How to get started with API - Optimize components in a joint 04

First steps

We recommend going through the tutorial How to get started with API - Basics 01, which teaches you about the API and how to set up the environment.

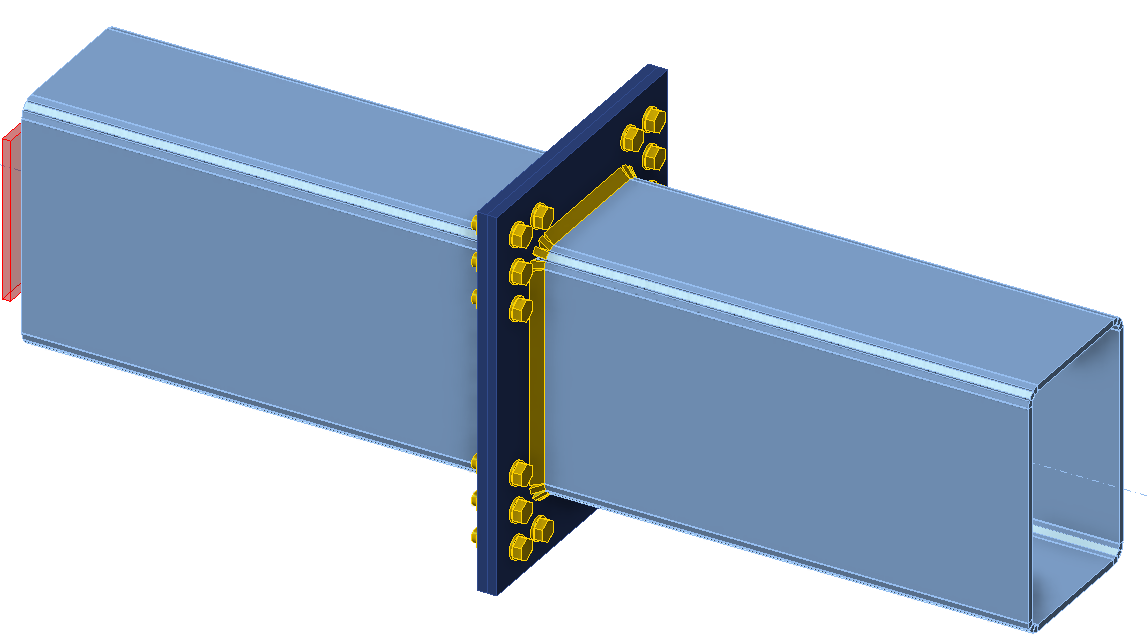

Connection file

This example is based on files created within the tutorial How to get started with API - Import a template and run calculation 03.

Please download the file tutorial 03 with template-new.ideaCon.

