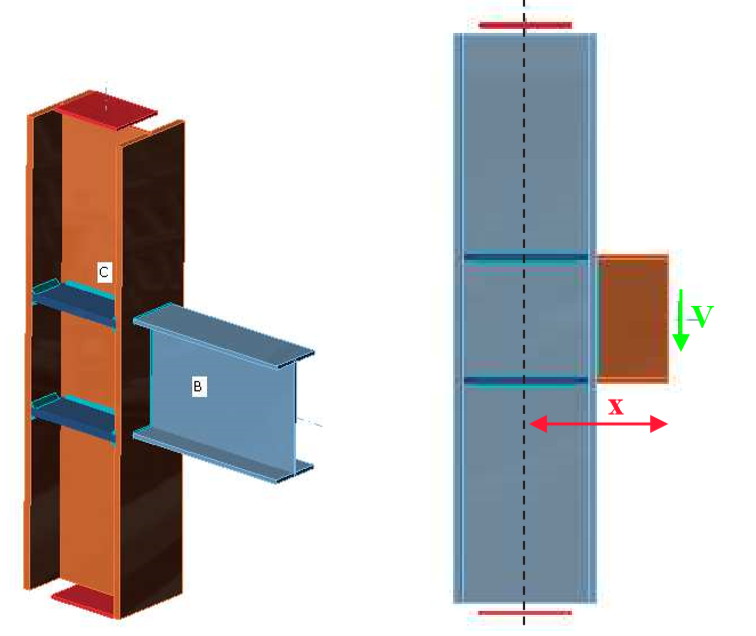

In this chapter, component-based finite element method (CBFEM) of a fillet weld in a fin plate joint is verified with component method (CM). A fin plate is welded to open section column HEB. The height of the fin plate is changed from 150 to 300 mm. The plate/weld is loaded by normal and shear force and bending moment.

Analytical model

The fillet weld is the only component examined in the study. The welds are designed to be the weakest component in the joint according to Chapter 4 in EN 1993-1-8:2005. The design resistance of the fillet weld is described in Section 4.1. Overview of considered examples and material is given in Tab. 4.3.1. Three load cases are considered: normal force N, shear force V, and bending moment M. Geometry of the joint with dimensions is shown in Fig. 4.3.1.

Weld normal resistance calculation

\[\sqrt{ \sigma_{\perp}^2 + 3 \cdot \left( \tau_{\perp}^2 + \tau_{\parallel}^2\right)} \leq \frac{f_u}{\beta_{\mathrm{w}} \cdot \gamma_{\mathrm{M2}}}\]

\[\sigma_{\perp} = \tau_{\perp} = \frac{\sigma_{N}}{\sqrt{2}} = \frac{N}{l \cdot a}\cdot \frac{1}{\sqrt{2}} \]

\[ \tau_{\parallel} = 0\]

\[ \sqrt{ \left( \frac{\sigma_{N}}{\sqrt{2}} \right)^2 + 3 \cdot \left( \frac{\sigma_{N}}{\sqrt{2}} \right)^2} \leq \frac{f_u}{\beta_{\mathrm{w}} \cdot \gamma_{\mathrm{M2}}}\]

\[ \sqrt{ \left( \frac{N}{l \cdot a}\cdot \frac{1}{\sqrt{2}} \right)^2 + 3 \cdot \left( \frac{N}{l_\mathrm{tw} \cdot a}\cdot \frac{1}{\sqrt{2}} \right)^2} \leq \frac{f_u}{\beta_{\mathrm{w}} \cdot \gamma_{\mathrm{M2}}}\]

\[ N \leq \frac{f_{u} \cdot l\cdot a }{\beta_{\mathrm{w}} \cdot \gamma_{\mathrm{M2}} \cdot \sqrt{2}} \]

\[ \sigma_{\perp} \leq \frac{f_{u} \cdot 0.9}{ \gamma_{\mathrm{M2}}} \]

\[ N \leq \frac{f_{u} \cdot l \cdot a \cdot 0.9 \cdot \sqrt{2}}{ \gamma_{\mathrm{M2}} } \]

Where:

\(a\) - weld throat thickness

\(N\) - the normal force acting on the beam

\(l\) - total weld length

\(\beta_{\mathrm{w}}\) - correlation factor taken from EN 1993-1-8 Table 4.1

\(f_u\) - nominal ultimate tensile strength of the weaker part joined

\(\gamma_{\mathrm{M2}}\) - partial safety factor for welds

Weld bending resistance calculation

\[\sqrt{ \sigma_{\perp}^2 + 3 \cdot \left( \tau_{\perp}^2 + \tau_{\parallel}^2\right)} \leq \frac{f_u}{\beta_{\mathrm{w}} \cdot \gamma_{\mathrm{M2}}}\]

\[\sigma_{\perp} = \tau_{\perp} = \frac{\sigma_{N}}{\sqrt{2}} = \frac{M}{W}\cdot \frac{1}{\sqrt{2}} \]

\[ \tau_{\parallel} = 0\]

\[ \sqrt{ \left( \frac{\sigma_{N}}{\sqrt{2}} \right)^2 + 3 \cdot \left( \frac{\sigma_{N}}{\sqrt{2}} \right)^2} \leq \frac{f_u}{\beta_{\mathrm{w}} \cdot \gamma_{\mathrm{M2}}}\]

\[ \sqrt{ \left( \frac{M}{W}\cdot \frac{1}{\sqrt{2}} \right)^2 + 3 \cdot \left( \frac{M}{W}\cdot \frac{1}{\sqrt{2}} \right)^2} \leq \frac{f_u}{\beta_{\mathrm{w}} \cdot \gamma_{\mathrm{M2}}}\]

\[ M \leq \frac{f_{u} \cdot W }{\beta_{\mathrm{w}} \cdot \gamma_{\mathrm{M2}} \cdot \sqrt{2}} \]

\[ \sigma_{\perp} \leq \frac{f_{u} \cdot 0.9}{ \gamma_{\mathrm{M2}}} \]

\[ M \leq \frac{f_{u} \cdot W \cdot 0.9 \cdot \sqrt{2}}{ \gamma_{\mathrm{M2}} } \]

Where:

\(a\) - weld throat thickness

\(W = \frac{1}{4} \cdot a \cdot l^2\) - weld plastic section modulus

\(M\) - bending moment acting on the beam

\(l\) - total weld length

\(\beta_{\mathrm{w}}\) - correlation factor taken from EN 1993-1-8 Table 4.1

\(f_u\) - nominal ultimate tensile strength of the weaker part joined

\(\gamma_{\mathrm{M2}}\) - partial safety factor for welds

Weld shear resistance calculation

\[\sqrt{ \sigma_{\perp}^2 + 3 \cdot \left( \tau_{\perp}^2 + \tau_{\parallel}^2\right)} \leq \frac{f_u}{\beta_{\mathrm{w}} \cdot \gamma_{\mathrm{M2}}}\]

\[\sigma_{\perp} = \tau_{\perp} = 0 \]

\[ \tau_{\parallel} = \frac{V}{l \cdot a}\]

\[ \sqrt{ 3 \cdot \left( \tau_{\parallel} \right)^2} \leq \frac{f_u}{\beta_{\mathrm{w}} \cdot \gamma_{\mathrm{M2}}}\]

\[ \sqrt{ 3 \cdot \left( \frac{V}{l \cdot a}\right)^2} \leq \frac{f_u}{\beta_{\mathrm{w}} \cdot \gamma_{\mathrm{M2}}}\]

\[ V = \frac{f_u \cdot l\cdot a }{\beta_{\mathrm{w}} \cdot \gamma_{\mathrm{M2}} \cdot \sqrt{3}} \]

Where:

\(a\) - weld throat thickness

\(V\) - shear force acting on beam

\(l\) - total weld length

\(\beta_{\mathrm{w}}\) - correlation factor taken from EN 1993-1-8 Table 4.1

\(f_u\) - nominal ultimate tensile strength of the weaker part joined

\(\gamma_{\mathrm{M2}}\) - partial safety factor for welds

\[ \textsf{\textit{\footnotesize{Tab. 4.3.1.N Examples overview}}}\]

\[ \textsf{\textit{\footnotesize{Tab. 4.3.1.V Examples overview}}}\]

\[ \textsf{\textit{\footnotesize{Tab. 4.3.1.M Examples overview}}}\]

\[ \textsf{\textit{\footnotesize{Fig. 4.3.1 Joint geometry with dimensions}}}\]

Numerical model

The weld component in CBFEM is described in General theoretical background and EN theoretical background. The weld model has an elastic-plastic material diagram, and stress peaks are redistributed along the weld length.

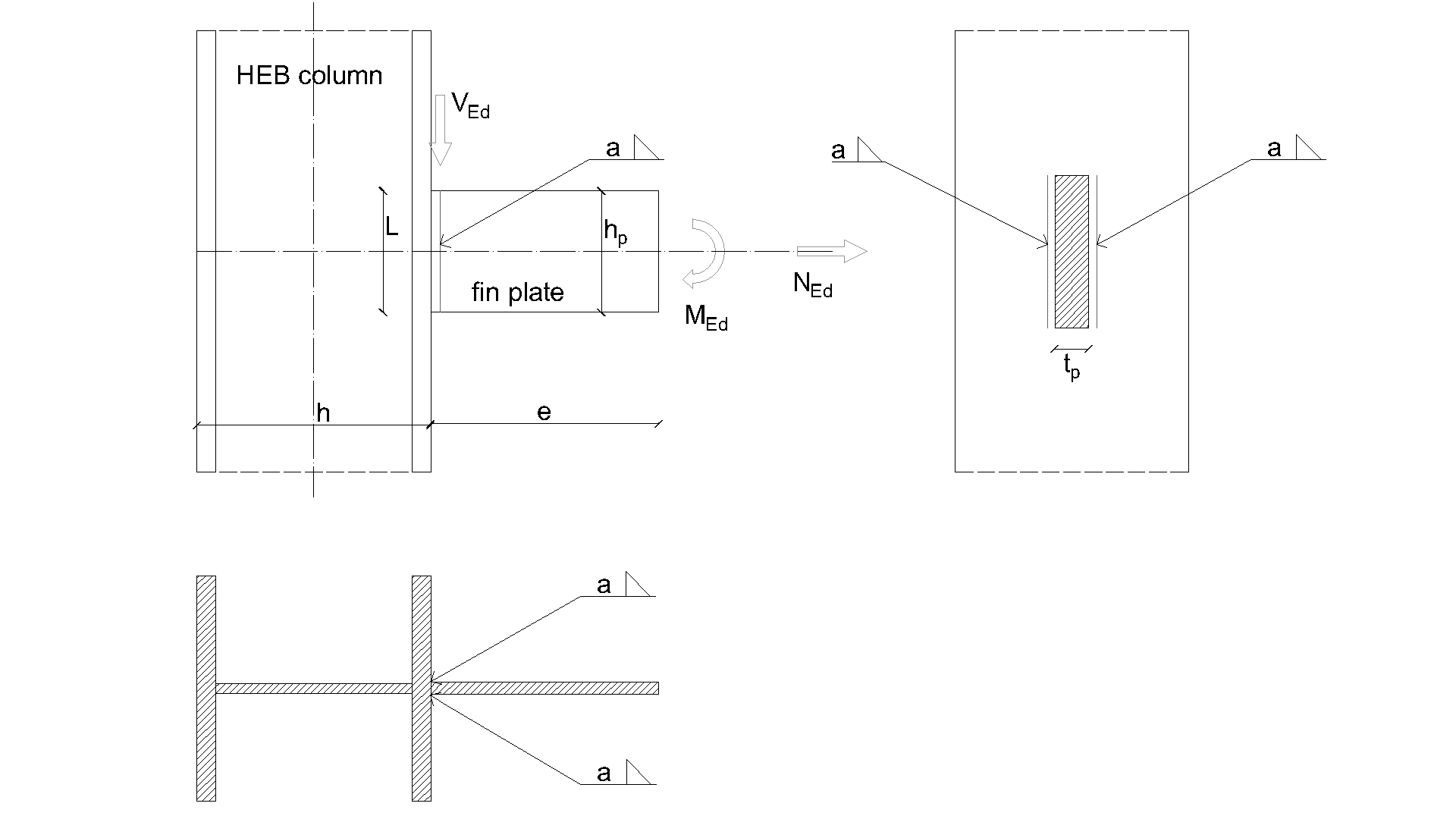

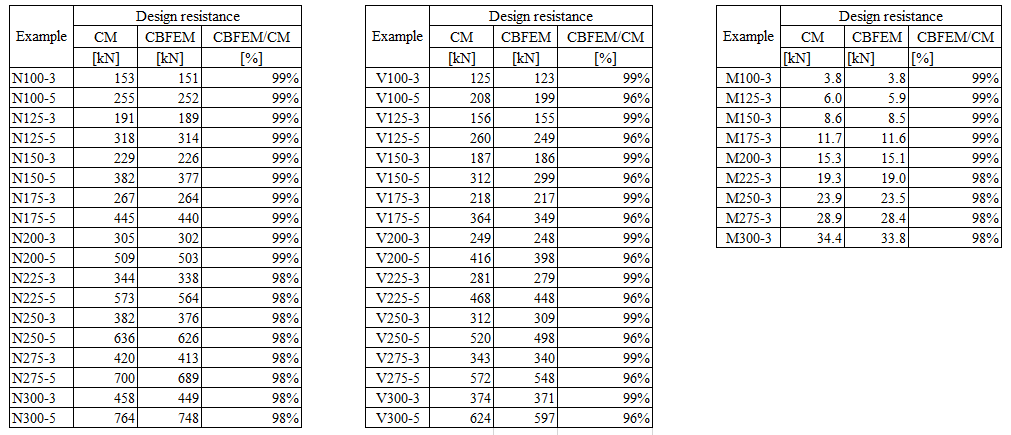

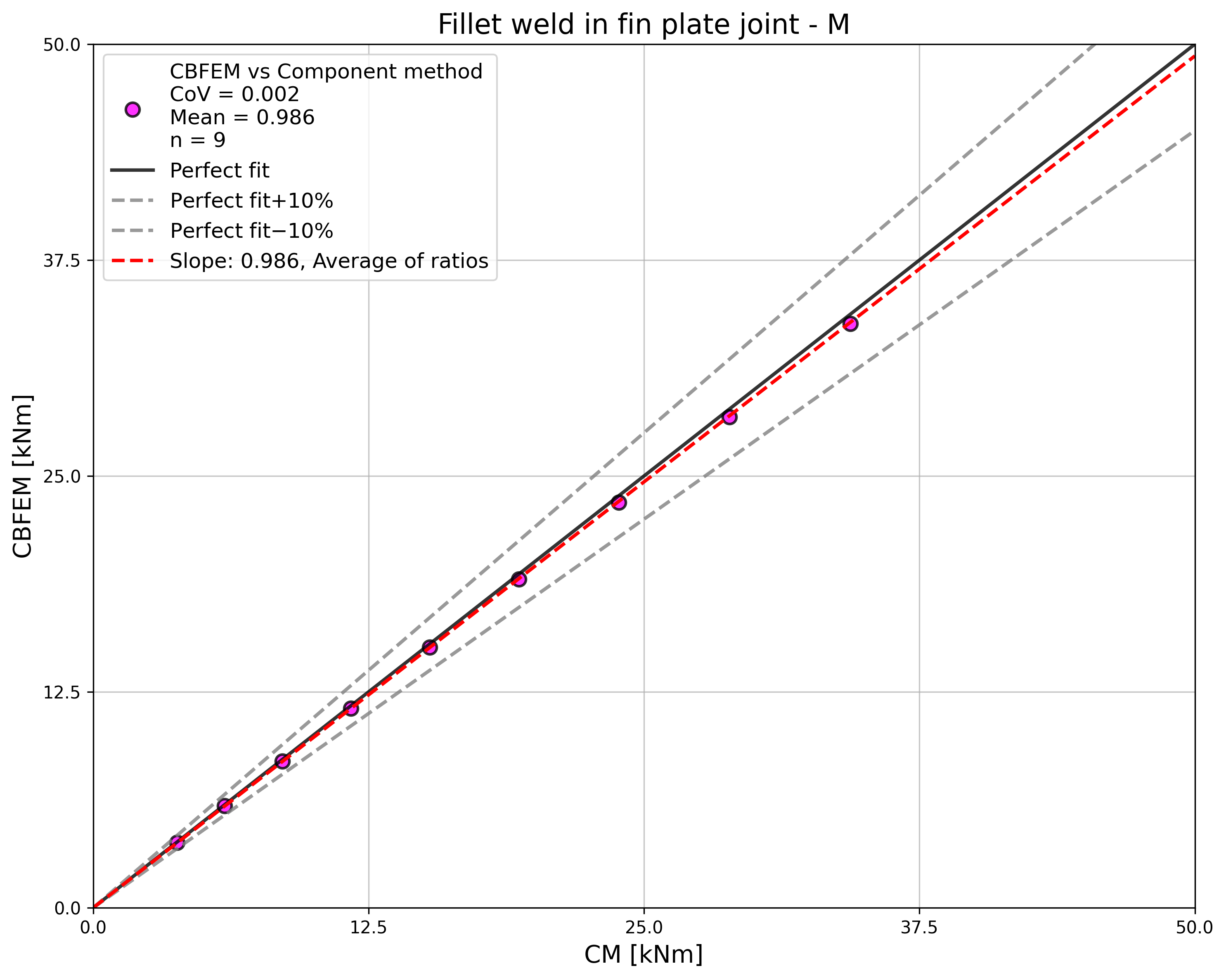

Verification of resistance

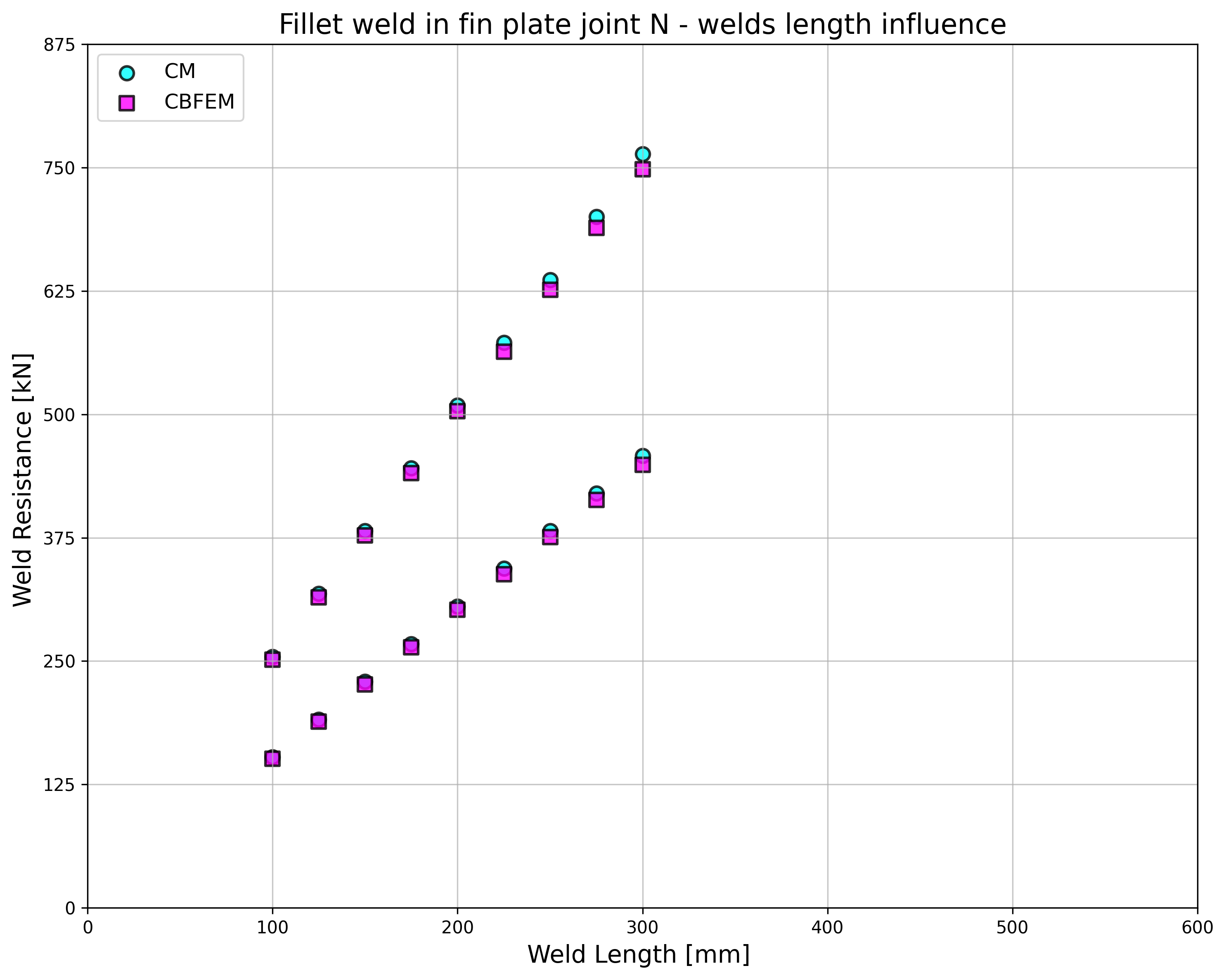

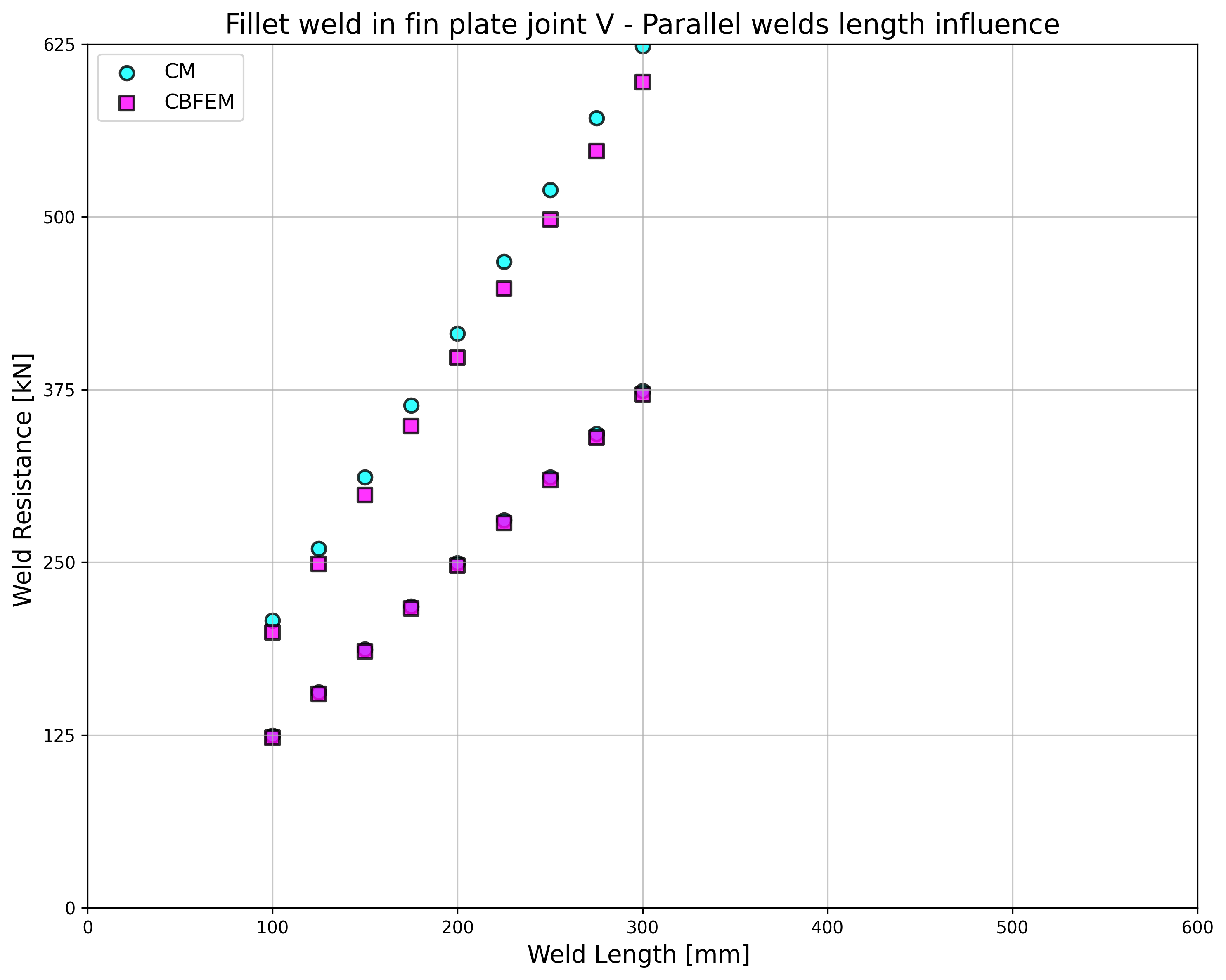

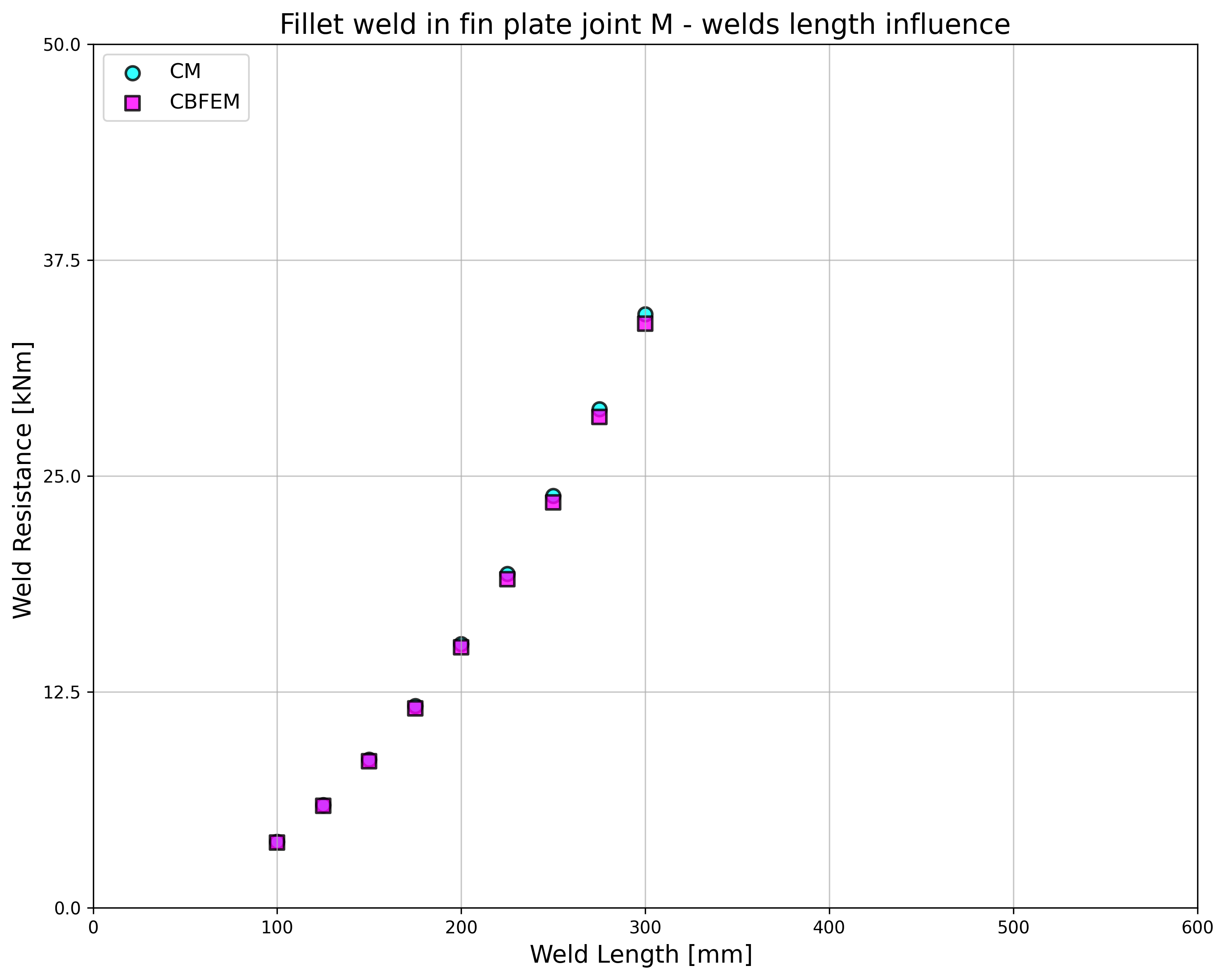

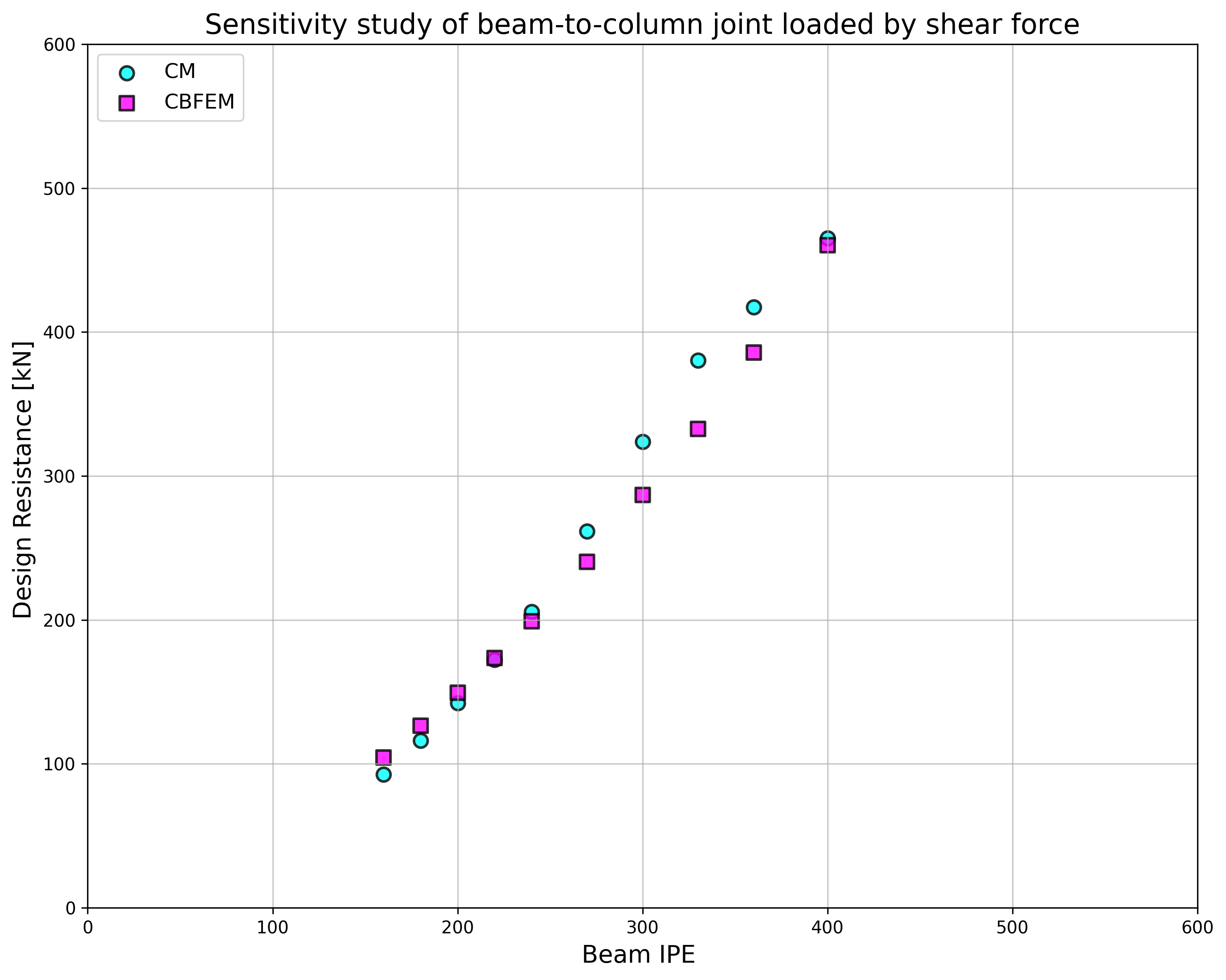

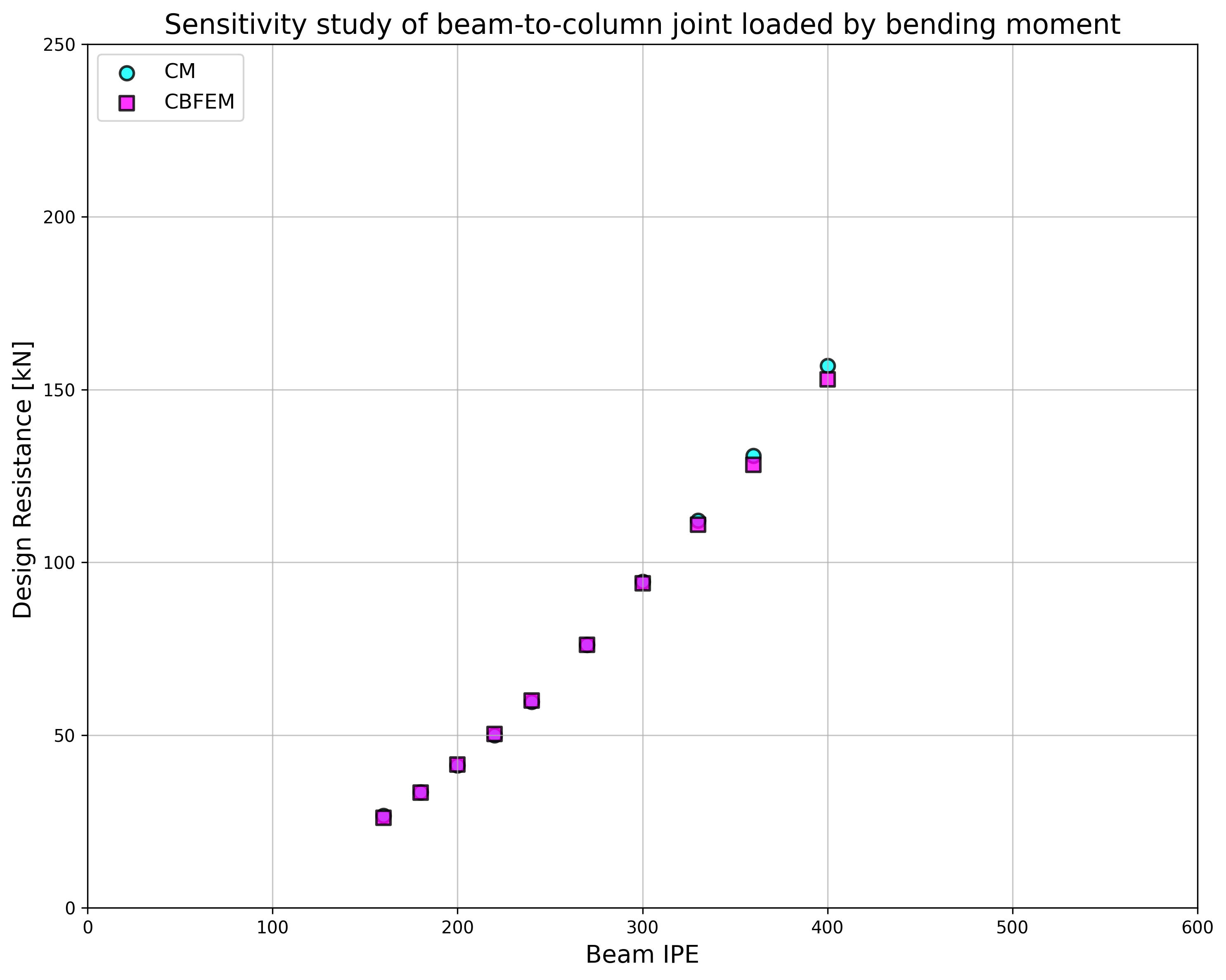

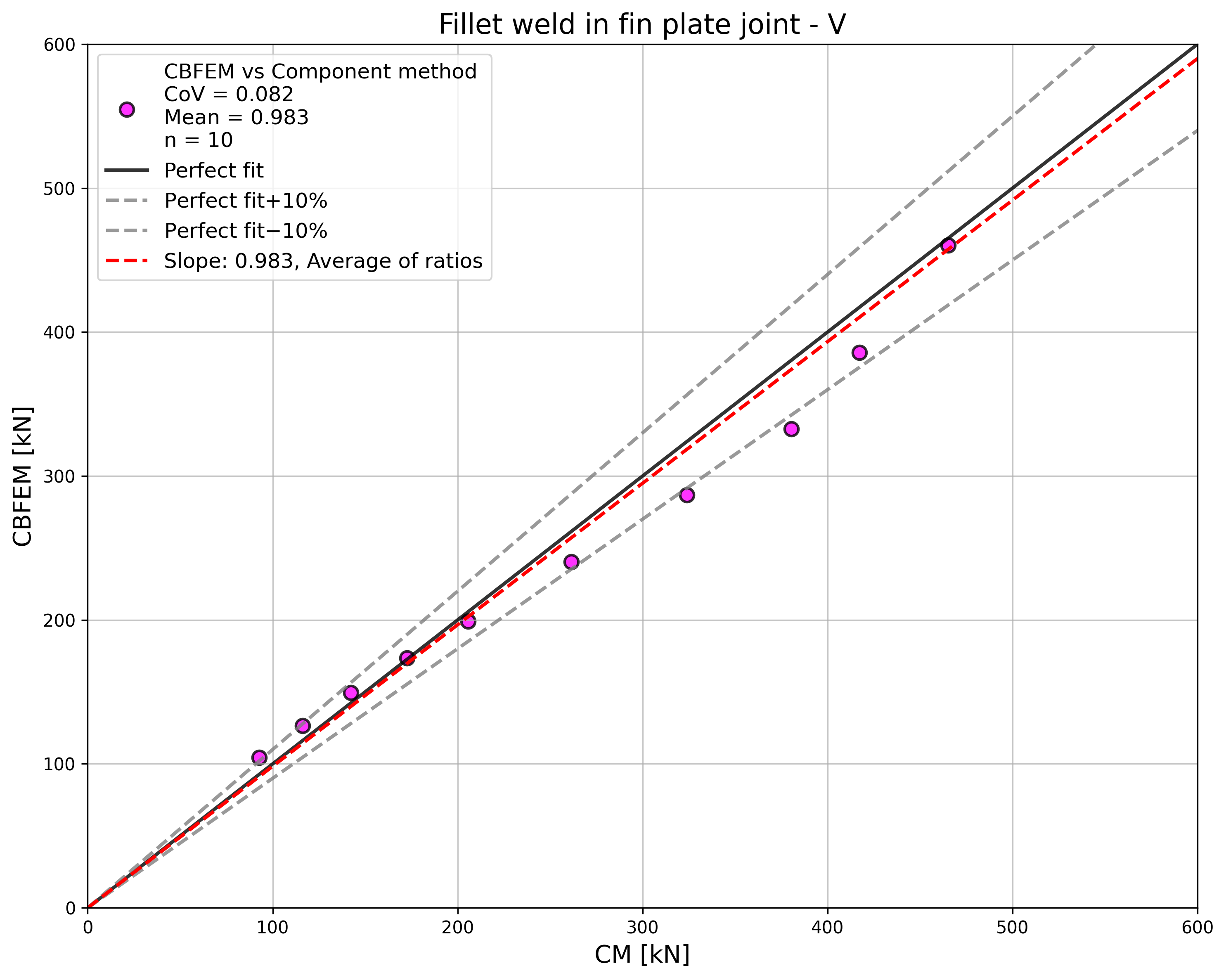

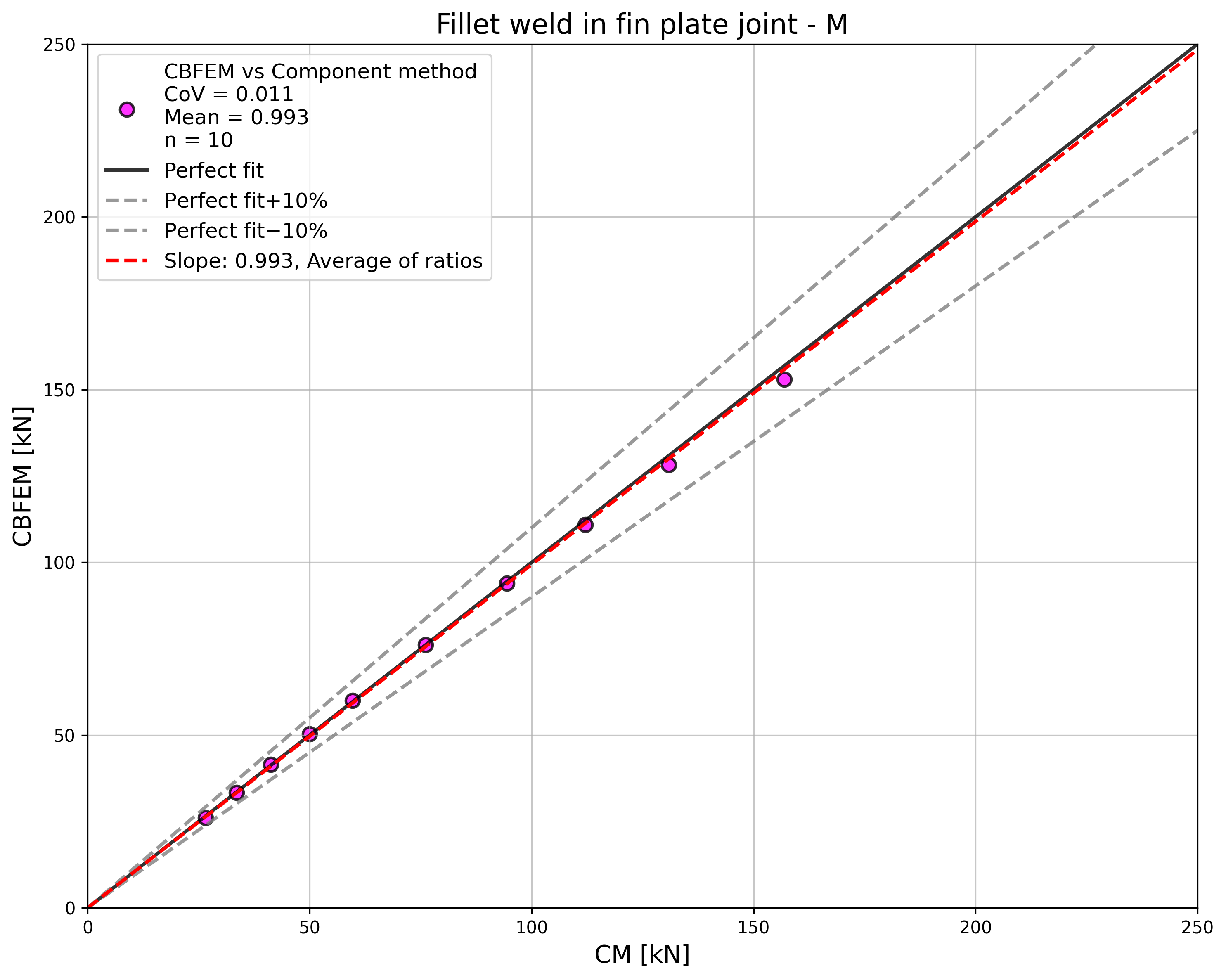

Design resistance calculated by CBFEM is compared with the results of CM. The comparison is presented in Tab. 4.3.2. The study is performed for one parameter: length of the weld, i.e. height of the fin plate, and three load cases: normal and shear force and bending moment. The shear force is applied in a weld plane to neglect the effect of an additional bending. The bending moment is applied at the end of the fin plate. The influence of the weld length on the design resistance of the fin plate joints loaded by the normal and shear force are shown in Fig. 4.3.2. The relation between the weld length and the bending moment resistance of the joint is shown in Fig. 4.3.3.

\[ \textsf{\textit{\footnotesize{Tab. 4.3.2 Comparison of CBFEM and CM}}}\]

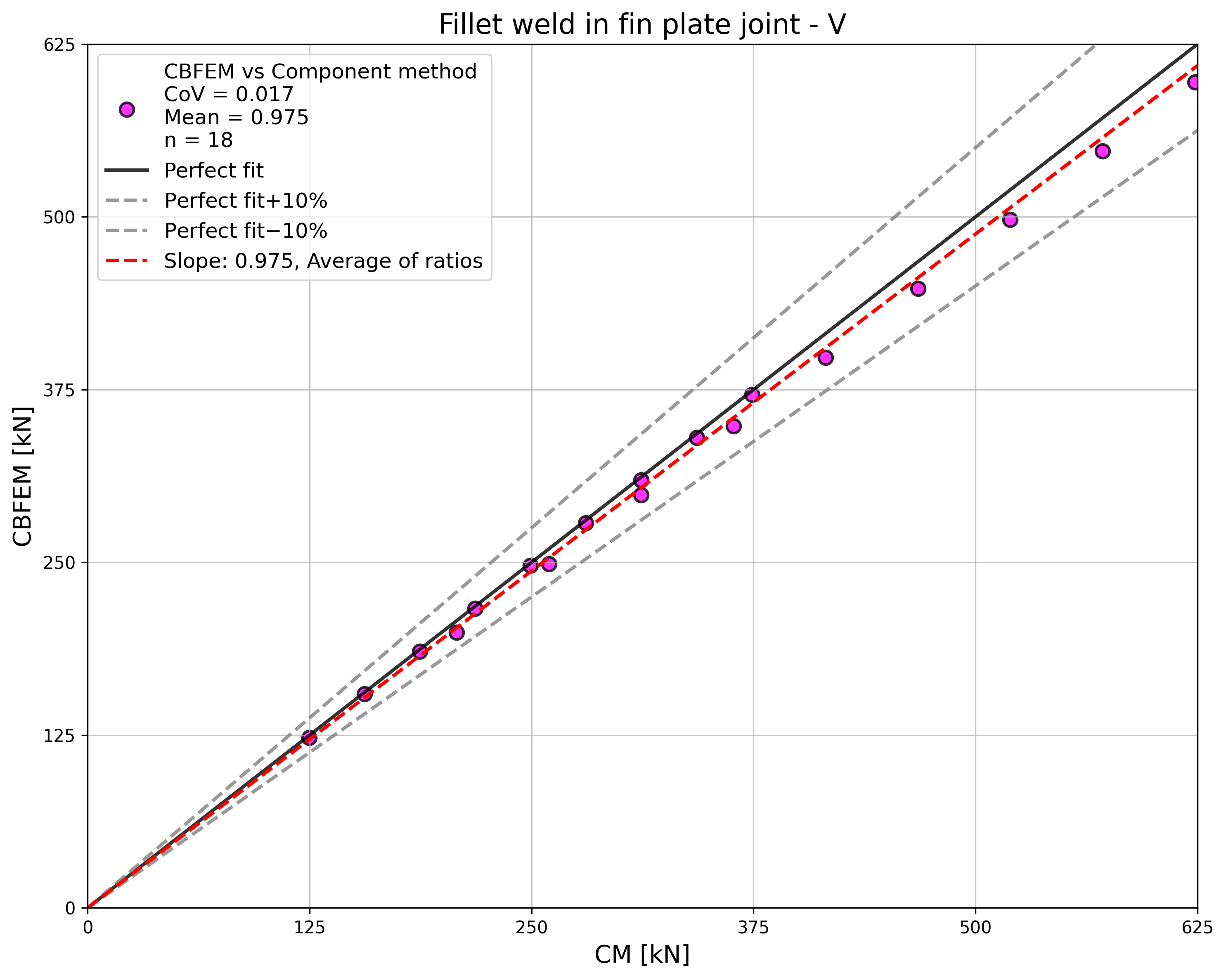

The results of CBFEM and CM are compared, and the sensitivity study is presented. The influence of weld length on the design resistance in a fin plate joint loaded by normal force is shown in Fig. 4.3.2, by shear force in Fig. 4.3.3, and by bending moment in Fig. 4.3.4. The study shows good agreement for all applied load cases.

\[ \textsf{\textit{\footnotesize{Fig. 4.3.2 Parametric study of fin plate joint loaded by normal force}}}\]

\[ \textsf{\textit{\footnotesize{Fig. 4.3.3 Parametric study of fin plate joint loaded by shear force}}}\]

\[ \textsf{\textit{\footnotesize{Fig. 4.3.4 Parametric study of fin plate joint loaded by bending moment}}}\]

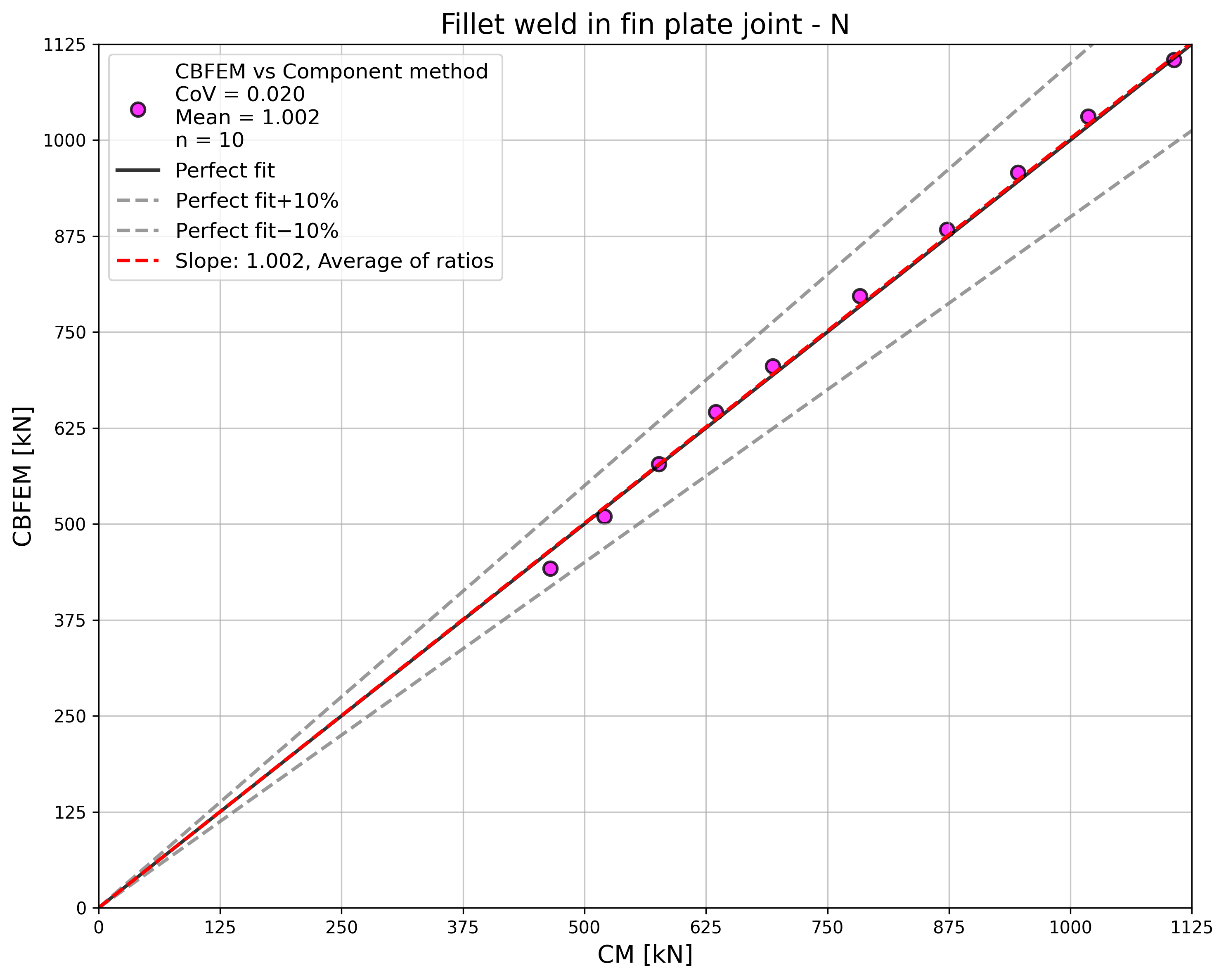

To illustrate the accuracy of the CBFEM model, the results of the parametric studies are summarized in a diagram comparing the design resistances of CBFEM and CM; see Fig. 4.3.5. The results show that the difference between the two calculation methods is in all cases less than 10 %.

\[ \textsf{\textit{\footnotesize{Fig. 4.3.5 Verification of CBFEM to CM}}}\]

Benchmark example

Inputs

Column

- Steel S235

- HEB 400

Fin plate

- Thickness tp = 15 mm

- Height hp = 175 mm

Weld, double fillet weld, see Fig. 4.3.6

- Throat thickness aw = 3 mm

Outputs

- Design resistance in pure bending MRd = 11.4 kNm

\[ \textsf{\textit{\footnotesize{Fig. 4.3.6 Benchmark example for the welded fin plate joint}}}\]

Fillet weld in beam to column joint

Description

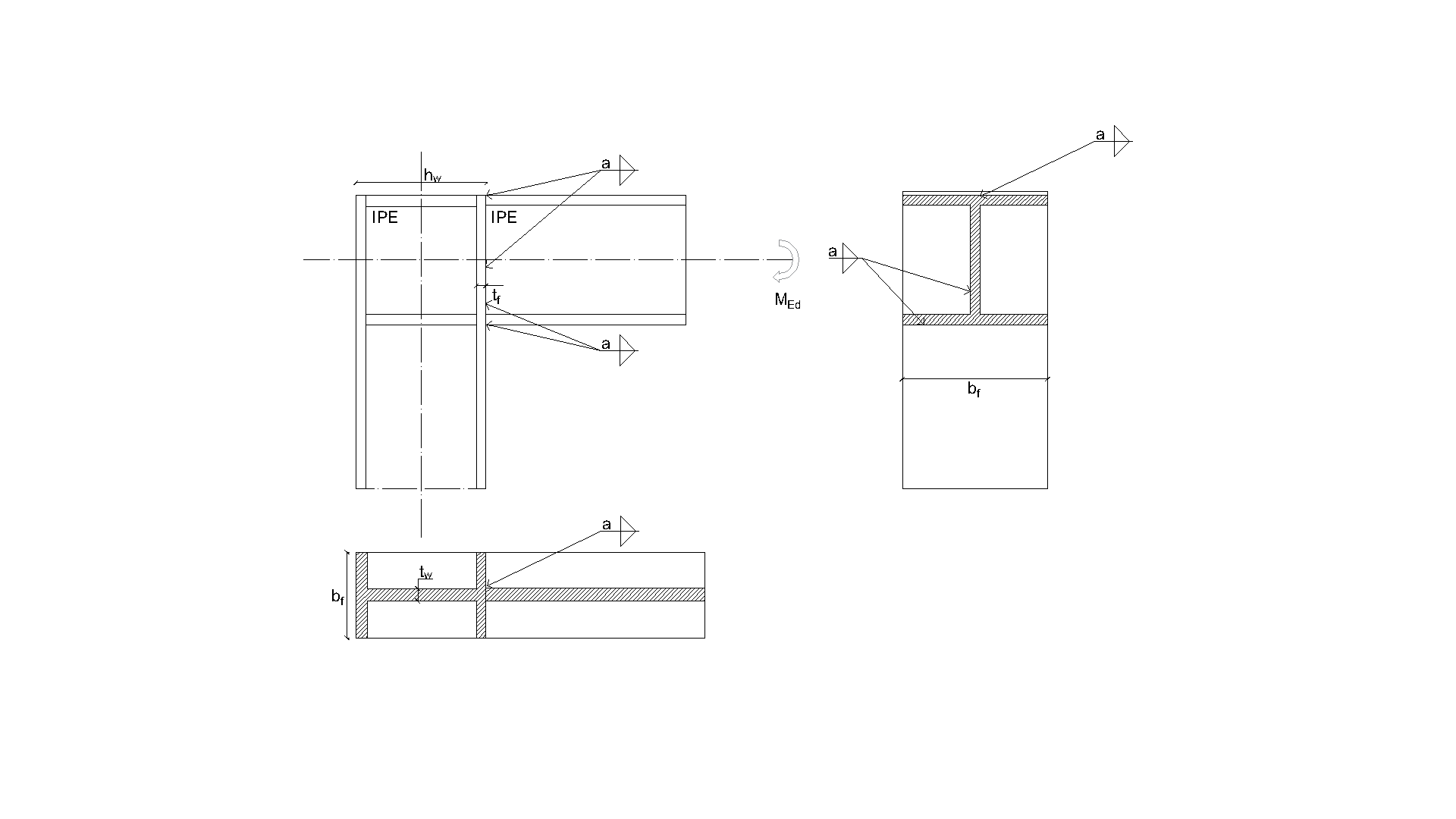

The object of this chapter is verification of component based finite element method (CBFEM) for a fillet weld in a stiffened beam-to-column joint with component method (CM). An open section beam IPE is connected to open section column HEB400. The stiffeners are inside column opposite to beam flanges. The beam section is the changing parameter. Three load cases are considered, i.e. the beam is loaded in tension, shear and bending.

