Complex over-the-edge hospital helicopter landing platform

About the project

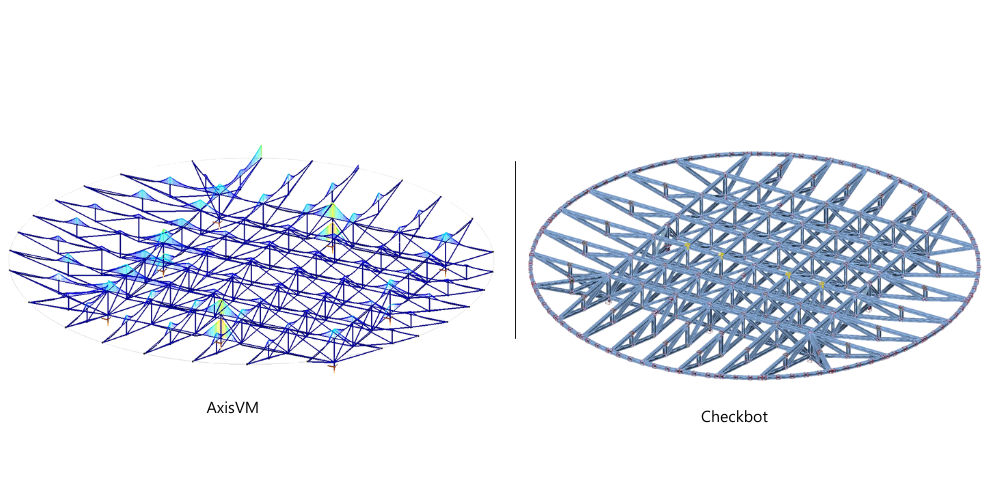

The structure is designed as a two-sided truss system that forms the steel substructure of the helicopter landing platform. Multiple primary and secondary trusses intersect in a dense network of nodes, with each node connecting different bars at different angles.

DESA Ingénieurs-Conseils s.à r.l. was responsible for the design and standards control of the steel substructure, in collaboration with the principal structural engineers, the architect, and the steel fabricator. The result is a hybrid platform of concrete and steel that can receive rescue flights on top of the hospital.

Technical challenges

The most demanding aspect of the engineering work was the detailed load definition and translation of global analysis forces into a connection-level model.

Dozens of nodes required accurate ULS load combinations, but the global static documentation gave only envelop forces that did not necessarily occur simultaneously. This posed the risk of overdesign or, worse, unconservative assumptions.

The structural layout presented additional challenges: a large number of connections, bars intersecting at irregular angles, mixed fabrication strategies (welded connections within prefabricated units and bolted connections for on-site assembly), and the need to efficiently organize the transport and lifting of large truss segments.

Each assembly operation required coordination with the steel contractor to minimize the number of on-site bolted connections without compromising structural integrity.

Solutions and results

To streamline the workflow, the engineer rebuilt the original global analysis in AxisVM using imported coordinates and element properties via VisualBasic, Excel, and the AxisVM COM interface. After the recreated model accurately matched the static calculations provided, the team used the BIM interface to export the model directly to IDEA StatiCa Checkbot. With only minor post-processing, mainly merging elements to correctly define continuous bars, the engineer obtained fully synchronized geometry and load cases for use in IDEA StatiCa Connection.

