Forging Strong Bonds: The Power of Steel Connections

Steel frames have become a popular choice in the construction industry due to their remarkable strength, durability, and versatility. To achieve optimal performance and structural integrity, steel beam connections play a vital role in transferring loads effectively between beams and columns. In this article, we will delve into various types of steel beam connections, including column splices and beam-to-beam connections, along with essential considerations for their design.

Understanding shear force and its impact on beams

Shear force is a crucial factor to consider when designing steel beam connections. It refers to the force acting parallel to the cross-sectional area of a beam, exerting a sideways or shearing effect.

It's something so obvious to every structural engineer that most of them never thought about the fact that also this had to have been developed somehow. And as with many other things in the construction world, the shear force has also evolved through years of observation, analysis, and experimentation. Big names such as Isaac Newton and Leonhard Euler have all contributed to the theoretical understanding of forces and moments in structural systems.

Shear forces can lead to shear failure, where the material fails due to excessive shear stress. To prevent shear failure in beams, engineers employ shear connection details, which ensure the transfer of shear forces from one beam to another or between beams and columns.

A lot more can be discussed on the topic of shear connections, and we have dedicated a separate article to them here.

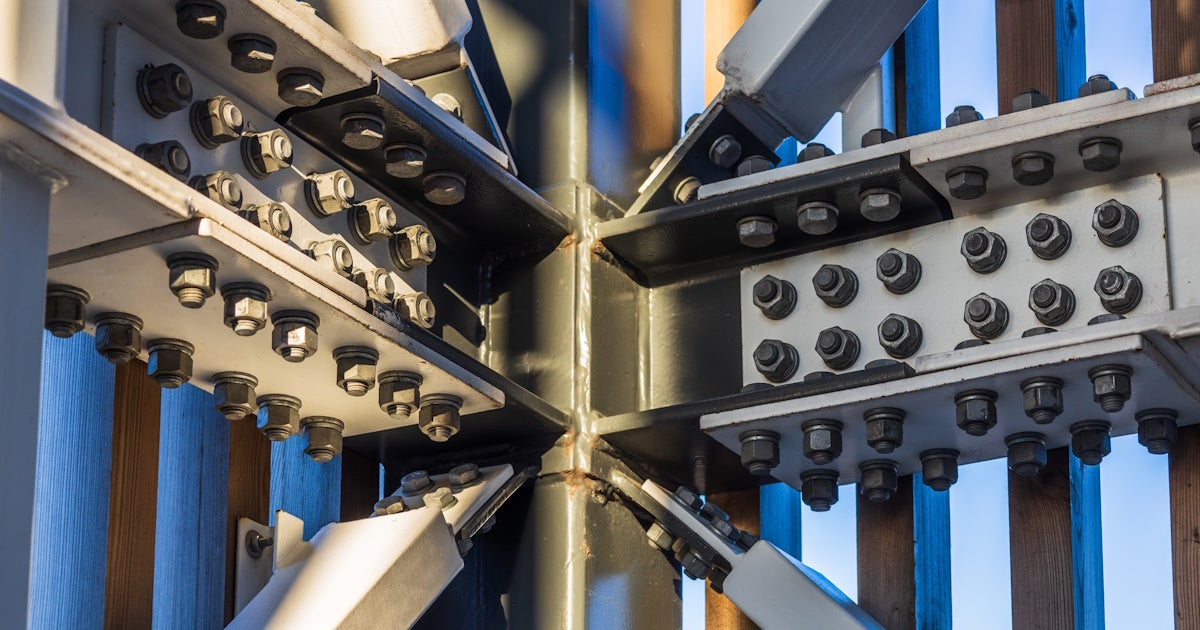

Types of steel beam connections

How many of them are out there today in the construction practice? Well, probably we can't answer that one 100% correctly as there is always space for some new type to be invented. But based on the long-term observation of steel structures, the majority belong to quite a narrow range. A few typical examples are:

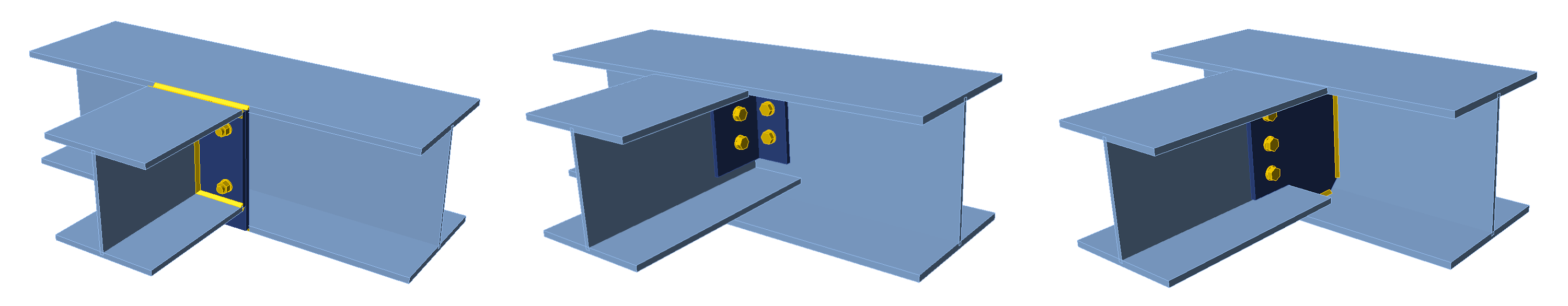

Beam-to-beam connections:

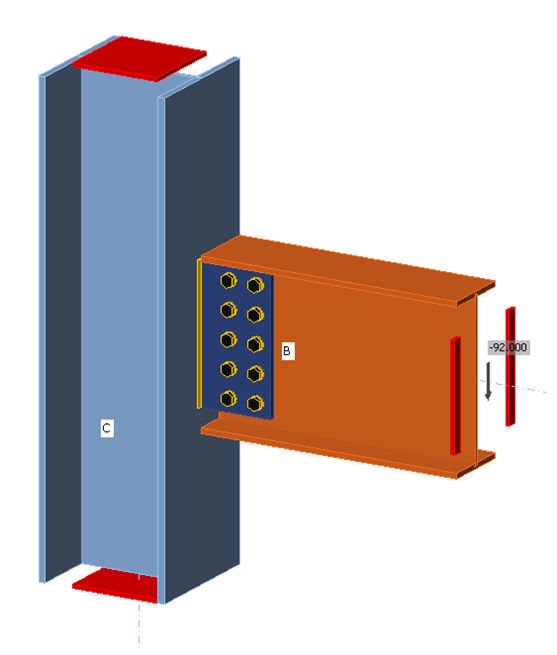

- End-plate connection: This connection involves attaching steel plates to the ends of beams and joining them using bolts. The plates are designed to resist shear and bending forces, ensuring a robust connection.

- Cleat connection: A cleat, typically made of a steel angle section, is bolted to the webs of both beams. This connection is commonly used in situations where a moment connection is not required.

- Fin plate connection: A fin plate is a single vertical plate welded to the main beam flanges and web, while bolted to the web of a secondary beam.