Analytical model

The fillet weld is the only component examined in the study. The welds are designed according to Chapter 4 in EN 1993-1-8:2005 to be the weakest component in the joint. The design resistance of the fillet weld is described in Section 4.1. Overview of the considered examples and the material are given in the Tab. 4.4.1. A geometry of the joint with dimensions is shown in Fig. 4.4.1.

Tab. 4.4.1 Examples overview

Hand Calculation of normal force N

\[\sqrt{ \sigma_{\perp}^2 + 3 \cdot \left( \tau_{\perp}^2 + \tau_{\parallel}^2\right)} \leq \frac{f_u}{\beta_{\mathrm{w}} \cdot \gamma_{\mathrm{M2}}}\]

\[\sigma_{\perp} = \tau_{\perp} = \frac{\sigma_{N}}{\sqrt{2}} = \frac{N}{l \cdot a}\cdot \frac{1}{\sqrt{2}} \]

\[ \tau_{\parallel} = 0\]

\[ \sqrt{ \left( \frac{\sigma_{N}}{\sqrt{2}} \right)^2 + 3 \cdot \left( \frac{\sigma_{N}}{\sqrt{2}} \right)^2} \leq \frac{f_u}{\beta_{\mathrm{w}} \cdot \gamma_{\mathrm{M2}}}\]

\[ \sqrt{ \left( \frac{N}{l \cdot a}\cdot \frac{1}{\sqrt{2}} \right)^2 + 3 \cdot \left( \frac{N}{l \cdot a}\cdot \frac{1}{\sqrt{2}} \right)^2} \leq \frac{f_u}{\beta_{\mathrm{w}} \cdot \gamma_{\mathrm{M2}}}\]

\[ N \leq \frac{f_{u} \cdot l \cdot a }{\beta_{\mathrm{w}} \cdot \gamma_{\mathrm{M2}} \cdot \sqrt{2}} \]

Where:

\(a\) - weld throat thickness

\(N\) - normal force acting on beam

\(l\) - total welds length

\(\beta_{\mathrm{w}}\) - correlation factor taken from EN 1993-1-8 Table 4.1

\(f_u\) - nominal ultimate tensile strength of the weaker part joined

\(\gamma_{\mathrm{M2}}\) - partial safety factor for welds

Hand Calculation of shear force V

The manual calculation presented in this chapter is predicated on certain assumptions. The shear force \(V\) is transmitted exclusively by the weld at the web. The bending moment resulting from the eccentricity of the force acting on the welds can be attributed to the flange welds. The weld section modulus of flange welds \(W\) is determined not by the distance measured from the centre of gravity of the welds, but from the edges of the flange to the beam centre of gravity, as calculated in practice.

The following equations demonstrate the derivation of the weld load-bearing capacity for shear force and bending moment according to the CM. The equivalent stress is specified in EN 1993-1-8, Equation (4.1). For the calculation of bending moment resistance, the plastic section modulus was assumed.

\[\sqrt{ \sigma_{\perp} + 3 \cdot \left( \tau_{\perp}^2 + \tau_{\parallel}^2\right)} \leq \frac{f_u}{\beta_{\mathrm{w}} \cdot \gamma_{\mathrm{M2}}}\]

\[V \le \min \left \{ \frac{f_\mathrm{u} \cdot l_V \cdot a}{\sqrt{3} \cdot \beta_{\mathrm{w}} \cdot \gamma_{M2}} , \, \frac{f_\mathrm{u} \cdot W}{\sqrt{2} \cdot \beta_{\mathrm{w}} \cdot \gamma_{\mathrm{M2}} \cdot e} \right \} \]

Where:

\(e\) - force eccentricity relative to the beam welds

\(a\) - weld throat thickness

\(V\) - shear force acting on beam

\(W= W_\mathrm{pl,flange}\) - welds section modulus

\(A_\mathrm{w,top,f} = B \cdot a\) - top flange edge weld area

\(A_\mathrm{w,bottom,f} = (B-t_\mathrm{w}) \cdot a\) - bottom flange edge weld area

\(z_\mathrm{w,top,f} = H / 2 \) - top flange edge weld lever arm

\(z_\mathrm{w,bottom,f} = (H - t_\mathrm{f}) / 2 \) - bottom flange edge weld lever arm

\(W_\mathrm{pl,flange} = 2 \cdot \left(A_\mathrm{w,top,f} \cdot z_\mathrm{w,top,f} + A_\mathrm{w,bottom,f} \cdot z_\mathrm{w,bottom,f}\right)\) - plastic flange section modulus

\(l_{\mathrm{V}}\) - total web welds length

\(\beta_{\mathrm{w}}\) - correlation factor taken from EN 1993-1-8 Table 4.1

\(f_\mathrm{u}\) - nominal ultimate tensile strength of the weaker part joined

\(\gamma_{\mathrm{M2}}\) - partial safety factor for welds

\(H\) - IPE beam height

\(B\) - IPE beam width

\(t_\mathrm{w}\) - IPE beam web thickness

\(t_\mathrm{f}\) - IPE beam flange thickness

Hand Calculation of bending moment M

In the calculation of bending moment without any interaction with shear force, the plastic section modulus of the whole weld section (both around flanges and around web) was assumed.

\[\sqrt{ \sigma_{\perp}^2 + 3 \cdot \left( \tau_{\perp}^2 + \tau_{\parallel}^2\right)} \leq \frac{f_u}{\beta_{\mathrm{w}} \cdot \gamma_{\mathrm{M2}}}\]

\[\sigma_{\perp} = \tau_{\perp} = \frac{\sigma_{N}}{\sqrt{2}} = \frac{M}{W}\cdot \frac{1}{\sqrt{2}} \]

\[ \tau_{\parallel} = 0\]

\[ \sqrt{ \left( \frac{\sigma_{N}}{\sqrt{2}} \right)^2 + 3 \cdot \left( \frac{\sigma_{N}}{\sqrt{2}} \right)^2} \leq \frac{f_u}{\beta_{\mathrm{w}} \cdot \gamma_{\mathrm{M2}}}\]

\[ \sqrt{ \left( \frac{M}{W}\cdot \frac{1}{\sqrt{2}} \right)^2 + 3 \cdot \left( \frac{M}{W}\cdot \frac{1}{\sqrt{2}} \right)^2} \leq \frac{f_u}{\beta_{\mathrm{w}} \cdot \gamma_{\mathrm{M2}}}\]

\[ M \leq \frac{f_{u} \cdot W }{\beta_{\mathrm{w}} \cdot \gamma_{\mathrm{M2}} \cdot \sqrt{2}} \]

\[ \sigma_{\perp} \leq \frac{f_{u} \cdot 0.9}{ \gamma_{\mathrm{M2}}} \]

\[ M \leq \frac{f_{u} \cdot W \cdot 0.9 \cdot \sqrt{2}}{ \gamma_{\mathrm{M2}} } \]

Where:

\(a\) - weld throat thickness

\(W \) - weld plastic section module

\(M\) - the bending moment acting on the beam

\(\beta_{\mathrm{w}}\) - correlation factor taken from EN 1993-1-8 Table 4.1

\(f_u\) - nominal ultimate tensile strength of the weaker part joined

\(\gamma_{\mathrm{M2}}\) - partial safety factor for welds

Numerical model

The weld component in CBFEM is described in General theoretical background and EN theoretical background.

Nonlinear elastic-plastic material is used for welds in this study. The limit plastic strain is reached in longer part of the weld and stress peaks are redistributed.

\[ \textsf{\textit{\footnotesize{Fig. 4.4.1 Joint’s geometry with dimensions}}}\]

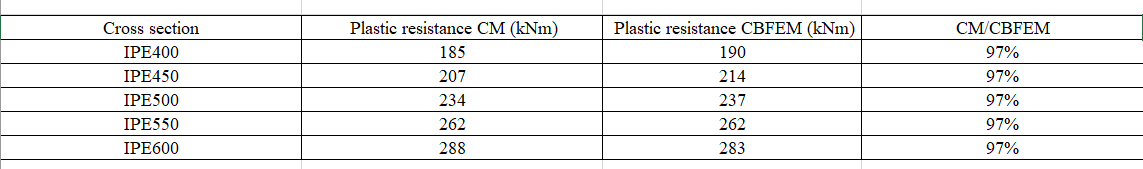

Verification of resistance

Design resistance calculated by CBFEM Idea RS software is compared with the results of CM. The weld’s design resistances are compared, see Tab. 4.4.2. The study is performed for one parameter beam section and three load cases: normal force NEd, shear force VEd, and bending moment MEd.

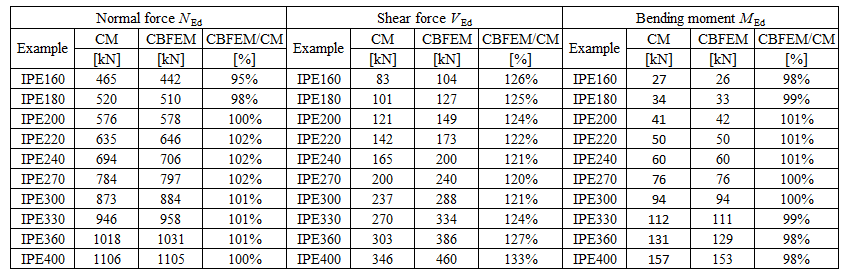

Tab. 4.4.2 Comparison of CBFEM and CM

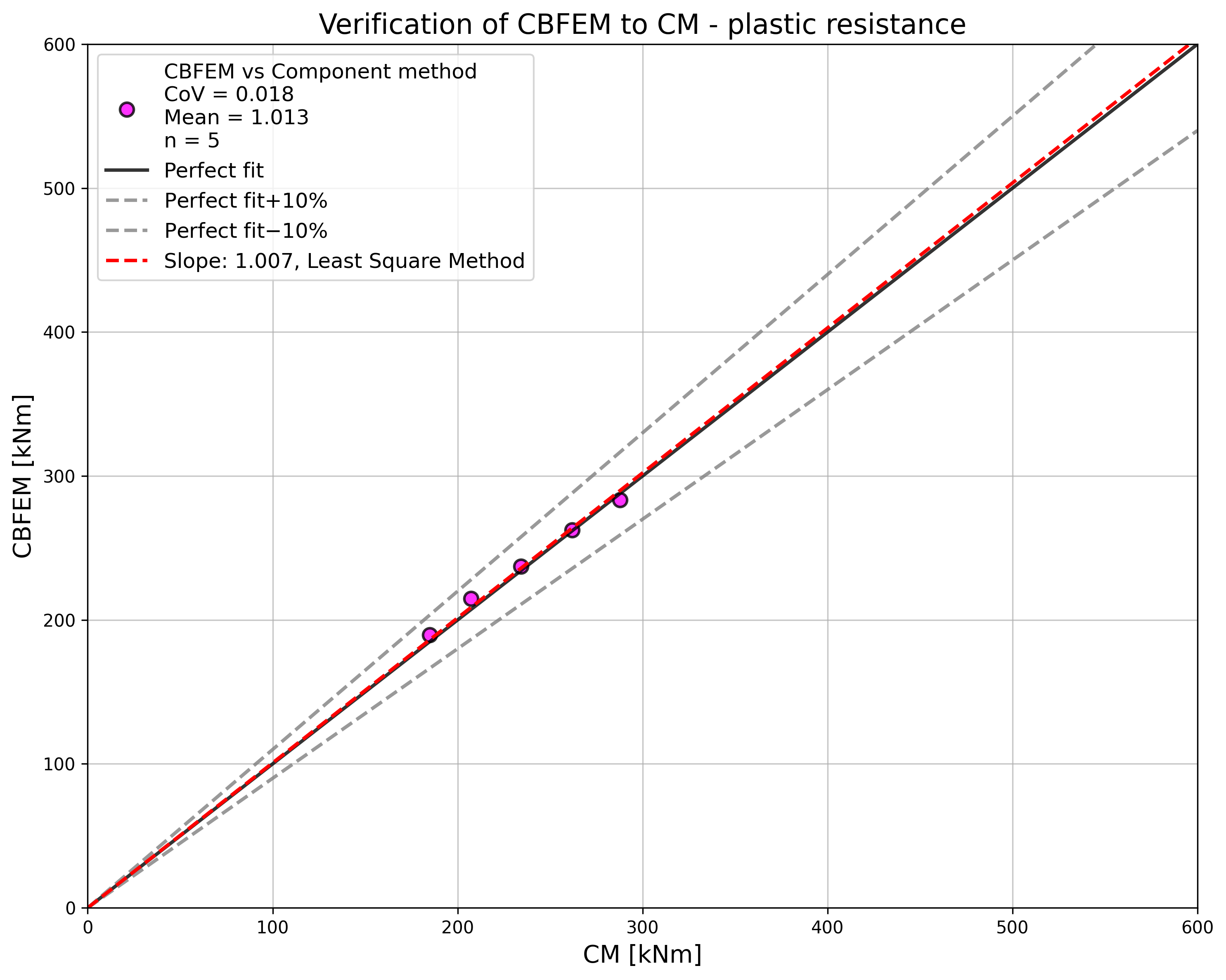

Results of CBFEM and CM are compared and a sensitivity study is presented. The influence of beam cross-section on the design resistance a welded beam-to-column joint loaded in tension is shown in Fig. 4.4.2, in shear in Fig. 4.4.3 and in bending in Fig. 4.4.4. The study shows good agreement for all applied load cases.

\[ \textsf{\textit{\footnotesize{Fig. 4.4.2}}}\]

\[ \textsf{\textit{\footnotesize{Fig. 4.4.3}}}\]

\[ \textsf{\textit{\footnotesize{Fig. 4.4.4}}}\]

To illustrate the accuracy of the CBFEM model, results of the sensitivity study is summarized in a diagram comparing CBFEM’s and CM’s design resistances, see Fig. 4.4.5. The results show that the difference of the two calculation methods is in all cases less than 10%.

\[ \textsf{\textit{\footnotesize{Fig. 4.4.5 Verification of CBFEM to CM}}}\]

Benchmark example

Inputs

Column

- Steel S235

- HEB 400

Beam

- Steel S235

- IPE 160

- Force eccentricity to weld x = 400 mm, see Fig. 4.4.6

Weld

- Throat thickness aw = 3 mm

Outputs:

- Design resistance in shear VRd = 105 kN

\[ \textsf{\textit{\footnotesize{Fig. 4.4.6 Benchmark example of the welded beam to column joint with force eccentricity}}}\]

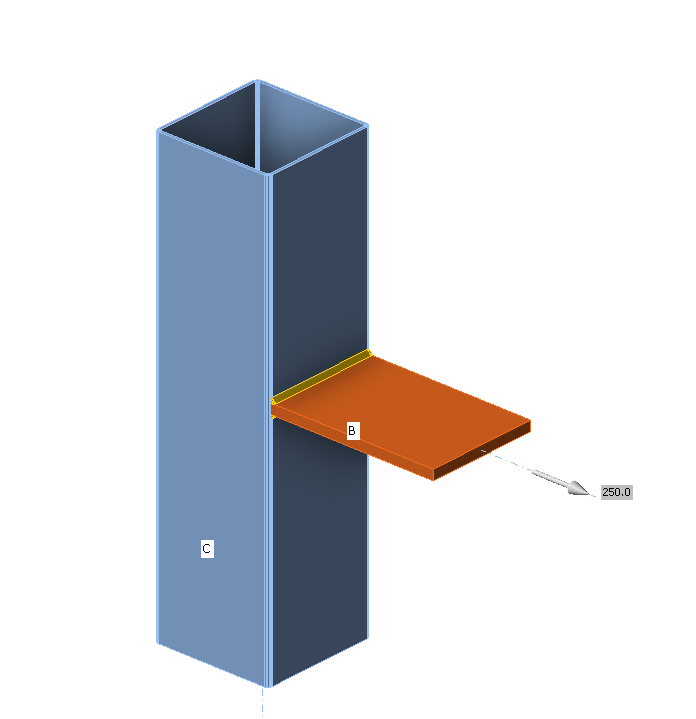

Connection to unstiffened flanges

Description

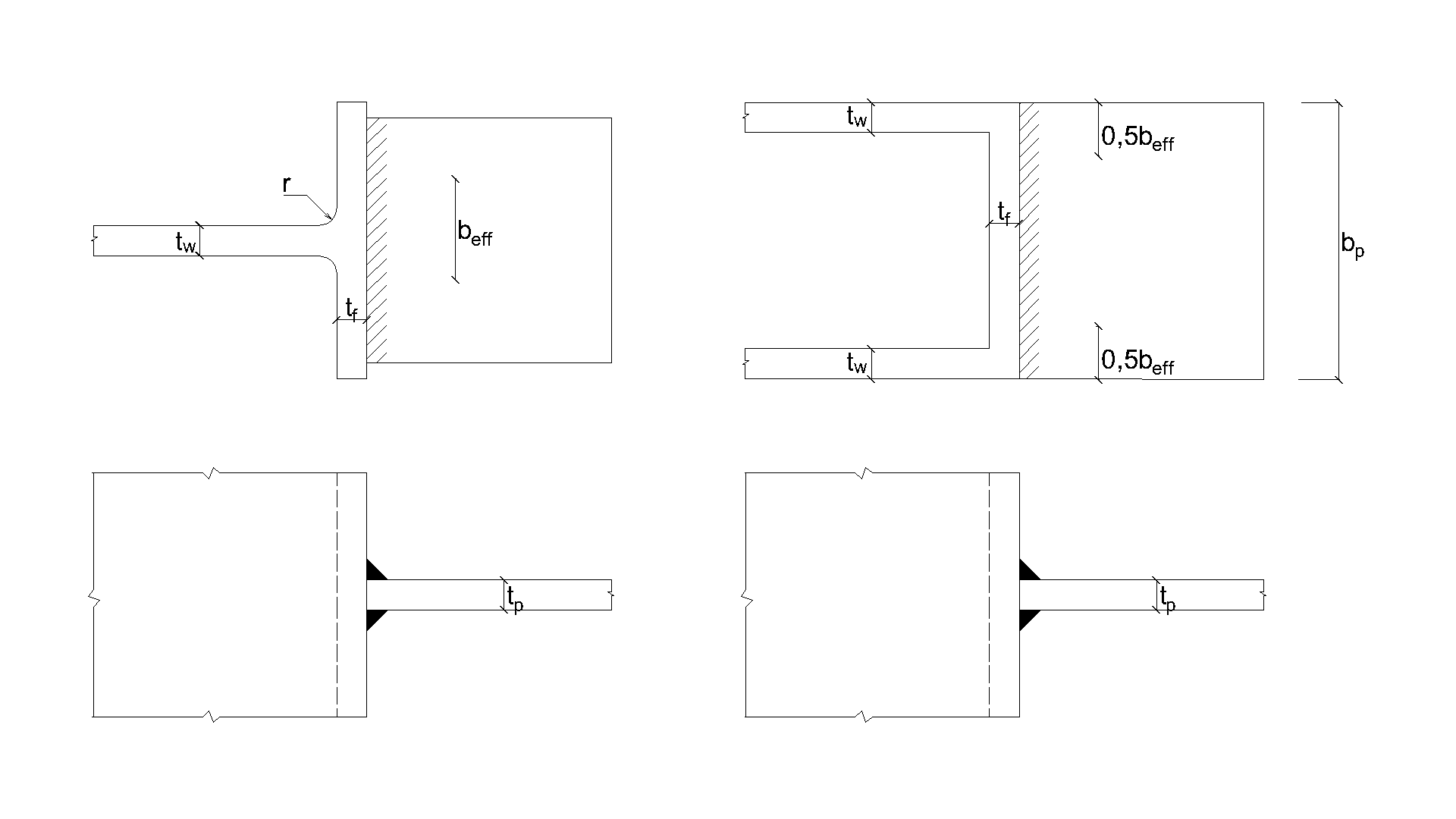

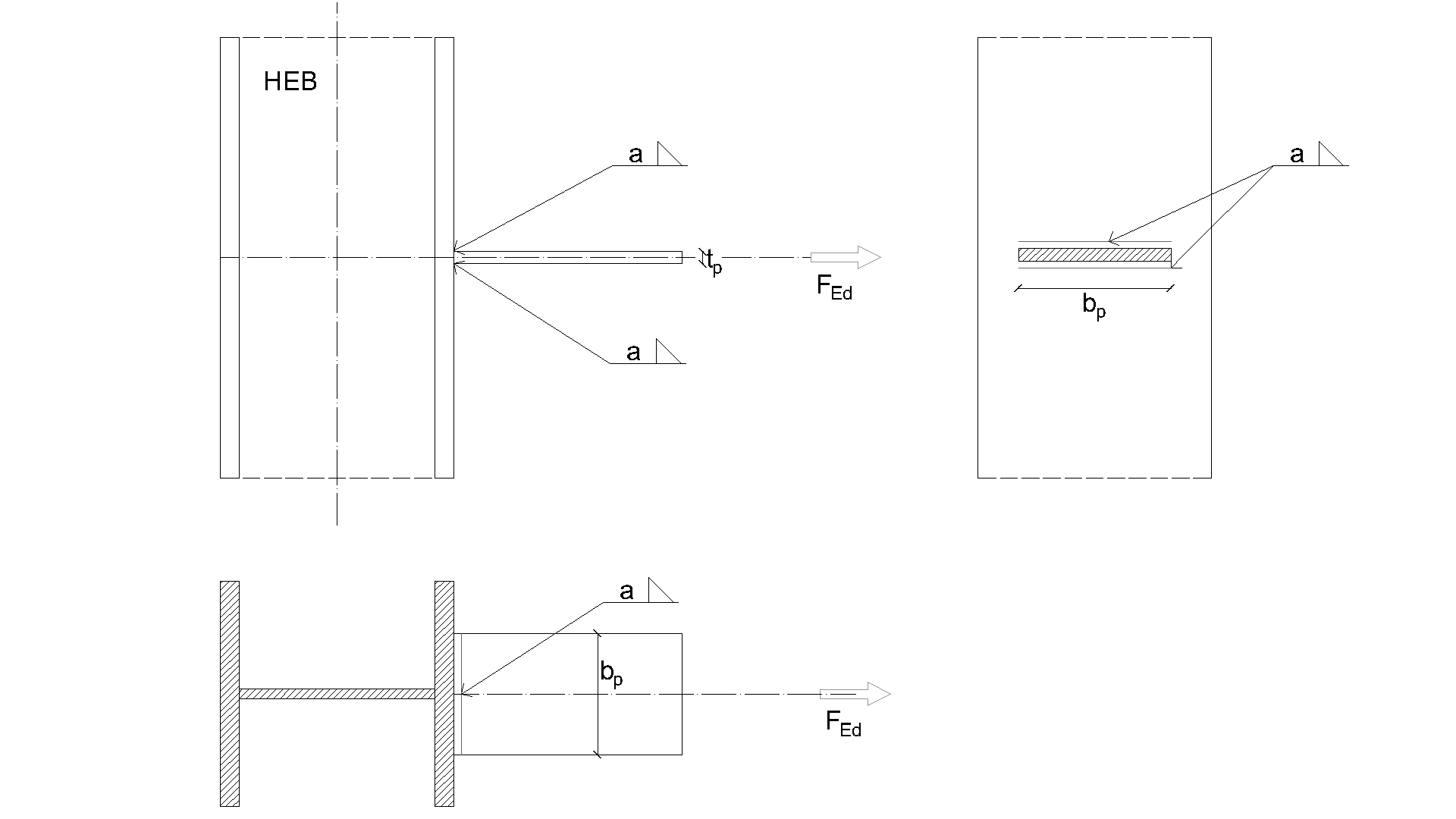

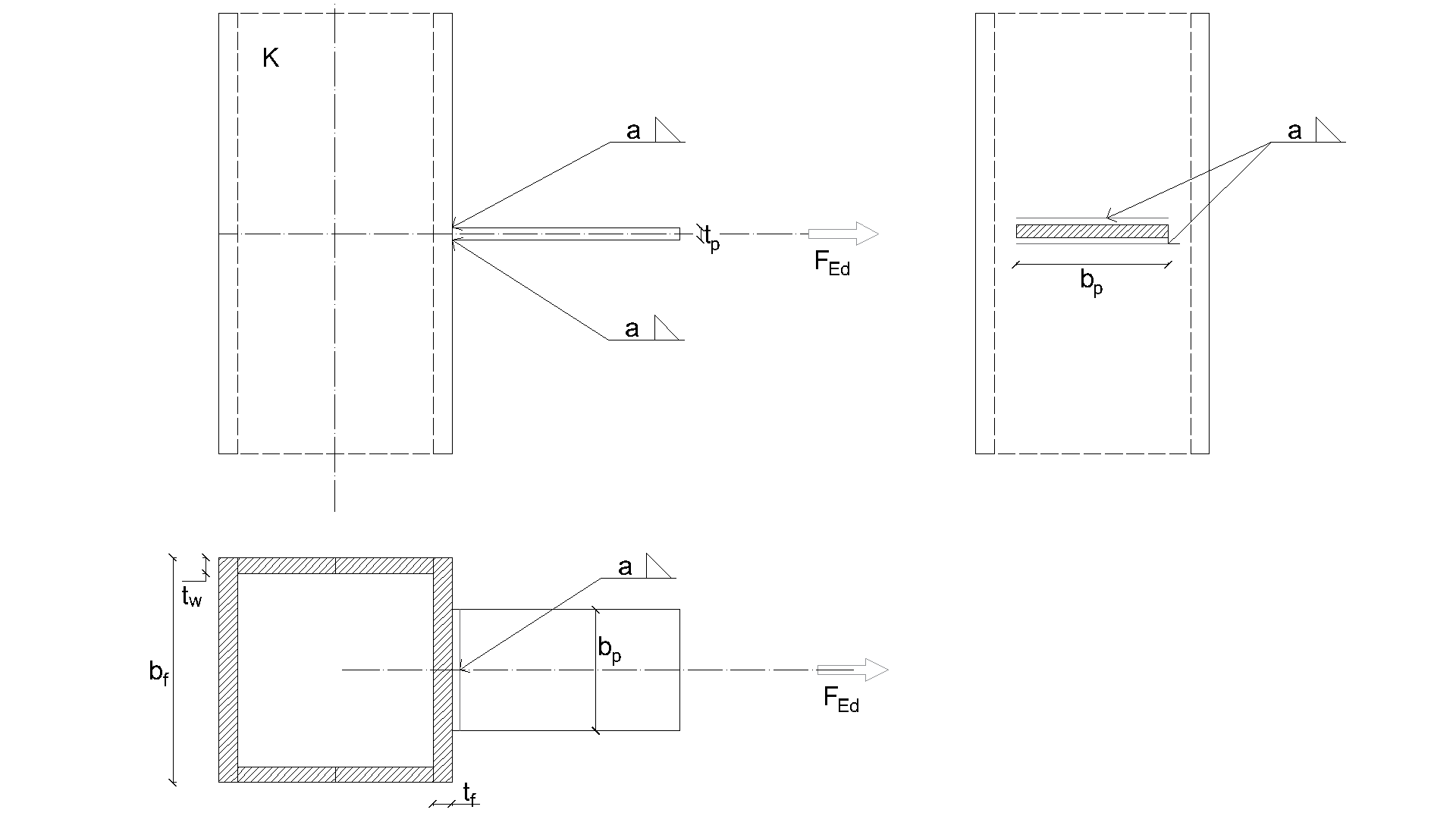

In this chapter, component-based finite element method (CBFEM) of a fillet weld connecting a plate to an unstiffened column is verified on component method (CM). The steel plate is connected to the open and box section columns and loaded in tension.

Analytical model

The fillet weld is the only component examined in the study. The welds are designed according to Chapter 4 in EN 1993-1-8:2005 to be the weakest component in the joint. The design resistance of the fillet weld is described in Section 4.1. The force applied perpendicular to a flexible plate, which is welded to an unstiffened section, is limited. The stresses are concentrated in an effective width while the weld resistance around the unstiffened parts is neglected, as shown in Fig. 4.5.1. For an unstiffened I or H section the effective width is obtained according to:

\[ b_\mathrm{eff} = t_\mathrm{w} + 2s + 7kt_\mathrm{f} \qquad (4.5.1)\]

\[ k = \frac{t_\mathrm{f} \cdot f_\mathrm{y,f} }{ t_\mathrm{p} \cdot f_\mathrm{y,p}} \qquad (4.5.2)\]

The dimension s is for a rolled section \(s =r\) and for a welded section \(s = \sqrt{2} \cdot a \) . For a box or channel section, the effective width should be obtained from:

\[ b_\mathrm{eff} = 2t_\mathrm{w} + 5 t_\mathrm{f} \quad \textrm{but}\quad b_\mathrm{eff} \leq 2t_\mathrm{w} + 5 kt_\mathrm{f}\qquad (4.5.1)\]

\[\sqrt{ \sigma_{\perp}^2 + 3 \cdot \left( \tau_{\perp}^2 + \tau_{\parallel}^2\right)} \leq \frac{f_u}{\beta_{\mathrm{w}} \cdot \gamma_{\mathrm{M2}}}\]

\[\sigma_{\perp} = \tau_{\perp} = \frac{\sigma_{N}}{\sqrt{2}} = \frac{N}{b_\mathrm{eff} \cdot a}\cdot \frac{1}{\sqrt{2}} \]

\[ \tau_{\parallel} = 0\]

\[ \sqrt{ \left( \frac{\sigma_{N}}{\sqrt{2}} \right)^2 + 3 \cdot \left( \frac{\sigma_{N}}{\sqrt{2}} \right)^2} \leq \frac{f_u}{\beta_{\mathrm{w}} \cdot \gamma_{\mathrm{M2}}}\]

\[ \sqrt{ \left( \frac{N}{b_\mathrm{eff} \cdot a}\cdot \frac{1}{\sqrt{2}} \right)^2 + 3 \cdot \left( \frac{N}{b_\mathrm{eff}\cdot a}\cdot \frac{1}{\sqrt{2}} \right)^2} \leq \frac{f_u}{\beta_{\mathrm{w}} \cdot \gamma_{\mathrm{M2}}}\]

\[ N \leq \frac{f_{u} \cdot b_\mathrm{eff} \cdot a }{\beta_{\mathrm{w}} \cdot \gamma_{\mathrm{M2}} \cdot \sqrt{2}} \]

Where:

\(a\) - weld throat thickness

\(N\) - normal force acting on beam

\(b_\mathrm{eff}\) - total effective welds length

\(\beta_{\mathrm{w}}\) - correlation factor taken from EN 1993-1-8 Table 4.1

\(f_u\) - nominal ultimate tensile strength of the weaker part joined

\(\gamma_{\mathrm{M2}}\) - partial safety factor for welds

\[ \textsf{\textit{\footnotesize{Fig. 4.5.1 Effective width of an unstiffened joint (Fig. 4.8 in EN 1993-1-8:2005)}}}\]

Numerical model

The weld component in CBFEM is described in General theoretical background and EN theoretical background. The plastic branch is reached in a part of the weld, and stress peaks are redistributed along the weld length.

Verification of resistance

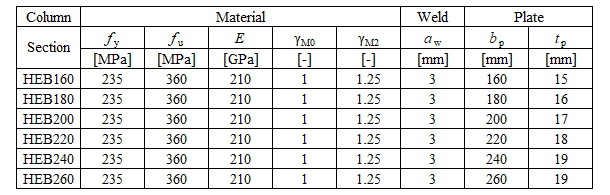

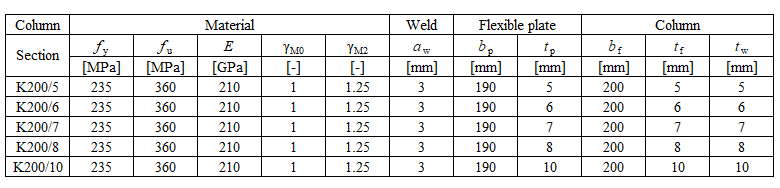

Design resistance calculated by CBFEM is compared with the results of CM. The weld design resistance is compared only. Overview of considered examples and material is given in Tab. 4.5.1. Geometry of joints with dimensions is shown in Fig. 4.5.2.

\[ \textsf{\textit{\footnotesize{Tab. 4.5.1 Examples overview}}}\]

\[ \textsf{\textit{\footnotesize{a) Flexible plate to open section b) Flexible plate to box section}}}\]

\[ \textsf{\textit{\footnotesize{Fig. 4.5.2 Joint geometry and dimentions}}}\]

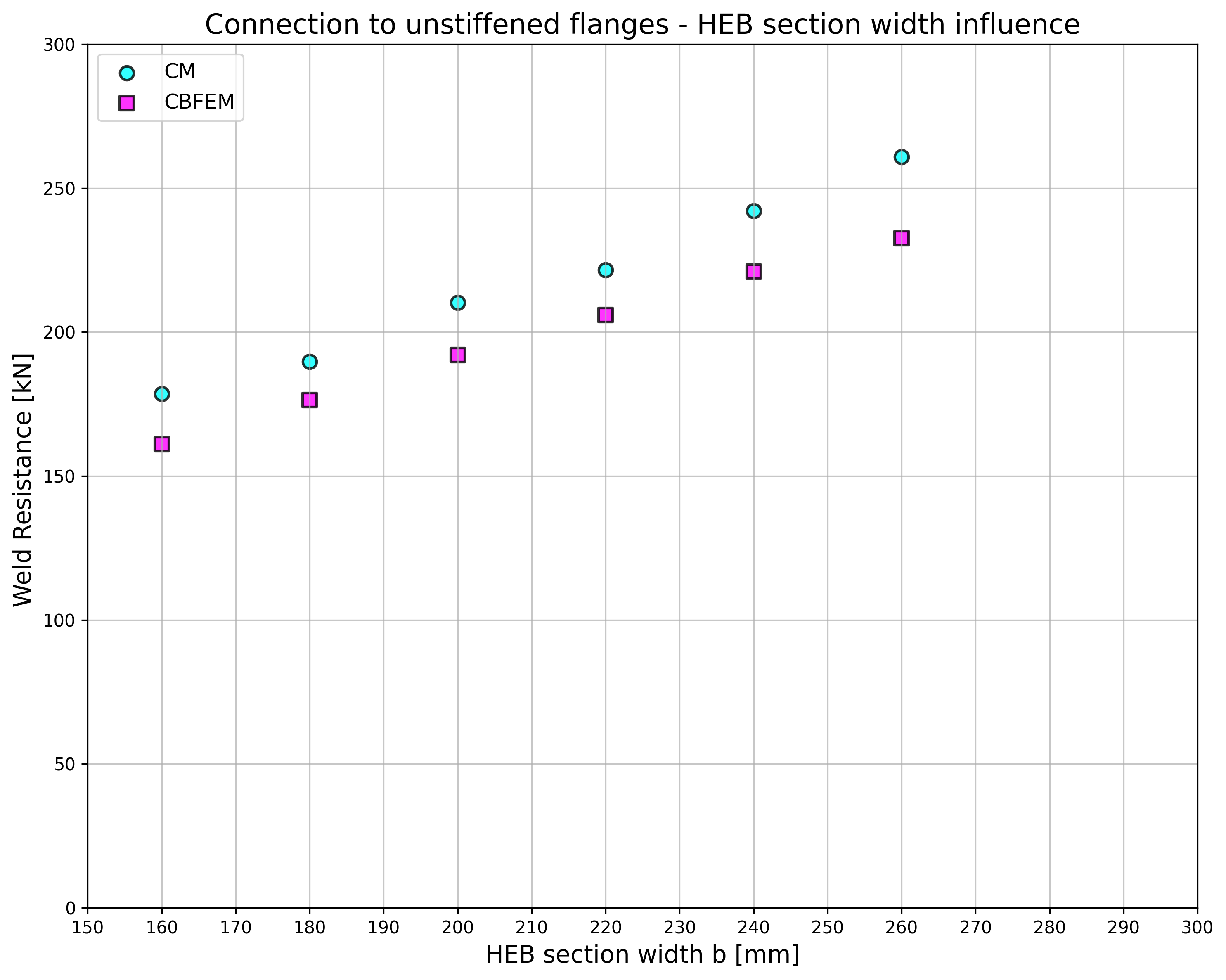

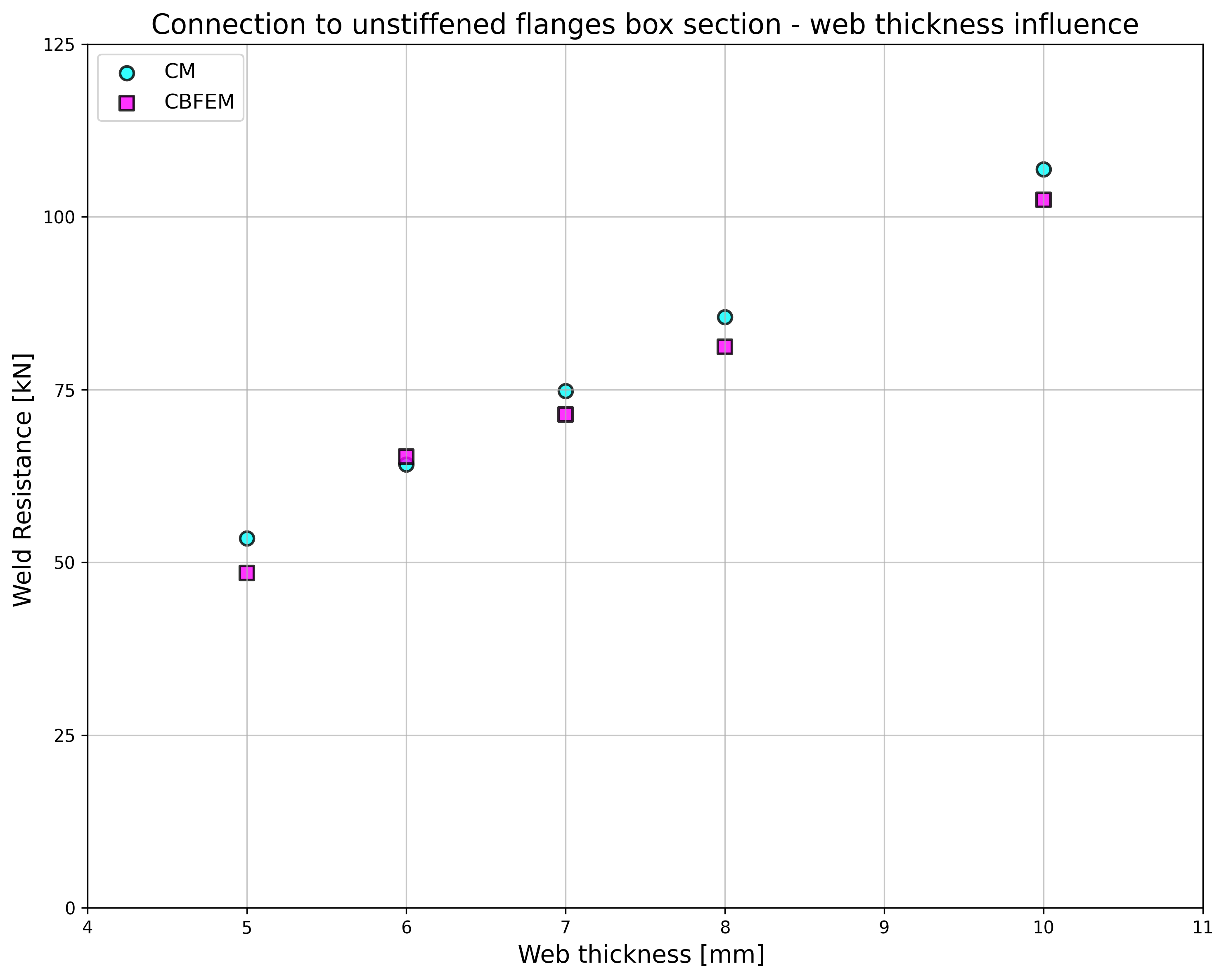

The results are presented in Tab. 4.5.2. The study is performed for two parameters: flange width of the HEB section and web thickness of the box section. The flexible plate is loaded in tension. The influence of the flange width of HEB section on design resistance of a joint is shown in Fig. 4.5.3. The relation between the web thickness of box section on design resistance of a joint is shown in Fig. 4.5.4.

\[ \textsf{\textit{\footnotesize{Tab. 4.5.2 Comparison of CBFEM and CM}}}\]

Results of CBFEM and CM are compared in a sensitivity study. The influence of the flange width of HEB section on design resistance of a joint is studied in Fig. 4.5.3. The influence of the web thickness of box section on design resistance of a joint is presented in Fig. 4.5.4. The parametric studies show very good agreement of the results for all weld configurations.

\[ \textsf{\textit{\footnotesize{Fig. 4.5.3 Flange width of the HEB section Fig. 4.5.4 Web thickness of the box section}}}\]

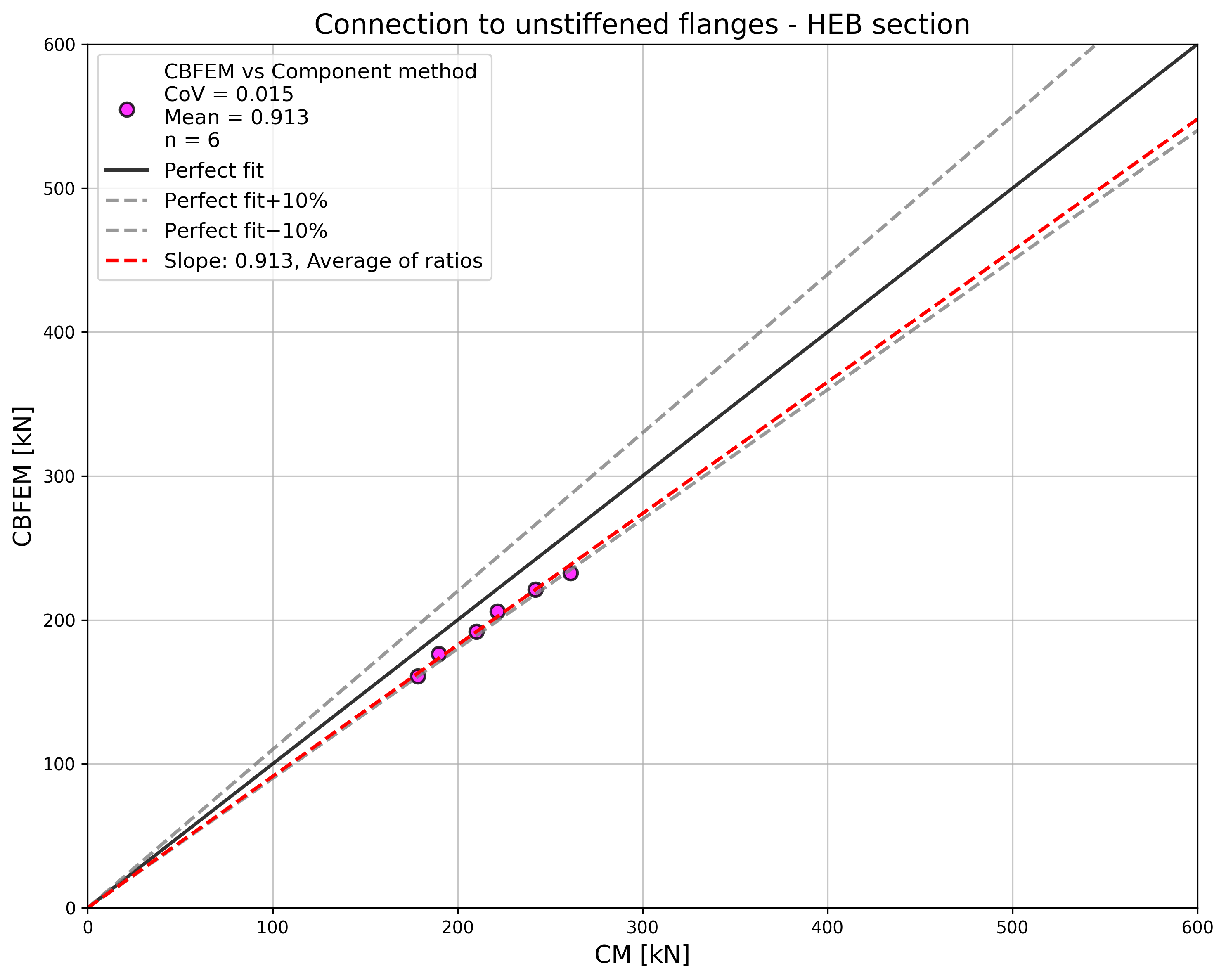

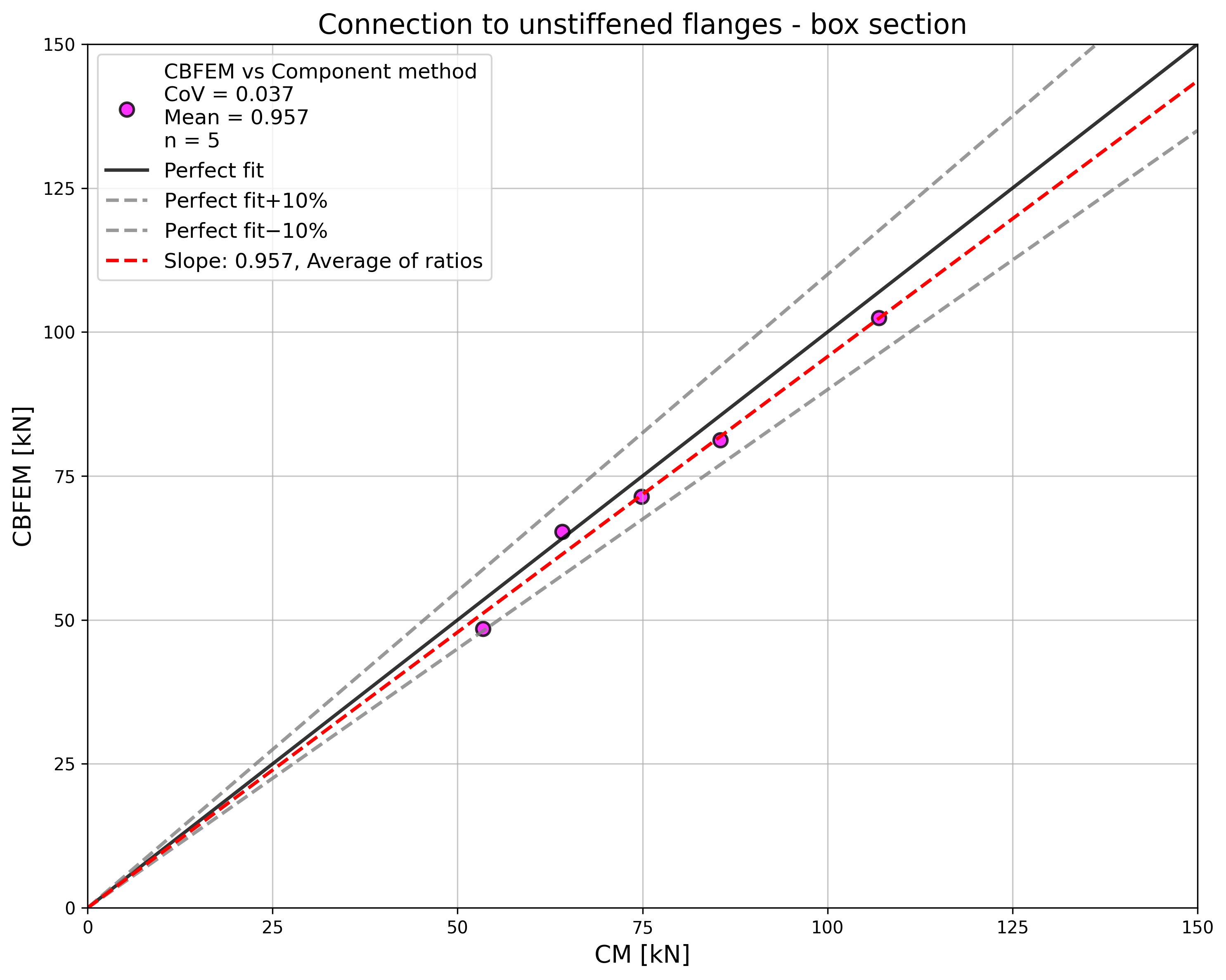

The results of the sensitivity study are summarized in a diagram comparing design resistances of CBFEM and CM; see Fig. 4.5.5 illustrating the accuracy of the CBFEM model.

\[ \textsf{\textit{\footnotesize{Fig. 4.5.5 Verification of CBFEM to CM}}}\]

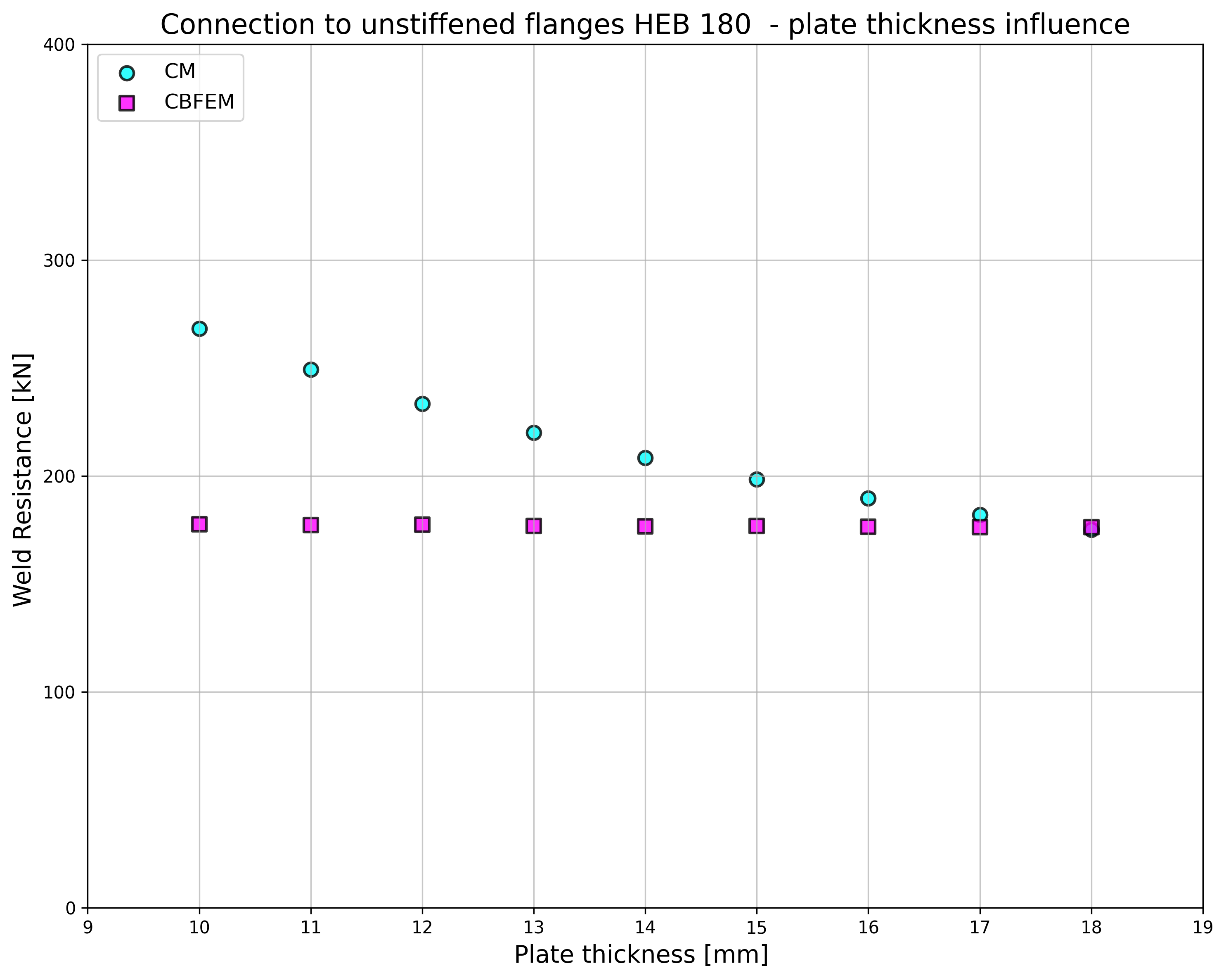

The influence of the plate thickness on the design resistance of the weld is shown in Fig. 4.5.6. The column cross-section is HEB 180 with a flange thickness of 14 mm. A weld connecting a plate thicker than the column flange has the same resistance for CM and CBFEM. On the other hand, the weld connecting the plate to column flange of the same or smaller thickness has in numerical models design resistance smaller by 20%. The plate thickness is not taken into account in numerical models with shell elements, which causes the difference.

\[ \textsf{\textit{\footnotesize{Fig. 4.5.6 Influence of plate thickness on the resistance of joint with unstiffened column HEB180}}}\]

Benchmark example

Inputs

Column

• Steel S235

• RHS 200/200/5

Flexible plate

• Steel S235

• Thickness tp = 17 mm

• Width bp = 190 mm

Weld, double fillet welds see Fig. 4.5.7

• Throat thickness aw = 5 mm

Outputs

• Design resistance in tension NRd = 68 kN

\[ \textsf{\textit{\footnotesize{Fig. 4.5.7 Benchmark example for the welded connection of plate to unstiffened column}}}\]

Bolted connections

Bolted connection - T-stub in tension

Description

The objective of this chapter is verification of component-based finite element method (CBFEM) of T-stubs connected with two bolts loaded in tension with component method (CM) and research FEM model (RM) created in Midas FEA software; see (Gödrich et al. 2019).