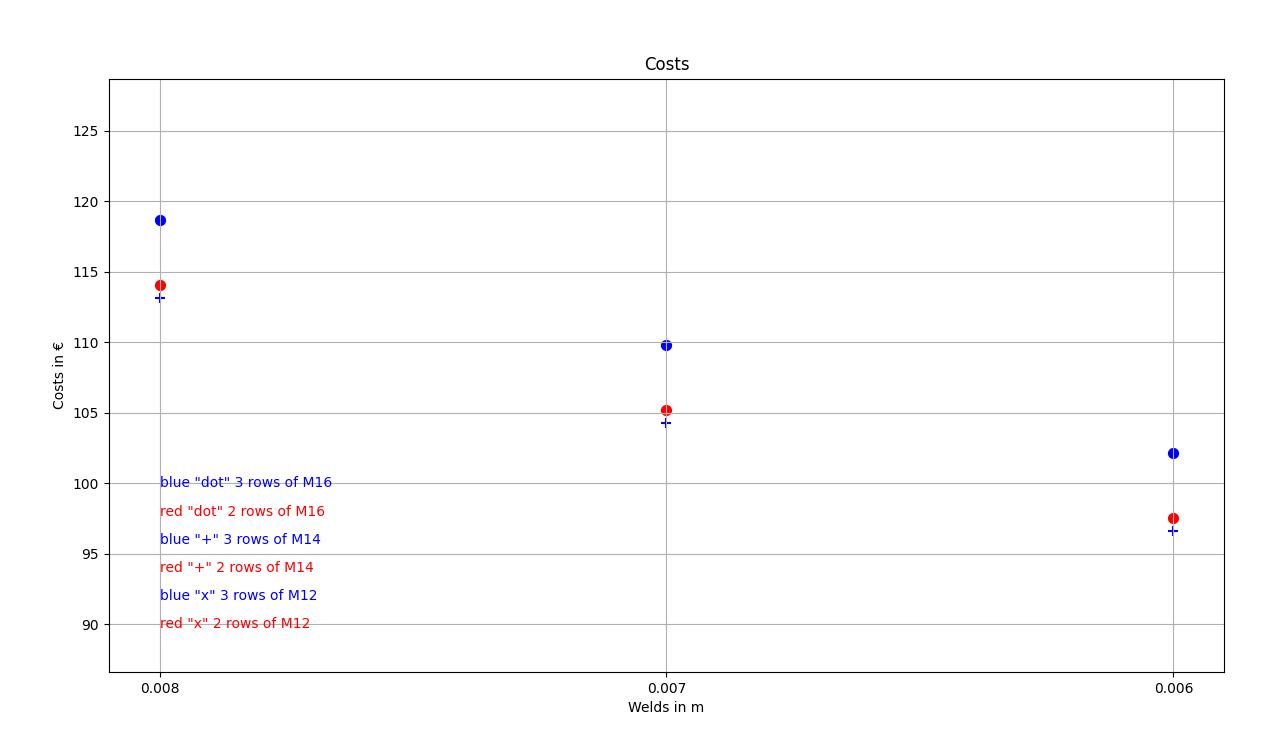

We want to optimize the connection's components (welds, diameter, and number of bolts). The result of the optimization is the joint's costs, which are neatly presented in a graph.