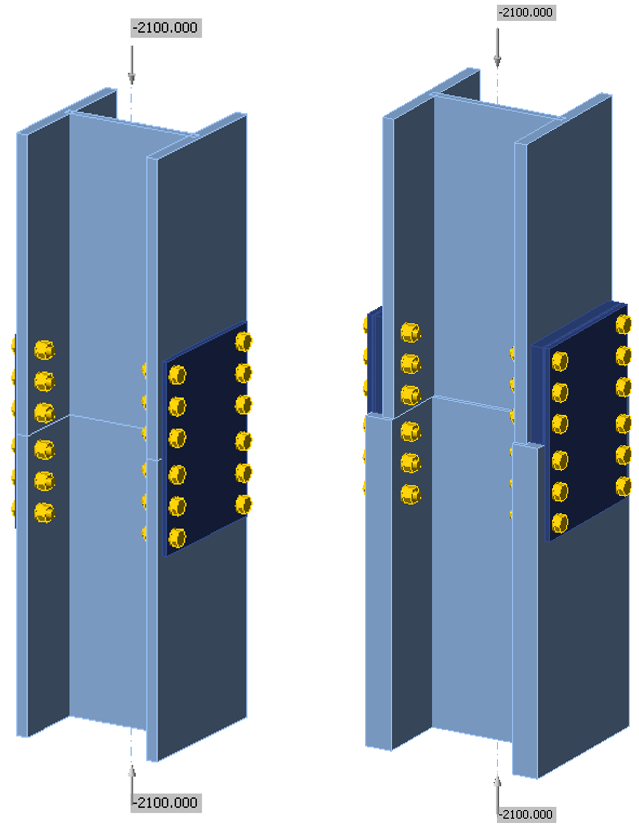

Column splice connections:

Column splice connections are crucial for joining steel columns, ensuring stability and load transfer. They can be categorized into the following types:

- Flange plate splice: In this connection, flange plates are welded or bolted to the ends of the columns to provide strength and rigidity. The flange plates resist the axial and bending forces, maintaining the stability of the structure.

- Extended end-plate splice: This connection involves extending the end plates of the columns to create a stronger joint. Bolts are used to secure the extended end plates, enhancing the connection's capacity to resist both axial and bending forces.

Design considerations for shear and axial forces

To design a steel beam for torsion, engineers must consider both shear and axial forces. Torsional forces induce twisting within a beam, which can lead to structural instability. By selecting appropriate beam sizes and cross-sectional shapes, engineers can mitigate torsion effects.

When designing bolted connections, it is important to consider the axial force, which refers to the force acting along the longitudinal axis of the member. Axial forces can influence the behavior of bolted connections and affect their load-carrying capacity. By analyzing the combined effects of axial, shear, bending, and torsional forces, engineers can ensure the connection's structural adequacy.

Designing bolted flange joints for optimal performance

Bolted flange joints are commonly used to connect the flanges of steel beams or columns. The design of these joints involves several considerations, such as:

- Bolt selection: Proper selection of bolts based on their strength, diameter, and grade is crucial for the connection's integrity. Bolts should be capable of resisting shear and tension forces imposed on the joint.

- Flange joint design: The design of the joint should provide sufficient stiffness and strength to withstand the expected loads. This includes the arrangement and number of bolts, spacing, and the use of stiffeners or washers, if necessary.

- Connection detailing: The detailing of the connection involves determining the bolt layout, edge distances, and end distances. Adequate clearance should be provided to ensure easy installation and inspection.