Analytical model

Welded T-stub and bolt in tension are components examined in the study. Both components are designed according to EN 1993-1-8:2005. The welds are designed not to be the weakest component. Effective lengths for circular and noncircular failures are considered according to EN 1993-1-8:2005 cl. 6.2.6. Only tension loads are considered. Three modes of collapse according to EN 1993-1-8:2005 cl. 6.2.4.1 are considered: 1. mode with full yielding of the flange, 2. mode with two yield lines by web and rupture of the bolts, and 3. mode for rupture of the bolts; see Fig. 5.1.1. Bolts are designed according to cl. 3.6.1 in EN 1993-1-8:2005. Design resistance considers punching shear resistance and rupture of the bolt.

\[ \textsf{\textit{\footnotesize{Fig. 5.1.1 Collapse modes of T-stub}}}\]

Design numerical model

T-stub is modeled by 4-nodes shell elements as described in Chapter 3 and summarised further. Every node has 6 degrees of freedom. Deformations of the element consist of membrane and flexural contributions. Nonlinear elastic-plastic material status is investigated in each layer of integration point. Assessment is based on the maximum strain given according to EN 1993‑1‑5:2006 by value of 5 %. Bolts are divided into three sub-components. The first is the bolt shank, which is modeled as a nonlinear spring and caries tension only. The second sub-component transmits tensile force into the flanges. The third sub-component solves shear transmission.

Research numerical model

In cases where the CBFEM gives higher resistance, initial stiffness, or deformation capacity, research FEM model (RM) from brick elements validated on experiments (Gödrich et al. 2013) is used to verify the CBFEM model. RM is created in Midas FEA software of hexahedral and octahedral solid elements, see Fig. 5.1.2 Mesh sensitivity study was provided to reach proper results in adequate time. Numerical model of the bolts is based on the model by (Wu et al. 2012). The nominal diameter is considered in the shank, and the effective core diameter is considered in the threaded part. Washers are coupled with the head and nut. Deformation caused by stripping of the threads in thread–nut contact area is modeled using interface elements. Interface elements are unable to transfer tensile stresses. Contact elements allowing the transmission of pressure and friction are used between washers and flanges of the T-stub. One-quarter of the sample was modeled using the symmetry.

\[ \textsf{\textit{\footnotesize{Fig. 5.1.2 Research FEM model}}}\]

\[ \textsf{\textit{\footnotesize{Fig. 5.1.3 Geometry of the T-stubs}}}\]

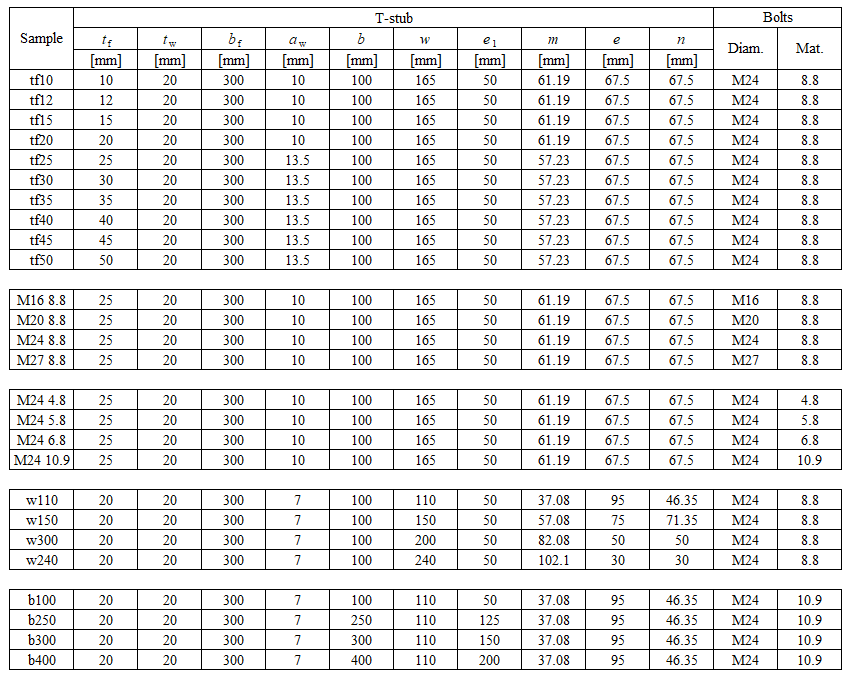

Range of validity

CBFEM was verified for the selected typical T-stub geometries. The minimal thickness of the flange is 8 mm. Maximal distance of the bolts to bolt diameter is limited by p/db ≤ 20. The distance of the bolt line to the web is limited to m/db ≤ 5. Overview of the considered samples with steel plates of S235: fy = 235 MPa, fu = 360 MPa, E = Ebolt = 210 GPa is shown in the Tab. 5.1.1 and in Fig. 5.1.3.

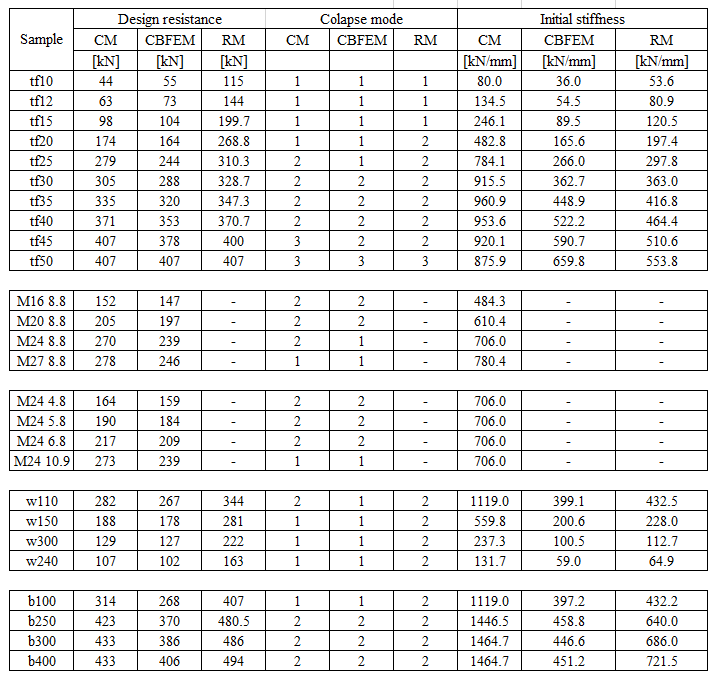

Tab. 5.1.1 Overview of the considered samples of T stubs

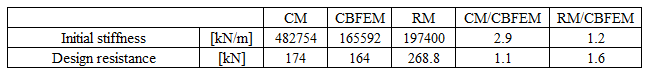

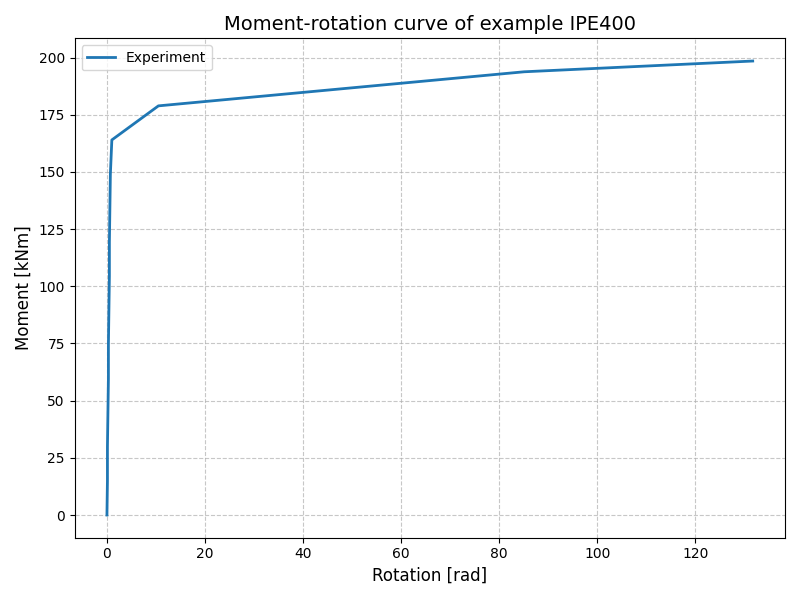

Global behavior

Comparison of the global behavior of the T-stub described by force–deformation diagrams for all design procedures was prepared. Attention was focused on the main characteristics: initial stiffness, design resistance, and deformation capacity. Sample tf20 was chosen to present as a reference; see Fig. 5.1.4 and Tab. 5.1.2. CM generally gives higher initial stiffness compared to CBFEM and RM. In all cases, RM gives the highest design resistance, as shown in chapter 6. Deformation capacity is also compared. Deformation capacity of T-stub was calculated according to (Beg et al. 2004). RM does not consider cracking of the material, so the prediction of deformation capacity is limited.

\[ \textsf{\textit{\footnotesize{Fig. 5.1.4 Force–deformation diagram}}}\]

Tab. 5.1.2 Global behavior overview

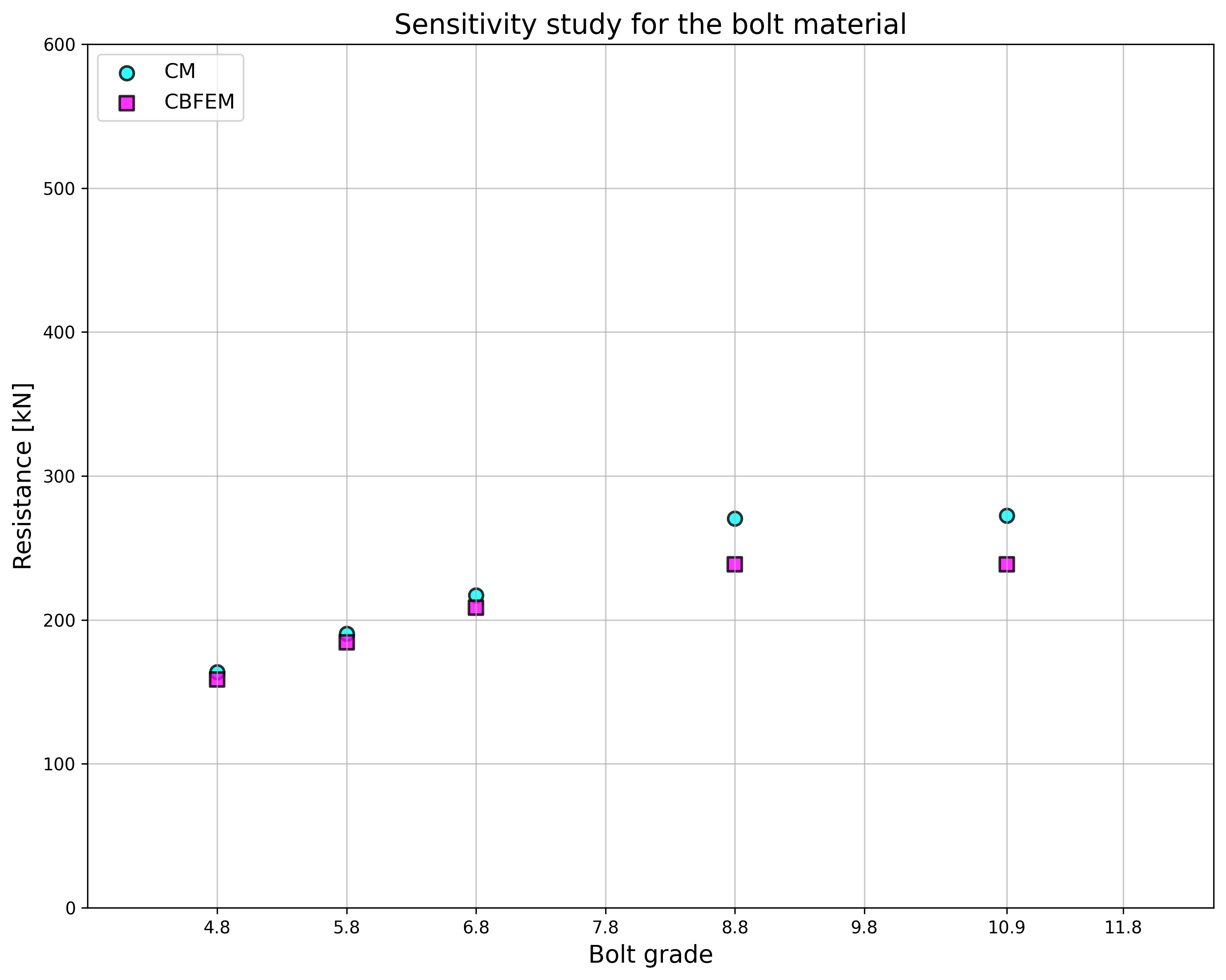

Verification of resistance

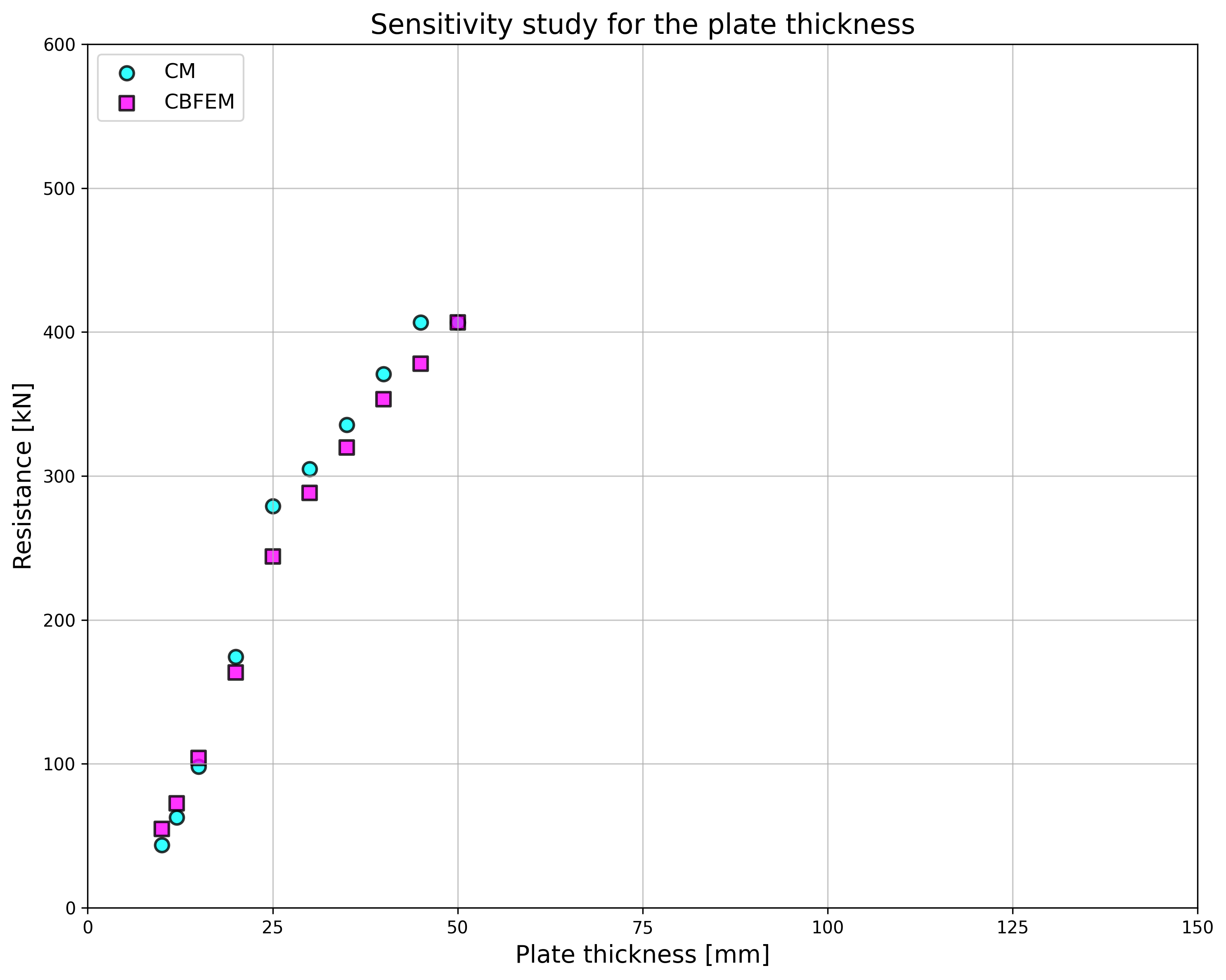

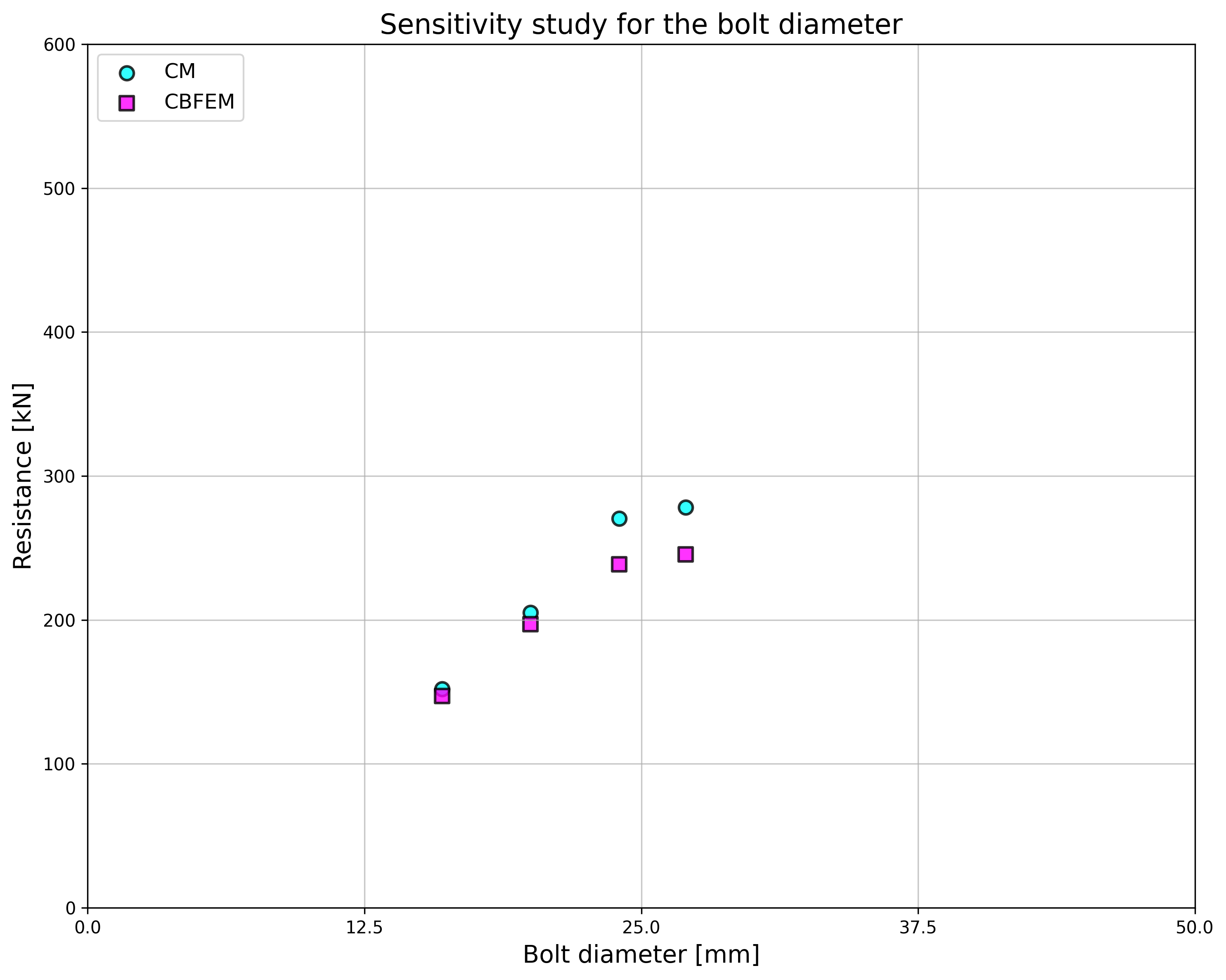

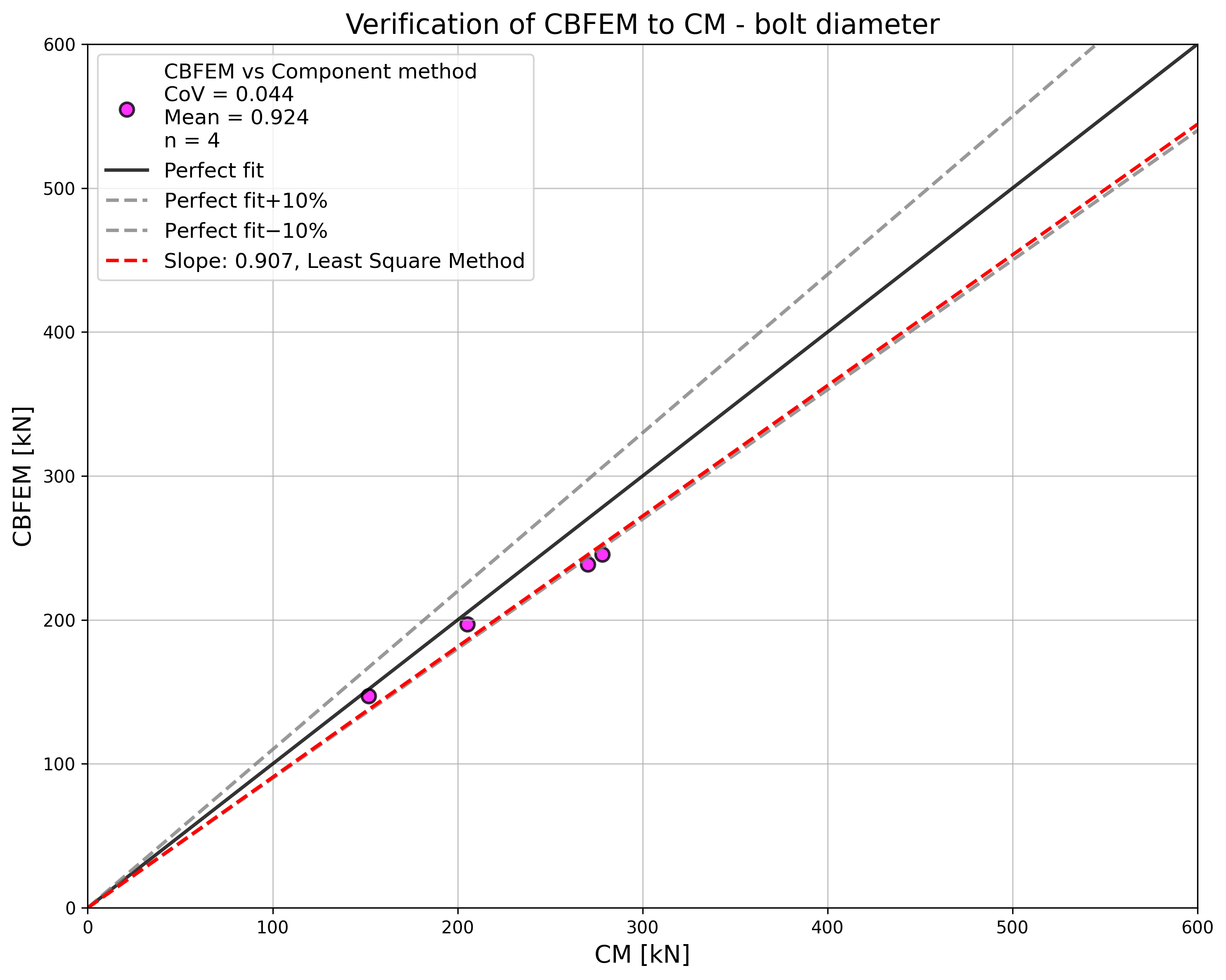

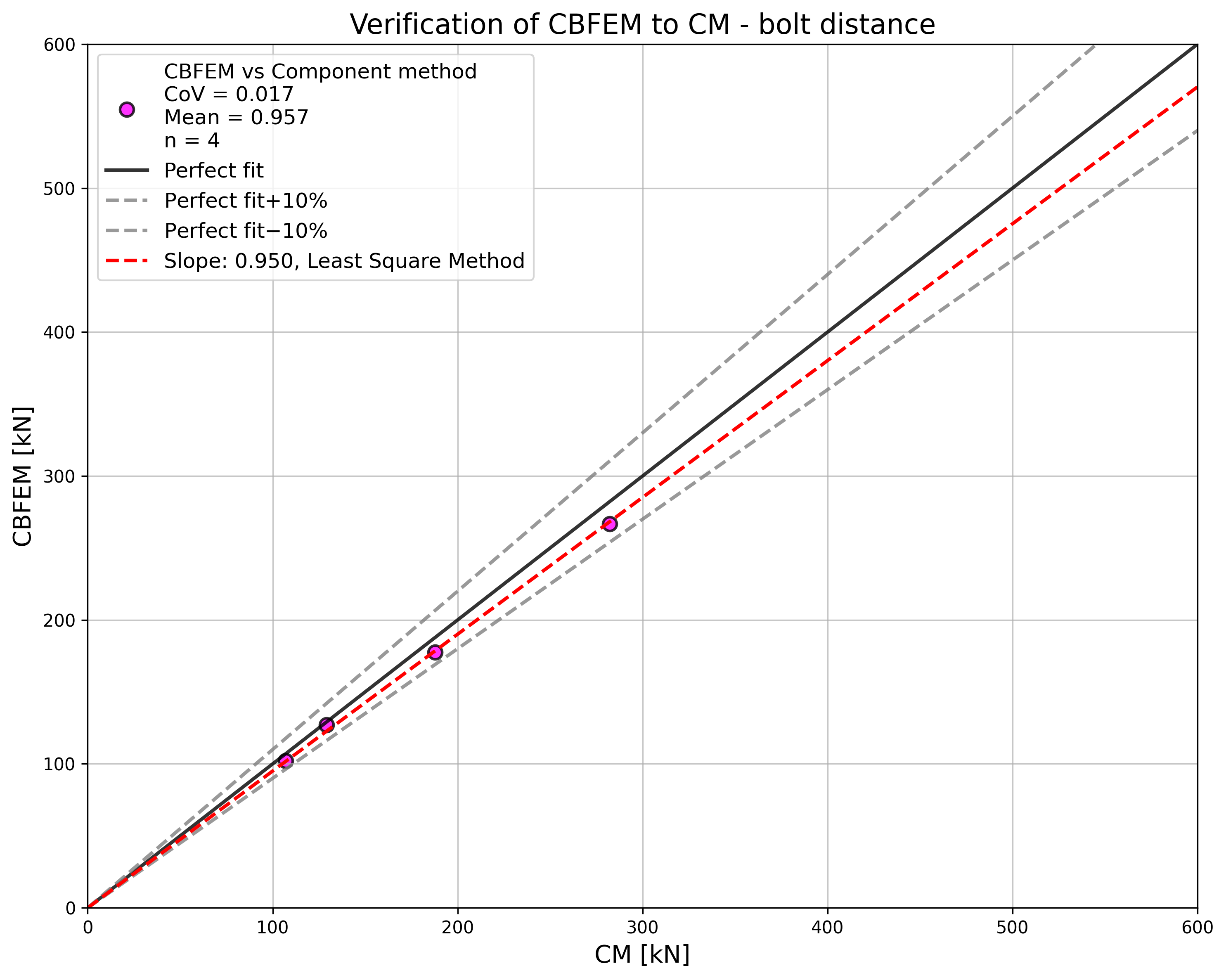

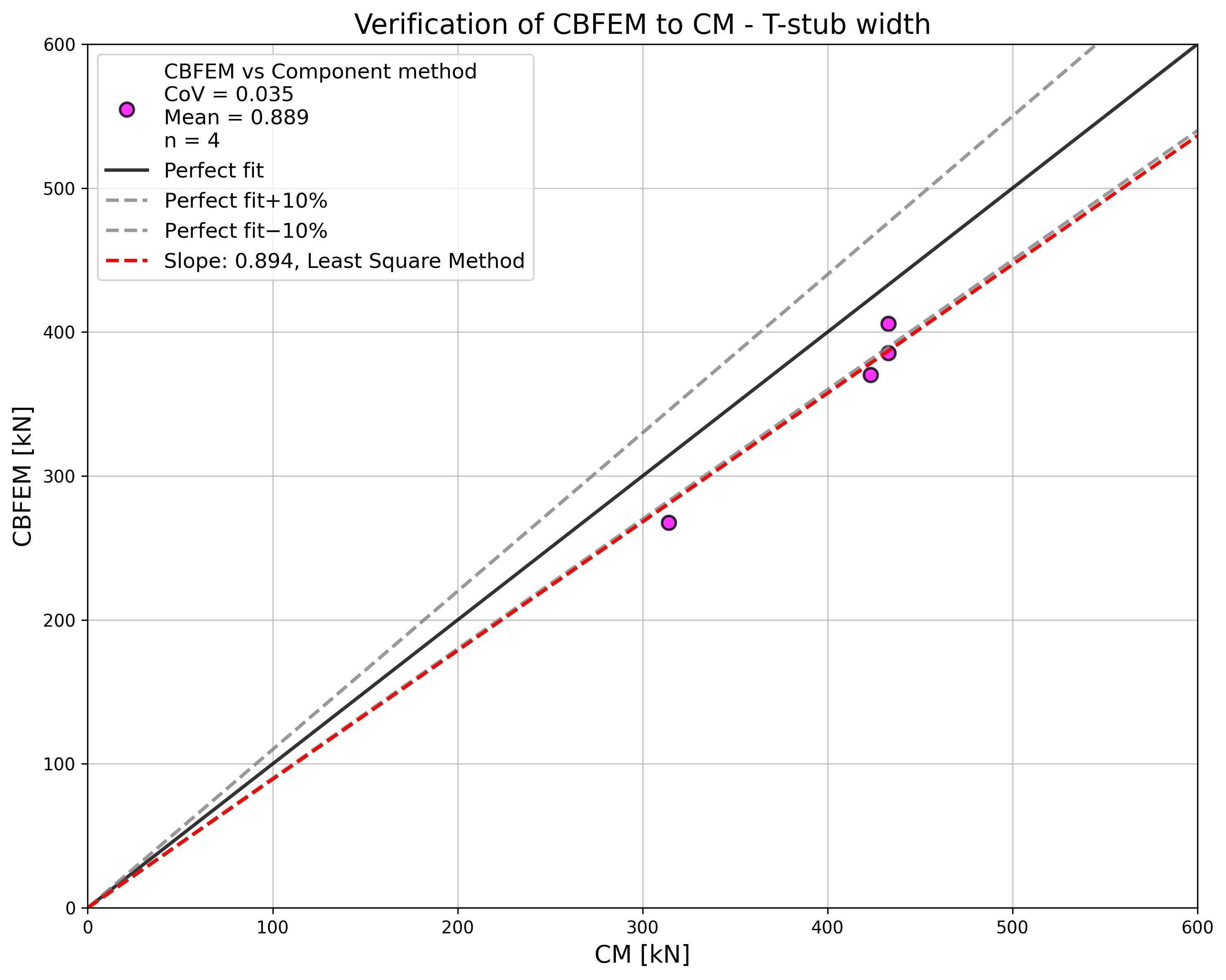

Design resistances calculated by CBFEM were compared with the results of CM and RM in the next step. The comparison was focused on the deformation capacity and determination of the collapse mode too. All results are ordered in Tab. 5.1.3. The study was performed for five parameters: thickness of the flange, bolt size, bolt material, bolt space, and T-stub width.

Tab. 5.1.3 Global behavior overview

\[ \textsf{\textit{\footnotesize{Fig. 5.1.5 Sensitivity study of flange thickness}}}\]

The sensitivity study of thickness of the flange shows higher resistance according to CBFEM compared to CM for samples with flange thicknesses up to 20 mm. RM gives even higher resistance for these samples; see Fig. 5.1.5. Higher resistance of both numerical models is explained by neglecting membrane effect in CM. In case of the bolt diameter and bolt material (see Fig. 5.1.6 and Fig. 5.1.7, respectively), the results of CBFEM correspond to these of CM. Due to a good agreement of both methods, the results of RM are not required.

\[ \textsf{\textit{\footnotesize{Fig. 5.1.6 Sensitivity study of the bolt diameter}}}\]

\[ \textsf{\textit{\footnotesize{Fig. 5.1.7 Sensitivity study of the bolt material}}}\]

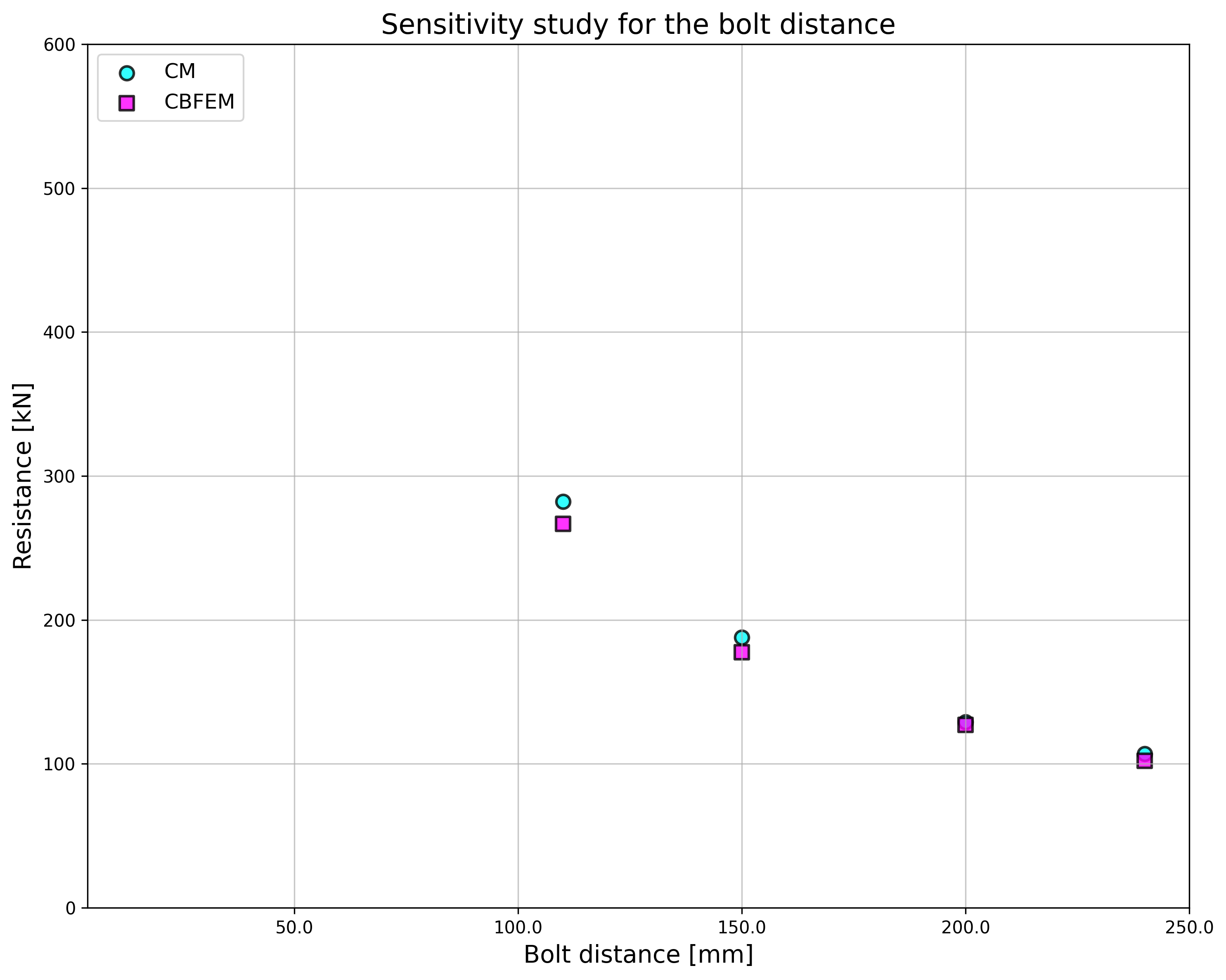

In the case of the bolt distances, the results of CBFEM and CM show generally good agreement; see Fig. 5.1.8. With an increase in bolt spacing, CBFEM gives slightly higher resistance compared to CM. For that reason, the results of RM are also shown. RM gives the highest resistance in all cases.

\[ \textsf{\textit{\footnotesize{Fig. 5.1.8 Sensitivity study of the bolt distance}}}\]

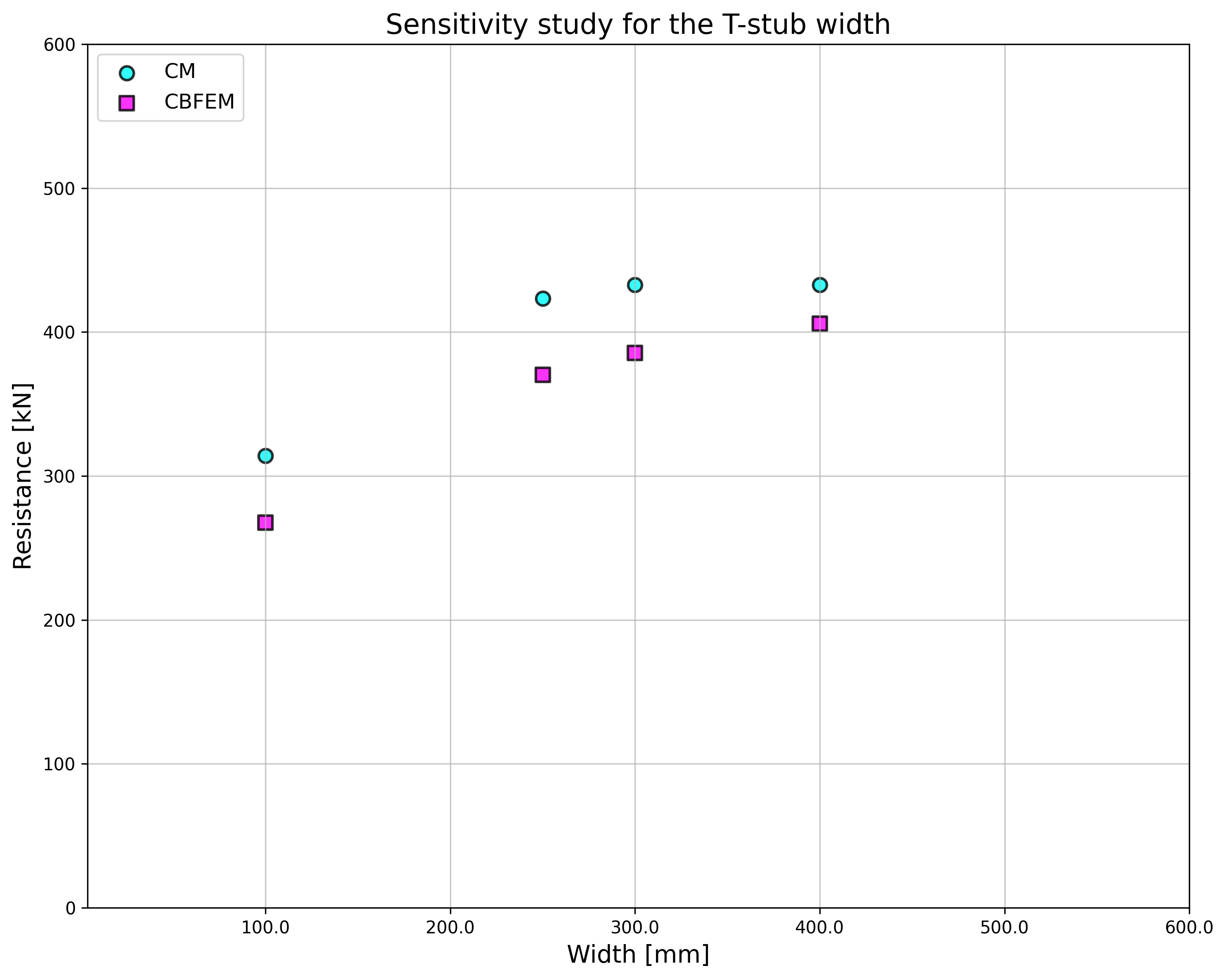

In the study of T-stub width, CBFEM shows higher resistance compared to CM with an increase in width. Results of RM were prepared, which again provide the highest resistance in all cases; see Fig. 5.1.9.

\[ \textsf{\textit{\footnotesize{Fig. 5.1.9 Sensitivity study of T-stub width}}}\]

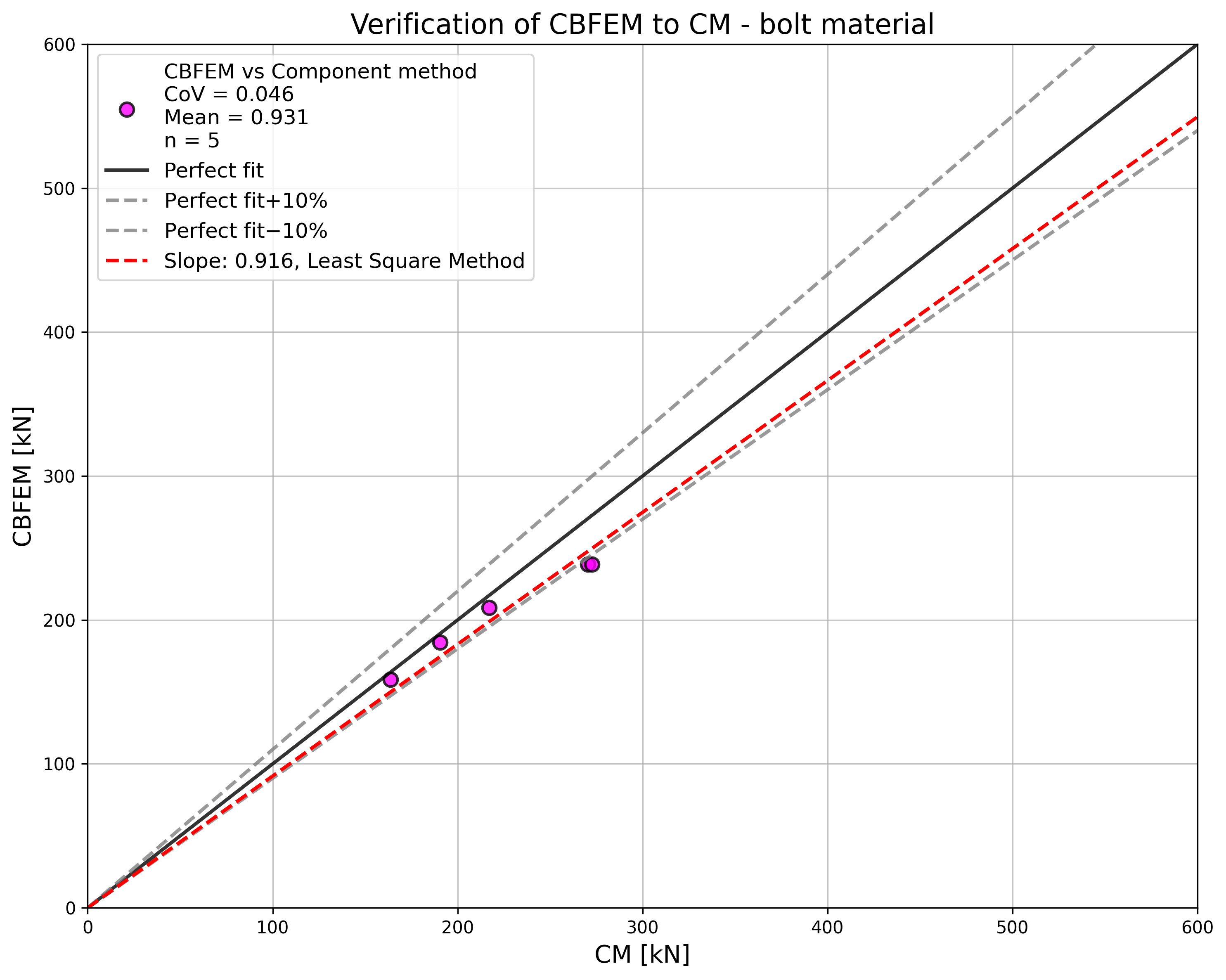

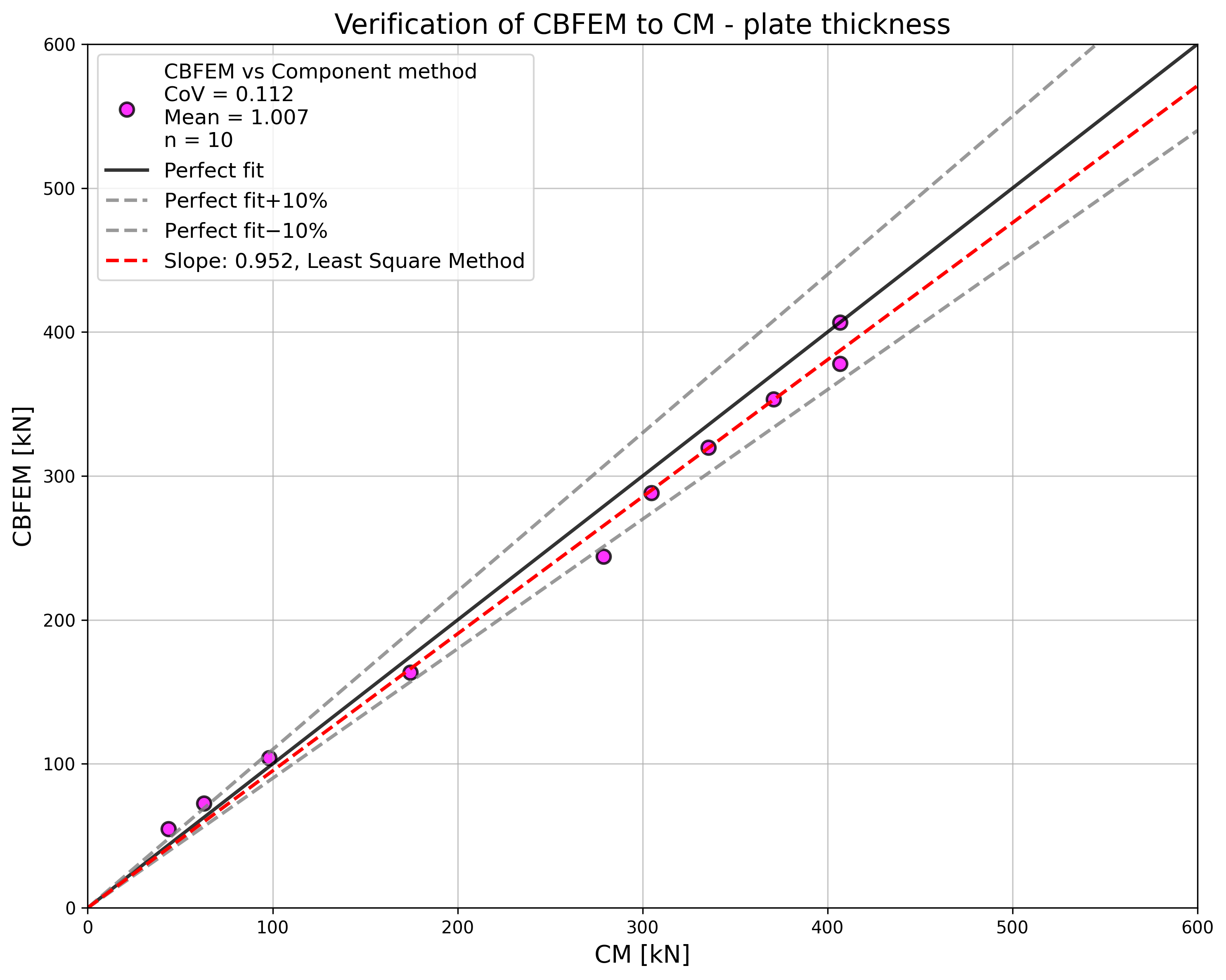

To show the prediction of the CBFEM model, the results of the studies were summarized in graph comparing resistances by CBFEM and CM; see Fig. 5.1.10. The results show that the difference between the two calculation methods is mostly up to 10 %. In cases with CBFEM/CM > 1,1, accuracy of CBFEM was verified by the results of RM, which gives the highest resistance in all selected cases.

\[ \textsf{\textit{\footnotesize{Fig. 5.1.10 Summary of verification of CBFEM to CM}}}\]

Benchmark example

Inputs

T-stub, see Fig. 5.1.11

- Steel S235

- Flange thickness tf = 20 mm

- Web thickness tw = 20 mm

- Flange width bf = 300 mm

- Length b = 100 mm

- Double fillet weld aw = 10 mm

Bolts

- 2 × M24 8.8

- Distance of the bolts w = 165 mm

Code setup – Model and mesh

- Number of elements on biggest member or flange 16

Outputs

- Design resistance in tension FT,Rd = 164 kN

- Collapse mode – full yielding of the flange with maximal strain 5 %

- Utilization of the bolts 86,4 %

- Utilization of the welds 45,7 %

\[ \textsf{\textit{\footnotesize{Fig. 5.1.11 Benchmark example for the T-stub}}}\]

References

EN 1993-1-5, Eurocode 3, Design of steel structures – Part 1-5: Plated Structural Elements, CEN, Brussels, 2005.