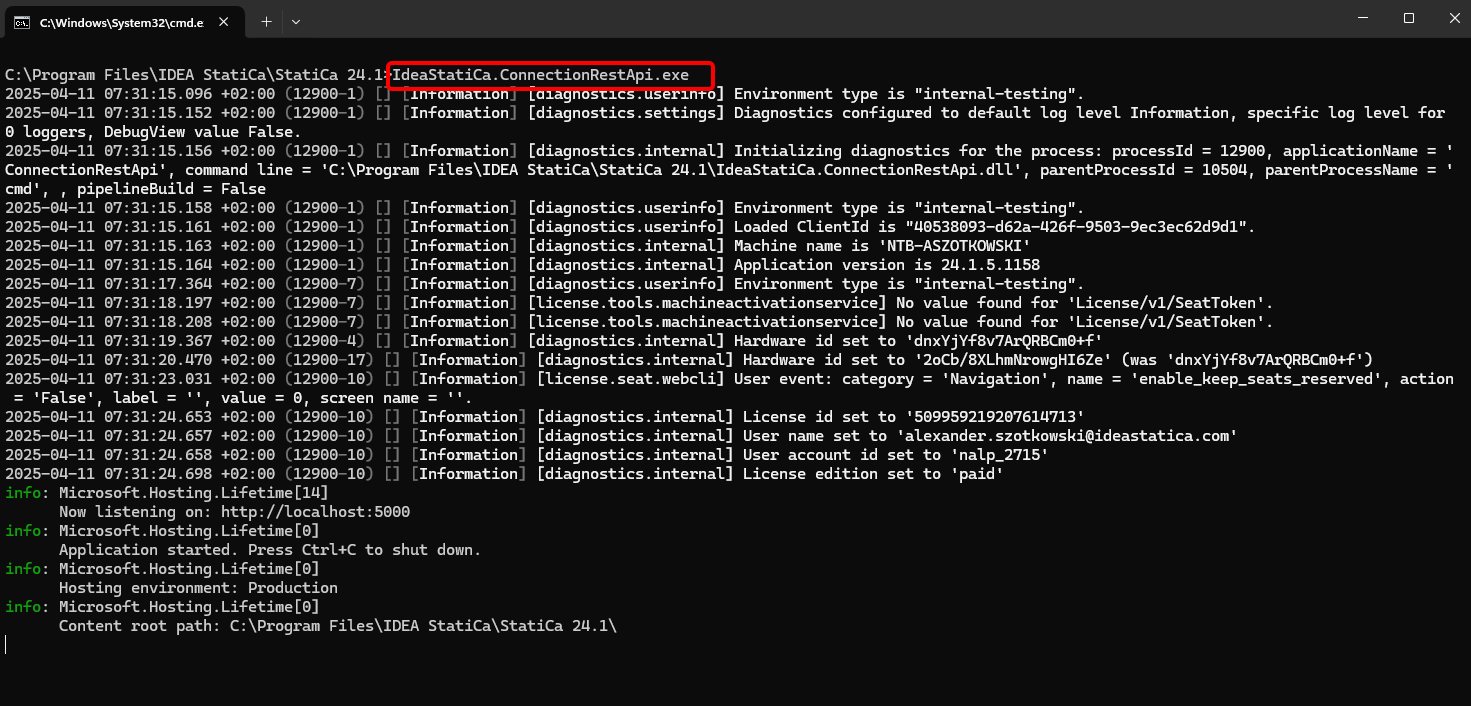

Python client

Run the "IdeaStatiCa.ConnectionRestApi.exe" in CMD within the proper IDEA StatiCa folder and open the IDE tool of your choice.

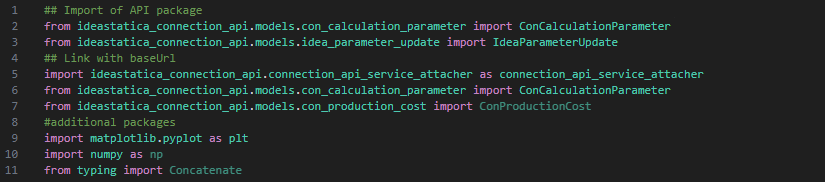

- Create a new file and import the packages that will enable the use of calculation and link with the localhost URL.

Source code:

## Import of API package

from ideastatica_connection_api.models.con_calculation_parameter import ConCalculationParameter

## Link with baseUrl

import ideastatica_connection_api.connection_api_service_attacher as connection_api_service_attacher

from ideastatica_connection_api.models.con_calculation_parameter import ConCalculationParameterfrom ideastatica_connection_api.models.con_production_cost import ConProductionCost

#additional packages

import matplotlib.pyplot as plt

import numpy as np

from typing import Concatenate

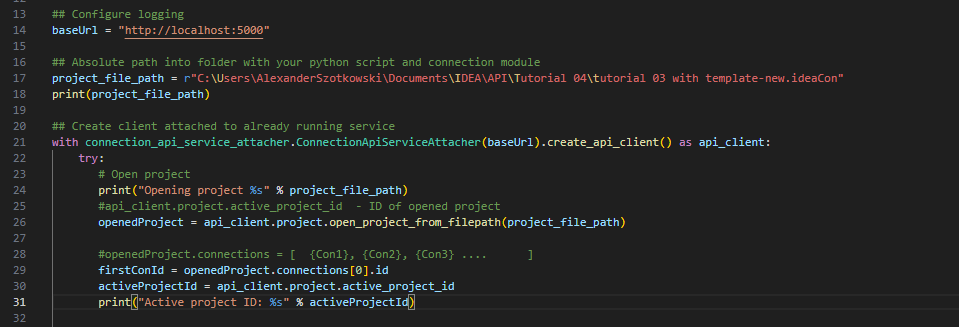

- Configure the logging via the variable "baseUrl," which will pull up your localhost. In the second step, pair the absolute path of your IDEA StatiCa Connection file.

## Configure logging

baseUrl = "http://localhost:5000"

## Absolute path into folder with your python script and connection module

project_file_path = r"C:\Users\AlexanderSzotkowski\Documents\IDEA\API\Tutorial 04\tutorial 03 with template -new.ideaCon"

print(project_file_path)

- Pair the client with an already running service. Use the block try/except - since the try block raises an error, the except block will be executed. In the first phase, it is necessary to open up the project and find the project ID of your project, which is unique for every IDEA StatiCa project. Then we select the first connection stored in our file.