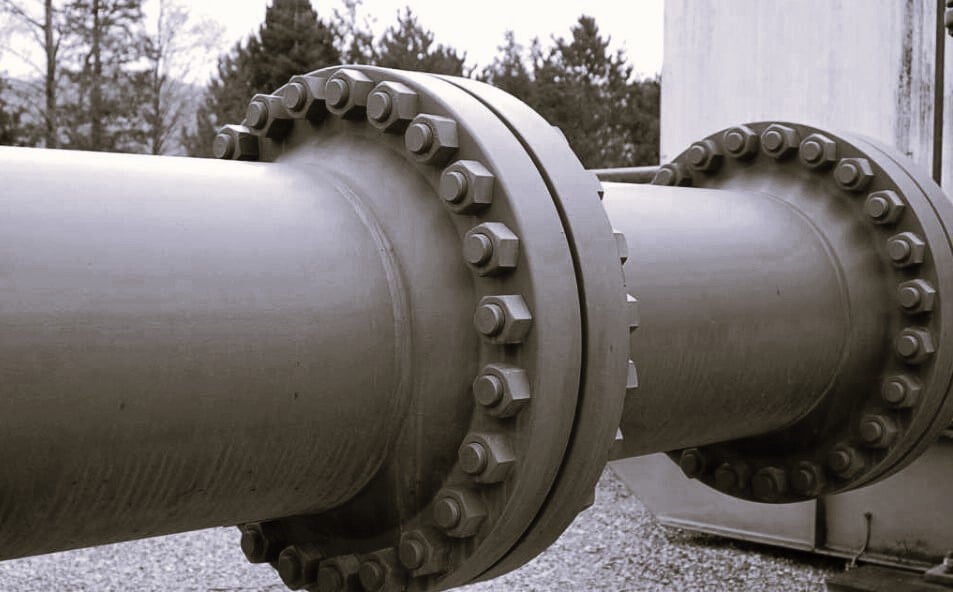

Pipe flange connection

A special kind of flange joint is the connection of hollow section members. It's the endplate connection with the opening in the plate for a continuous tube. What seems to be a task for the mechanical or pipeline engineer can also often be solved by a structural engineer. These connections are also easily solvable in the Connection app. Well-designed and well-manufactured bolted flange joint design is crucial for so many infrastructural projects to run seamlessly.

Getting up to pace

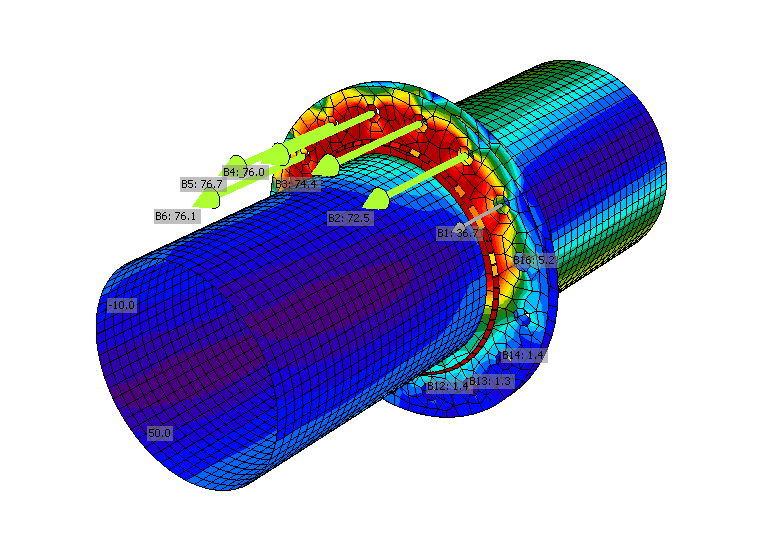

If it comes to the design of bolted flange joints the spreadsheet-like analytic solution isn't always enough and the FEA should be used instead. Solving steel connections in an advanced FEA tool can seem challenging at the beginning, but when an intuitive tool is used, the first models can be built quicker than normally expected. For those looking for some assistance at the beginning of their modeling journey, there is a whole 'Tackling IDEA StatiCa Connection' series of getting started Webinars prepared:

How can we be so sure that the CBFEM method used in IDEA StatiCa apps really works as planned? Because it's also built on tests, experiments, and verifications. One of them was dedicated solely to Single Plate Shear Connections.

A similar experiment was done for Bolted Wide Flange Splice Connections, where the typical steel column connection was verified.

Conclusion

Steel beam connections play a critical role in ensuring the structural integrity and performance of steel structures. By considering shear forces, designing appropriate connections, such as column splices and beam-to-beam connections, and accounting for an axial, moment, and torsion forces, engineers can create robust and reliable steel connections. Through meticulous design and implementation, these connections contribute to the overall safety and longevity of steel structures, meeting the demands of modern construction methods and designs.

Remember, a comprehensive understanding of the various types of steel beam connections and their design principles is crucial for architects, structural engineers, and construction professionals to deliver projects that withstand the test of time and ensure the safety of occupants.

If you are interested in these connection models and want to inspire yourself, just browse through our Sample projects gallery.