EN 1993-1-8, Eurocode 3, Design of steel structures – Part 1-8: Design of joints, CEN, Brussels, 2005.

Beg D., Zupančič E., Vayas I. On the rotation capacity of moment connections, Journal of Constructional Steel Research, 60 (3–5), 2004, 601–620.

Gödrich L., Wald F., Sokol Z. To Advanced modelling of end plate joints, Connection and Joints in Steel and Composite Structures, Rzeszow, 2013.

Gödrich L., Wald F., Kabeláč J., Kuříková M. Design finite element model of a bolted T-stub connection component, Journal of Constructional Steel Research. 2019, (157), 198-206.

Wu Z., Zhang S., Jiang S. Simulation of tensile bolts in finite element modelling of semi-rigid beam-to-column connections, International Journal of Steel Structures 12 (3), 2012, 339-350.

Bolted connection - Splices in shear

Description

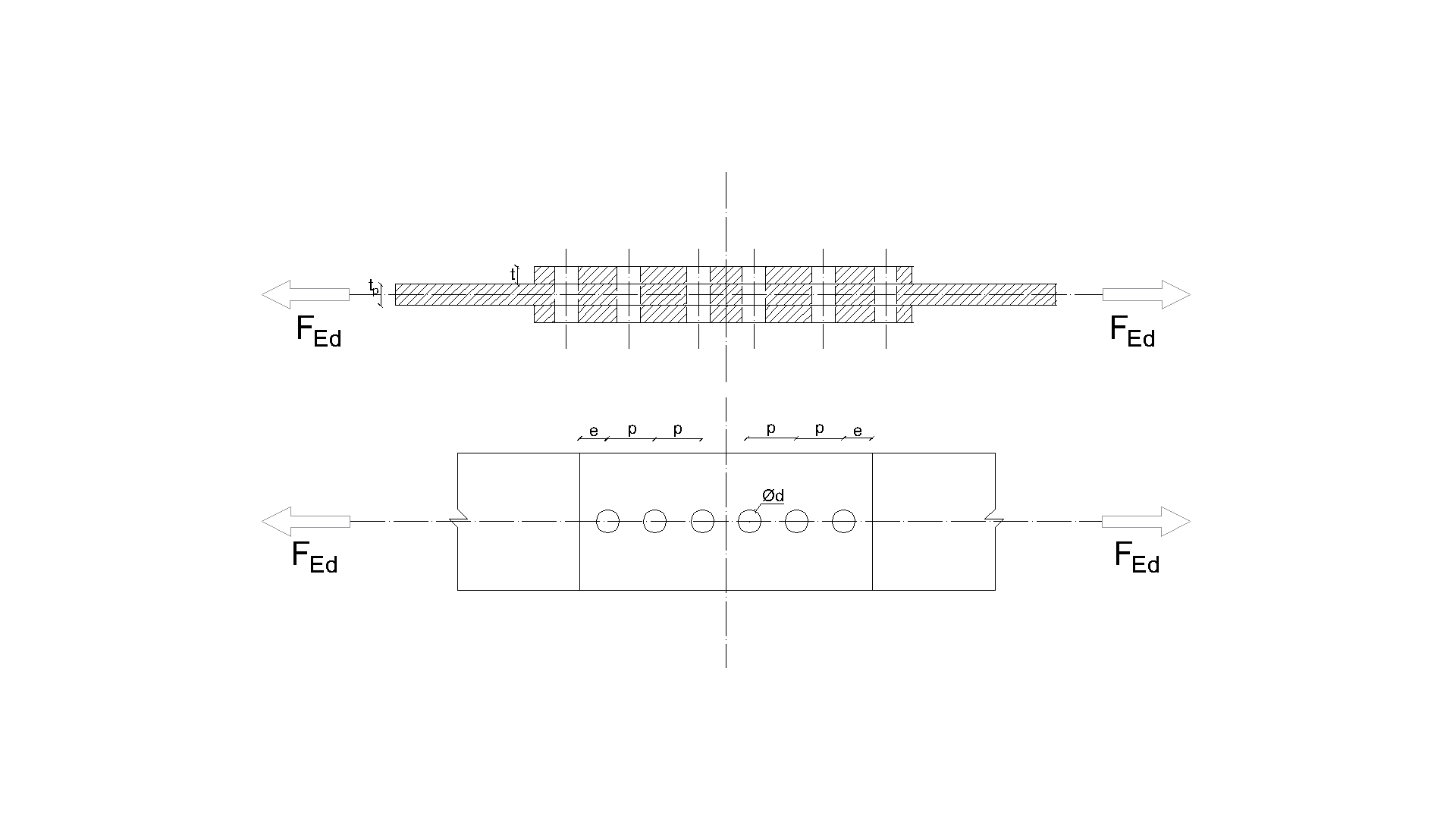

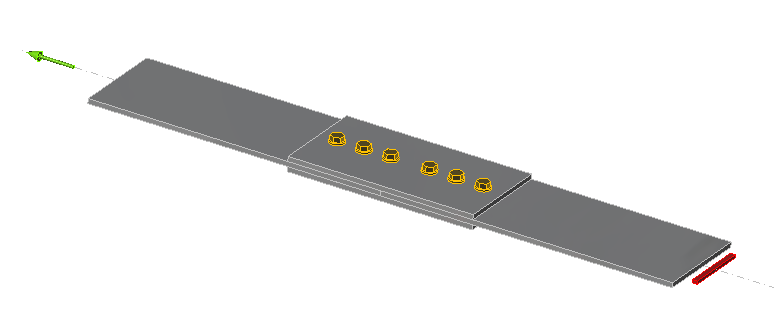

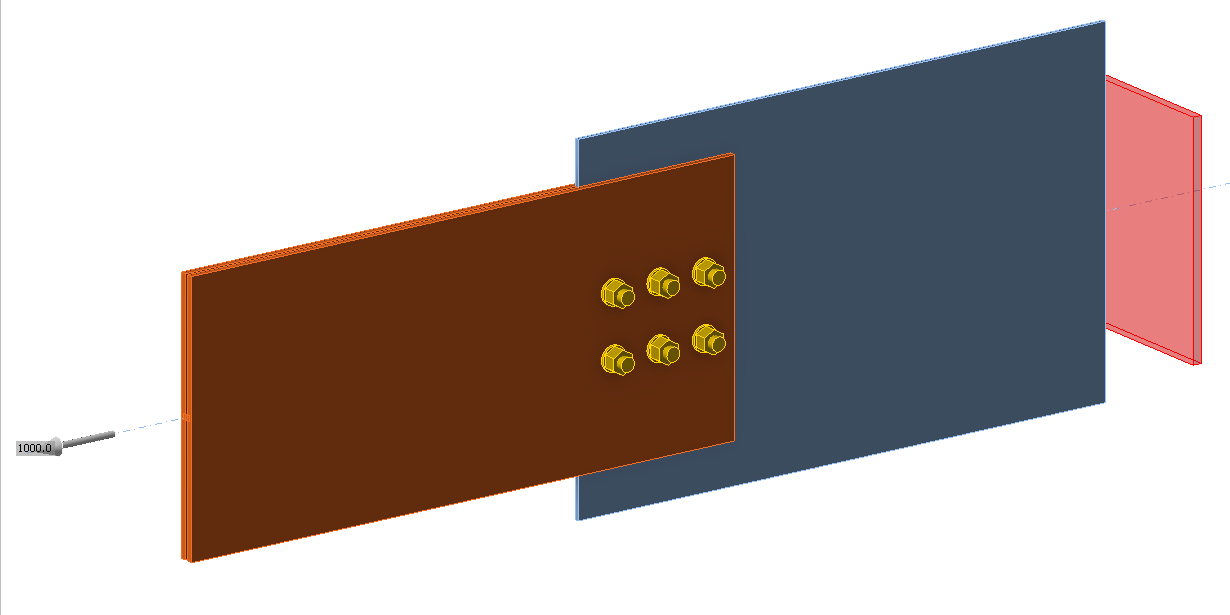

This study is focused on the verification of component-based finite element method (CBFEM) for the resistance of the symmetrical double splice bolted connection to an analytical model (AM).

Analytical model

The bolt resistance in shear and the plate resistance in bearing are designed according to Tab. 3.4 in chapter 3.6.1 in EN 1993-1-8:2005. For long connection, reduction factor according to cl. 3.8 is considered. Design resistance of connected members with reductions for fastener holes is taken into account according to cl 3.10.

\[ \textsf{\textit{\footnotesize{ Drawing 5.2.1 Joint geometry and dimensions}}}\]

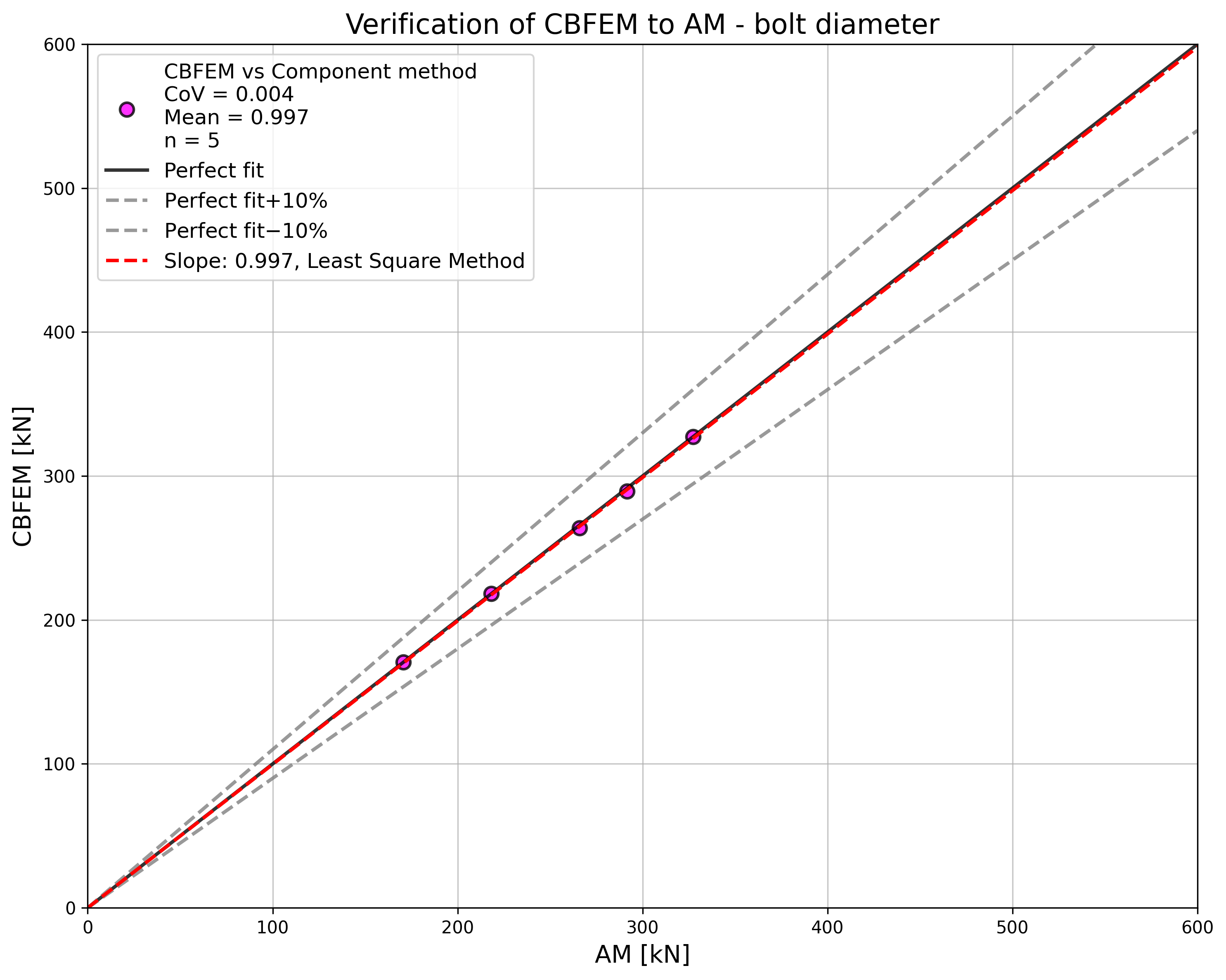

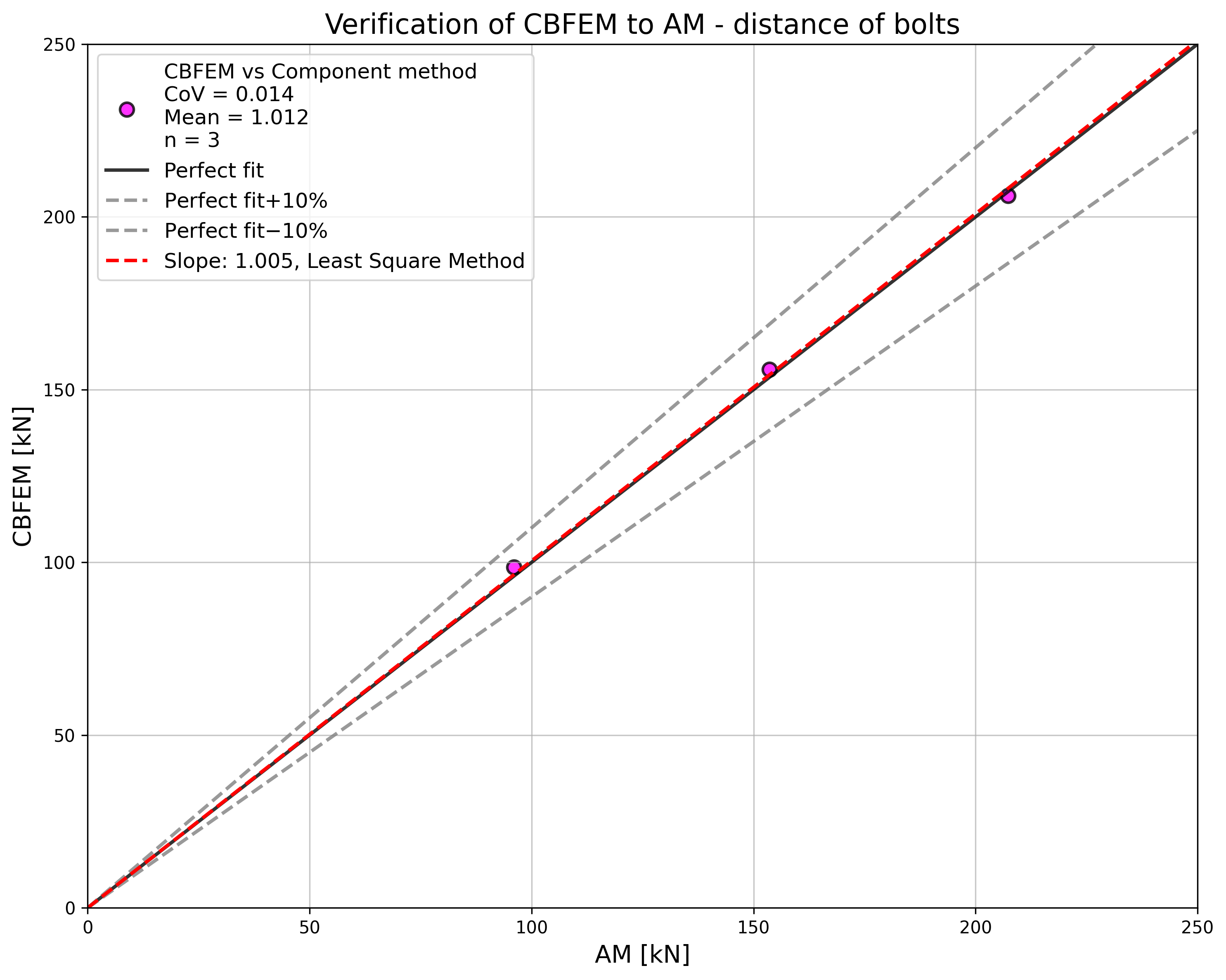

Verification of resistance

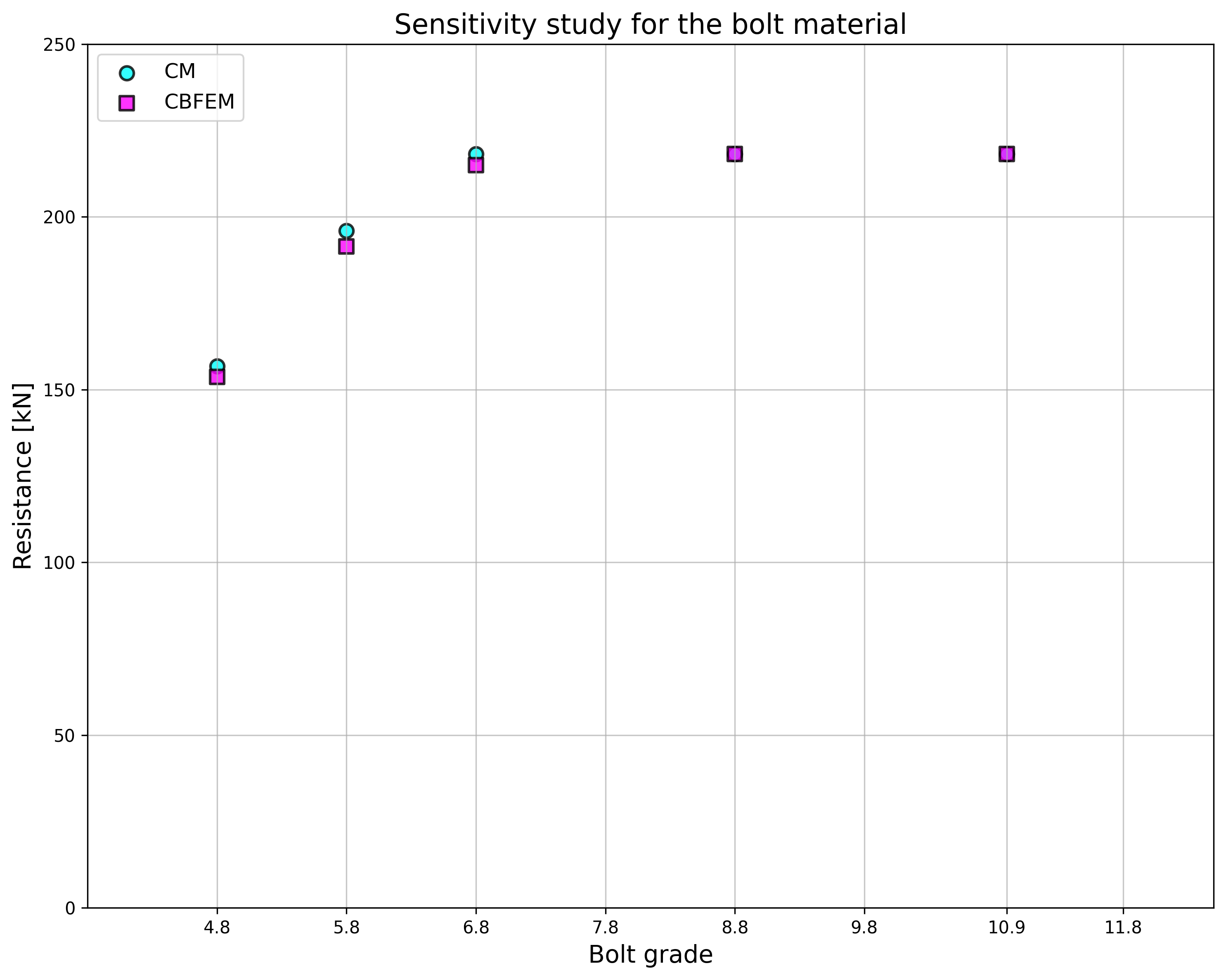

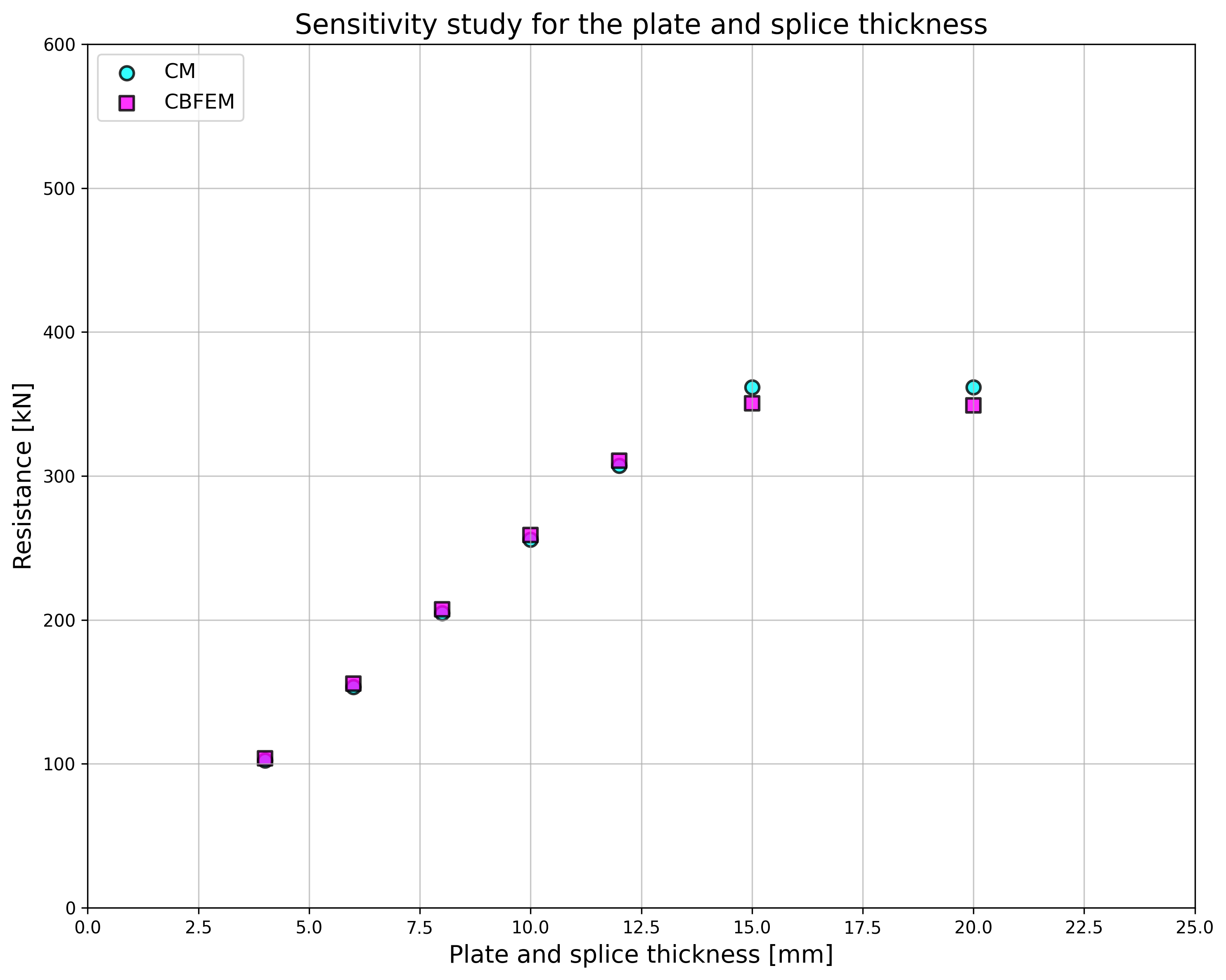

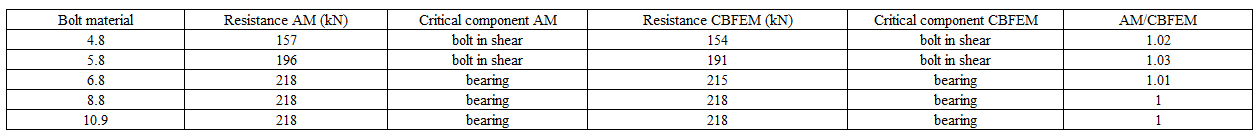

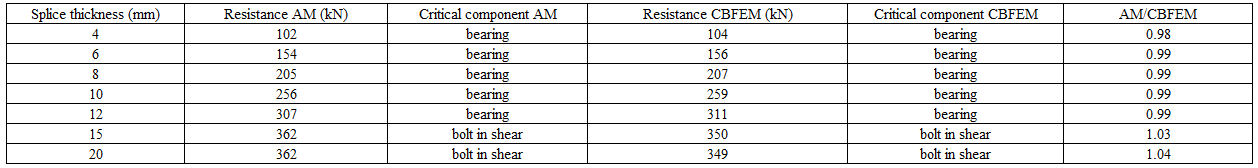

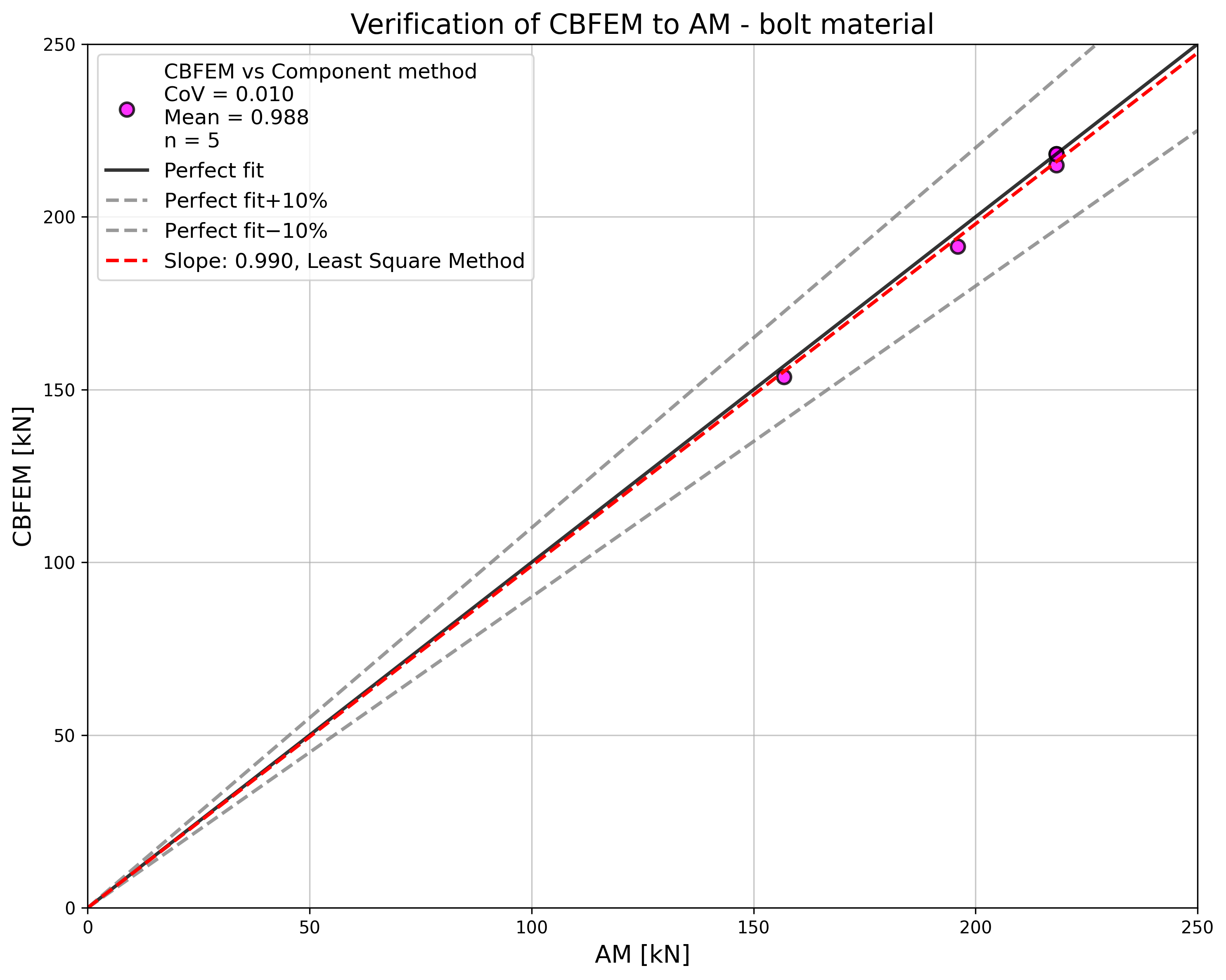

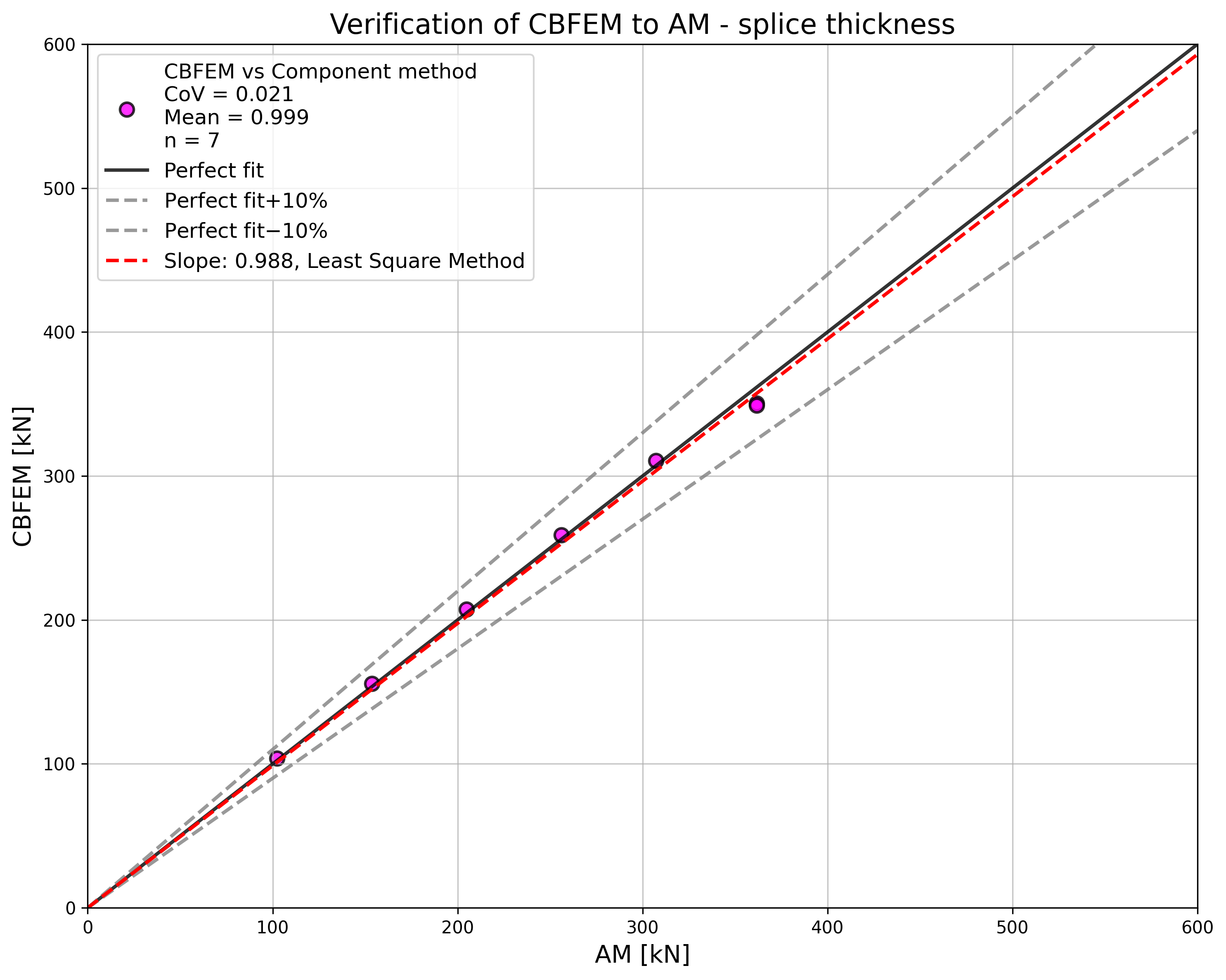

Design resistances calculated by CBFEM were compared with results of analytical model (AM). Results are summarised in Tab. 5.2.1. The parameters are bolt material, splice thickness, bolt diameter, and bolt distances, see Figs. 5.2.1 to 5.2.4.

\[ \textsf{\textit{\footnotesize{Fig. 5.2.1 Sensitivity study for the bolt material}}}\]

\[ \textsf{\textit{\footnotesize{Fig. 5.2.2 Sensitivity study for the splice thickness}}}\]

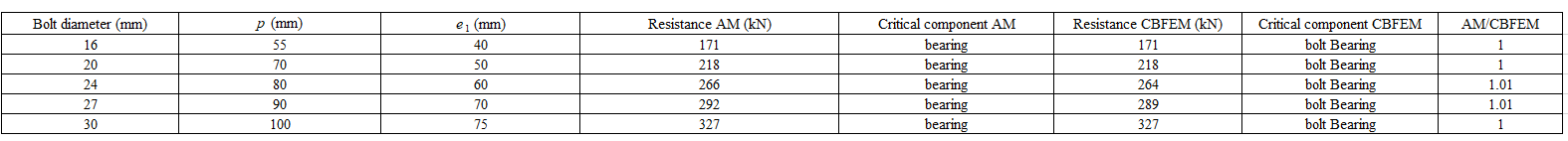

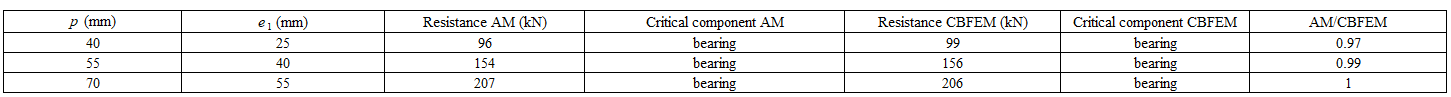

Tab. 5.2.1 Sensitivity study of resistance

Joint description: splice 150/10mm, bolts 2×M20 in distances p =70, e1=50, plates 2×150/6mm, steel S235

Joint description: splice height 200mm, bolts 3×M16 8,8 in distances p = 55mm e1 = 40mm, plates 2×200/t mm, steel S235

Joint description: splice 120/10mm, bolts 2×MX 8,8, plates 2×120/10 mm, steel S235

Joint description: Splice 200/6 mm, bolts 3×M16 8,8, plates 2×200/6mm, steel S235

\[ \textsf{\textit{\footnotesize{Fig. 5.2.3 Sensitivity study for the bolt diameter}}}\]

\[ \textsf{\textit{\footnotesize{Fig. 5.2.4 Sensitivity study for the distance of bolts}}}\]

The results of sensitivity studies are summarized in the graph in Fig. 5.2.5. The results show that the differences between the two calculation methods are below 5 %. The analytical model gives generally higher resistance.

\[ \textsf{\textit{\footnotesize{Fig. 5.2.5 Verification of CBFEM to AM for the symmetrical double splice connection}}}\]

Benchmark example

Inputs

Connected member

- Steel S235

- Splice 200/10 mm

Connectors

Bolts

- 3 × M16 8.8

- Distances e1 = 40 mm, p = 55 mm

2 x splice

- Steel S235

- Plate 380×200×10

Outputs

- Design resistance FRd = 258 kN

- Critical is bearing of the connected splice

\[ \textsf{\textit{\footnotesize{Fig. 5.2.6 Benchmark example of the bolted splices in shear}}}\]

End plate minor axis connection

Description

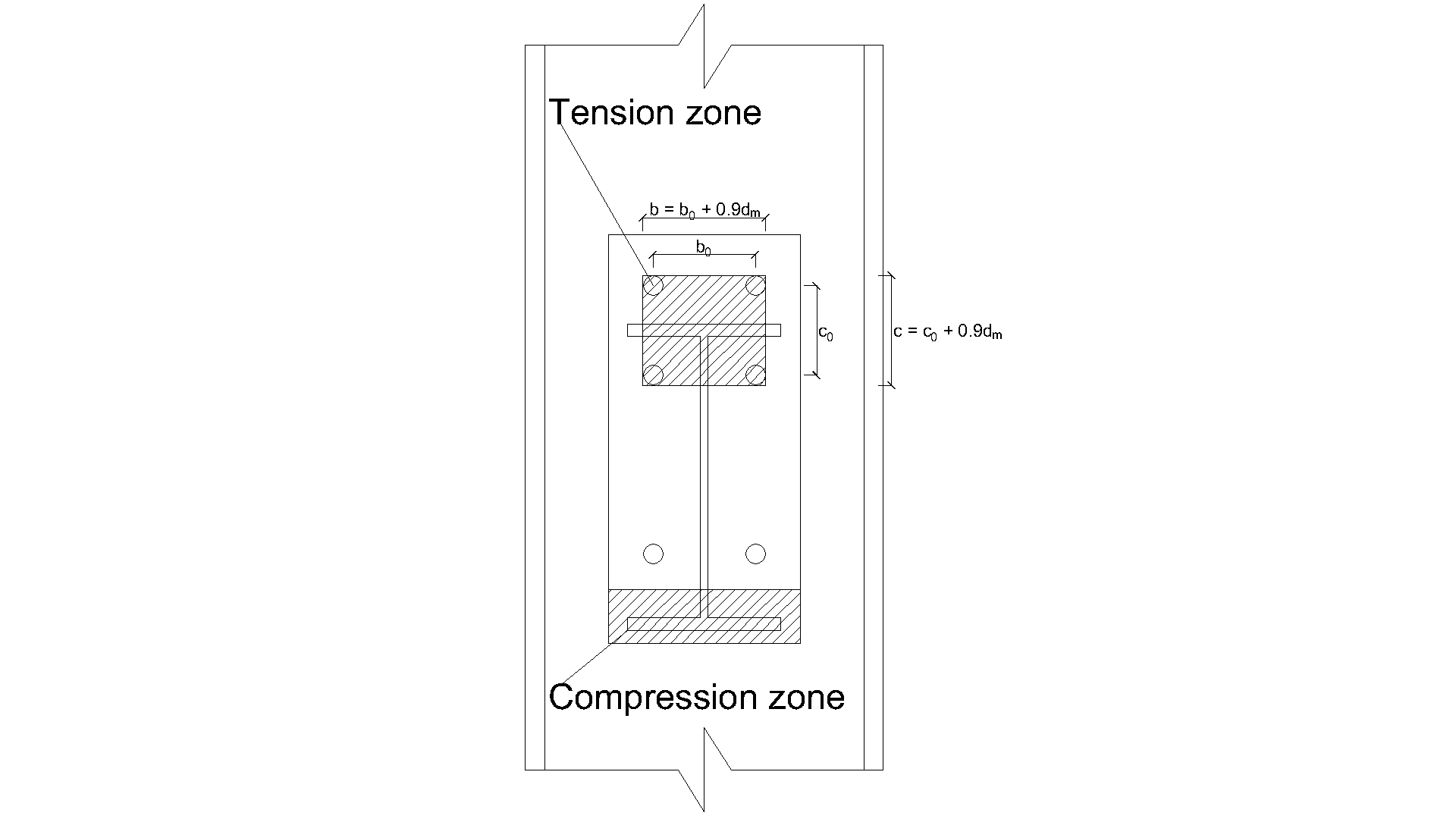

Component-based finite element method (CBFEM) model of the beam to column joint is verified on Component method (CM). The extended end plate with three bolt rows is connected to column web and loaded by bending moment; see Fig. 5.3.1.

\[ \textsf{\textit{\footnotesize{Fig. 5.3.1 Joint geometry - all dimensions in mm}}}\]

Analytical model

Three components, which are guiding the behavior, are the end plate in bending, the beam flange in tension and in compression, and the column web in bending. The end plate and the beam flange in tension and in compression are designed according to EN 1993-1-8:2005. The behavior of the column web in bending is predicted according to (Steenhuis et al. 1998). The results of experiments of the beam to column minor axis joints, e.g. (Lima et al. 2009), show good prediction of this type of joint loaded in-plane of a connected beam.

\[ \textsf{\textit{\footnotesize{Fig. 5.3.2 Definition of the tension zone}}}\]

\[F_\mathrm{{local.Rd }}=\min \left(F_\mathrm{{punch.Rd }} ; F_\mathrm{{comb.Rd }}\right)\]

\[F_\mathrm{ {punch.Rd }} = n \cdot \pi\cdot d_\mathrm{m} \cdot t_\mathrm{w c} \cdot f_\mathrm{y} /\left(\sqrt{3} \cdot \gamma_\mathrm{M 0}\right) \quad \text{bolted end plate }\]

\[b = b_0 + 0.9 \cdot d_\mathrm{m}\]

\[c = c_0 + 0.9 \cdot d_\mathrm{m}\]

\[a = L - b\]

\[k= 1 \quad \text{ if }\quad(b+c) / L>0.5\]

\[k=0.7+0.6(b+c) / L \quad \text{ if }\quad(b+c) / L \leq 0.5\]

\[b_\mathrm{m}=L\left[1-0.82 \frac{t_\mathrm{w c}^2}{c^2}\left(1+\sqrt{1+2.8 \frac{c^2}{t_\mathrm{w c} L}}\right)^2\right], \quad \text{ but } \quad b_\mathrm{m} \geq 0\]

\[x_0=L\cdot\left[\left(\frac{t_\mathrm{w c}}{L}\right)^{\frac{2}{3}}+0.23 \frac{c}{L}\left(\frac{t_\mathrm{w c}}{L}\right)^{\frac{1}{3}}\right] \cdot\left(\frac{b-b_\mathrm{m}}{L-b_\mathrm{m}}\right)\]

\[x = 0 \quad b \leq b_\mathrm{m}\]

\[x=-a+\sqrt{a^2-1.5 a c+\frac{\sqrt{3}}{2} t_\mathrm{w c}\left[\pi \sqrt{L\left(a+x_0\right)}+4 c\right]} \quad \text{ if }\quad b>b_\mathrm{m}\]

\[F_\mathrm{c o m b . R d}=k\cdot t_\mathrm{w c}^2 \cdot f_\mathrm{y}\left[\frac{\pi \sqrt{L(a+x)}+2 c}{a+x}+\frac{1.5 c x+x^2}{\sqrt{3} t_\mathrm{w c}(a+x)}\right] / \gamma_\mathrm{M 0}\]

\[\rho = 1 \quad \text{ if }\quad z / (L-b) \leq 1\]

\[\rho = z / (L-b) \quad \text{ if }\quad 1<z / (L-b) \leq 10\]

\[F_\mathrm{g l o b a l . R d}=\frac{F_\mathrm{c o m b . R d}}{2}+\frac{t_\mathrm{w c}^2 f_\mathrm{y}}{4}\left(\frac{2 b}{z}+\pi+2 \rho\right) / \gamma_\mathrm{M 0}\]

\[F_\mathrm{Rd} = \min \left(F_\mathrm{{local.Rd }} ; F_\mathrm{g l o b a l . R d}\right)\]

\[M_\mathrm{Rd} = z \cdot F_\mathrm{Rd}\]

Where:

- \(t_\mathrm{w c} \quad\) is the thickness of the column web

- \(f_\mathrm{y} \quad\) is the yield strength of the column web

- \(\gamma_{\mathrm{M} 0}\) is the partial safety factor of steel

- \(\gamma_{\mathrm{M} 0}\) is the partial safety factor of steel

- \(n\) number bolt rows in tension

- \(d_\mathrm{m}\) bolt head diagonal diameter

- \(b_0\) horizontal distance between bolts

- \(c_0\) vertical distance between bolts

- \(z\) lever arm of the joint

- \(F_\mathrm{ {punch.Rd }} \quad\) is the resistance to punching shear

- \(F_\mathrm{ {comb.Rd }} \quad\) is the resistance to combined punching, shear and bending

Numerical model

Assessment is based on the maximum strain given according to EN 1993-1-5:2006 by the value of 5 %. Detailed information about CBFEM model is summarized in Chapter 3.