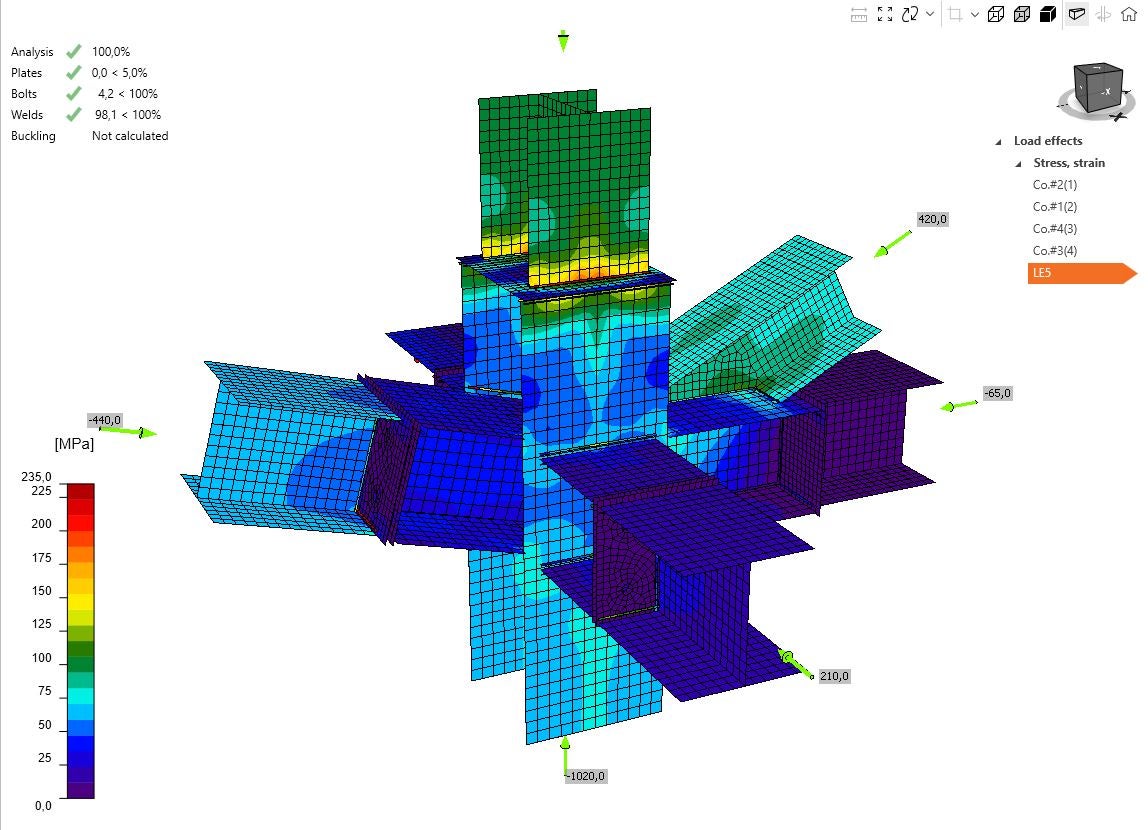

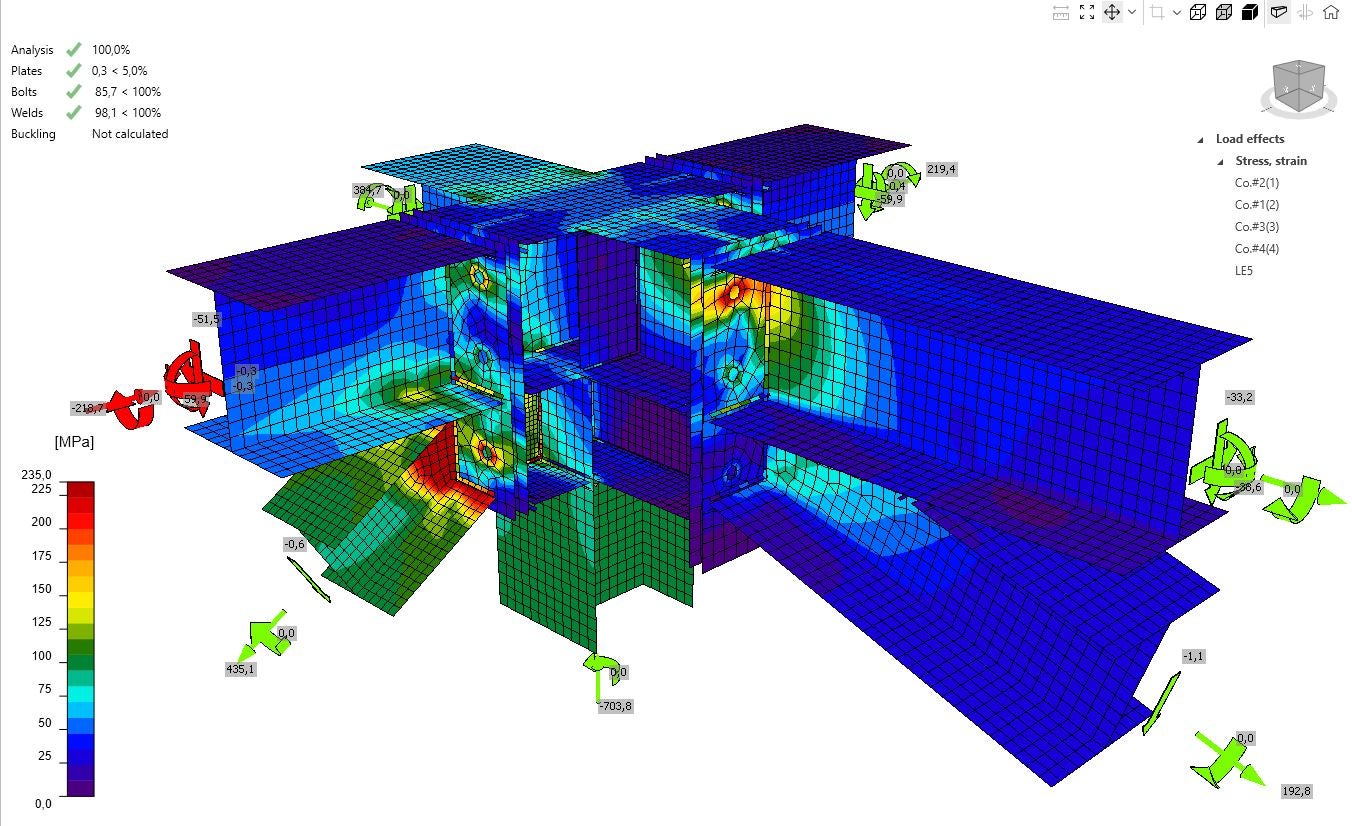

This collaborative workflow proved significantly more efficient and reliable than manually extracting forces. IDEA StatiCa allowed the engineer to consider only concurrent bar loads, reducing unnecessary conservatism and the potential for human error.

Two other IDEA StatiCa applications were crucial. The Connection Library allowed reuse of designs for the many similar but not identical nodes. Bulk design in Checkbot grouped similar connections so that a reference connection could be analyzed and then automatically verified across the group, leaving only a handful that required local refinement. For communication with the steel contractor, the ideacon file and calculation report completely replaced traditional sketches. IDEA StatiCa Viewer allowed the contractor to independently inspect the geometry, loads, and details of the connections. Even the inspection office used IDEA StatiCa, allowing transparent verification of the entire connection design.

By using Checkbot, the BIM link, library, and bulk verification workflow, the engineer achieved significant time savings, reduced manual work, and provided fully optimized, standards-compliant steel connections for the helicopter pad.

About Desa's engineer

Dr. András Kozma, the engineer in charge, graduated from the Budapest University of Technology and Economics (BME) with a specialization in bridge structures and computational engineering. He later completed a PhD at the University of Luxembourg on demountable steel-concrete composite systems. His experience bridges academic research and practical engineering, with a strong focus on advanced structural workflows and integrated digital design environments.

Prova IDEA StatiCa gratis