Verification of resistance

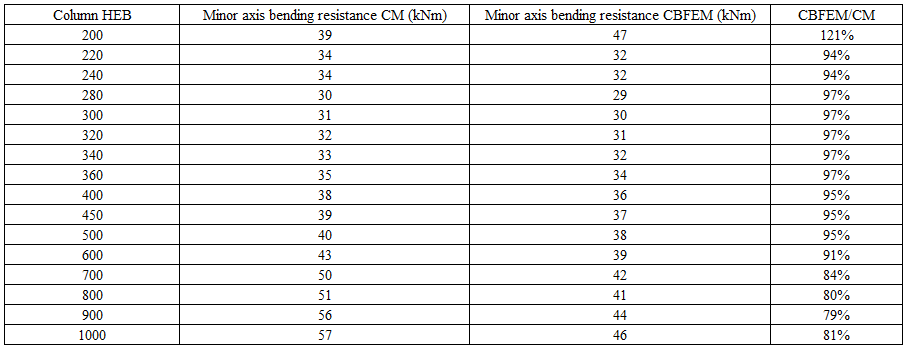

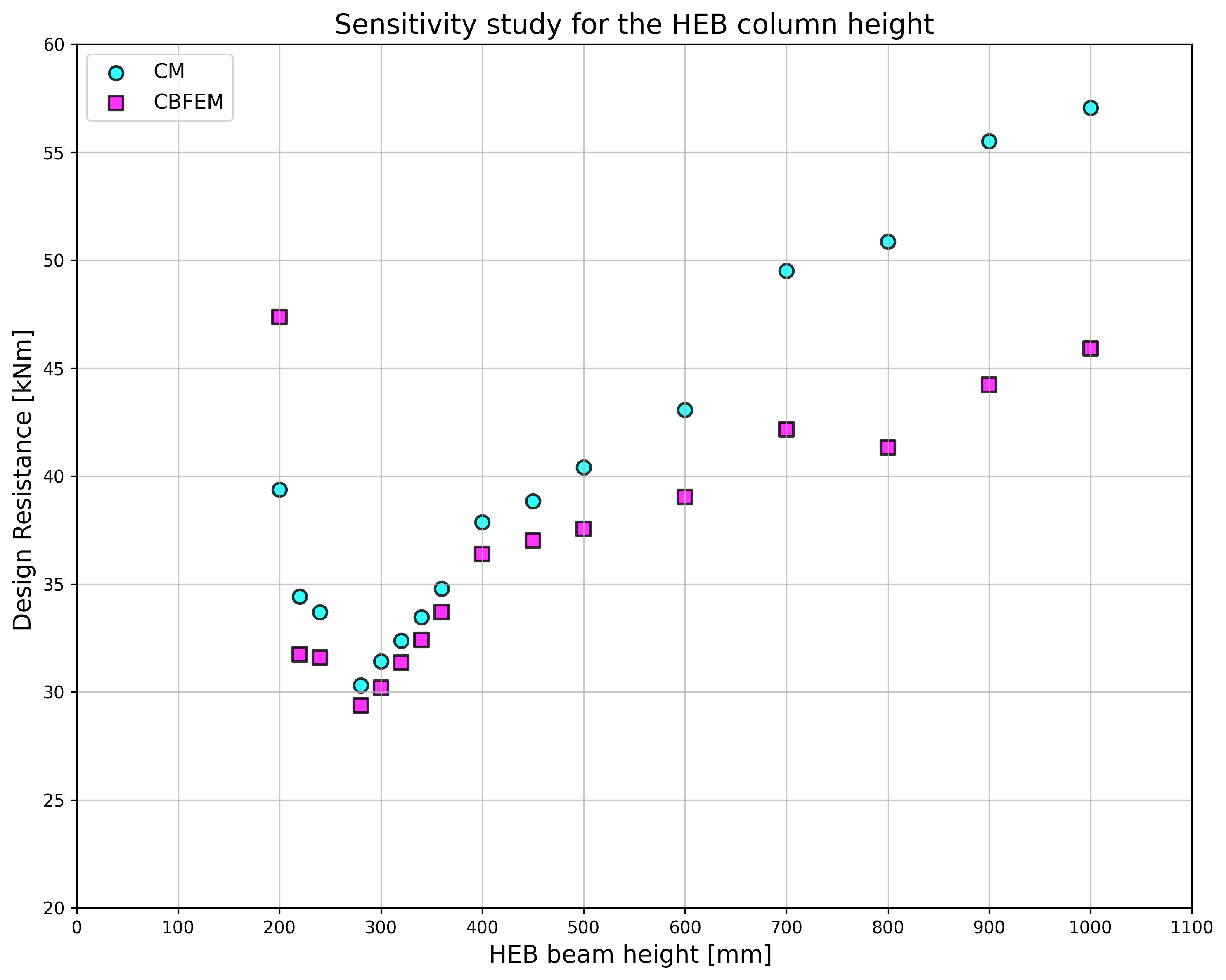

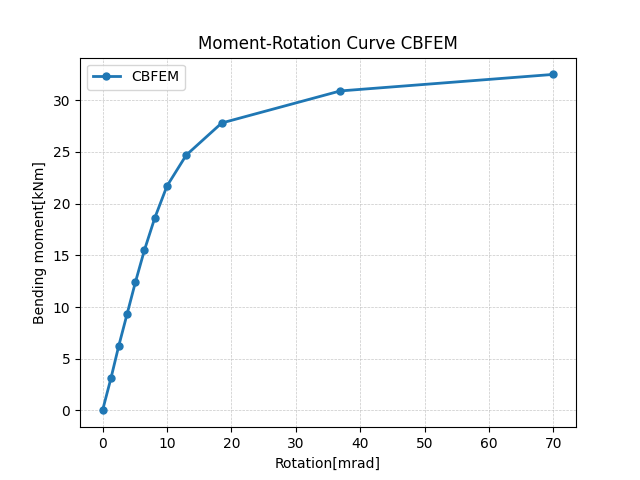

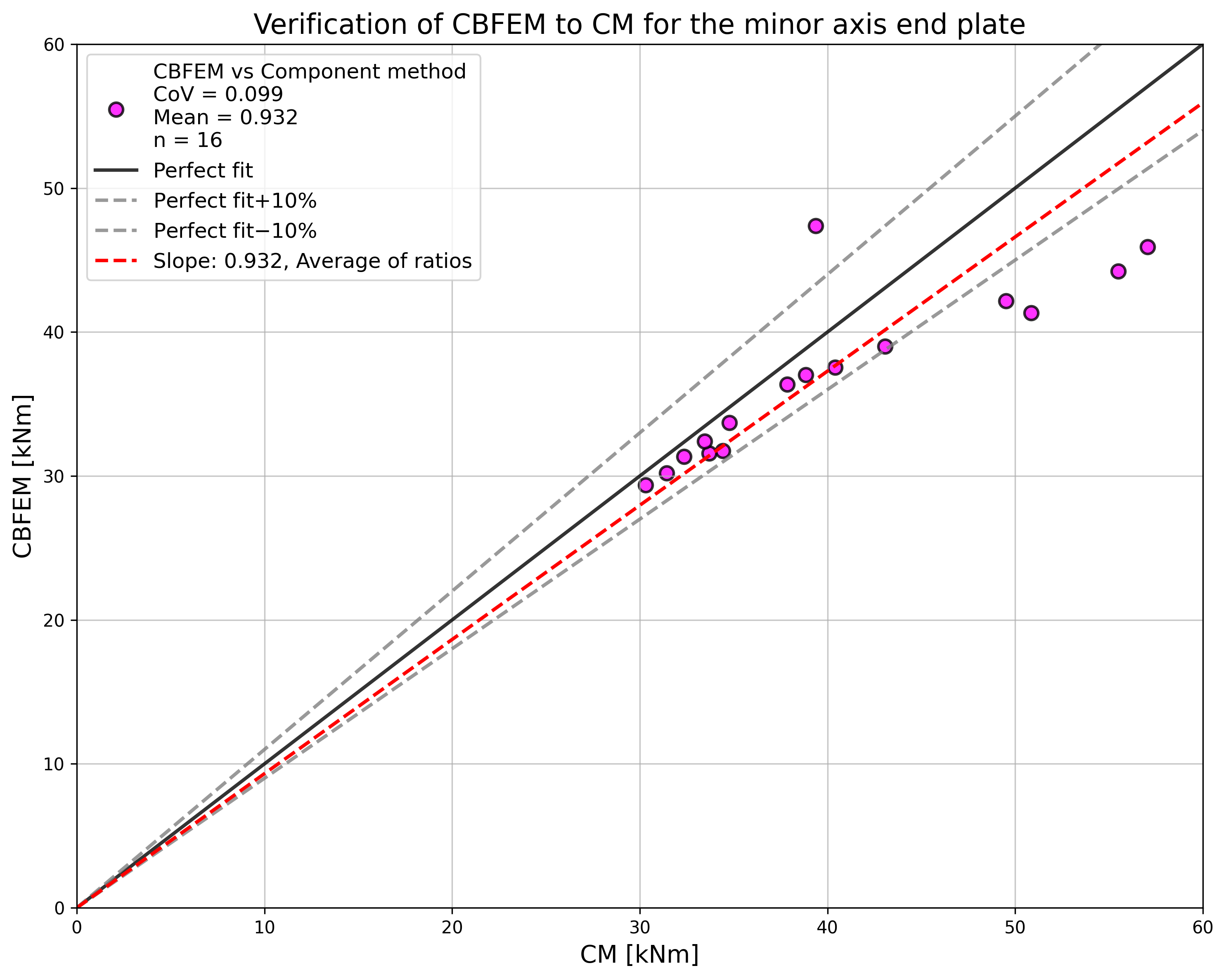

The sensitivity study of the joint resistance was prepared for column cross-sections. Joint geometry is shown in Fig. 5.3.1. In Tab. 5.3.1 and in Fig. 5.3.3, the results of calculations in case of enlarging end plate P18 relatively with the column section are summarized.

Tab. 5.3.1 Results of prediction of the of end plate minor axis connection for different rafters

\[ \textsf{\textit{\footnotesize{Fig. 5.3.3 Comparison resistance of end plate minor axis connection predicted by CBFEM and CM}}}\]

Global behavior

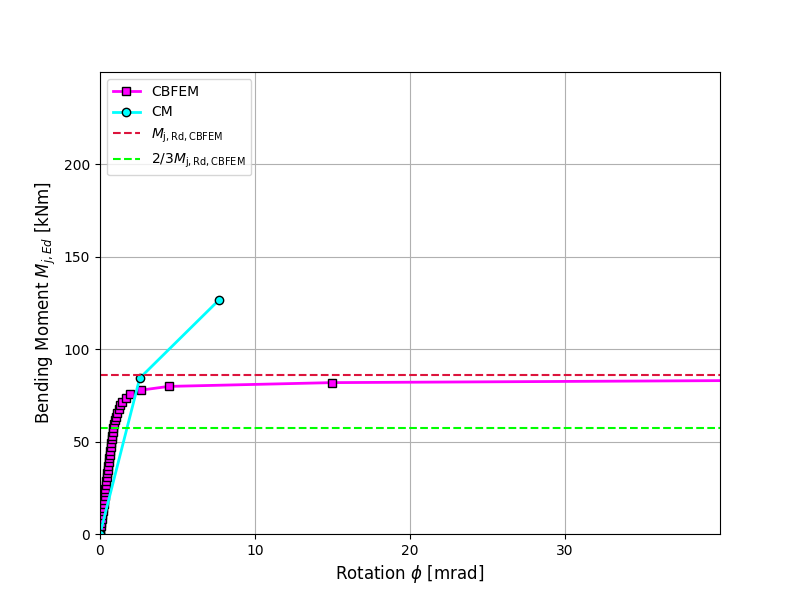

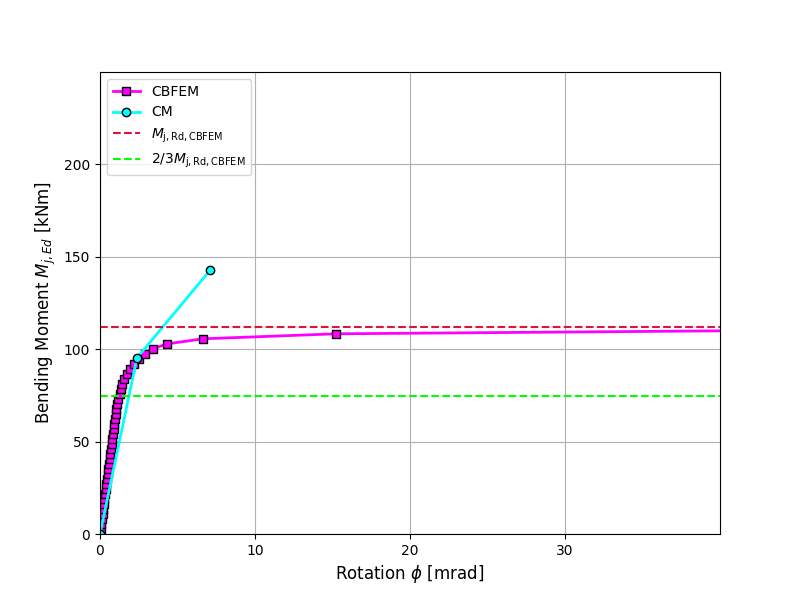

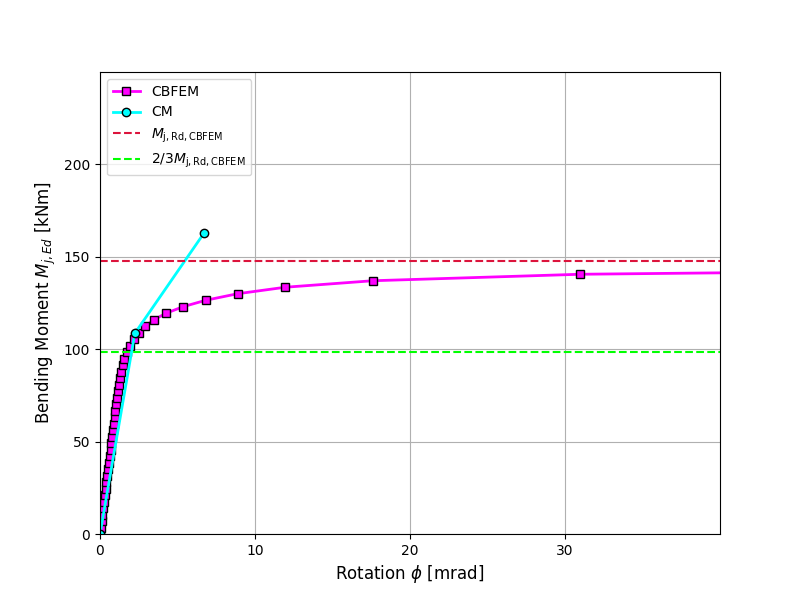

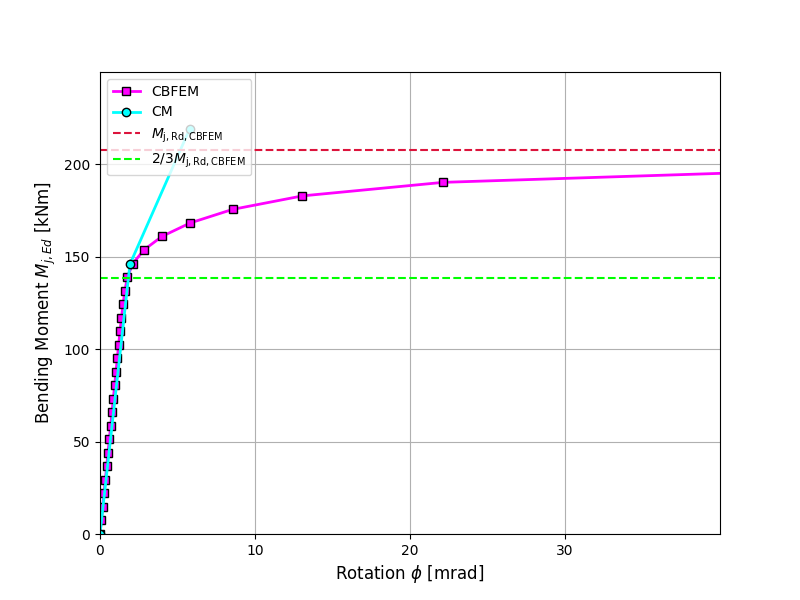

Global behavior is presented on force-deformation curve. Beam IPE 240 is connected to column HEB 300 with six bolts M16 8.8. End plate geometry is shown in Fig. 5.3.1 and in Tab. 5.3.1. Comparison of both methods results is presented in Fig. 5.3.4 and in Tab.5.3.2. Both methods predict similar design resistance. CBFEM generally gives lower initial stiffness compared to CM.

\[ \textsf{\textit{\footnotesize{Fig. 5.3.4 Prediction of behavior of end plate minor axis connection on moment rotational curve CBFEM}}}\]

Tab. 5.3.2 Main characteristics for global behavior

| CM | CBFEM | CM/CBFEM | ||

| Initial stiffness | [kNm/rad] | 16130 | 2232 | 7.23 |

| Design resistance | [kNm] | 31 | 30 | 1,03 |

The results of studies are summarized in the graph comparing resistances by CBFEM and component method; see Fig. 5.3.5. The results show that the difference between methods is up to 14 %. CBFEM predicts in all cases lower resistance compared to CM, which is based on simplification in (Steenhuis et al. 1998). Similar results may be observed in work by (Wang and Wang, 2012).

\[ \textsf{\textit{\footnotesize{Fig. 5.3.5 Summary of verification of CBFEM to CM for the end plate minor axis connection}}}\]

Benchmark example

The benchmark case is prepared for the end plate minor axis connection according to Fig. 5.3.1 with modified geometry as summarized below.

Inputs

- Steel S235

- Column HEB 300

- Beam IPE 240

- Bolts 6×M16 8.8

- Welds thickness 5 mm

- End-plate thickness tp = 18 mm

Outputs

- Design resistance in bending MRd = 30 kNm

- Governing component – column web in bending

References

EN 1993-1-5, Eurocode 3, Design of steel structures – Part 1-5: Plated Structural Elements, CEN, Brussels, 2005.

Steenhuis M., Jaspart J. P., Gomes F., Leino T. Application of the component method to steel joints, in Control of the Semi-rigid Behaviour of Civil Engineering Structural Connections Conference, COST C1, Liege, Belgium, 1998, 125-143.

Wang Z., Wang T. Experiment and finite element analysis for the end plate minor axis connection of semi-rigid steel frames, Tumu Gongcheng Xuebao/China Civil Engineering Journal, 45 (8), 2012, 83-89.

Bolted connection - Interaction of shear and tension

Description

The objective of this chapter is a verification of the component-based finite element method (CBFEM) for the interaction of shear and tension in a bolt to an analytical model (AM). A beam-to-beam joint with end plates and two rows of bolts was selected for verification; see Fig. 5.5.1. The bending stiffness of the joint is high enough to be classified as rigid.

\[ \textsf{\textit{\footnotesize{Fig. 5.5.1 Joint arrangement of bolted beam-to-beam joint}}}\]

Analytical model

Bolt resistance in interaction of shear and tension is designed according to Tab. 3.4 in chapter 3.6.1 in EN 1993-1-8:2005. A bilinear relation is used. The geometry and the end plate dimensions of the joint are selected to limit the design resistance of the joint by bolt failure. The design resistance of equivalent T-stub in tension is modeled according to Tab. 6.2 in chapter 6.2.4 in EN 1993‑1‑8:2005.

Verification of resistance

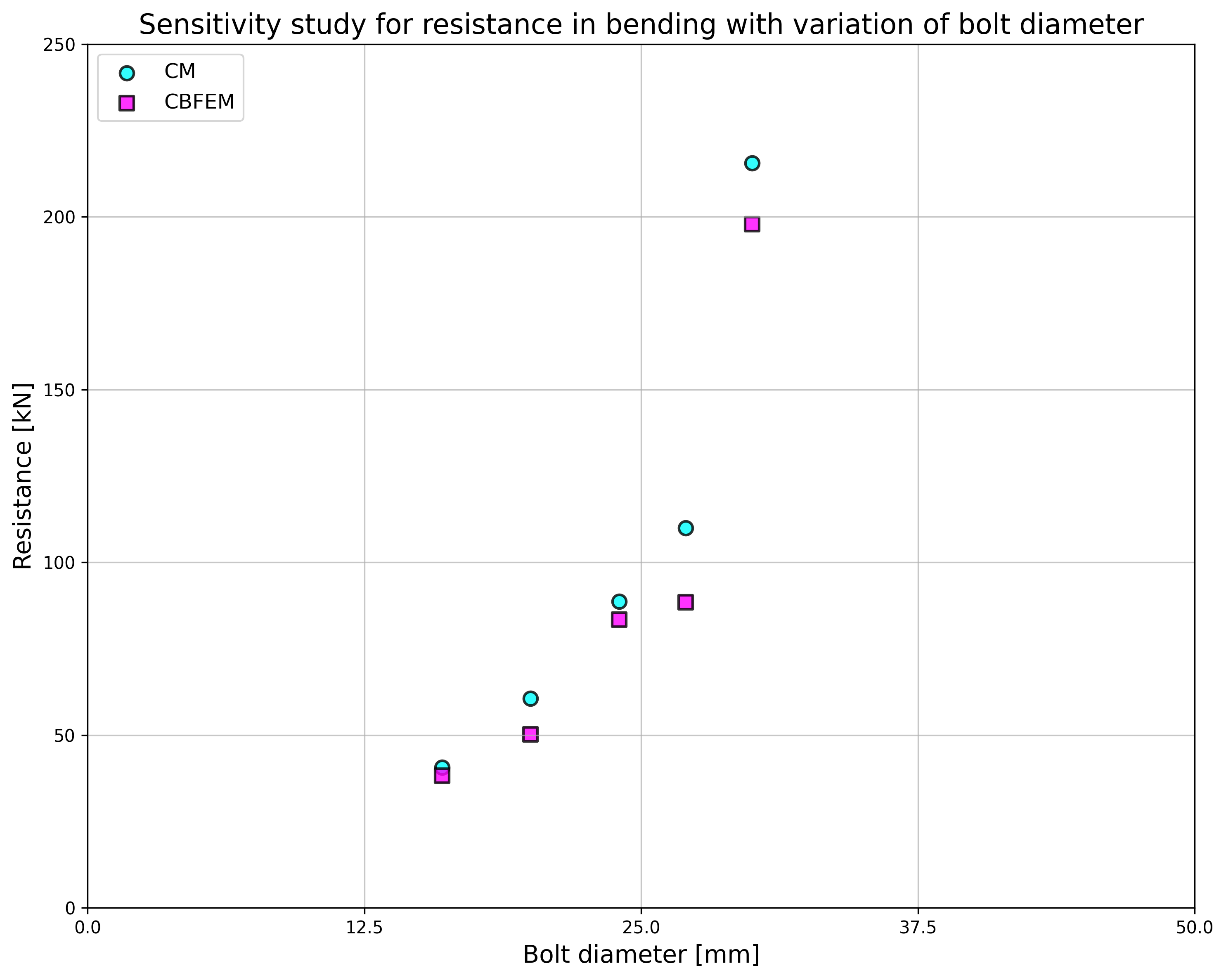

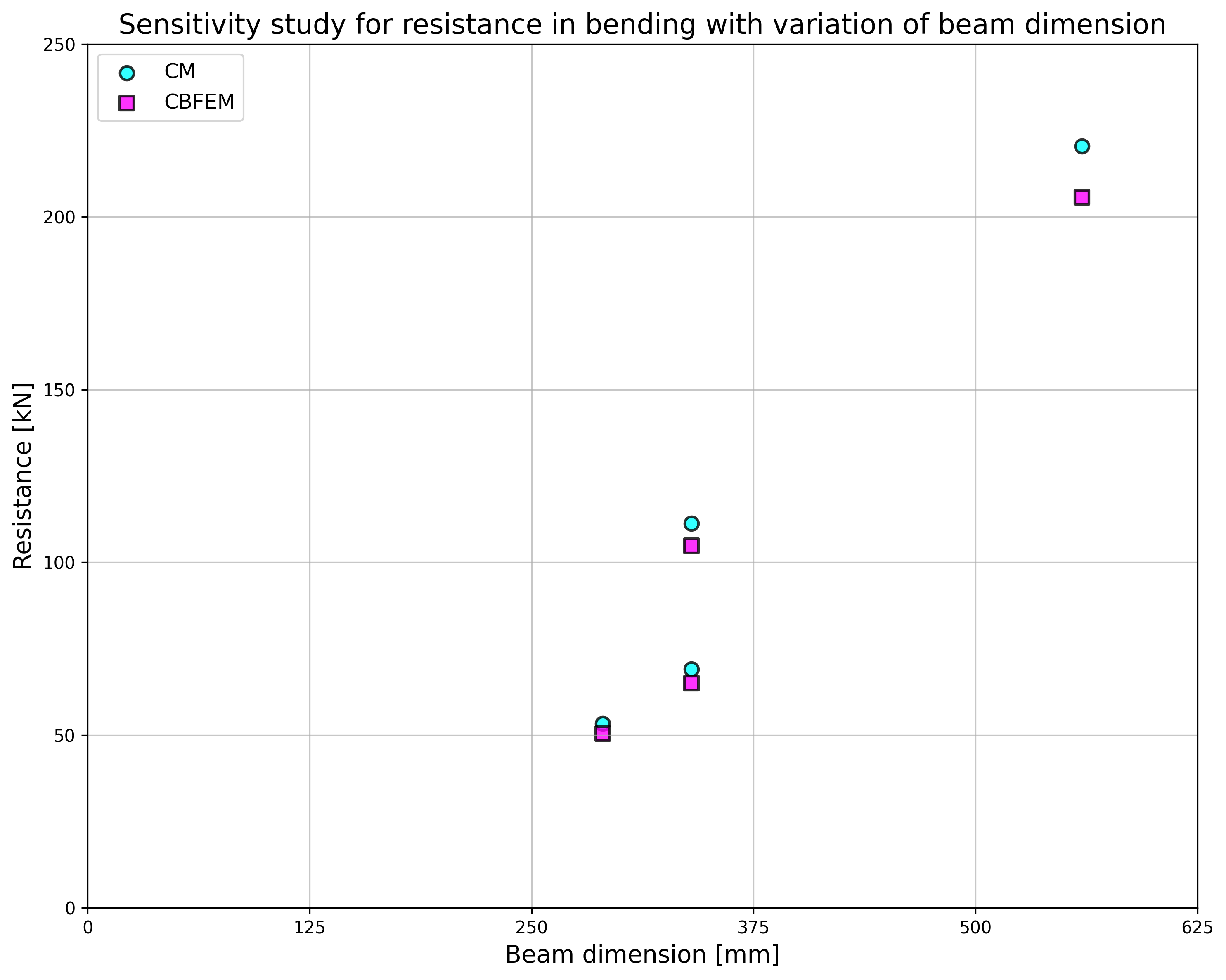

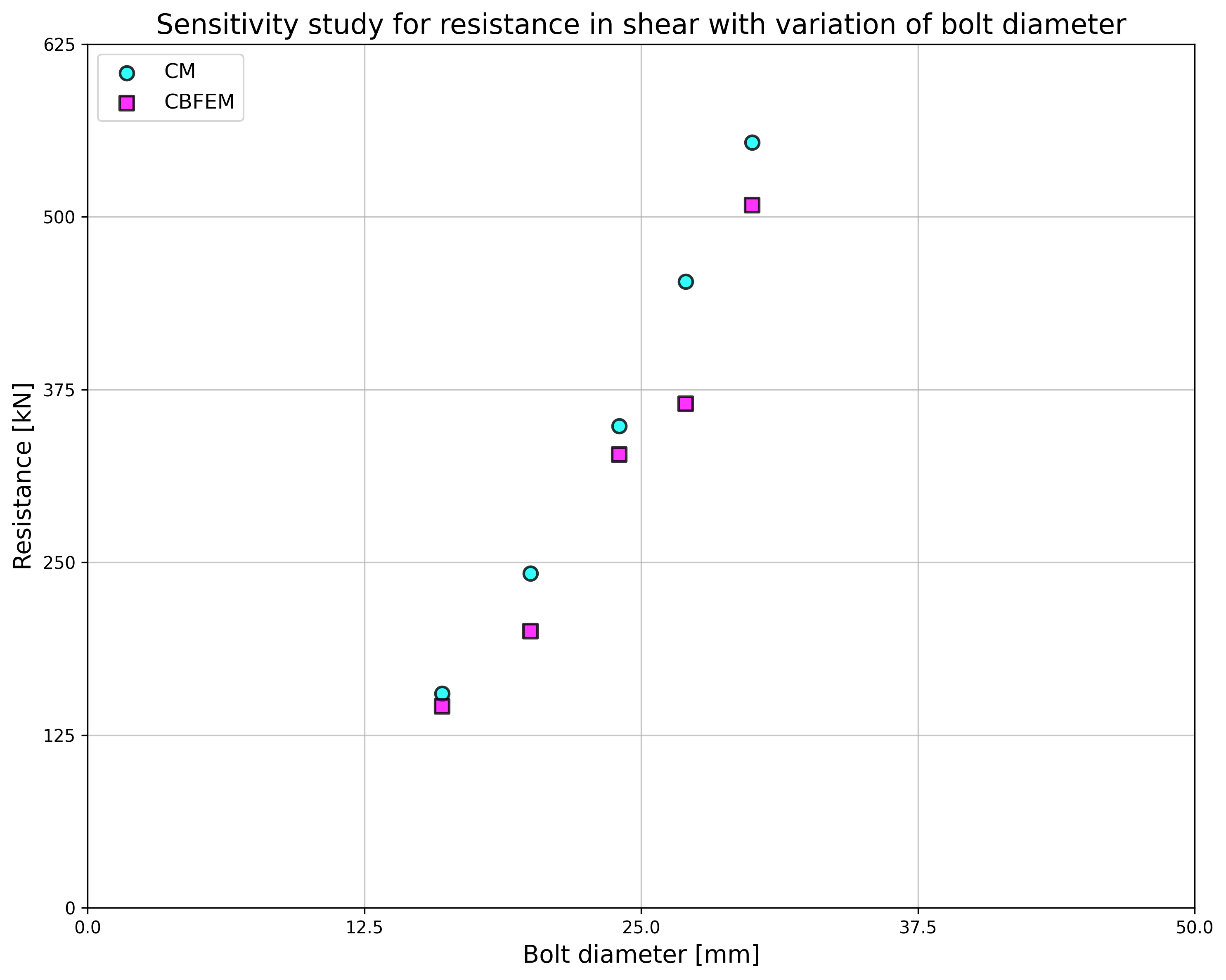

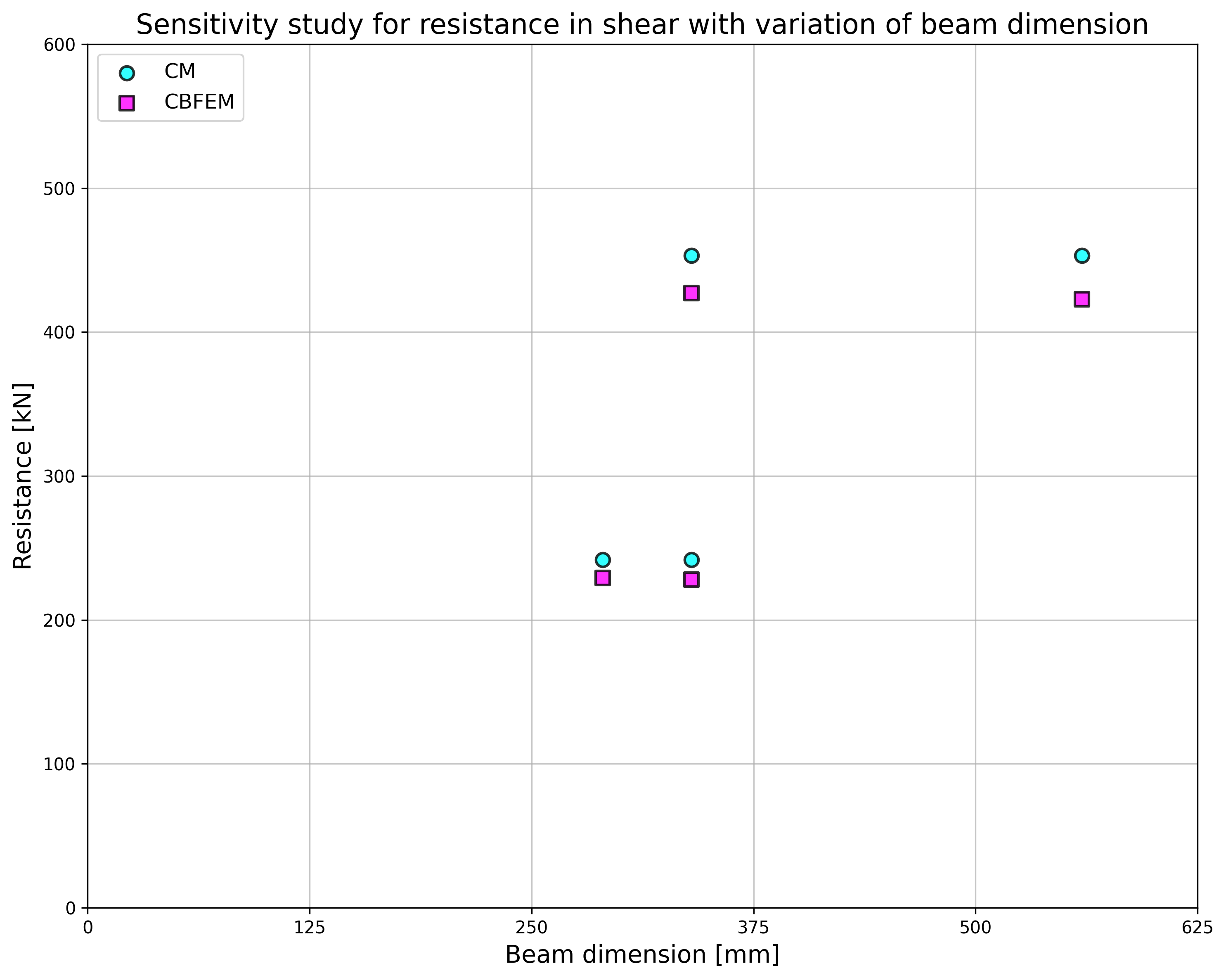

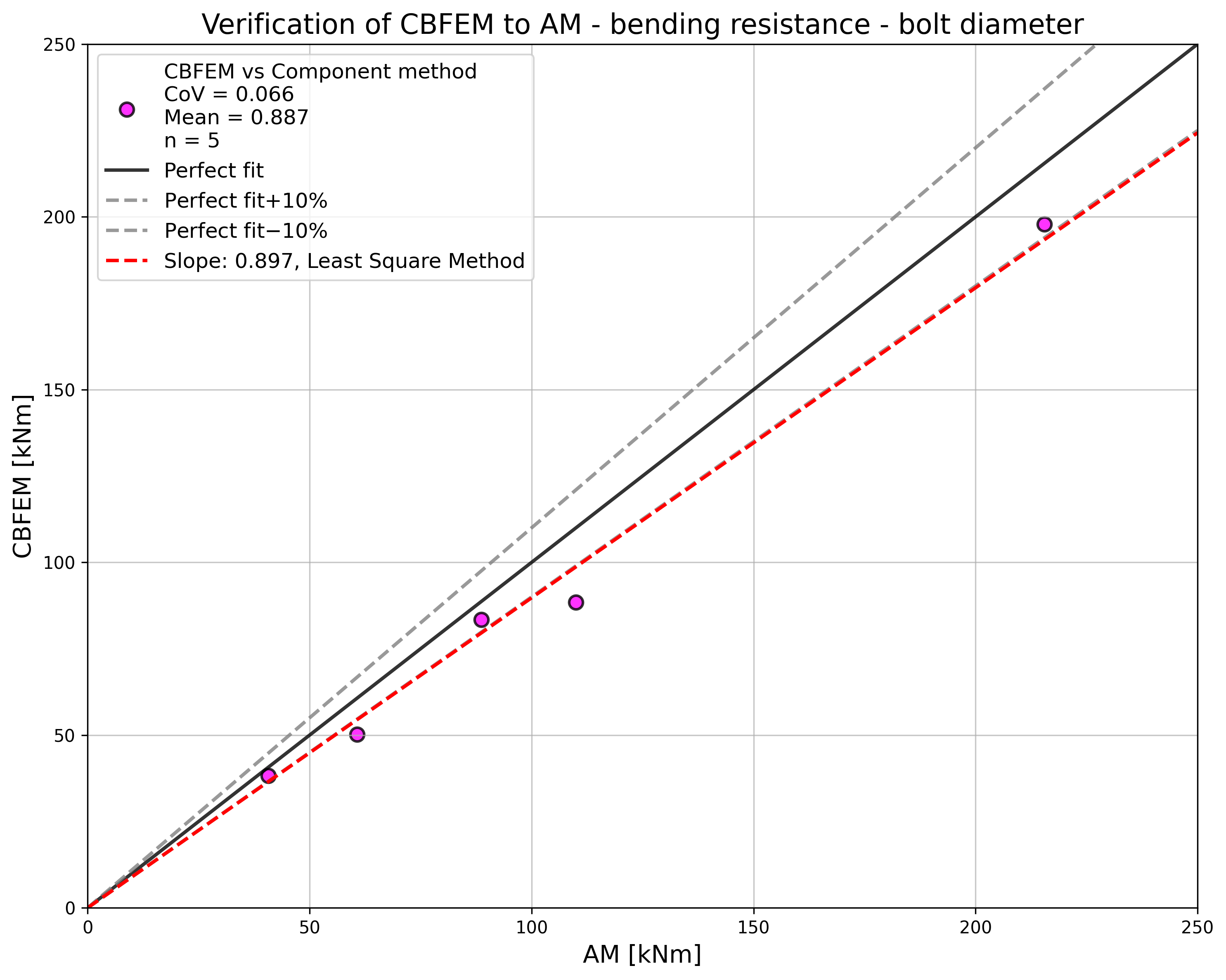

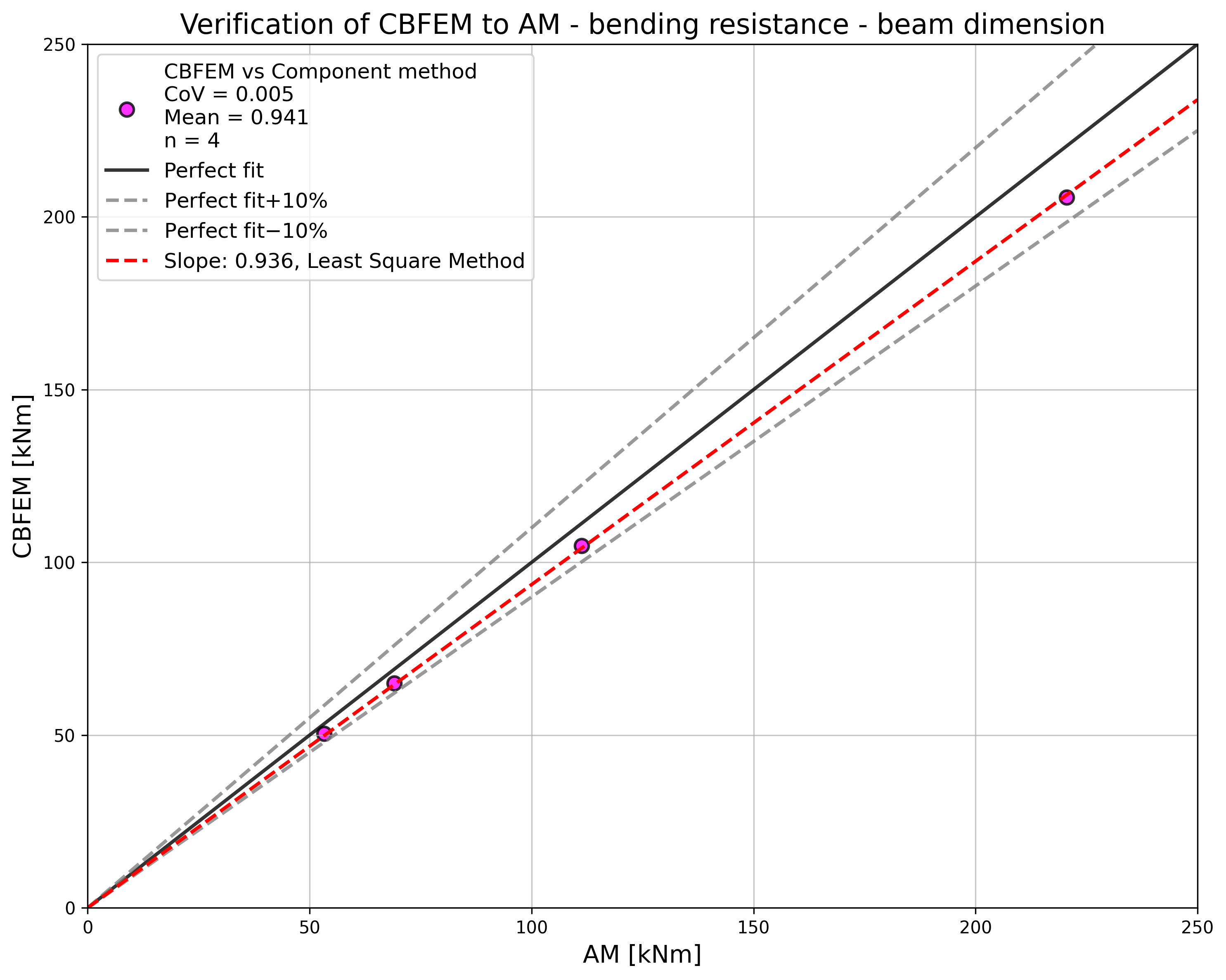

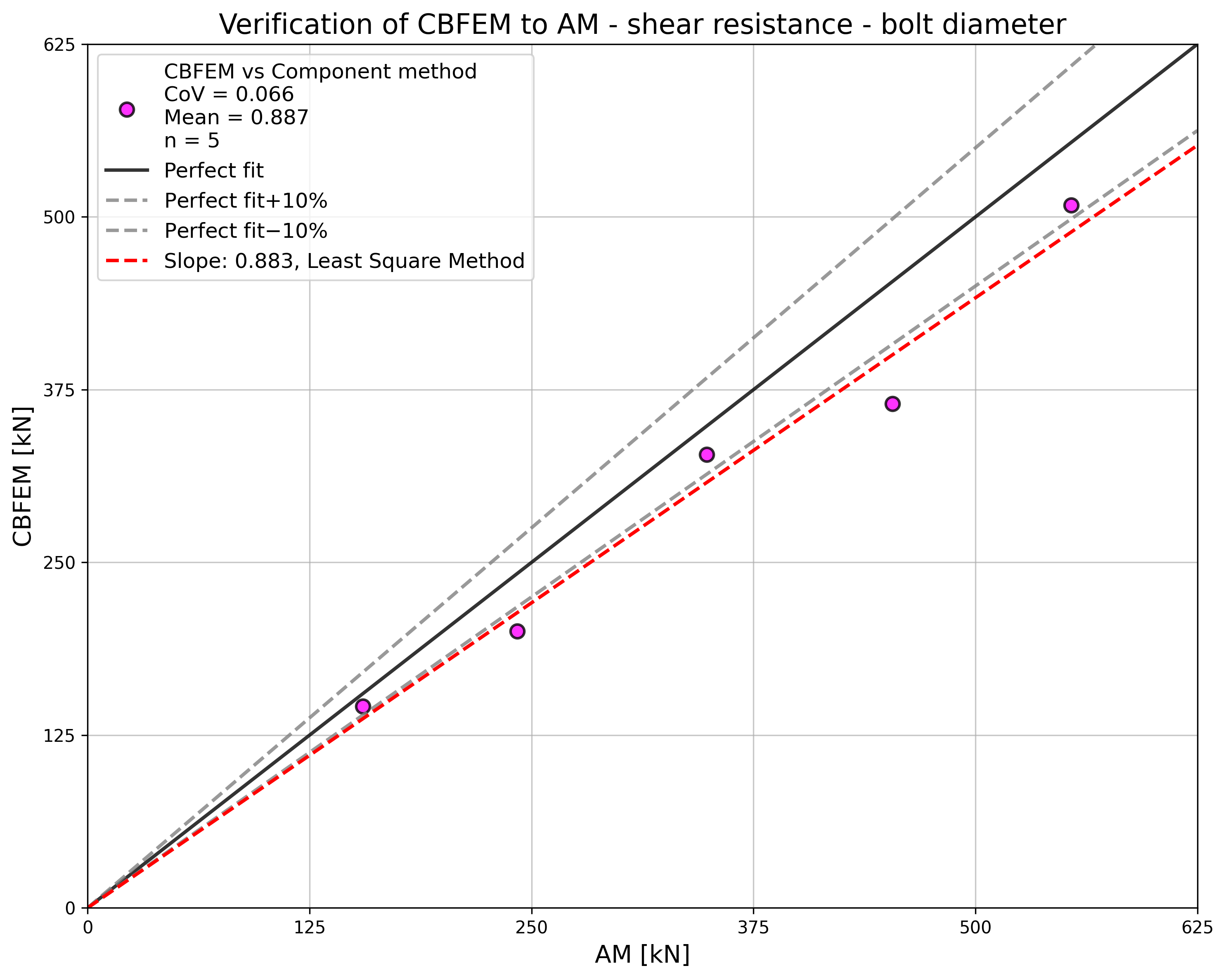

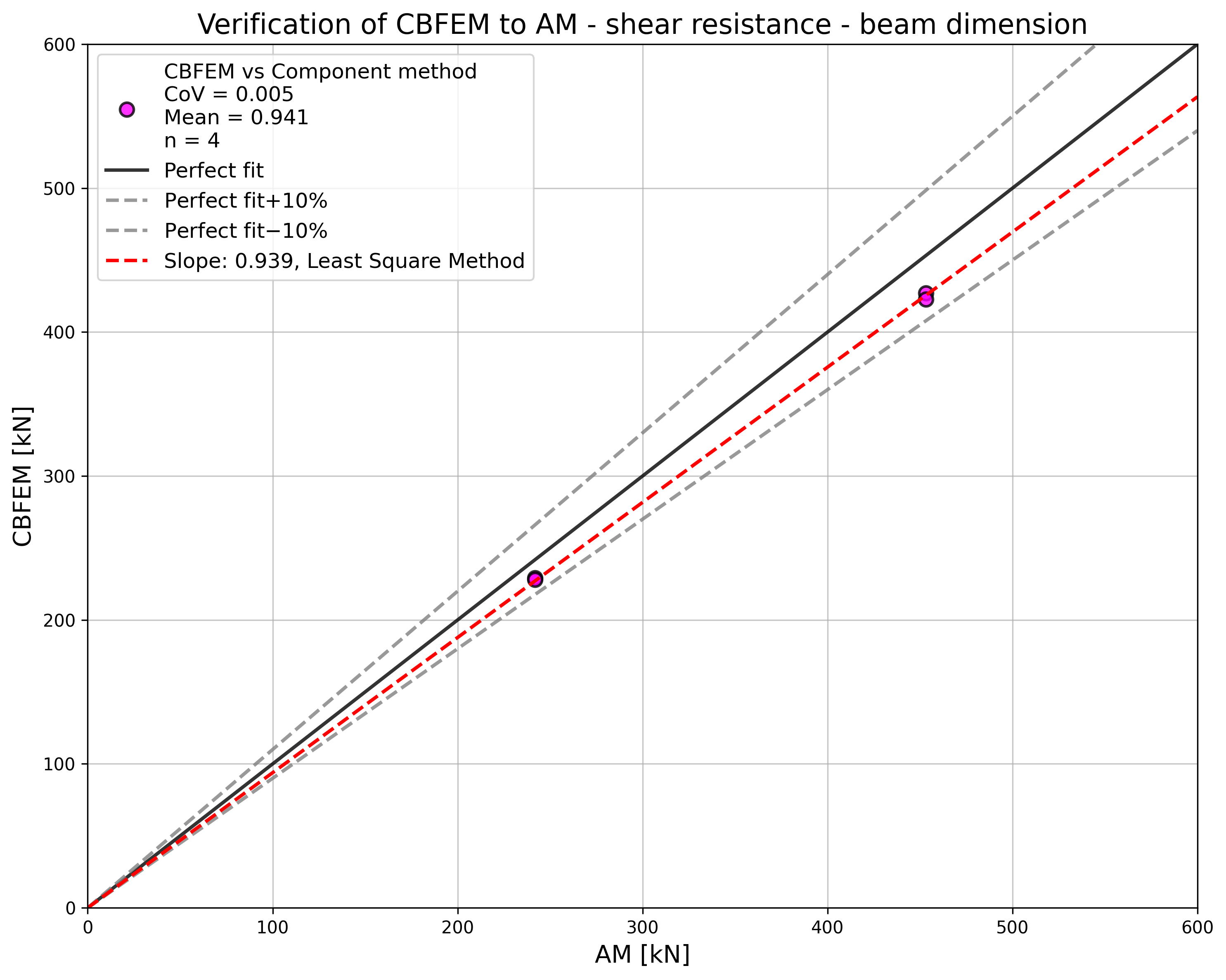

Parameters of the model are a bolt diameter and a beam dimension; see Figs 5.5.2 to 5.5.5. Dimensions of the end plate and the bolt distances are modified to limit the joint resistance by the bolt failure. The shear and bending resistance of the joint is compared in loading at the bolt failure. The results are summarised in Tab. 5.5.1 and 5.5.2.

\[ \textsf{\textit{\footnotesize{Fig. 5.5.2 Sensitivity study for resistance in bending with variation of bolt diameter}}}\]

\[ \textsf{\textit{\footnotesize{Fig. 5.5.3 Sensitivity study for resistance in bending with variation of beam dimension}}}\]

\[ \textsf{\textit{\footnotesize{Fig. 5.5.4 Sensitivity study for resistance in shear with variation of bolt diameter}}}\]

\[ \textsf{\textit{\footnotesize{Fig. 5.5.5 Sensitivity study for resistance in shear with variation of beam dimension}}}\]

Tab. 5.5.1 Sensitivity study for resistance with variation of bolt diameter

| Parameter | AM | CBFEM | AM/CBFEM | |||||

| Beam; end plate | Diameter | Distances | MRd [kNm] | VRd [kN] | MRd [kNm] | VRd [kN] | MRd | VRd |

| IPE270; tp = 30mm; 150×310mm | M16/8.8 | e1 = 60 mm; p1 = 190 mm; w = 90 mm | 41 | 155 | 38 | 146 | 1,06 | 1,06 |

| M20/8.8 | e1 = 70 mm; p1 = 170 mm; w = 90 mm | 61 | 242 | 50 | 200 | 1,21 | 1,21 | |

| HEA300; tp = 40mm; 300×330mm | M24/8.8 | e1 = 85 mm; p1 = 160 mm; w = 150 mm | 89 | 349 | 83 | 328 | 1,06 | 1,06 |

| M27/8.8 | e1 = 95 mm; p1 = 140 mm; w = 150 mm | 110 | 453 | 89 | 365 | 1,24 | 1,24 | |

| HEA500; tp = 40mm; 330×520mm | M30/8.8 | e1 = 160 mm; p1 = 200 mm; w = 150 mm | 216 | 554 | 198 | 509 | 1,09 | 1,09 |

Tab. 5.5.2 Sensitivity study for resistance with variation of the beam dimension

| Parameter | AM | AM | CBFEM | CBFEM | AM/CBFEM | AM/CBFEM | ||

| Beam; fin plate | Diameter | Distances | MRd [kNm] | VRd [kN] | MRd [kNm] | VRd [kN] | MRd | VRd |

| HEA260; tp = 25mm; 260×290mm | M20/8.8 | e1 = 75 mm; p1 = 140 mm; w = 130 mm | 53 | 242 | 50 | 229 | 1,06 | 1,06 |

| IPE300; tp = 30mm; 150×340mm | M20/8.8 | e1 = 70 mm; p1 = 200 mm; w = 90 mm | 69 | 242 | 65 | 228 | 1,06 | 1,06 |

| HEB300; tp = 40mm; 300×340mm | M27/8.8 | e1 = 100 mm; p1 = 140 mm; w = 150 mm | 111 | 453 | 105 | 427 | 1,06 | 1,06 |

| IPE500; tp = 45mm; 220×560mm | M27/8.8 | e1 = 105 mm; p1 = 350 mm; w = 120 mm | 220 | 453 | 206 | 423 | 1,07 | 1,07 |

\[ \textsf{\textit{\footnotesize{Drawing 5.5.1 Joint geometry and dimensions}}}\]

The results of sensitivity studies are summarized in graphs in Fig. 5.5.6 and 5.5.7. The results show that the differences between the two calculation methods are below 10 %. The analytical model gives generally higher resistance.

\[ \textsf{\textit{\footnotesize{Fig. 5.5.6 Verification of CBFEM to AM for the interaction of shear and tension in bolt in case of loading to bending resistance of a joint}}}\]

\[ \textsf{\textit{\footnotesize{Fig. 5.5.7 Verification of CBFEM to AM for the interaction of shear and tension in bolt in case of loading to shear resistance of a joint}}}\]

Benchmark example

Inputs

Connected members

- Steel S355

- Beams HEA300

- End plate thickness tp = 40 mm

- End plate dimensions 300 × 330 mm

Bolts

- 4 × M24 8.8

- Distances e1 = 85 mm; p1 = 160 mm; w1 = 75 mm; w = 150 mm

Outputs

- Design resistance in bending MRd = 93 kNm

- Design resistance in shear VRd = 291 kN

- Collapse mode is bolt failure in interaction of shear and tension

Splices in shear in slip-resistant connection

Description

This study is focused on the verification of component-based finite element method (CBFEM) for the resistance of the symmetrical double splice slip-resistant connection to an analytical model (AM).

Analytical model

The slip resistance of a preloaded bolt is designed according to chapter 3.9.1 in EN 1993-1-8:2005. The preloading force is taken at 70 % of the ultimate strength of a bolt according to equation (3.7).

Verification of resistance

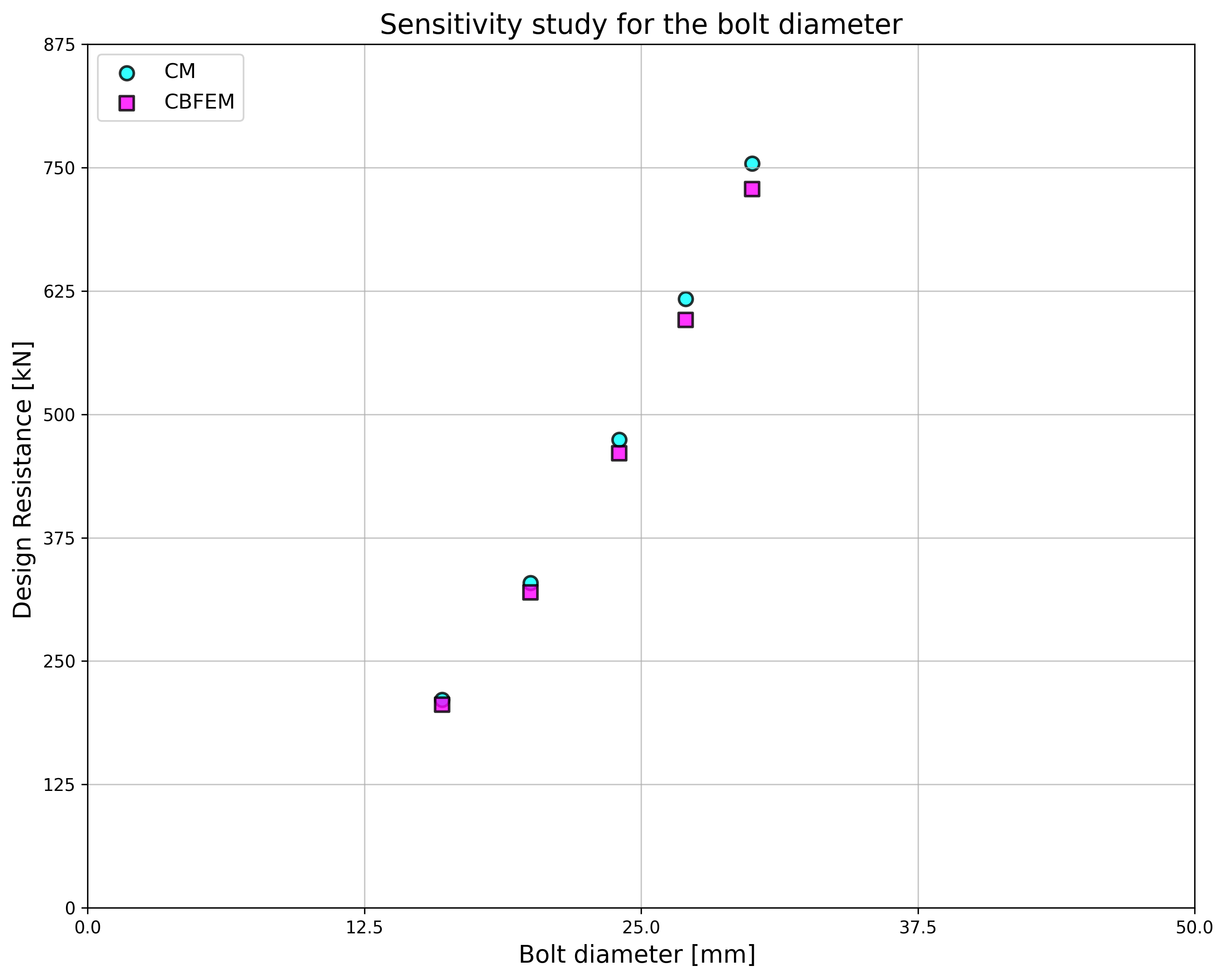

Design resistances calculated by CBFEM are compared with the results of analytical model (AM); see (Wald et al. 2018). The results are summarized in Tab. 5.5.1. The parameter is bolt diameter; see Fig. 5.5.1.

\[ \textsf{\textit{\footnotesize{Drawing 5.5.1 Joint geometry and dimensions}}}\]

Tab. 5.5.1 Comparison of bolt resistance predicted by FE model to analytical one for bolt diameter; joint: splice 200/12 mm, bolts 2 × M× 8.8, plates 2 × 200/20 mm, steel S235

| Parameter | Analytical Model (AM) | CBFEM | AM/ CBFEM | |||

| Diam. | Distances | Resist. [kN] | Critical component | Resist. [kN] | Critical component | |

| M16 | p = 55 e1 = 40 | 211 | Slip | 205 | Slip | 1,03 |

| M20 | p = 70 e1= 50 | 329 | Slip | 320 | Slip | 1,03 |

| M24 | p = 80 e1 = 60 | 474 | Slip | 463 | Slip | 1,02 |

| M27 | p = 90 e1 = 70 | 617 | Slip | 596 | Slip | 1,04 |

| M30 | p = 100 e1 = 75 | 754 | Slip | 728 | Slip | 1,04 |

\[ \textsf{\textit{\footnotesize{Fig. 5.5.1 Sensitivity study for the bolt diameter}}}\]

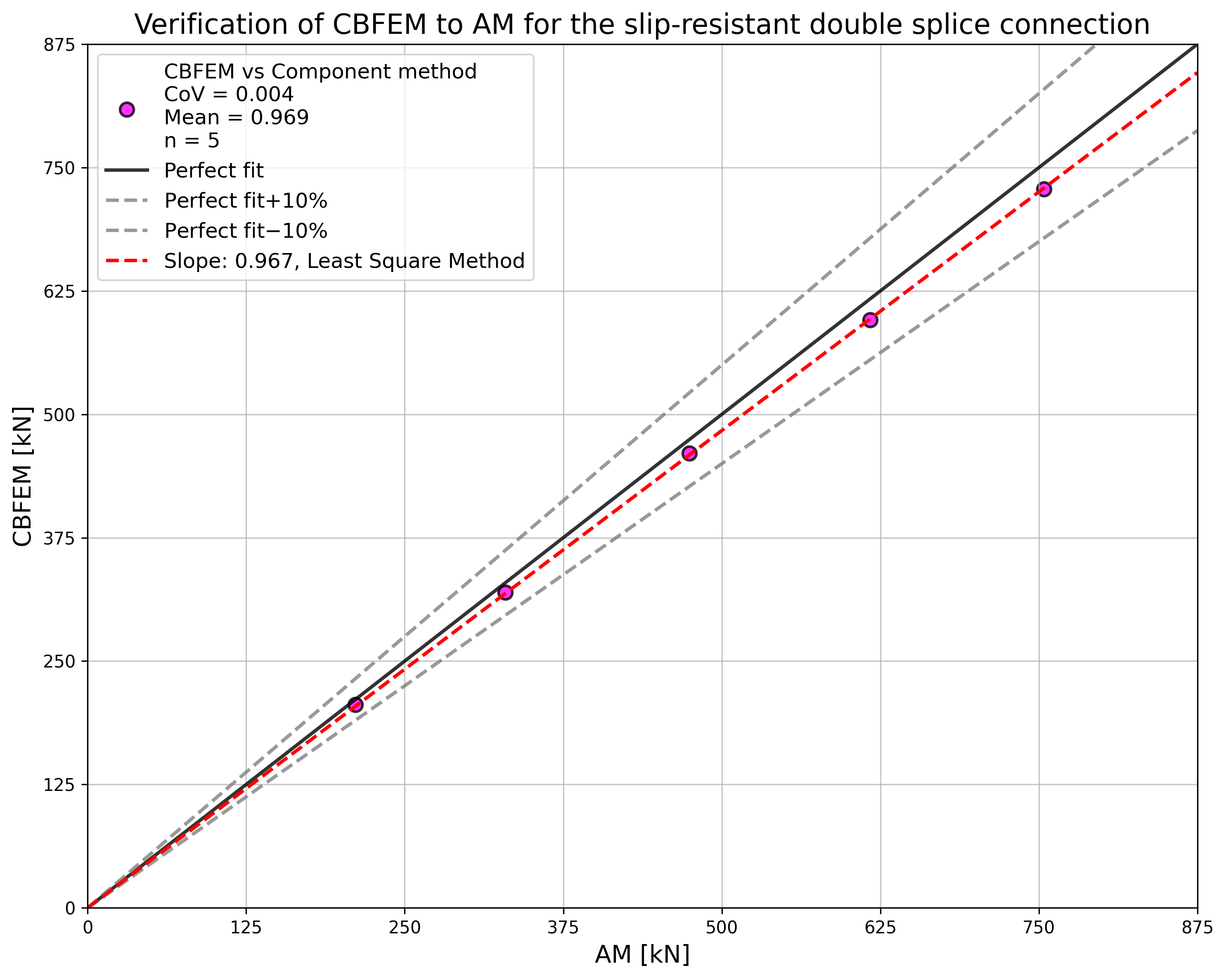

The results of sensitivity studies are summarized in the graph in Fig. 5.5.2. The results show that the differences between the two calculation methods are below 5 %. Analytical model gives generally higher resistance.

\[ \textsf{\textit{\footnotesize{Fig. 5.5.2 Verification of CBFEM to AM for the slip-resistant double splice connection}}}\]

Benchmark example

Inputs

Connected member

- Steel S235

- Splice 200×12 mm

Connectors

Bolts

- 3 × M20 8.8

- Distances e1 = 50 mm, p = 70 mm

Two splices

- Steel S235

- Plate 480×200×20 mm

Code setup

- Friction coefficient in slip-resistance 0.5

Outputs

- Design resistance FRd = 320 kN

- Design failure mode is slip of the bolts

\[ \textsf{\textit{\footnotesize{Fig. 5.5.3 Benchmark example of the bolted splices in shear}}}\]

Block shear resistance

Description

This chapter is focused on the verification of component-based finite element method (CBFEM) for the resistance of block shear resistance of bolted connection loaded in shear to the validated research-oriented finite element model (ROFEM) and major analytical models (AM).

Analytical model

There are several analytical models for block shear resistance of bolted connection. The models from codes EN 1993-1-8:2005, EN 1993-1-8:2020, AISC 360-10, and CSA S16-9 are investigated. Furthermore, analytical models by Driver et al. (2005) and Topkaya et al. (2004) are used in comparison.

\[V_{\mathrm{eff,1,Rd}} = \frac{f_\mathrm{u} A_\mathrm{nt}}{\gamma_\mathrm{M2}} + \left(\frac{1}{\sqrt{3}}\right)\frac{f_\mathrm{y} A_\mathrm{nv}}{\gamma_\mathrm{M0}}\]

\[V_{\mathrm{eff,2,Rd}} = 0.5 \cdot \frac{f_\mathrm{u} A_\mathrm{nt}}{\gamma_\mathrm{M2}} + \left(\frac{1}{\sqrt{3}}\right) \frac{f_\mathrm{y} A_\mathrm{nv}}{\gamma_\mathrm{M0}}\]

\[V_{\mathrm{eff,1,Rd}} =\left[A_\mathrm{nt} f_\mathrm{u} + \min \left(\frac{A_\mathrm{gv} \cdot f_\mathrm{y}}{\sqrt{3}} \; ; \;\frac{A_\mathrm{nv} f_\mathrm{u}}{\sqrt{3}}\right)\right] \bigg/ \gamma_\mathrm{M2}\]

\[V_{\mathrm{eff,2,Rd}} =\left[0.5 A_\mathrm{nt} f_\mathrm{u} + \min \left(\frac{A_\mathrm{gv} \cdot f_\mathrm{y}}{\sqrt{3}}\;;\;\frac{A_\mathrm{nv} f_\mathrm{u}}{\sqrt{3}}\right)\right] \bigg/ \gamma_\mathrm{M2}\]

\[\varphi R_\mathrm{n} =\varphi \left(0.6 f_u A_\mathrm{nv} + U_\mathrm{bs} f_\mathrm{u} A_\mathrm{nt}\right)\leq 0.6 f_\mathrm{y} A_\mathrm{gv} + U_\mathrm{bs} f_\mathrm{u} A_\mathrm{nt}\]

\[T_\mathrm{r} =\varphi_\mathrm{u} \left[U_t A_\mathrm{nt} f_\mathrm{u} + 0.6 A_\mathrm{gv} \frac{f_\mathrm{y} + f_\mathrm{u}}{2} \right]\]

where:

\(f_\mathrm{y}\) - yield strength

\(f_\mathrm{u}\) - ultimate strength

\(\gamma_{\mathrm{M2}}\), \(\varphi_\mathrm{u}\), \(\varphi\) - safety factors

For \(A_\mathrm{nt}\), \(A_\mathrm{nv}\), \(A_\mathrm{gv}\) see Fig. 5.6.1.

\[ \textsf{\textit{\footnotesize{Fig. 5.6.1 Failure planes during the block shear failure}}}\]

Validation and verification of resistance

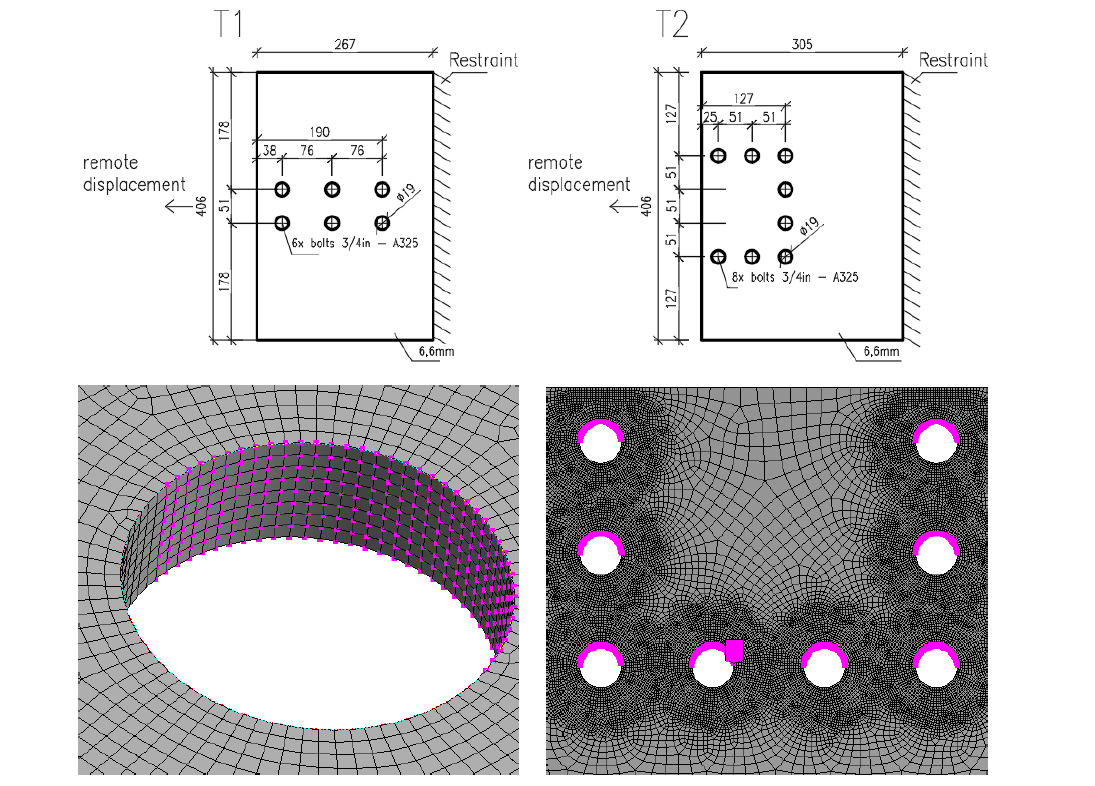

The experiments by Huns et al. (2002) are used for validation of ROFEM created by Sekal (2019) in ANSYS software, see Fig. 5.6.2. True stress-strain material diagram is used. Only the thinnest plate meant to fail are modeled. Bolts are simplified as only bearing displacements on the half-circle of the bolt hole. The displacements in all holes are coupled. The ROFEM model shows very good agreement with the test results.

\[ \textsf{\textit{\footnotesize{Fig. 5.6.2 ROFEM with fine mesh of the specimens tested by Huns et al. (Sekal, 2019)}}}\]

Design-oriented CBFEM model uses shell elements with rather coarse mesh. The mesh is predefined near bolt holes. Bolts are modeled as nonlinear springs which are connected to the nodes at the edges of the bolt’s holes by links. The bilinear material diagram with negligible strain-hardening is used for plates. The limit resistance of a group of bolts in bearing is determined when the plastic strain at the plate reaches 5 % (EN 1993-1-5: 2005). The bearing and hole tear-out resistances of each individual bolt are checked by formulas in appropriate code.

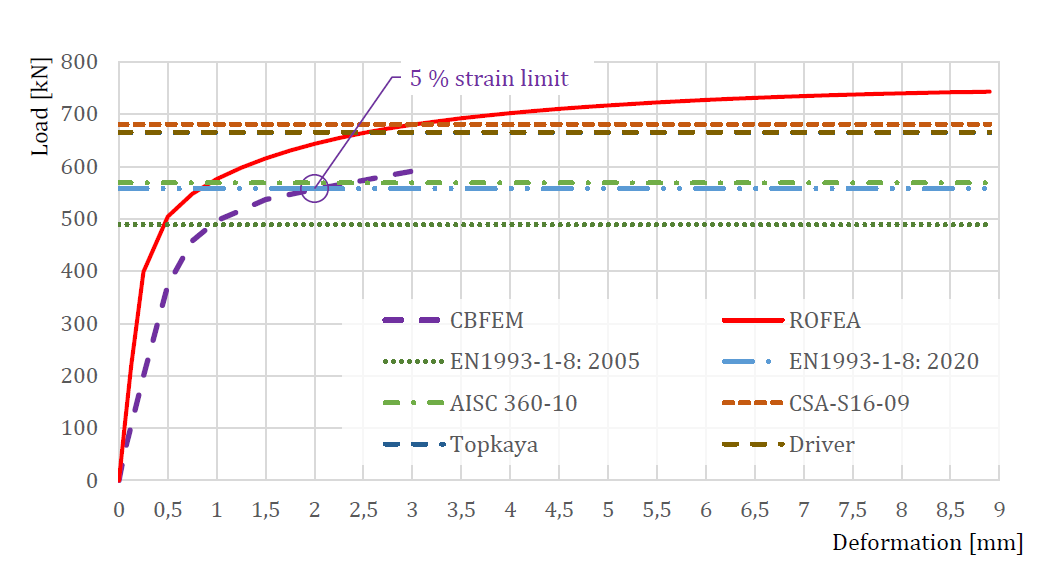

\[ \textsf{\textit{\footnotesize{Fig. 5.6.3 Comparison of specimen T2 tested by Huns et al. (Sekal, 2019)}}}\]

The comparison of ROFEM, CBFEM, and analytical models is shown in Fig. 5.6.3. The most conservative is the model in EN 1993-1-8: 2005 because, unlike other models, it uses the net shear plane in combination with yield strength. Yielding in the gross shear plane is observed in experiments and numerical models. In the next generation of prEN 1993-1-8:2022, the formula for block shear resistance will be changed. The stiffness of CBFEM model is lower compared to ROFEM. In the experiments, the holes were drilled with the same diameter as bolts, so there was no initial slip. The ROFEM model also disregards any slip, but in CBFEM, the shear model of bolts is approximated with the assumption of the regular bolt holes.

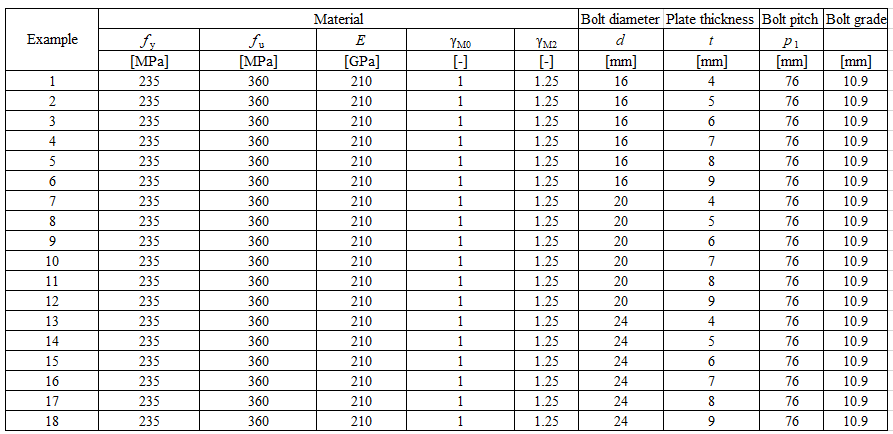

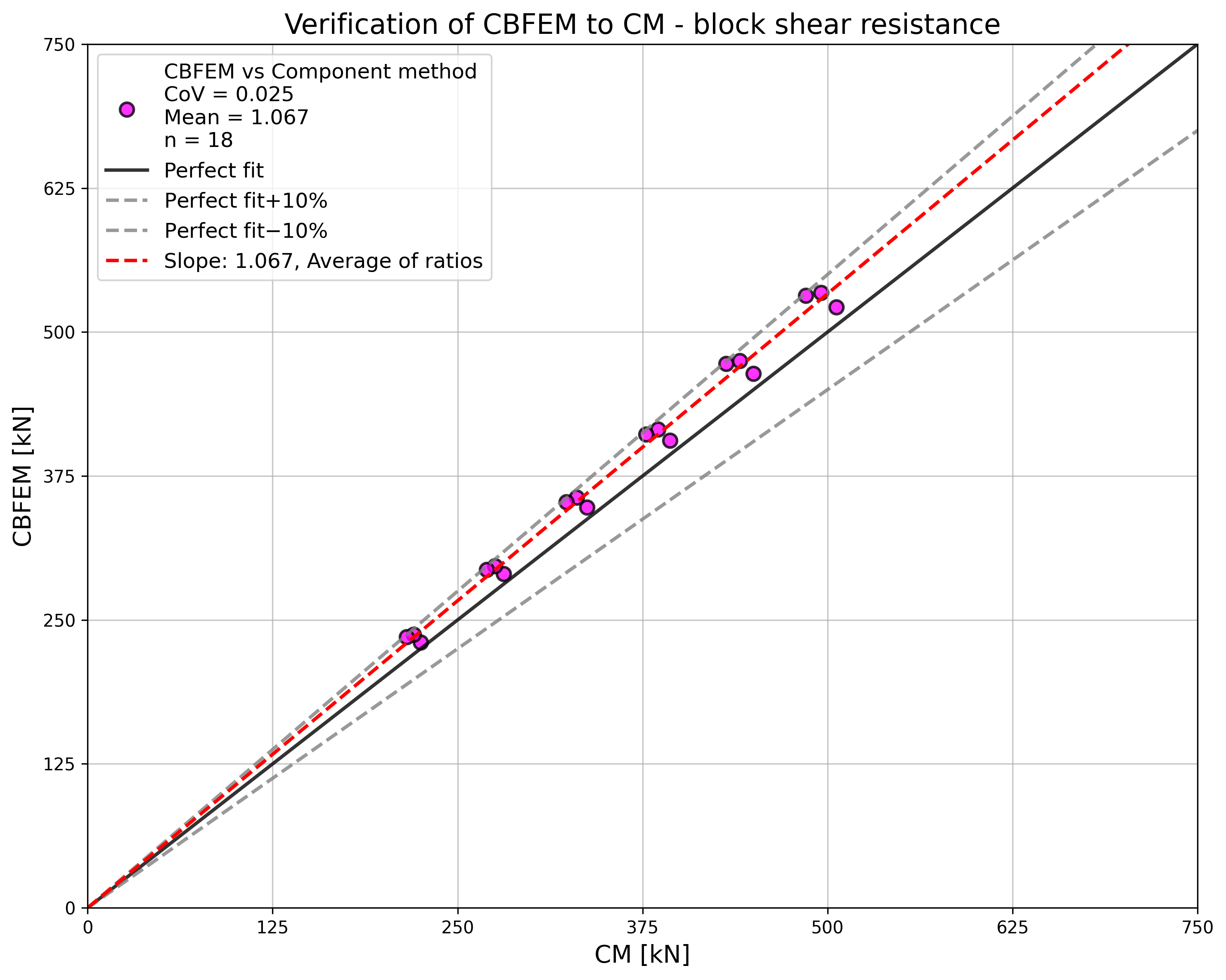

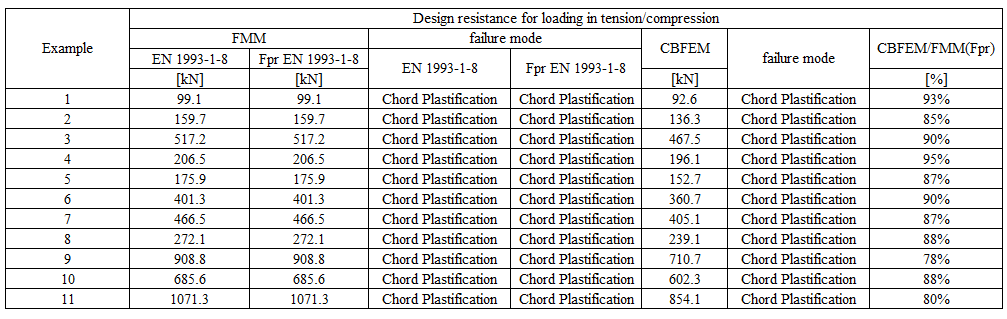

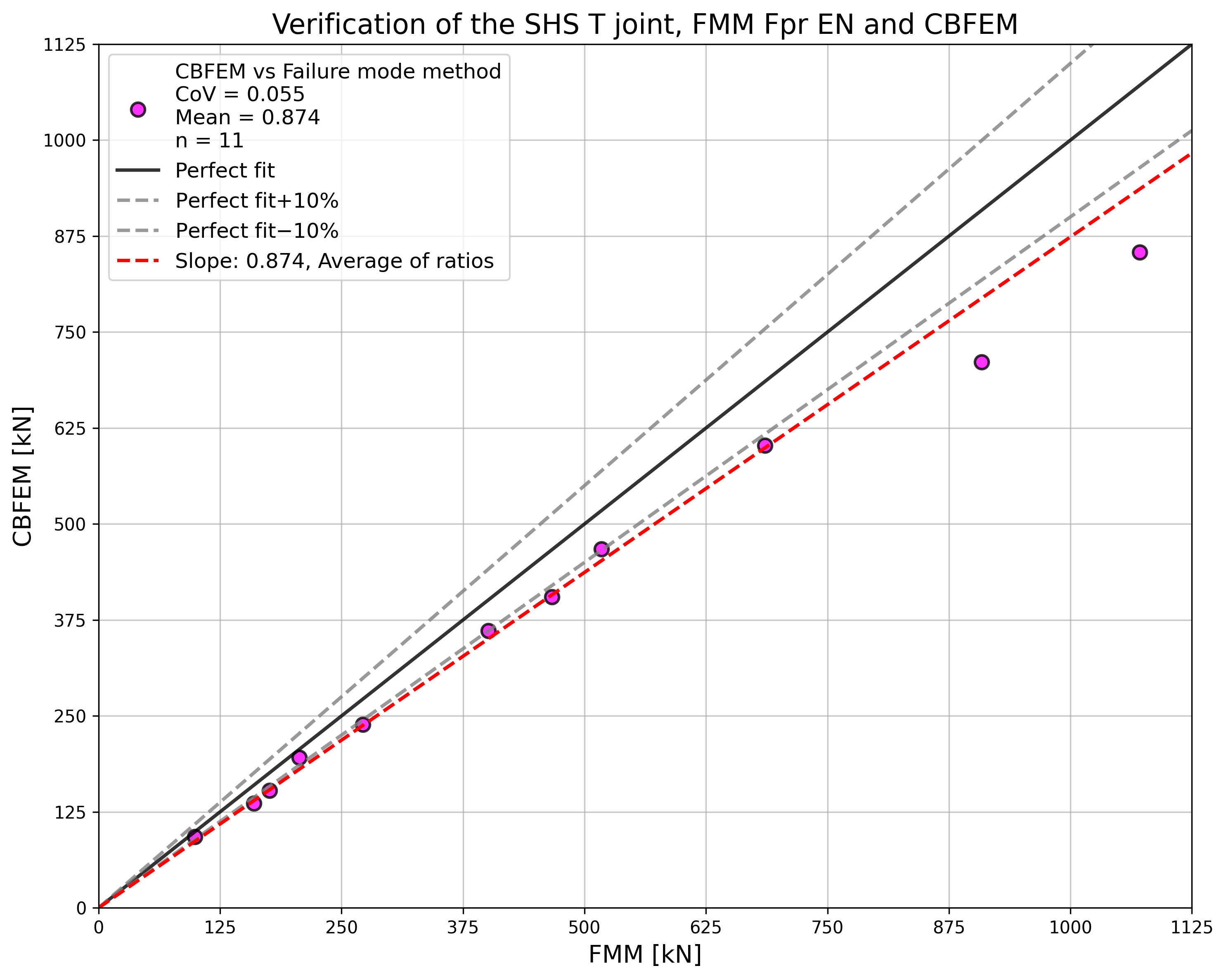

Sensitivity study

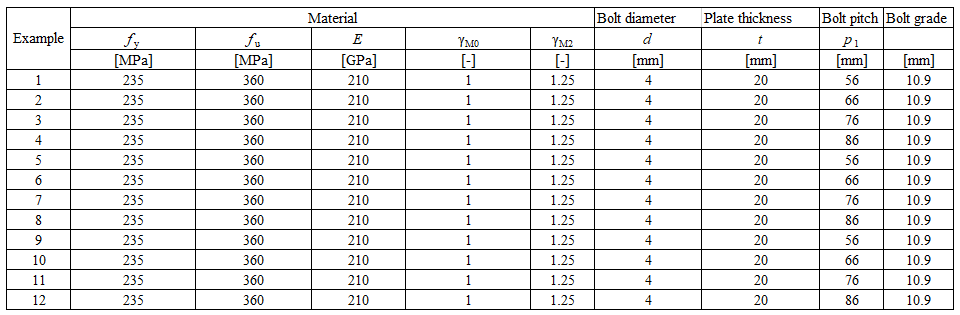

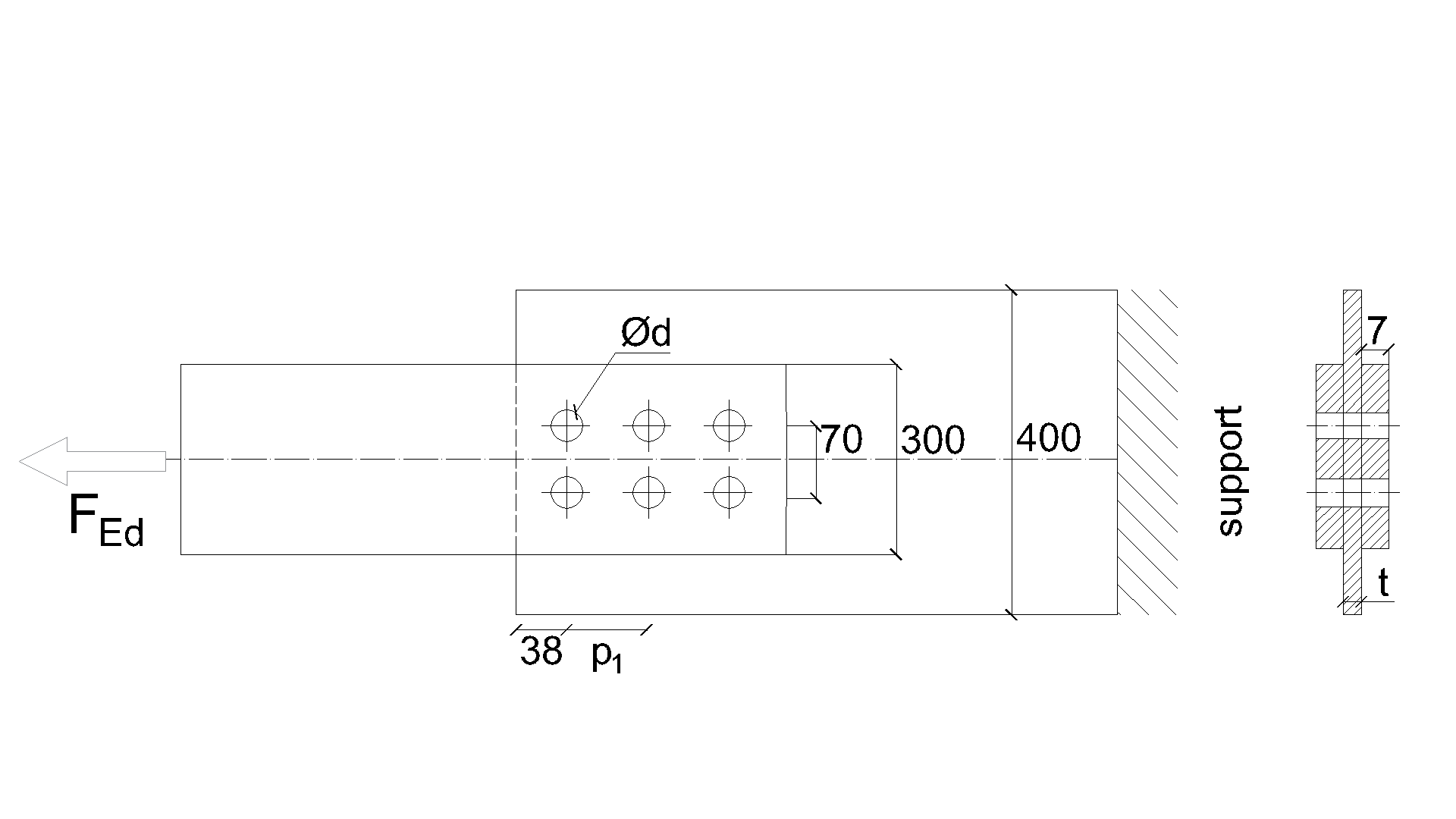

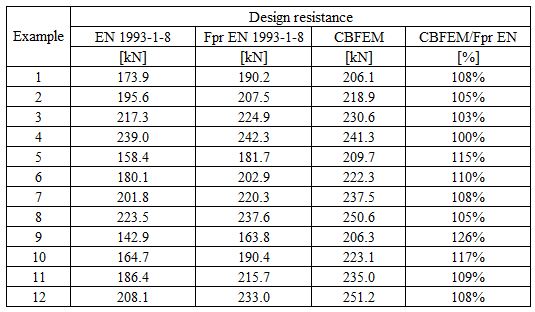

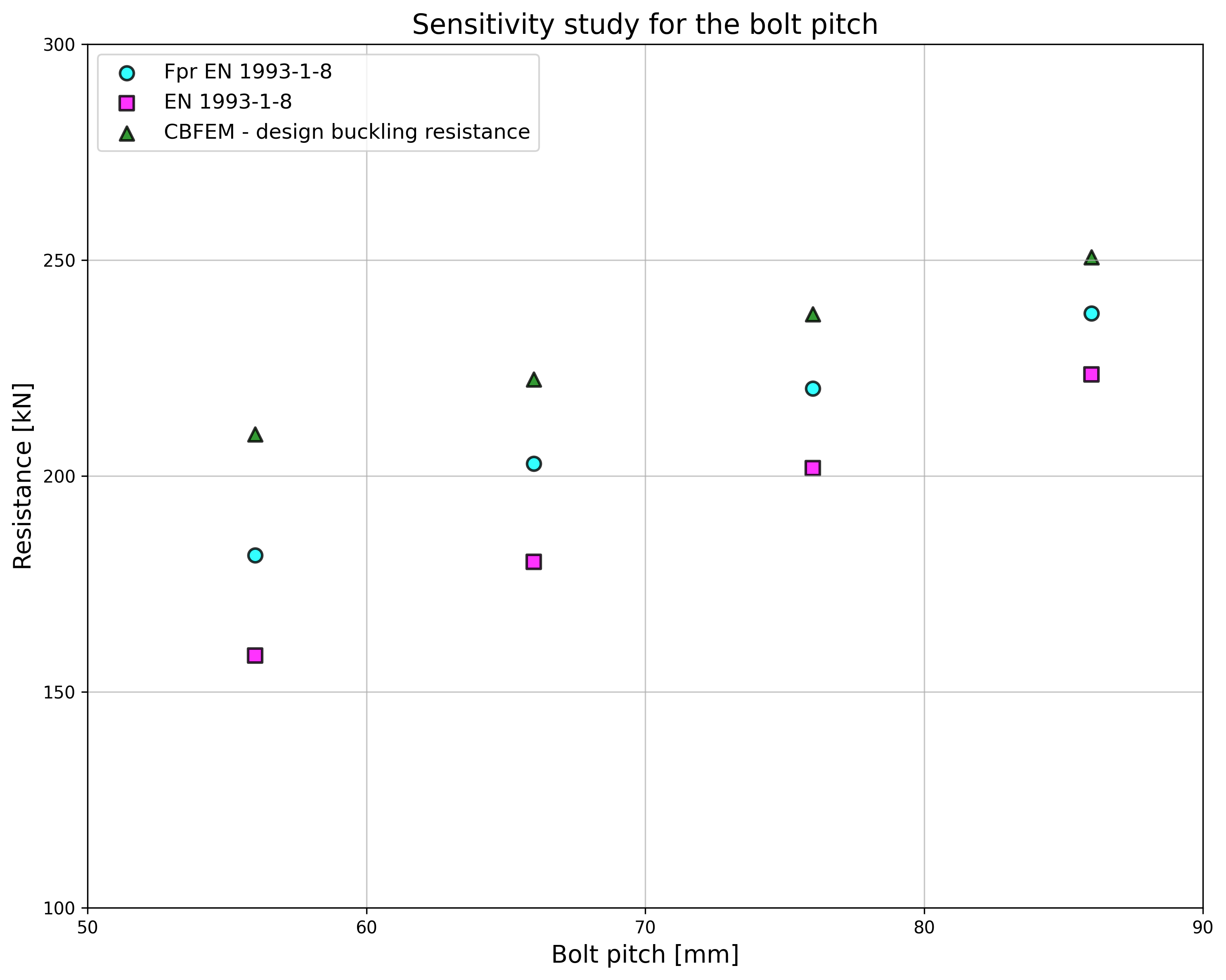

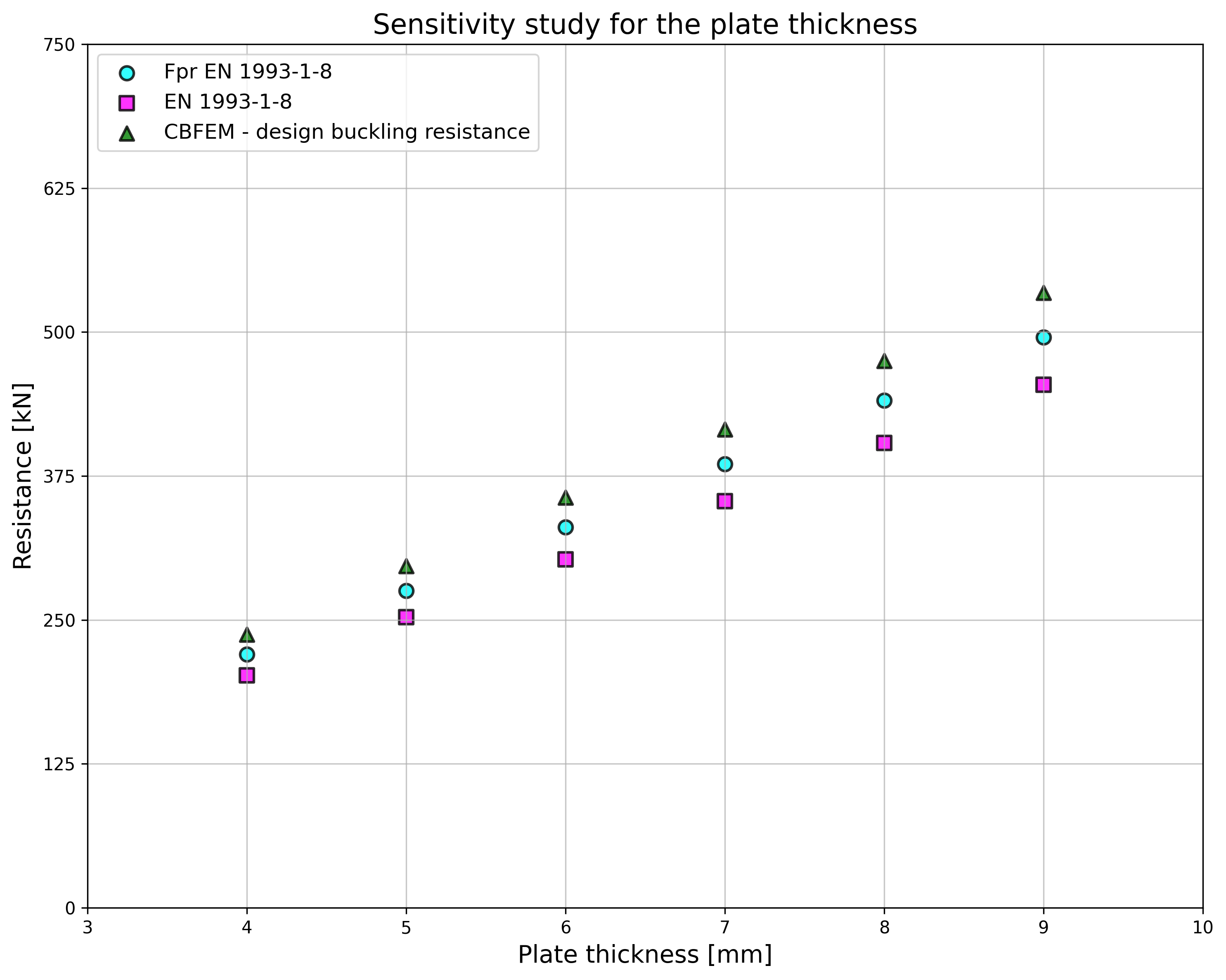

Specimen T1 was used for the study how bolt pitch, Fig. 5.6.4, and plate thickness, Fig. 5.6.6, affects the block shear resistance. The models provide expected results. Tables 5.6.1 and 5.6.2 show examples overview. Drawing 5.6.1 shows joint geometry ang dimensions. Results of verification are shown in Tables 5.6.3 and 5.6.4 and in Fig. 5.6.5. , Fig. 5.6.7.

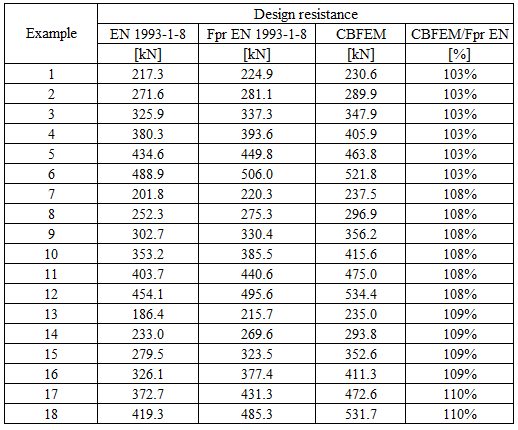

Table 5.6.1 Examples overview. Effect of bolt pitch

Table 5.6.2 Examples overview. Effect of plate thickness

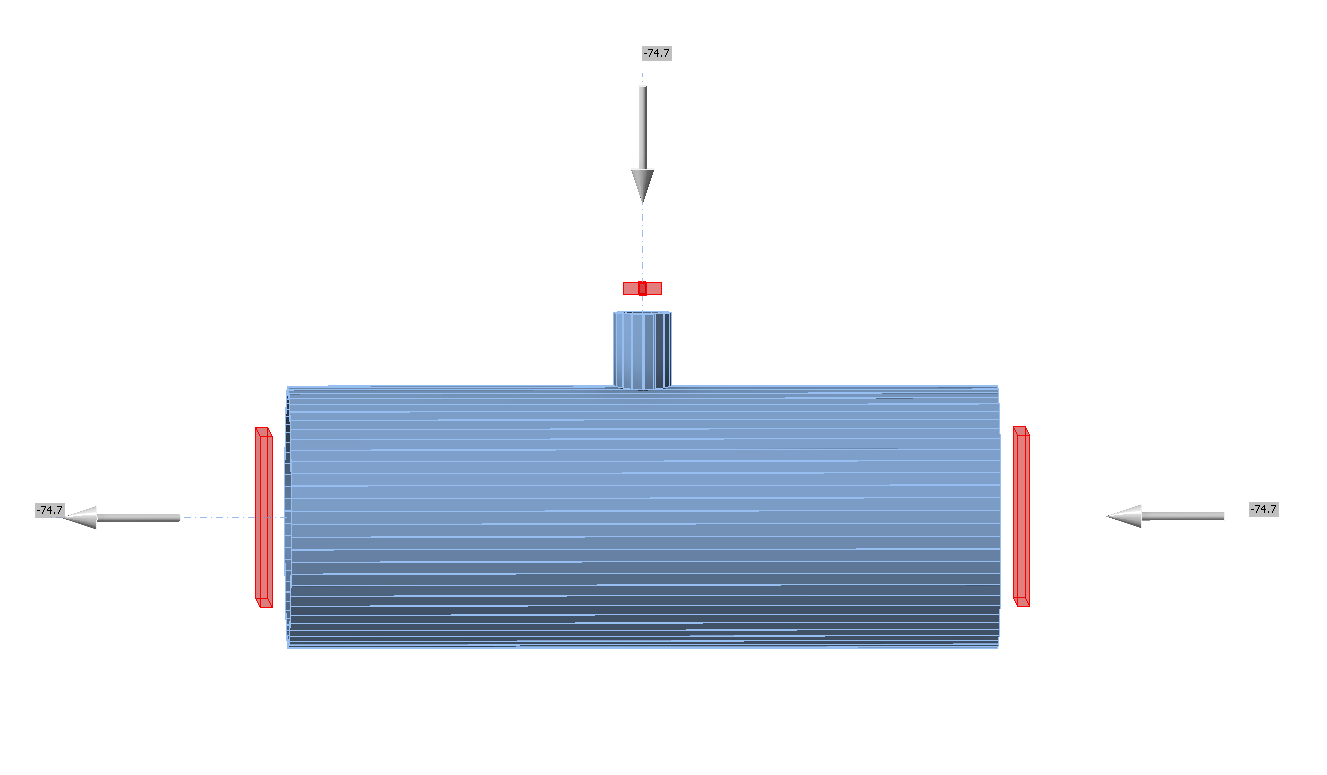

\[ \textsf{\textit{\footnotesize{Drawing 5.6.1 Joint geometry and dimensions}}}\]

Effect of bolt pitch

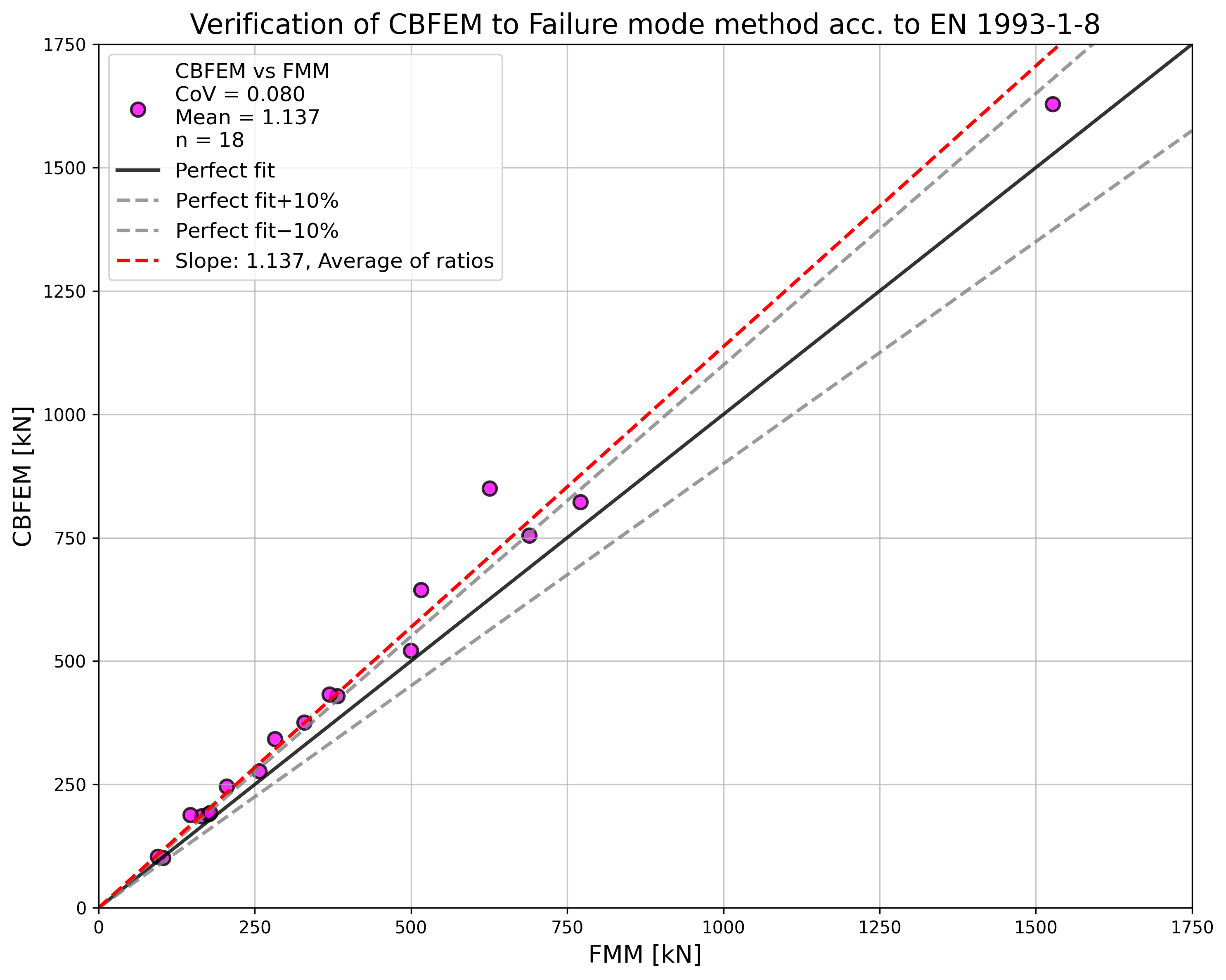

Table 5.6.3 Comparison of results of design resistances predicted by CBFEM, EN 1993-1-8 and Fpr EN 1993-1-8. Effect of bolt pitch

\[ \textsf{\textit{\footnotesize{Fig. 5.6.4 Effect of bolt pitch}}}\]

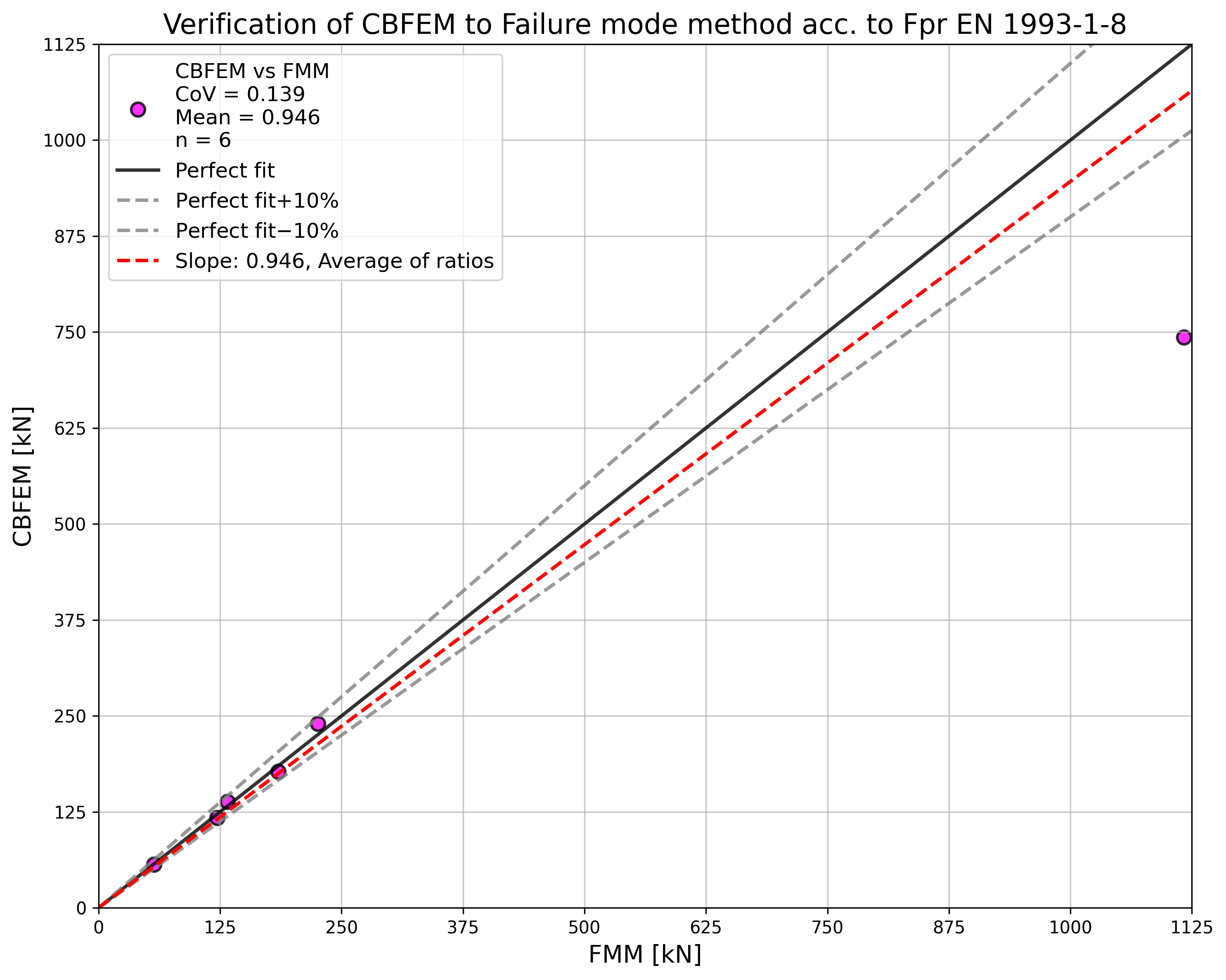

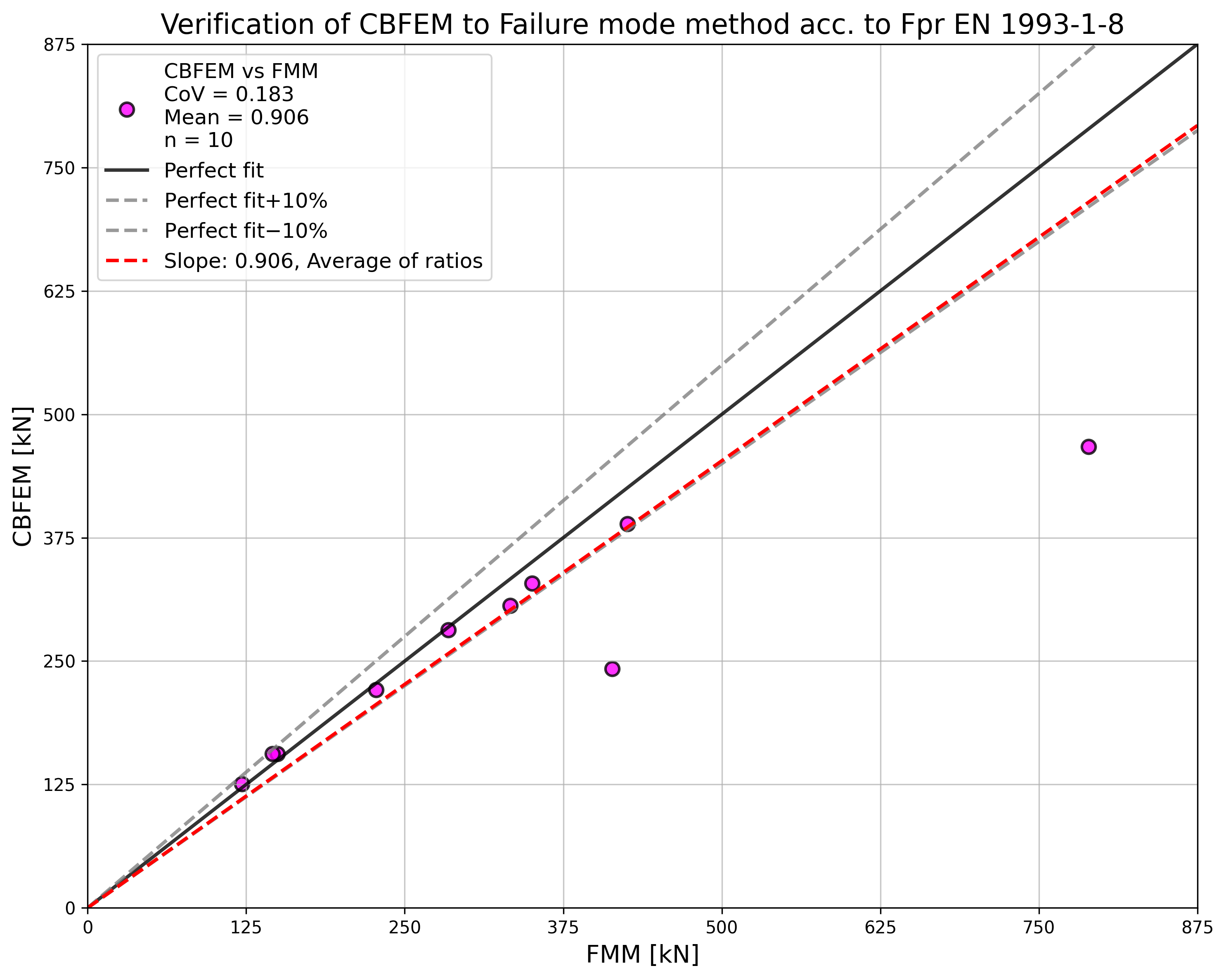

\[ \textsf{\textit{\footnotesize{Fig. 5.6.5 Verification of resistance determined by CBFEM to Fpr EN 1993-1-8}}}\]

Effect of plate thickness

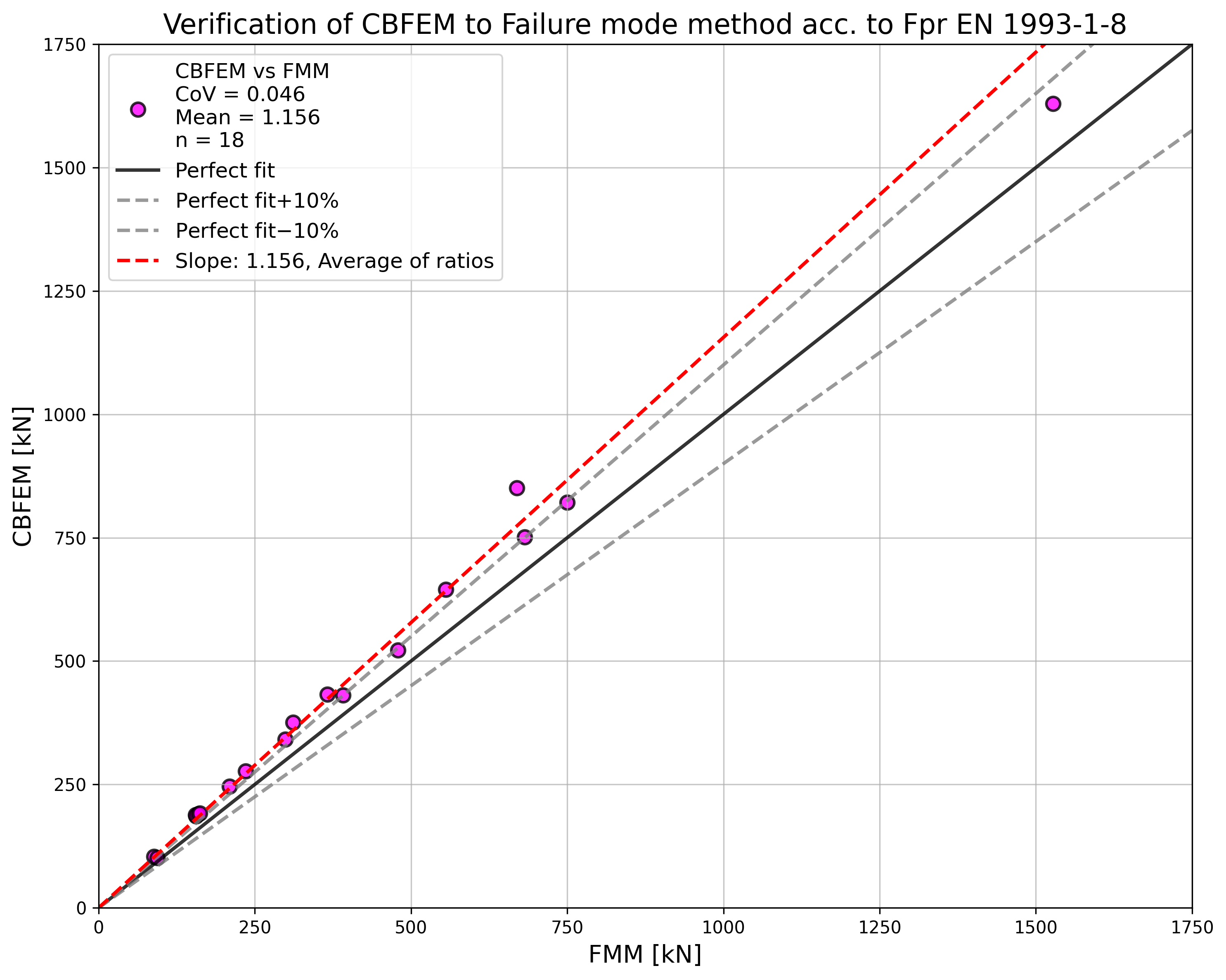

Table 5.6.4 Comparison of results of design resistances predicted by CBFEM, EN 1993-1-8 and Fpr EN 1993-1-8. Effect of plate thickness

\[ \textsf{\textit{\footnotesize{Fig. 5.6.6 Effect of plate thickness}}}\]

\[ \textsf{\textit{\footnotesize{Fig. 5.6.7 Verification of resistance determined by CBFEM to Fpr EN 1993-1-8}}}\]

Benchmark example

Inputs

Member

- Steel S450

- Rolled I

- b = 300mm

- h = 19mm

- tf = 7mm

- tw = 6.2mm

Plate- bearing member

- Steel S235

- b = 400mm

- t = 4mm

Bolts

- 6 × M16 10.9

- Distances e1 = 38 mm; p1 = 70 mm; p2 = 56 mm

Outputs

- Design resistance NRd = 206.1 kN

- Critical is plastic strain of gusset plate

\[ \textsf{\textit{\footnotesize{Fig. 5.6.9 Benchmark example}}}\]

End plate connection with four bolts in row

Description

This study is focused on the verification of the component-based finite element method (CBFEM) for the resistance of the end plate connection with four bolts in a row to an analytical model (AM), and a research-oriented finite element model (ROFEM) validated on experiments.

Analytical model

The bolt resistance in shear and tension and the plate resistance in bearing and punching shear are designed according to Tab. 3.4, Chapter 3.6.1 in EN 1993-1-8:2006. The equivalent T-stub in tension, according to Chapter 6.2.4, was modified by Jaspart et al. (2010) , see Fig. 5.7.1 and Tab. 5.7.1.

\[ \textsf{\textit{\footnotesize{Fig. 5.7.1 Failure modes of T-stub with four bolts in a row: mode 1 (left), mode 2 (middle), mode 3 (right)}}}\]

Tab. 5.7.1 Failure modes of T-stub with four bolts in a row (Jaspart et al. 2010)

In Tab 5.7.1 is 𝐹t,Rd the bolt tensile resistance, 𝑒w=𝑑w/4, 𝑑w is the diameter of the washer, or the width across points of the bolt head or nut, as relevant, 𝑚, 𝑛=𝑒1+𝑒2;𝑛≤1.25𝑚, 𝑛1=𝑒1, 𝑛2=𝑒2;𝑛2≤1,25𝑚+𝑛1 see Fig. 5.8.2, 𝑀pl,1,Rd=0.25𝑙eff,1𝑡f2𝑓y/𝛾M0, 𝑀pl,2,Rd=0.25𝑙eff,2𝑡f2𝑓y/𝛾M0, 𝑙eff is effective length, 𝑡f is the flange thickness, and 𝑓y is the yield strength, see Fig. 5.7.2.

\[ \textsf{\textit{\footnotesize{Fig. 5.7.2 T-stub geometry with four bolts in a row}}}\]

Validation and verification of resistance

Design resistances calculated by CBFEM were compared with the results of the analytical model (Zakouřil, 2019) and experiments with research-oriented finite element model (Samaan et al. 2017), see Fig. 5.7.3. The results are summarized in Fig. 5.7.4. Bolt grade 8.8 and steel grade S450 were used. The yield and tensile strengths correspond closely to the experimental values, e.g. bolt yield strength is 600 MPa, bolt tensile strength is 800 MPa.

\[ \textsf{\textit{\footnotesize{Extended unstiffened end plate labeled ENS}}}\]

\[ \textsf{\textit{\footnotesize{Flushed end plate labeled F}}}\]

\[ \textsf{\textit{\footnotesize{Extended stiffened end plate labeled EX}}}\]

\[ \textsf{\textit{\footnotesize{Fig. 5.7.3 Tested specimens}}}\]

The bending moment resistance determined by CBFEM is usually between resistances determined by the component method and experimentally. Table 5.7.2 shows the comparison between the CM, CBFEM, ROFEM, and experimental resistances for the specimens with end plate thicknesses of 20 mm and 32 mm. Both the component method and CBFEM underestimate the resistance of the specimen with a flushed end plate.

Tab. 5.7.2 Comparison between the CM , ROFEM, CBFEM, and Experiment

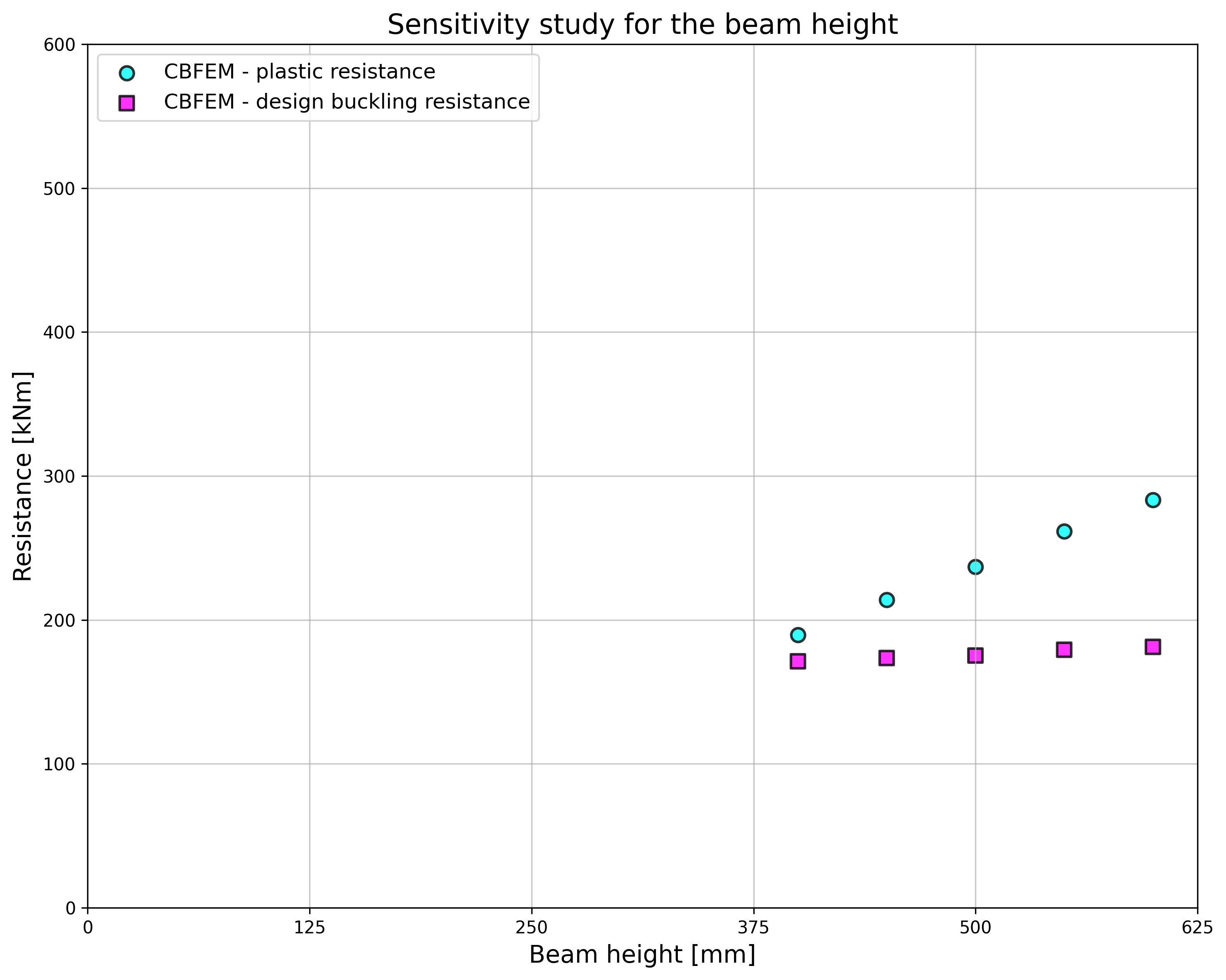

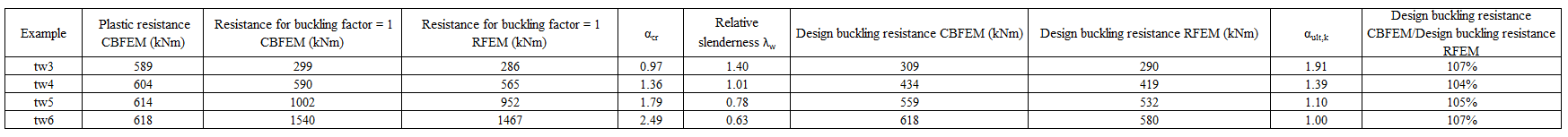

Table 5.7.3 and Fig. 5.7.4 show verification of CBFEM to CM for models ENS with different end plate thickness, bolt diameter, and beam height

Tab. 5.7.3 Verification CBFEM to CM ENS

\[ \textsf{\textit{\footnotesize{Fig. 5.7.4 Verification of CBFEM to CM}}}\]

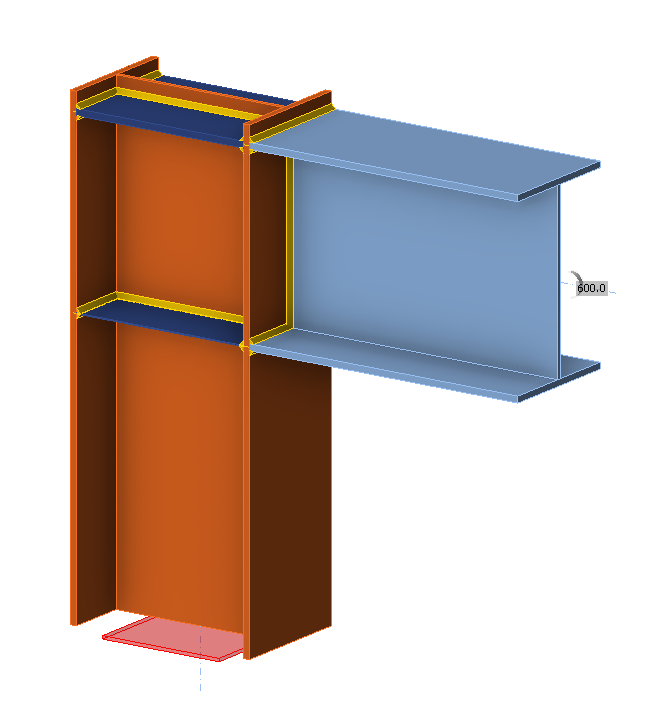

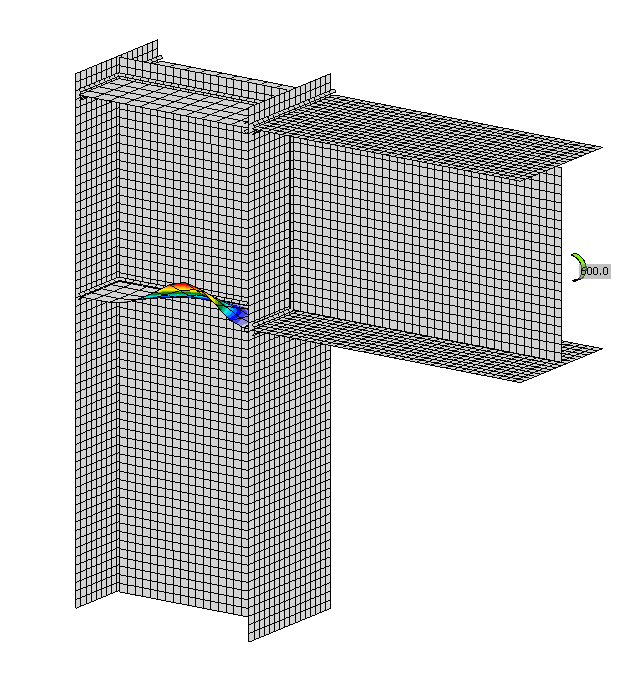

The results of sensitivity studies are summarized in plots in Fig. 5.7.5, Fig. 5.7.6, Fig. 5.7.7

\[ \textsf{\textit{\footnotesize{Fig. 5.7.5 Sensitivity study for plate thickness}}}\]

\[ \textsf{\textit{\footnotesize{Fig. 5.7.6 Sensitivity study for bolt diameter}}}\]

\[ \textsf{\textit{\footnotesize{Fig. 5.7.7 Sensitivity study for beam height}}}\]

Table 5.7.4 and Fig. 5.7.8 show verification of CBFEM to CM for models F with different end plate thickness and bolt diameter

Tab. 5.7.4 Verification CBFEM to CM F

\[ \textsf{\textit{\footnotesize{Fig. 5.7.8 Verification of CBFEM to CM}}}\]

The results of sensitivity studies are summarized in plots in Fig. 5.7.9 and 5.7.10

\[ \textsf{\textit{\footnotesize{Fig. 5.7.9 Sensitivity study for plate thickness}}}\]

\[ \textsf{\textit{\footnotesize{Fig. 5.7.10 Sensitivity study for bolt diameter}}}\]

Table 5.7.5 and Fig. 5.7.11 show verification of CBFEM to CM for models F with different end plate thickness and bolt diameter

Tab. 5.7.5 Verification CBFEM to CM EX

\[ \textsf{\textit{\footnotesize{Fig. 5.7.11 Verification of CBFEM to CM}}}\]

The results of sensitivity studies are summarized in plots in Fig. 5.7.12 and 5.7.13.

\[ \textsf{\textit{\footnotesize{Fig. 5.7.12 Sensitivity study for plate thickness}}}\]

\[ \textsf{\textit{\footnotesize{Fig. 5.7.13 Sensitivity study for bolt diameter}}}\]

Benchmark example

Inputs

- Steel S450

Column

- Rolled I

- h = 390mm

- b = 350mm

- tf = 20mm

- tw = 12mm

- r = 27mm

Column stiffeners

- ts = 16mm

Beam

- Rolled I

- hb = 340mm

- bb = 350mm

- tf = 20mm

- tw = 12mm

- r = 27mm

End plate

- tp = 20mm

- bp = 350mm

- hp= 540mm

Bolts

- 4 rows x 4 x M16 8.8

- Distances e1 = 50 mm, p1 = 120 mm, p2 = 100mm, e2= 50mm, w1 = 75mm, w2 = 100mm

Welds

- aw = 7mm

Outputs

- Design resistance FRd = 247 kN

- Critical components are bolts with forces increased by the prying of the end plate

\[ \textsf{\textit{\footnotesize{Fig. 5.7.14 Benchmark example}}}\]

Slender plate in compression

Triangular haunch

Description

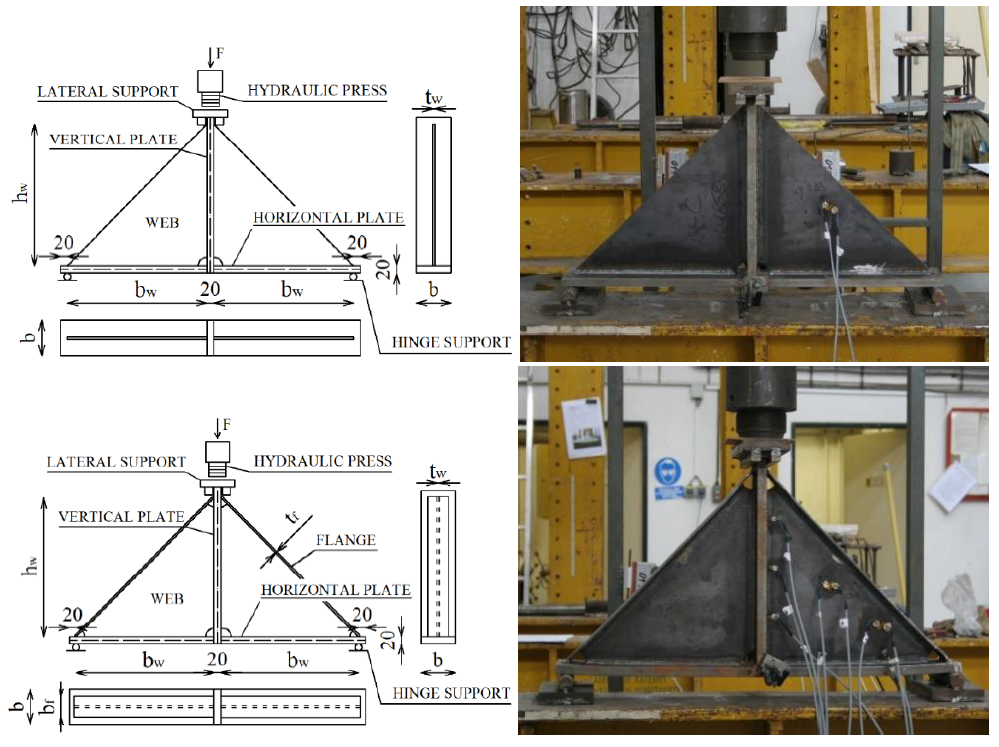

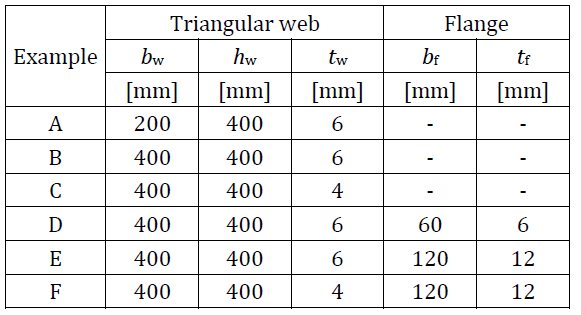

The object of this study is verification of component-based finite element method (CBFEM) for a class 4 triangular haunch without a flange and a class 4 triangular haunch with a flange with reduced stiffness with research FEM model (RFEM) and design FEM model (DFEM).

Experimental investigation

Experimental results of six specimens of haunches with and without flanges are presented. Three specimens are without flanges and three specimens are supported by additional flanges. Unstiffened specimens differ in the web thickness tw and the web width bw. Reinforced specimens differ in the web thickness tw, the flange thickness tf, and the flange width bf. The dimensions of specimens are summarized in Tab. 6.1.1. The test set-up for the specimen without a flange is shown in Fig. 6.1.1 (top) and for the specimen with a flange in Fig. 6.1.1 (bottom). Material characteristics of the steel plates are summed up in Tab. 6.1.2.

\[ \textsf{\textit{\footnotesize{Fig. 6.1.1 Specimens geometry and test set-up}}}\]

Tab. 6.1.1 Examples overview

Tab. 6.1.2 Material characteristics used in numerical models

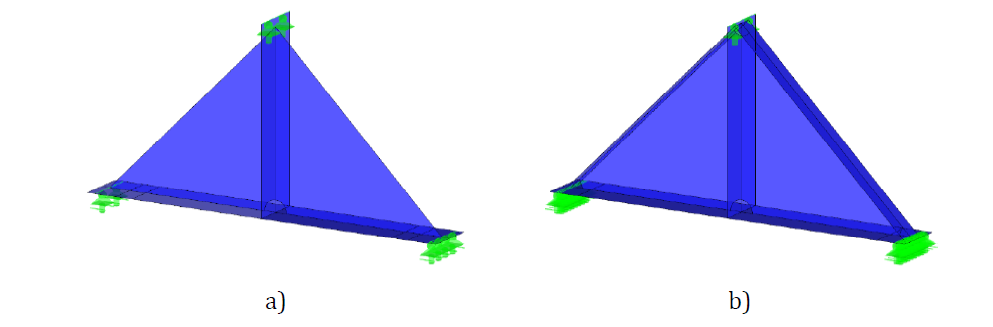

Research FEM model

Research FEM model (RFEM) is used to verify the DFEM model and is validated on the experiments. In the numerical model, 4-node quadrilateral shell elements with nodes at their corners are applied, with a maximum side length of 10 mm. Materially and geometrically nonlinear analysis with imperfections (GMNIA) is applied. Equivalent geometric imperfections are derived from the first buckling mode, and the amplitude is set according to Annex C of EN 1993-1-5:2006. Numerical models are shown in Fig. 6.1.2.

\[ \textsf{\textit{\footnotesize{Fig. 6.1.2 Research FEM model a) haunch without a flange b) haunch with a flange}}\]

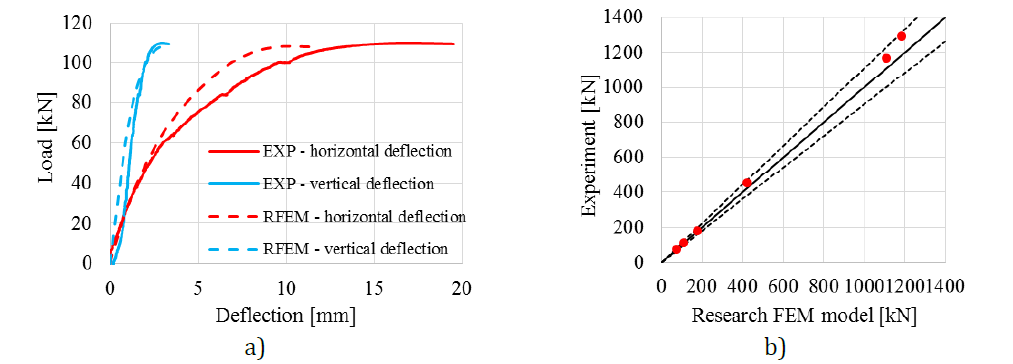

An example of the comparison of RFEM and experimental test on the load-deflection behavior is shown in Fig. 6.1.3a. The comparison of resistances measured in the experiment and obtained from RFEM is shown in Fig. 6.1.3b. The resistance calculated in the numerical model is displayed on the horizontal axis. The resistance measured in the experimental study is displayed on the vertical axis. It can be seen that a good agreement exists.

\[ \textsf{\textit{\footnotesize{Fig. 6.1.3 a) Load-deflection curve of a haunch without a flange b) Experiments’ resistances compared against RFEMs’}}}\]

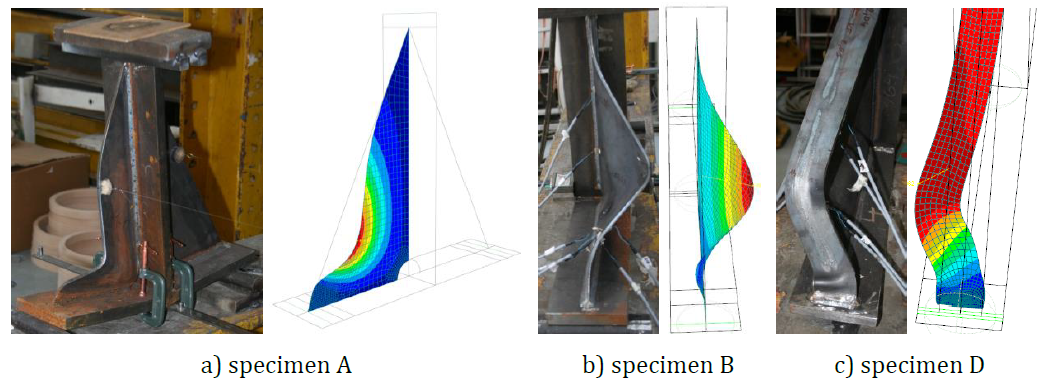

The comparisons of the final deformation states between numerical simulations and experimental results are performed at the end of the tests. Fig. 6.1.4 presents the comparison of the deformation of specimens A, B, and D after failure with RFEA. It can be found that good agreements between numerical models and experimental results of the haunches exist in the failure mode. For more details, see (Kurejková and Wald, 2017).

\[ \textsf{\textit{\footnotesize{Fig. 6.1.4 Experimental and numerical deflection of specimens A, B and D after failure}}}\]

Design FEM model

Design procedure for class 4 cross-sections is described in section 3.10 Local buckling.

The design procedure is verified on the comparison of DFEM and RFEM models. Both models are created in Dlubal RFEM software. The procedure is applied in CBFEM models; see (Kurejková et al. 2015). The resistance governed by 5% plastic strain is obtained in the first step and followed by linear buckling analysis. The critical component in the buckling analysis is studied. The design resistance is interpolated until the condition ρ∙αult,k = 1 is reached.

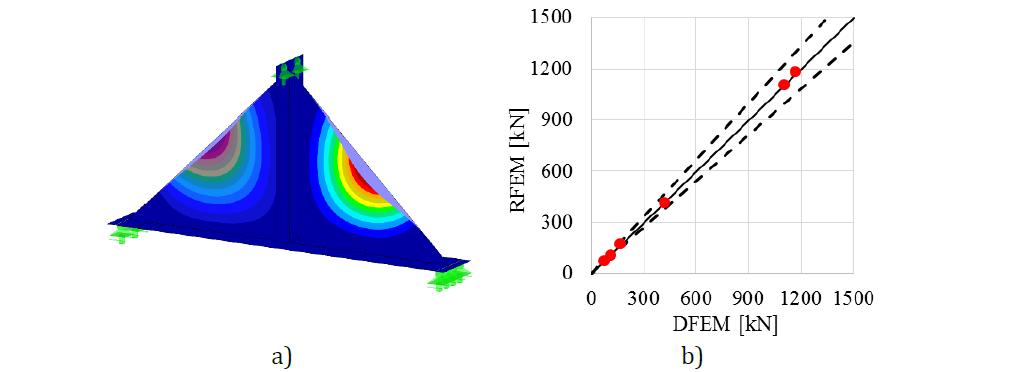

The first buckling mode of a haunch without a flange is shown in Fig. 6.1.5 a). The resistance is assessed according to formula (3.10.2) in section 3.10. The comparison of DFEM’s and RFEM’s resistances is shown in Fig. 6.1.5 b). The resistance calculated in the DFEM is displayed on the horizontal axis. The resistance calculated in RFEM is displayed on the vertical axis. It can be seen that a good agreement exists and the procedure is verified.

\[\textsf{\textit{\footnotesize{Fig. 6.1.5 a) First buckling mode of DFEM model b) Comparison of DFEM and RFEM resistances}}}\]

Global behavior and verification

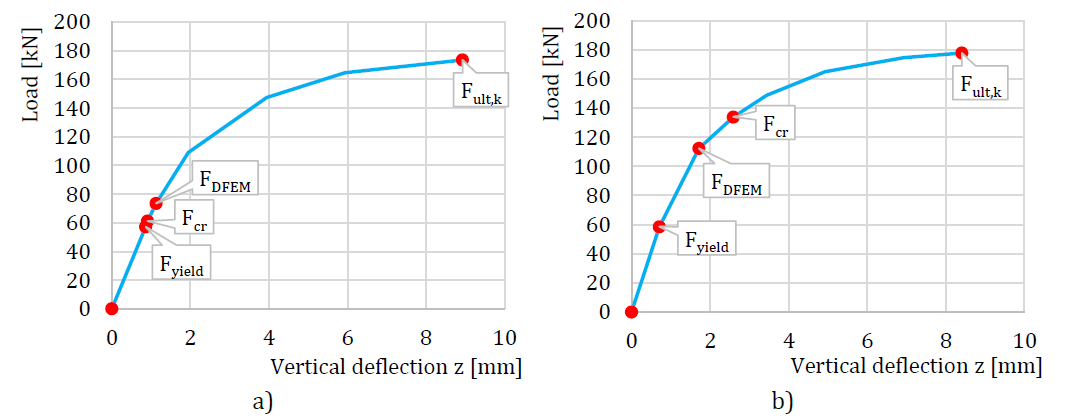

Comparison of the global behavior of a haunch without flange described by load-deflection diagrams in DFEM model is prepared. The deflection is measured in the vertical direction in the middle of the specimen. Attention is focused on the main characteristics: design resistance and critical load. Two examples of a haunch without a flange are chosen to present as a reference; see Fig. 6.1.6. The design procedure in DFEM models covers the post-buckling reserve, which is observed in Fig. 6.1.6 a). The critical load Fcr is smaller than the design resistance FDFEM. The post-buckling reserve is observed in cases with very slender plates. The typical diagram is shown in Fig. 6.1.6 b), where the design resistance FDFEM does not reach the critical load Fcr. The load Fult,k refers to resistance by 5 % of plastic strain.

\[ \textsf{\textit{\footnotesize{Fig. 6.1.6 a) Load-deflection curve with post-buckling reserve b) Load-deflection curve without post-buckling reserve (Kuříková et al. 2019)}}}\]

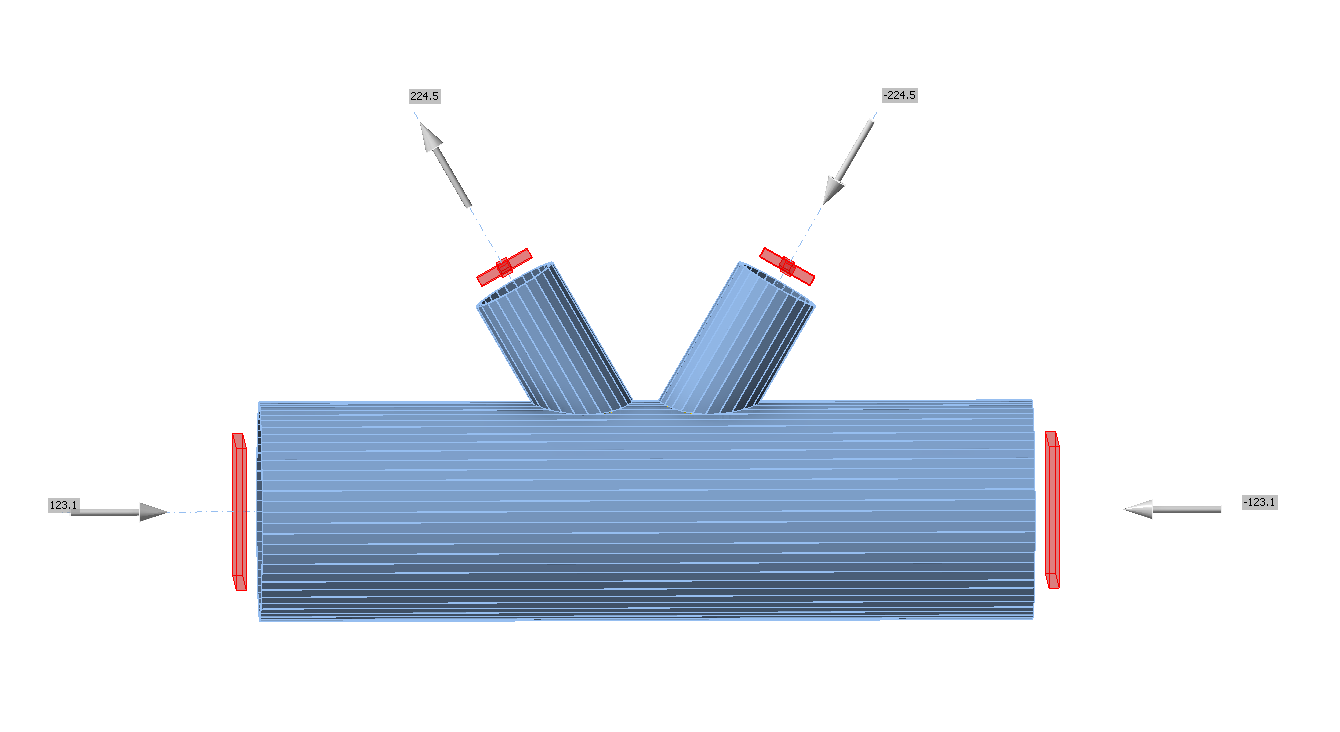

The design procedure in CBFEM models is described in section 3.10 Local buckling. The buckling analysis is implemented in the software. The calculation of the design resistances is done manually according to the design procedure. FCBFEM is interpolated by the user until the formula (2) is equal to 1. A beam-column joint with a haunch without a flange is studied. The thicknesses of beam and column webs are changing in the same way as the thickness of the triangular haunch. The same cross-section is used for beam and column. The geometry of the examples is described in Tab. 6.1.3. The joint is loaded by bending moment.

Tab. 6.1.3 Examples overview (Kuříková et al. 2019)

Verification of resistance

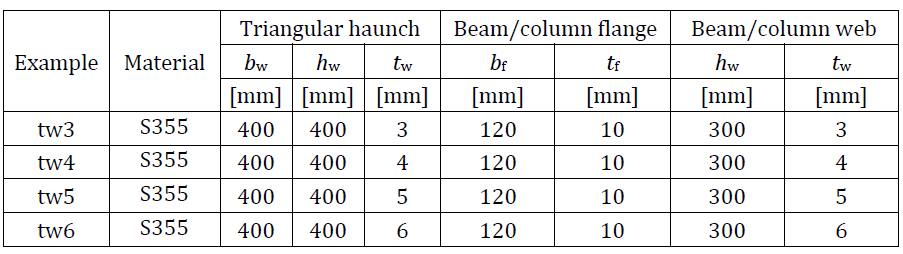

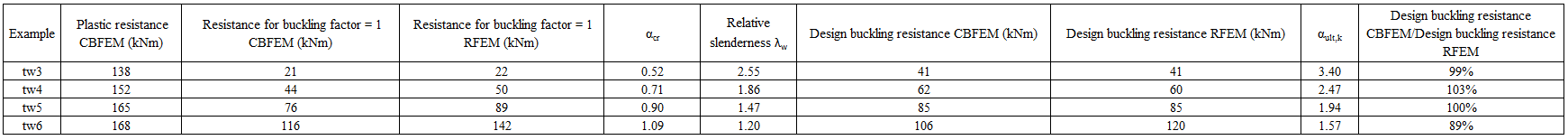

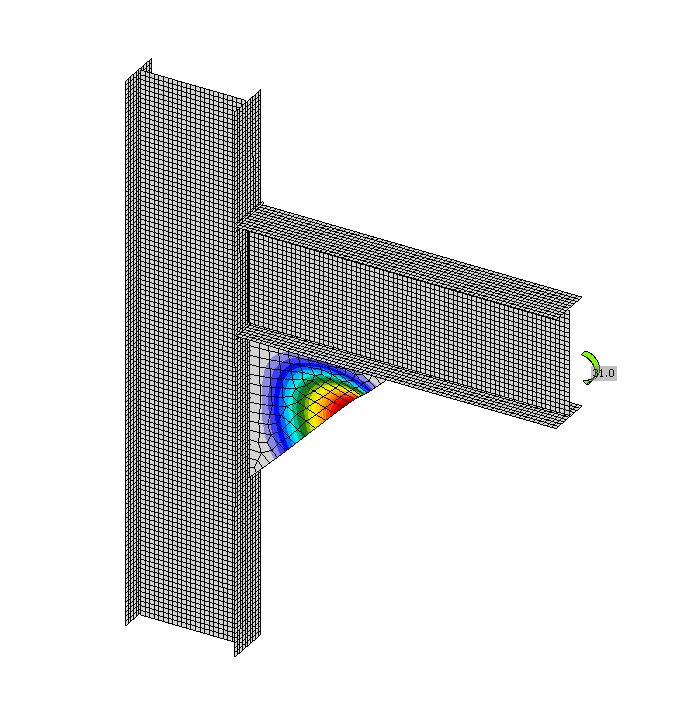

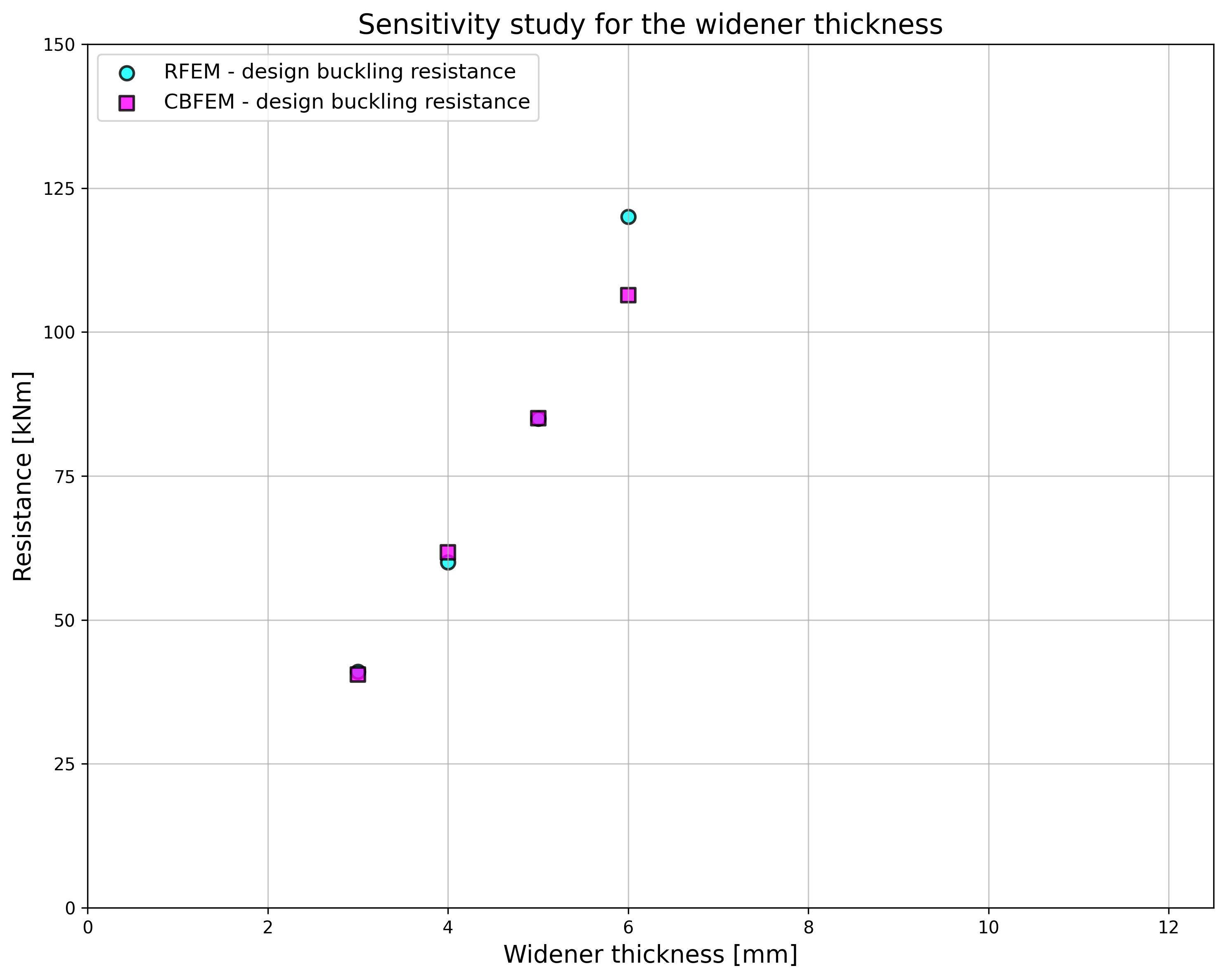

The design resistance calculated by CBFEM is compared with the results obtained by RFEM. The comparison is focused on the design resistance and critical load. The results are ordered in Tab. 6.1.4. The diagram in Fig. 6.1.7 c) shows the influence of the widener thickness on the resistances and critical loads in the examined examples.

The results show very good agreement in critical load and design resistance. The post-buckling reserve is observed for beam web and triangular widener with thicknesses of 3 and 4 mm. The CBFEM model of the joint with a haunch with a thickness of 3 mm is shown in Fig. 6.1.7 a). The first buckling mode of the joint is shown in Fig. 6.1.7 b).

Tab. 6.1.4 Design resistance

\[ \textsf{\textit{\footnotesize{a)}}}\]

\[ \textsf{\textit{\footnotesize{b)}}}\]

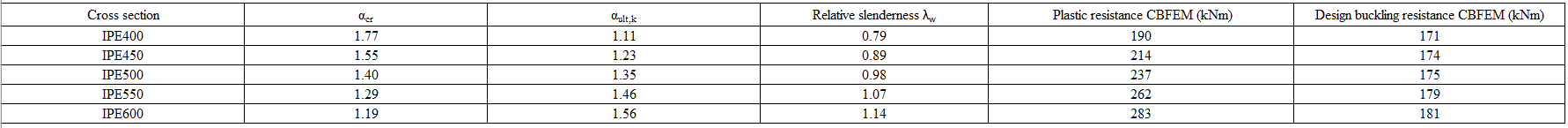

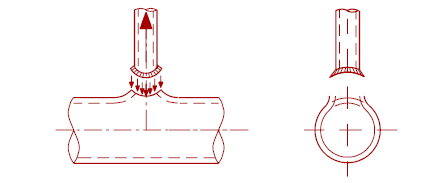

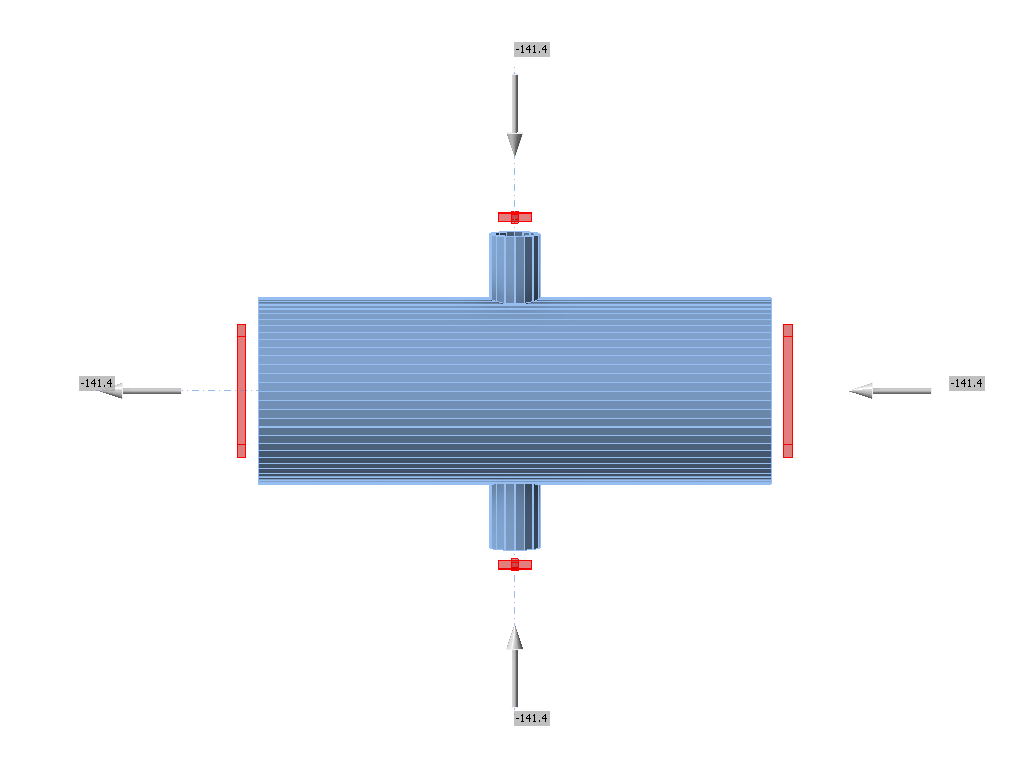

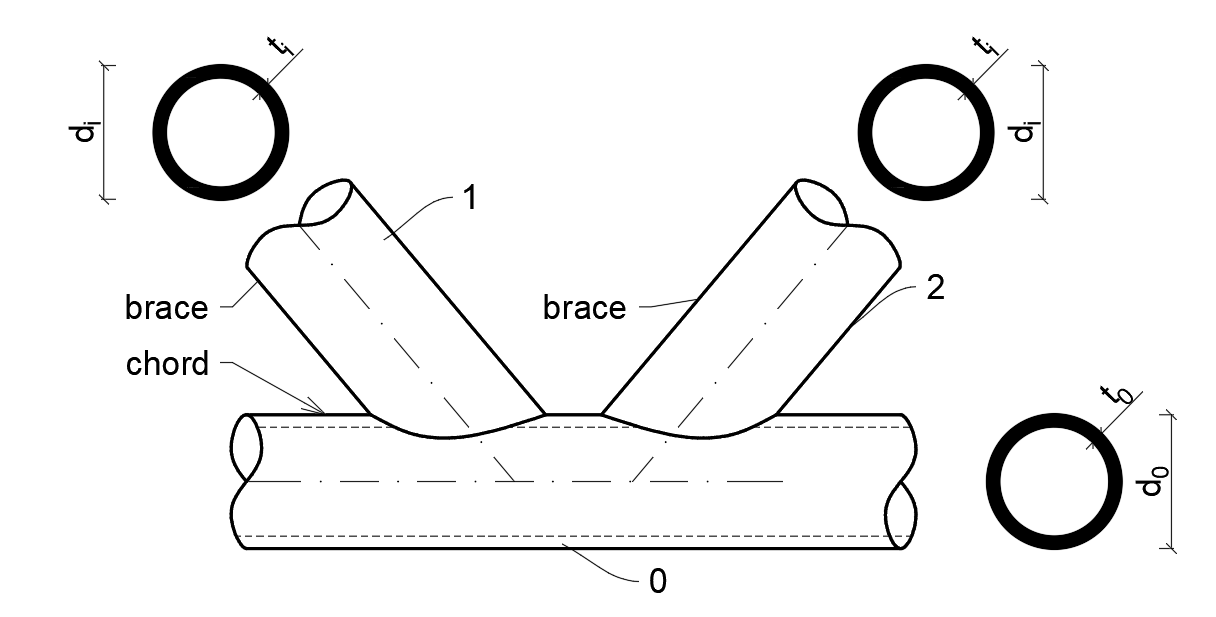

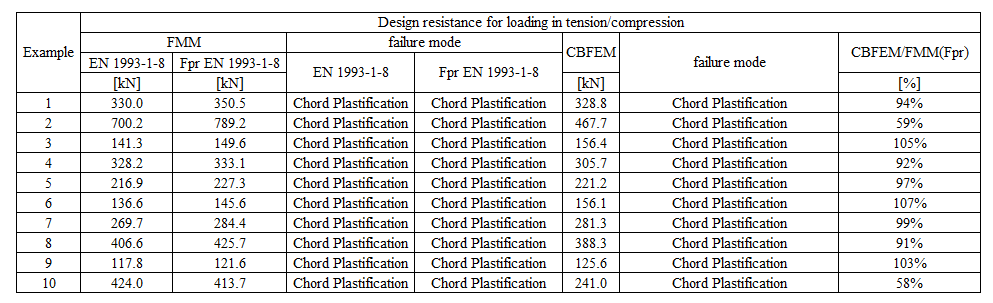

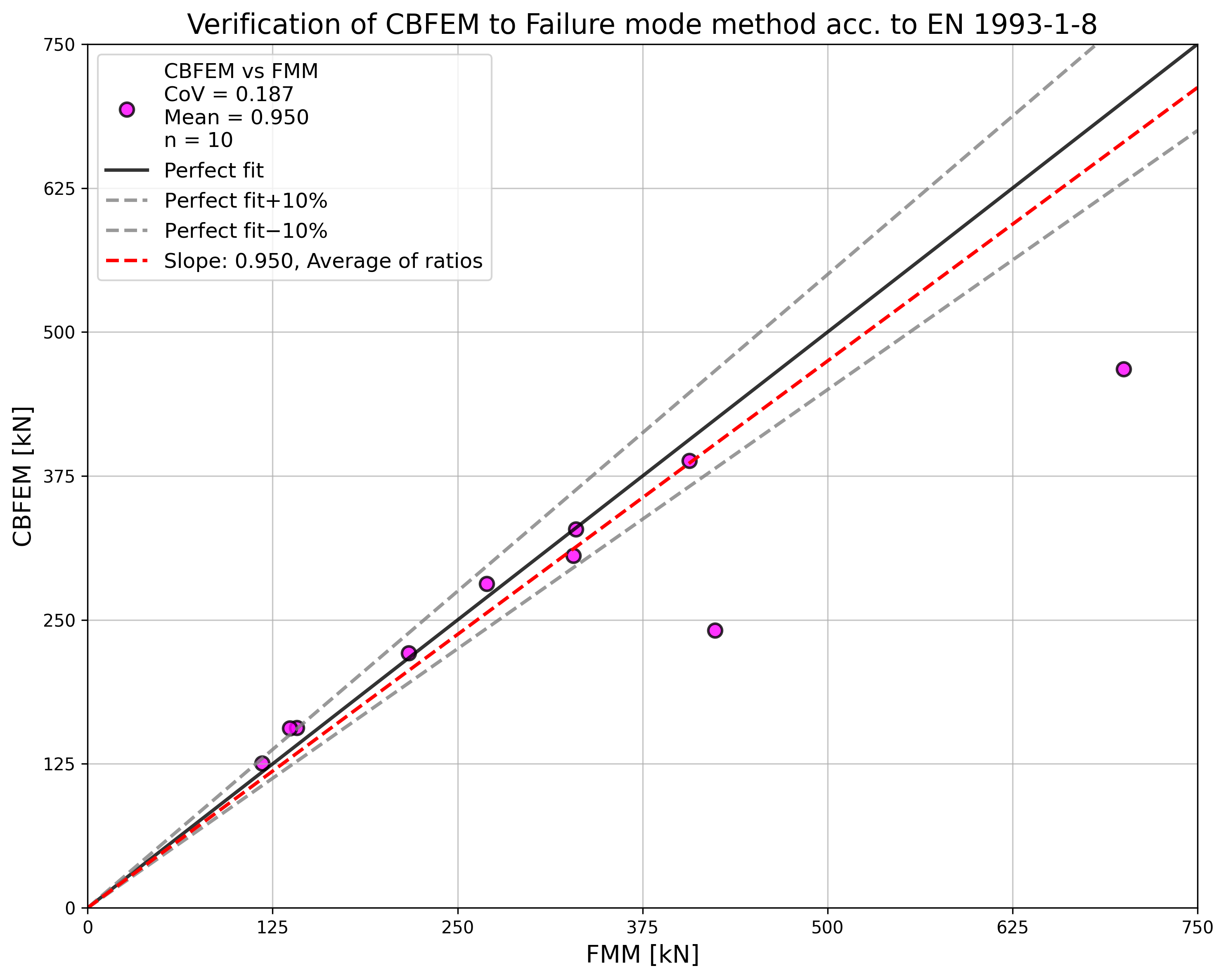

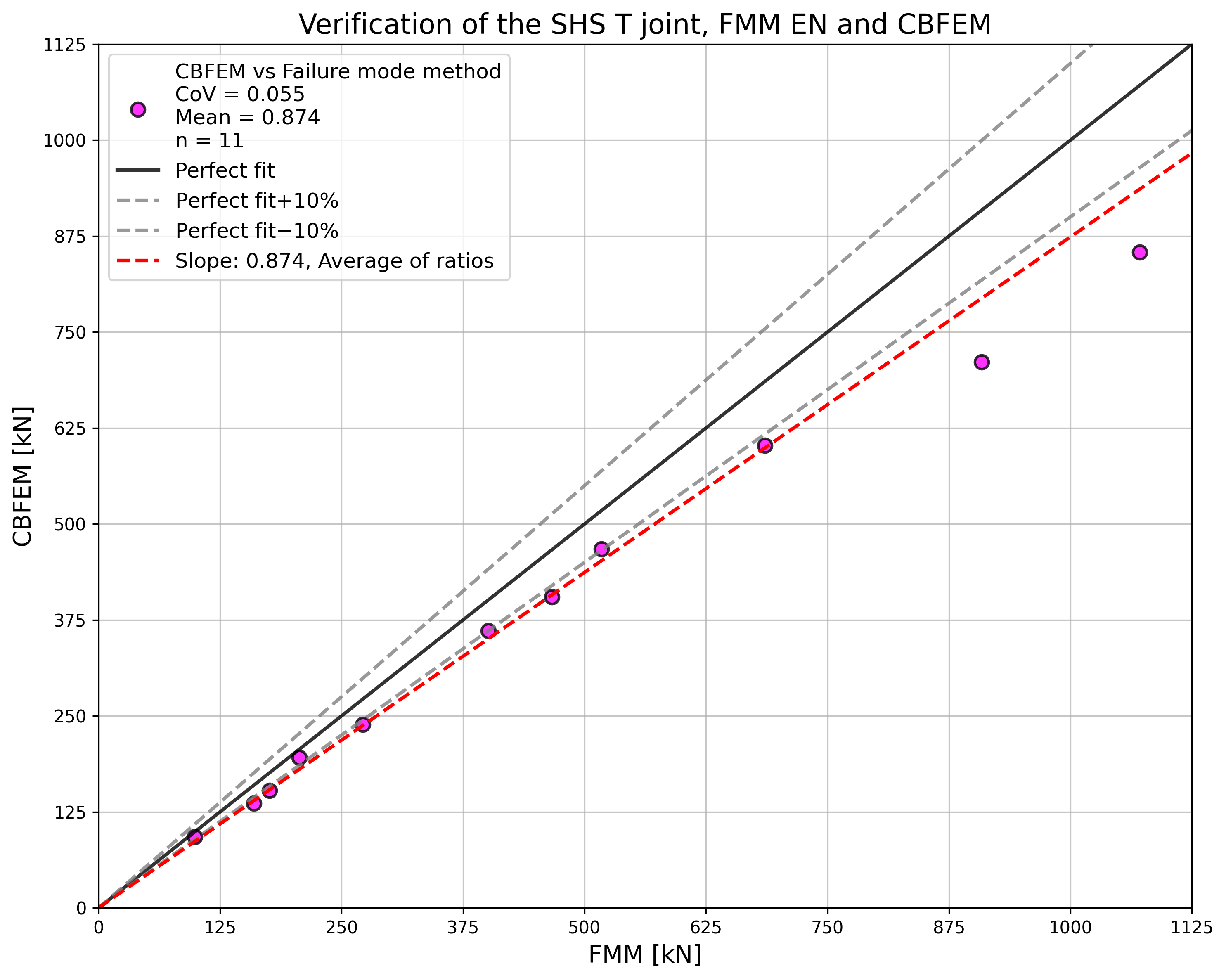

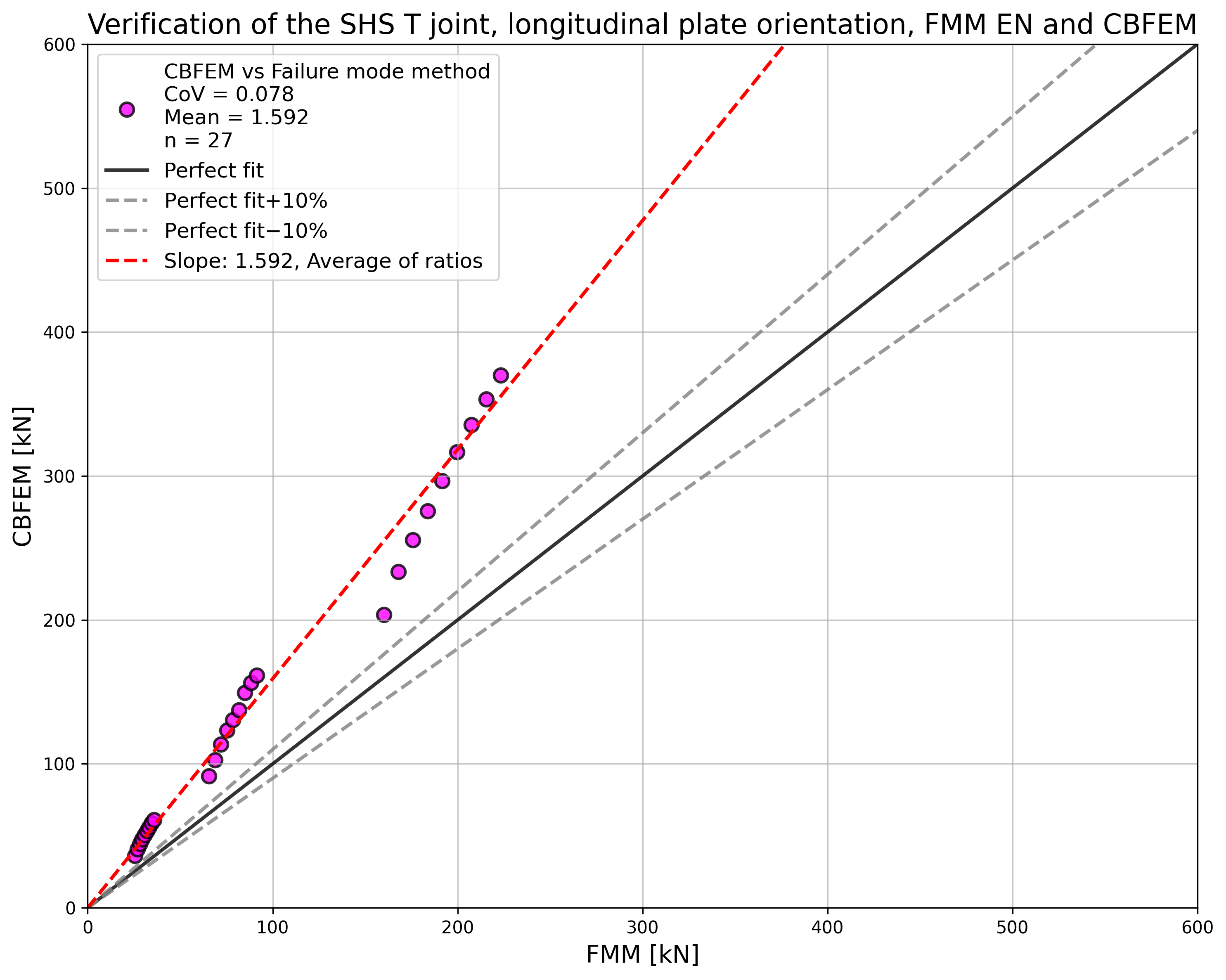

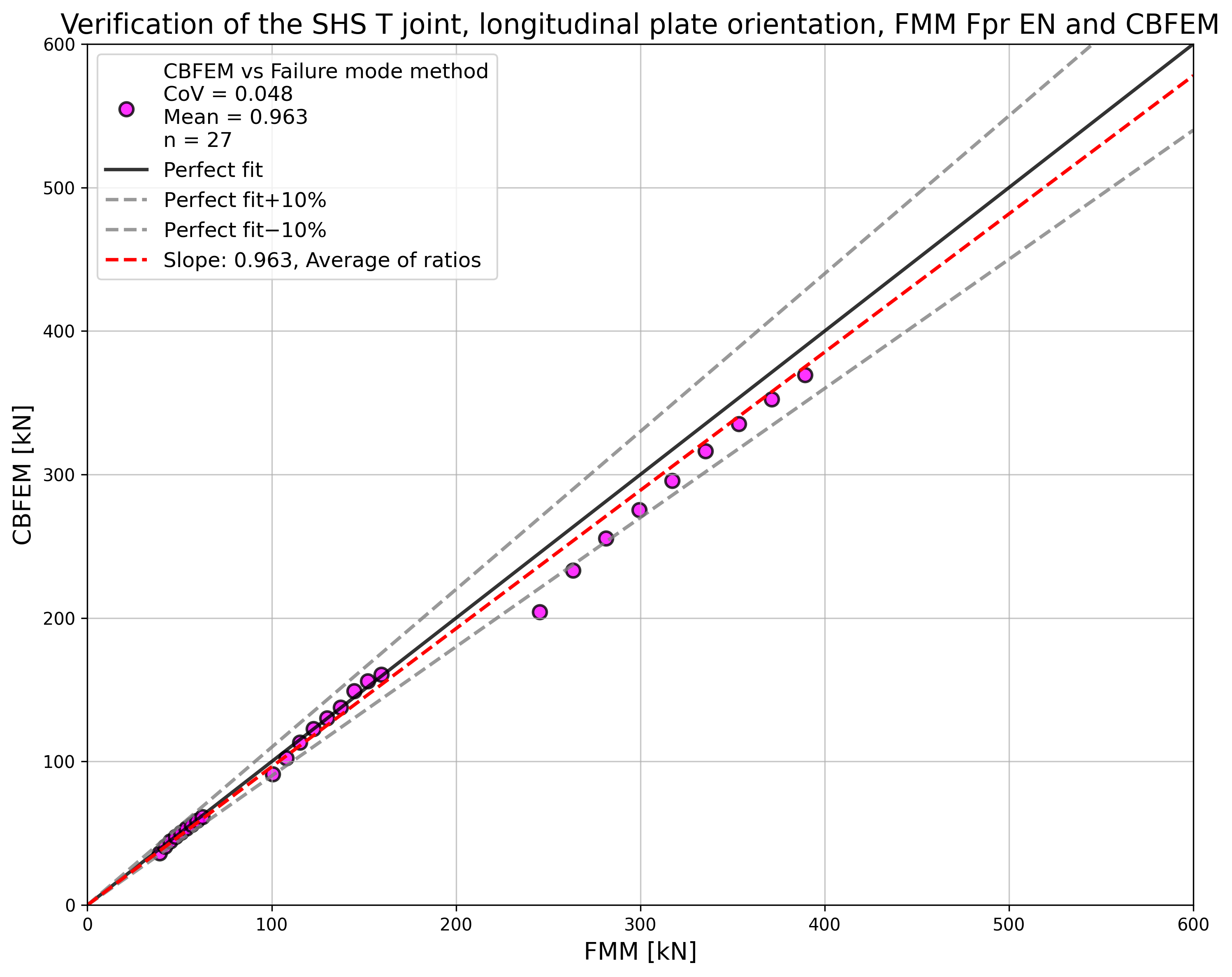

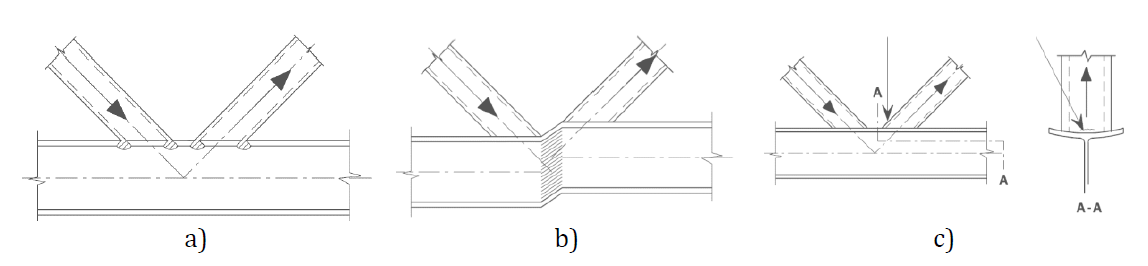

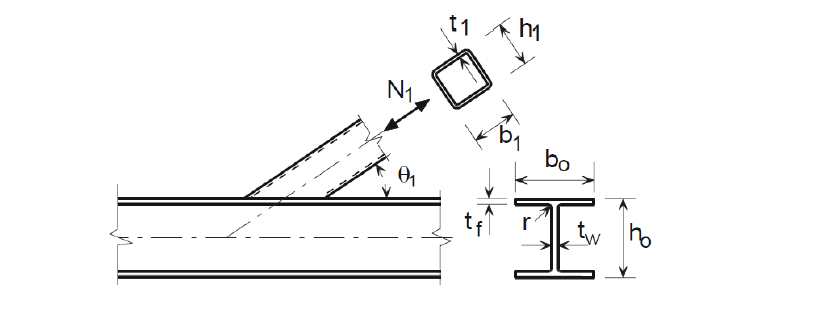

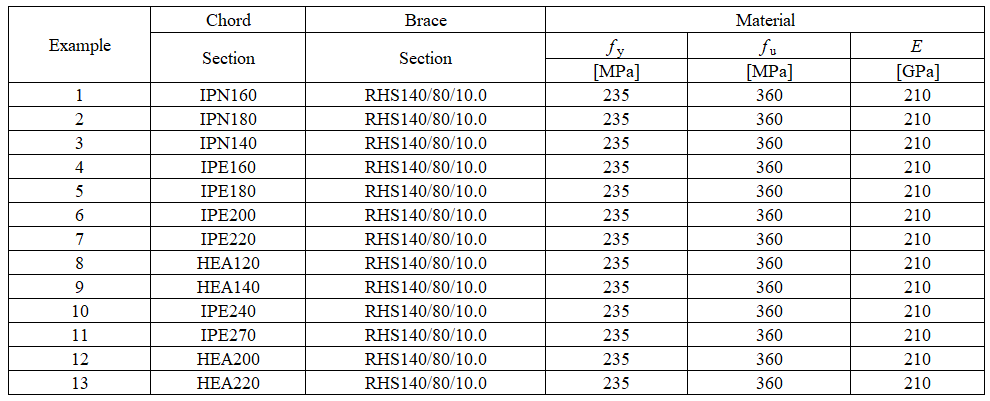

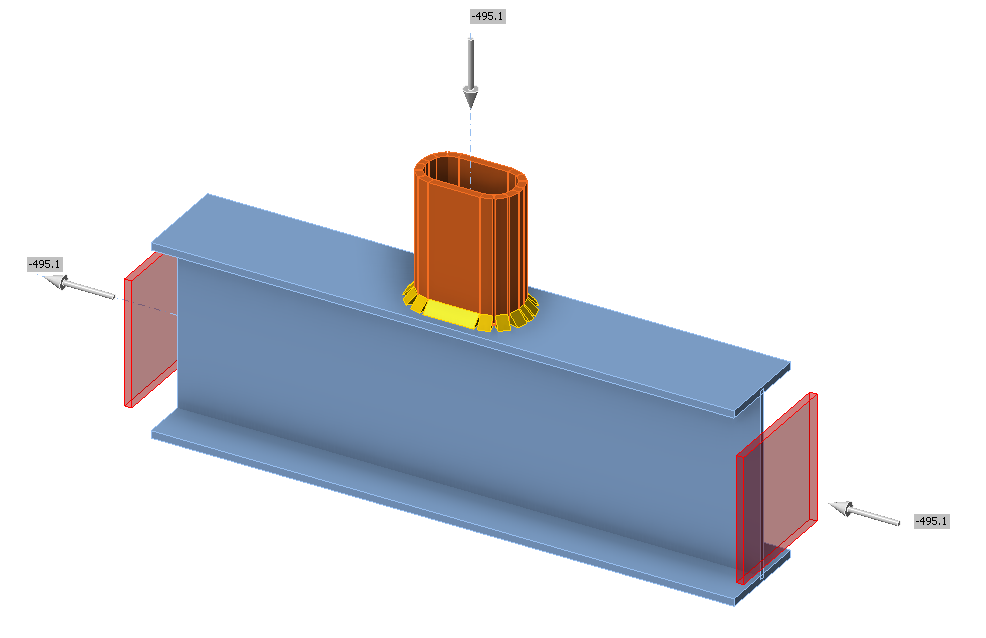

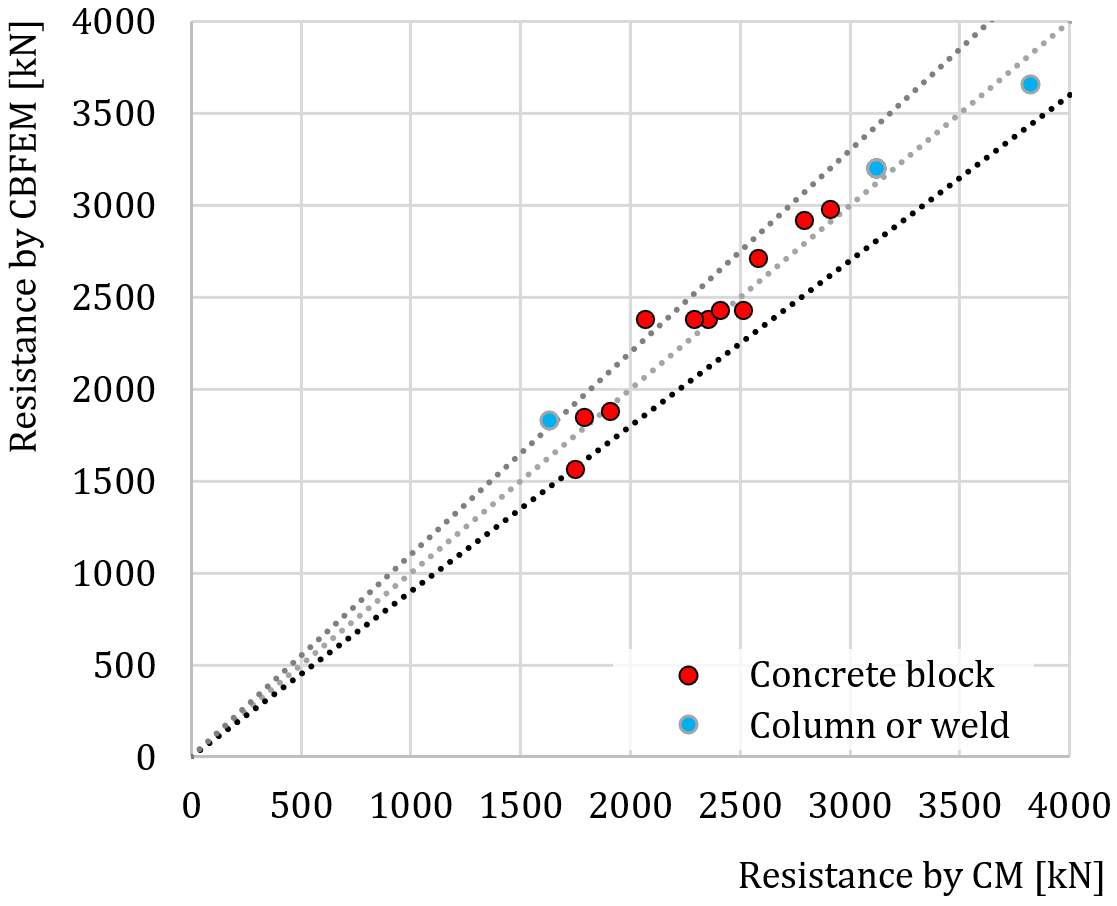

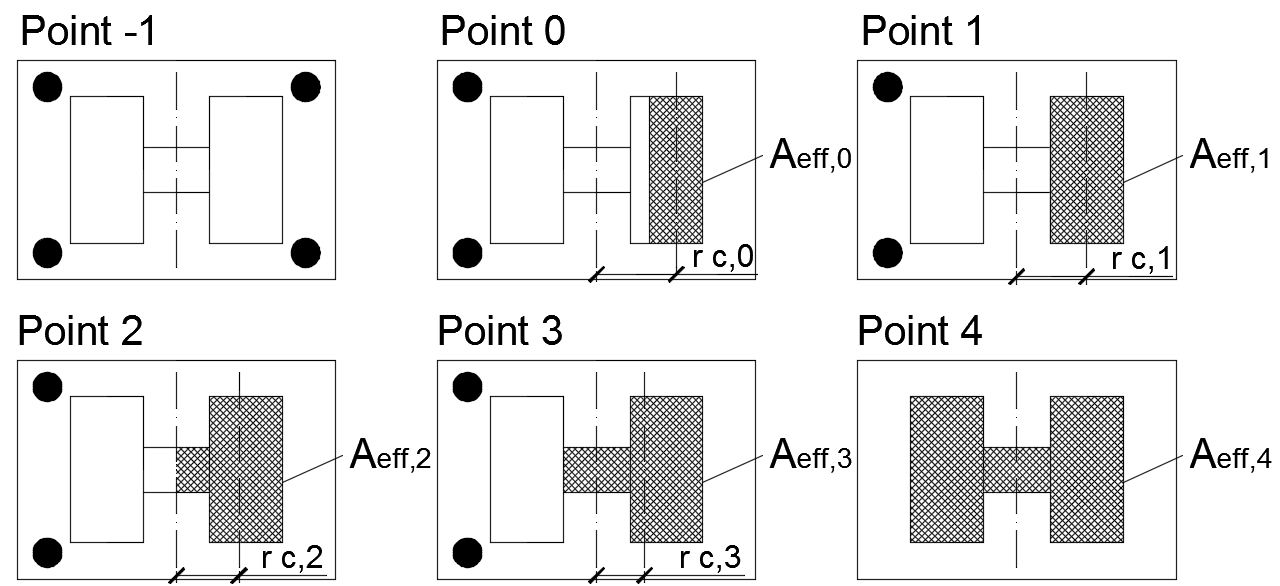

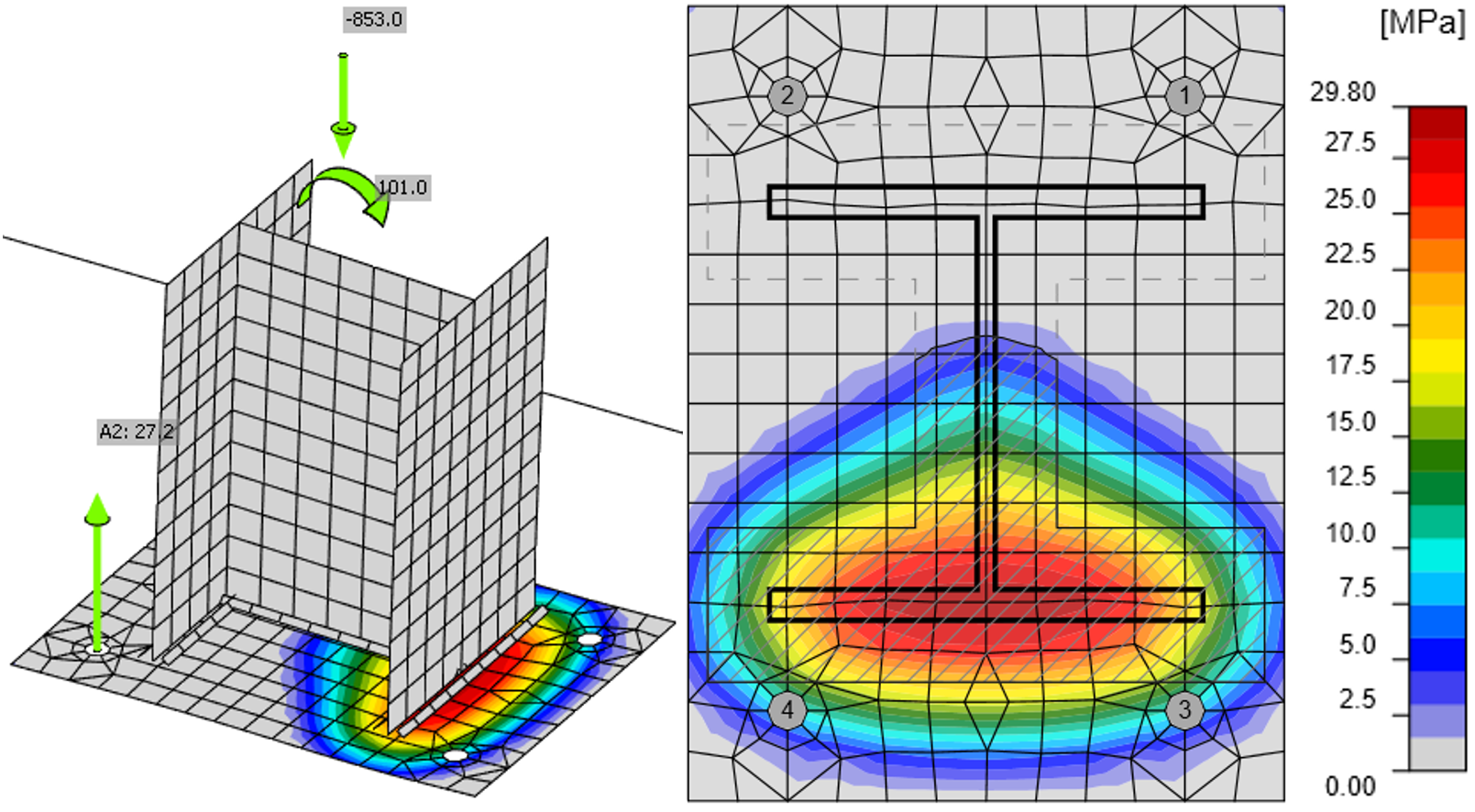

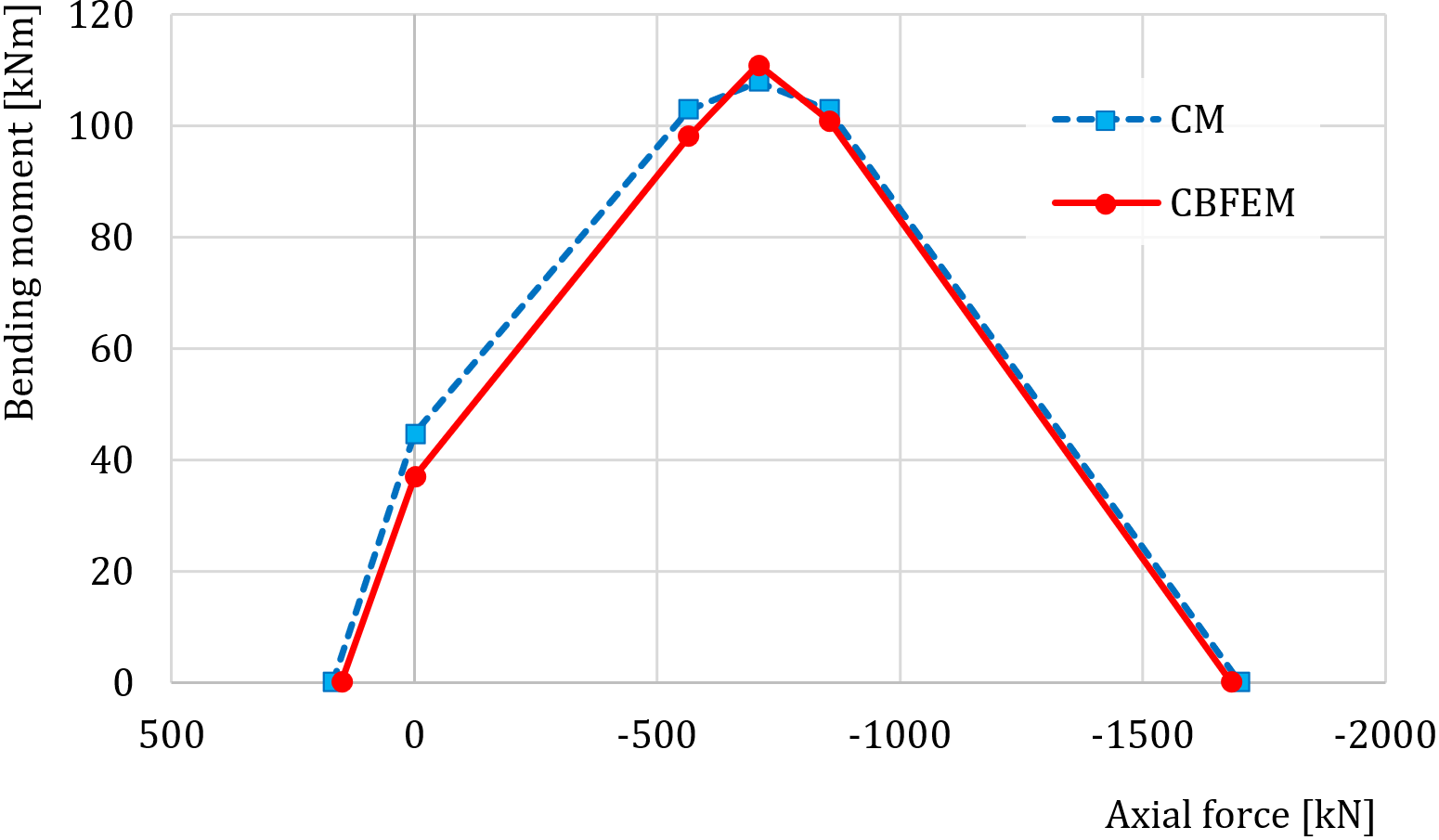

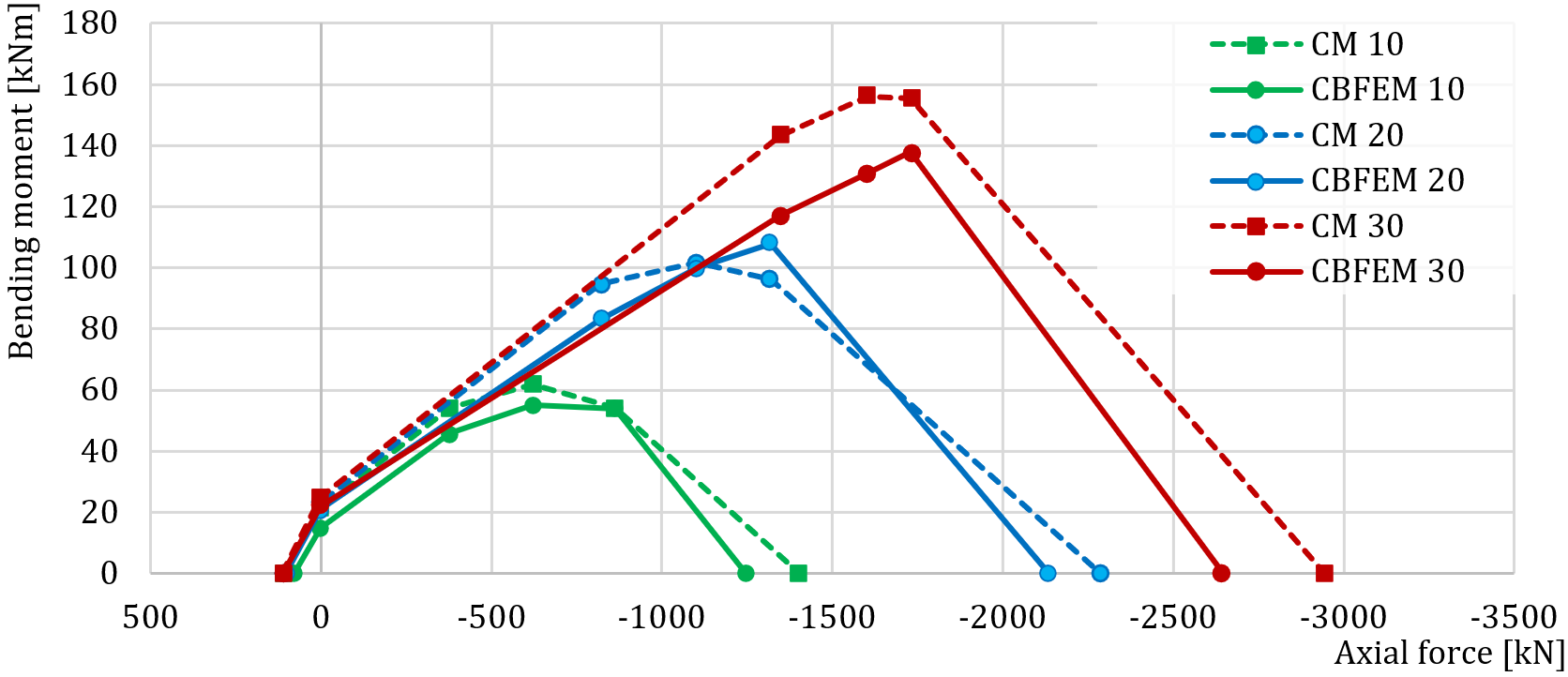

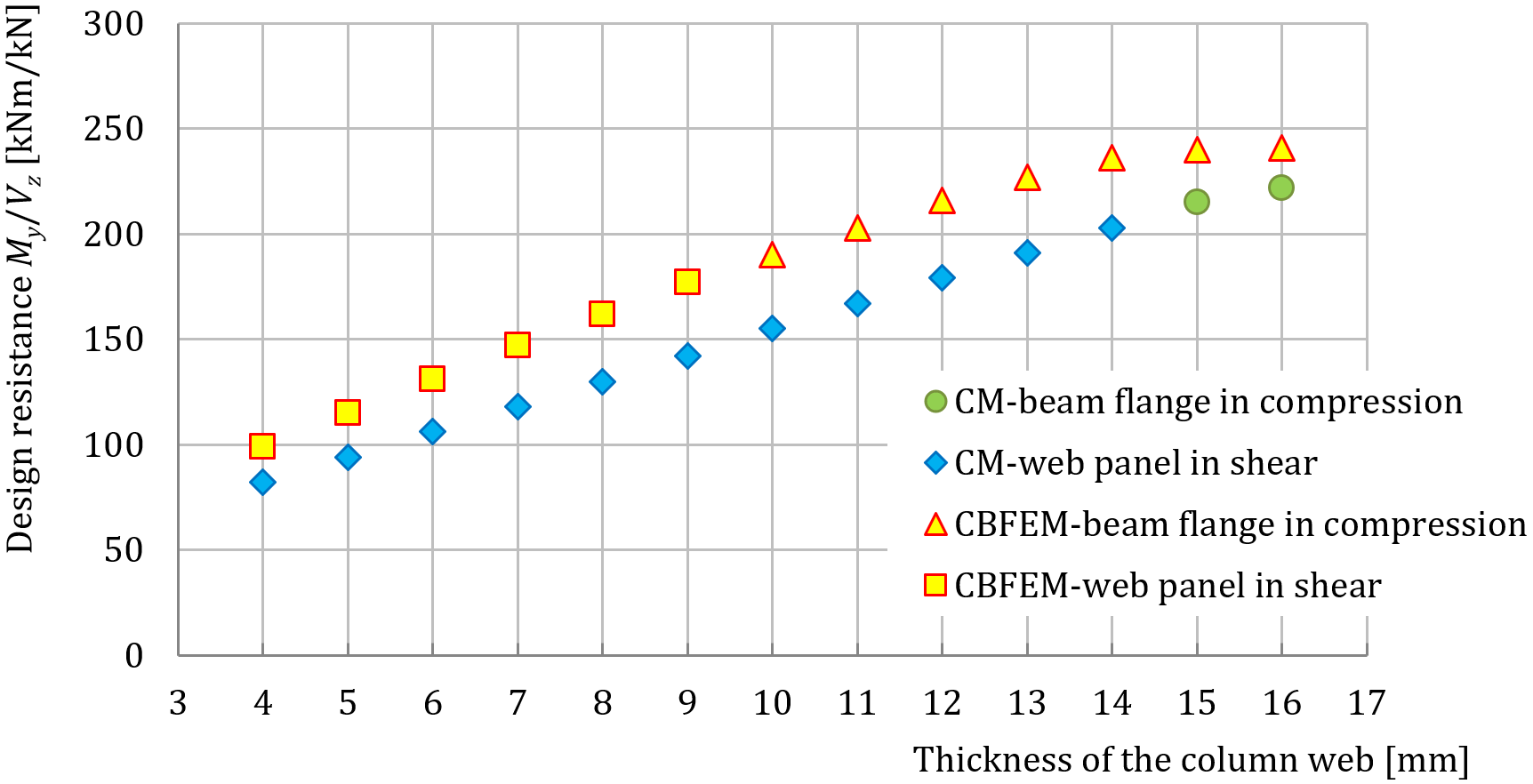

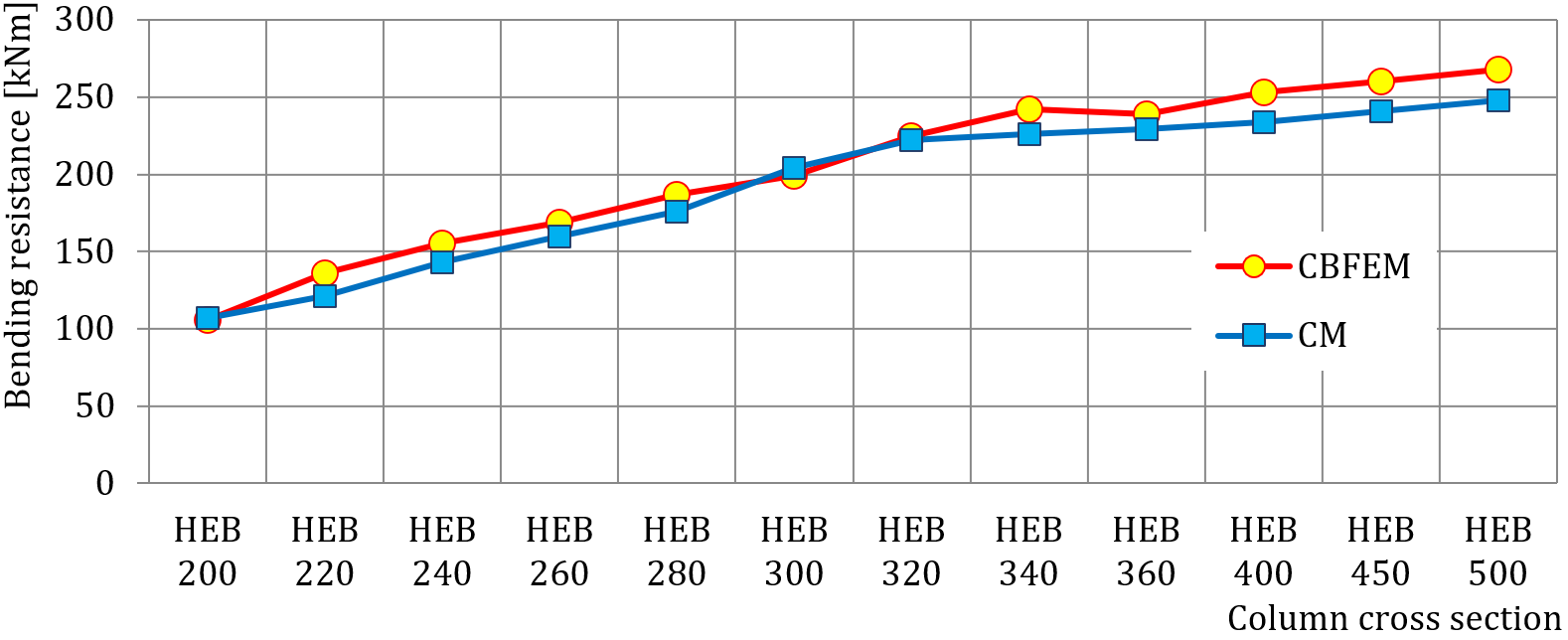

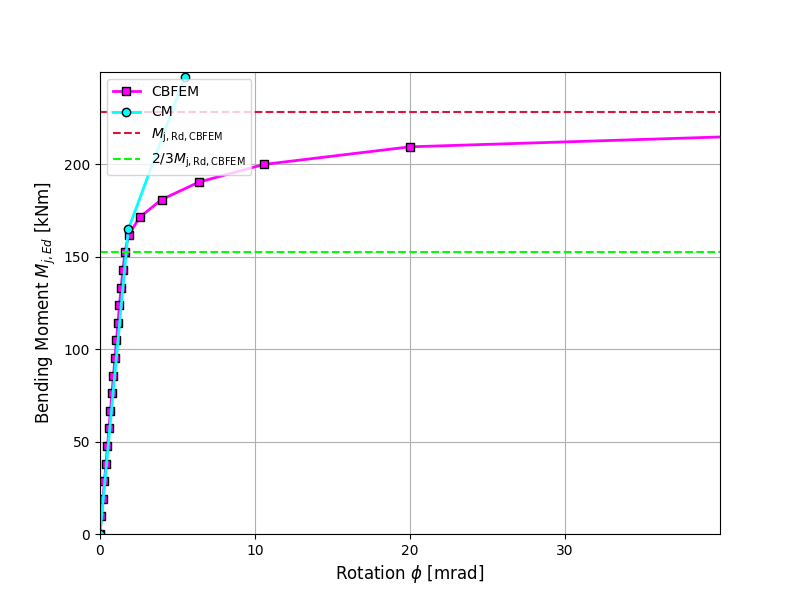

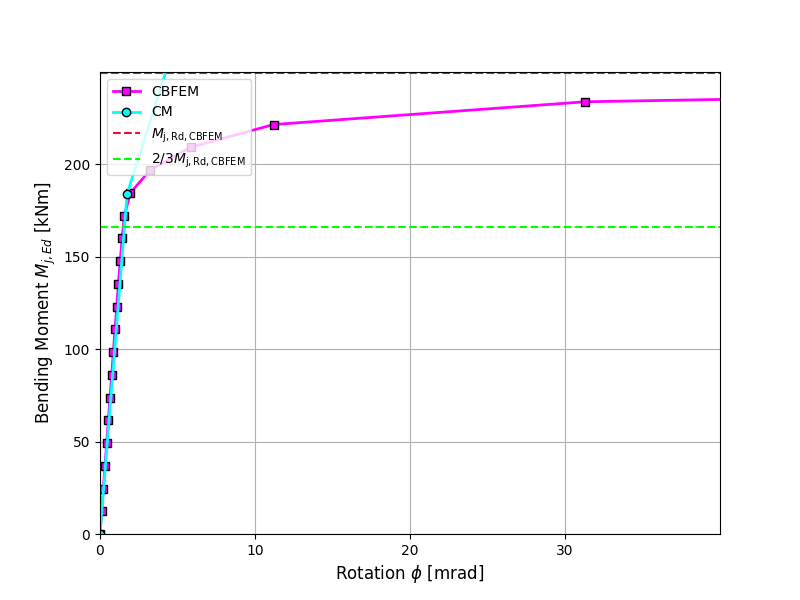

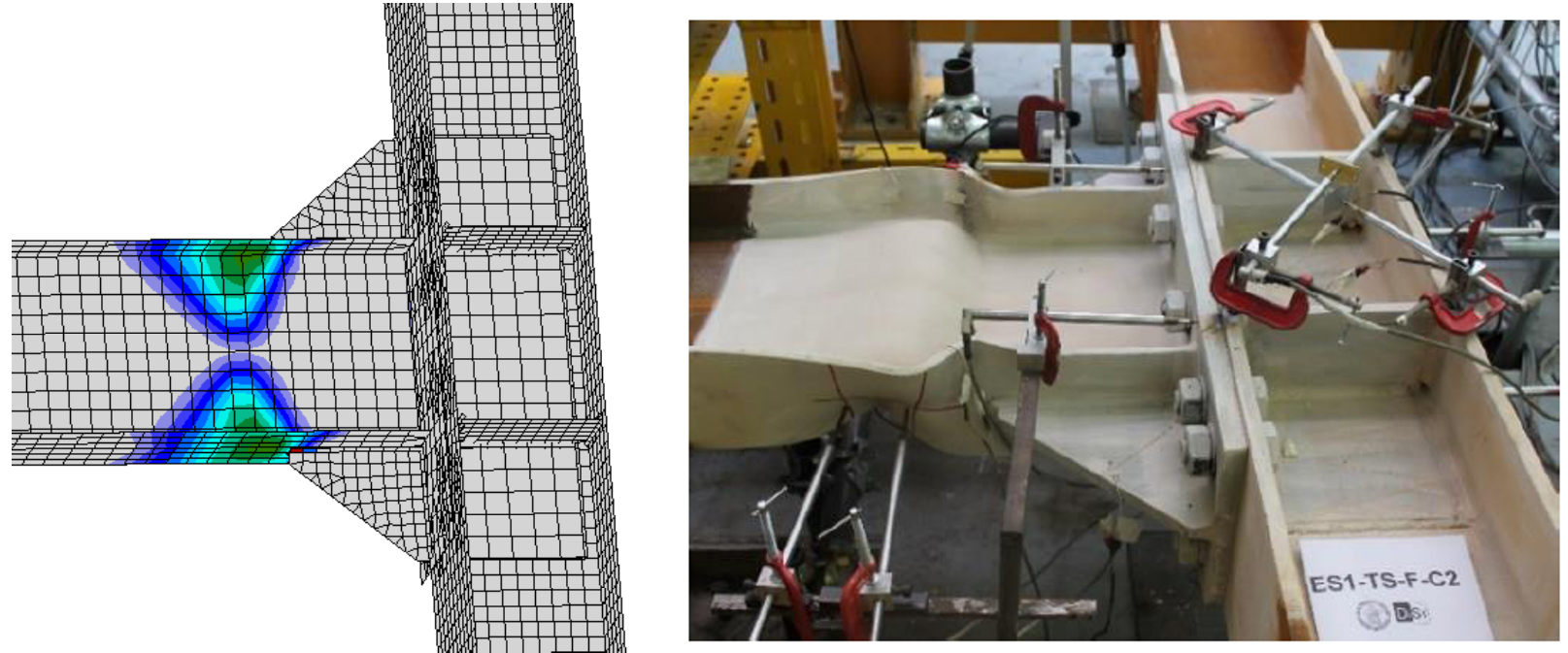

\[ \textsf{\textit{\footnotesize{c)}}}\]