# Create a client attached to an already running service

with connection_api_service_attacher.ConnectionApiServiceAttacher(baseUrl).create_api_client() as api_client:

try:

# Open project

print("Opening project %s" % project_file_path)

#api_client.project.active_project_id - ID of opened project

openedProject = api_client.project.open_project_from_filepath(project_file_path)

#openedProject.connections = [ {Con1}, {Con2}, {Con3} .... ]

firstConId = openedProject.connections[0].id

activeProjectId = api_client.project.active_project_id

print("Active project ID: %s" % activeProjectId)

- Retrieve all needed parameters from the ideaCon (number of bolts, diameter, weld size, bolt assembly)

#get parameters from ideaCon file

include_hidden = True

parameters = api_client.parameter.get_parameters(activeProjectId, firstConId, include_hidden=include_hidden)

#get default values from the ideaCon file

#Diameter of the bolt

boltParameter = parameters[3]

#print('bolt ',boltParameter.value)

#Number of bolt rows

rowParameter = parameters[11]

#print('row ',rowParameter.value)

#Weld size

weldParameter = parameters[28]

#print('weld ',weldParameter.value)

#Bolt assembly

boltAssemblyParameter = parameters[29]

#print('bolt assembly ',boltAssemblyParameter.value)

- We want to get results only when the calculation is 100% positive for all parts (plates, welds, bolts), so we have to set the Stop at the limit strain on True. Results will be stored in a list, called matrix, which we then use to display a graph.

#setup

updateSettings = api_client.settings.get_settings(api_client.project.active_project_id)

from typing import Dict

updateSettings: Dict [str, object] = {

"calculationCommon/Analysis/AnalysisGeneral/Shared/StopAtLimitStrain@01" : True,

"calculationCommon/Checks/Shared/LimitPlasticStrain@01" : 0.05

}

api_client.settings.update_settings(api_client.project.active_project_id, updateSettings)

#Final results database

matrix = []

- Now, we start a cycle by changing the welds (from t = 8 to 5 mm), bolt diameter (from M16 to M12), and number of rows (from 3 to 1). The numbers 8, M16, and 3 are values taken from the ideaCon file. The ongoing results are printed on the screen and also added to the list of results.

#cycling through welds with given rows and bolts

for row in range(rowParameter.value,1, -1):

#print ('Number of bolt rows is', row)

for bolt in range(int(1000*boltParameter.value), 12,-2):

for weld in range(int(1000*weldParameter.value), 5,-1):

par_row = IdeaParameterUpdate() # Create a new instance

par_row.key = rowParameter.key

par_row.expression = str(row)

par_bolt = IdeaParameterUpdate() # Create a new instance

par_bolt.key = boltParameter.key

par_bolt.expression = str(bolt/1000) # Decrement the expression

par_boltAssembly = IdeaParameterUpdate() # Create a new instance

par_boltAssembly.key = boltAssemblyParameter.key

par_boltAssembly.expression = str('M'+ str(bolt) + ' 8.8')

par_weld = IdeaParameterUpdate() # Create a new instance

par_weld.key = weldParameter.key

par_weld.expression = str(weld/1000) # Decrement the expression

updateResponse = api_client.parameter.update(activeProjectId, firstConId, [par_row, par_bolt, par_boltAssembly, par_weld] )

updateResponse.set_to_model

# Check if the parameters were updated successfully

if updateResponse.set_to_model == False:

print('Parameters failed: %s' % ', '.join(updateResponse.failed_validations))

#set the type of analysis

ConCalculationParameter.analysis_type = "stress_strain"

conParameter = ConCalculationParameter()

conParameter.connection_ids = [ firstConId ]

summary = api_client.calculation.calculate(activeProjectId, conParameter.connection_ids)

# Get results after calculation, store it in separate file and print the actual results

results = api_client.calculation.get_results(activeProjectId, conParameter.connection_ids)

CheckResSummary = results[0].check_res_summary

costs = api_client.connection.get_production_cost(api_client.project.active_project_id, firstConId)

api_client.project.download_project(activeProjectId, r'C:\Users\AlexanderSzotkowski\Documents\IDEA\API\Tutorial 04\tutorial 03 with template-updated.ideaCon')

if CheckResSummary[0].check_status == False:

break

if CheckResSummary[0].check_status == True:

print (row,'rows of', bolt, 'bolts', 'and weld size ',par_weld.expression,' results are OK. Costs: ', costs.total_estimated_cost)

values= [row, bolt,par_weld.expression,costs.total_estimated_cost]

#print(values)

matrix.append(values)

else:

print ('Iteration %i failed' % weld)

else:

print ('Iteration %i for weld failed' % weld)

else:

print ('Iteration %i for bolts failed' % bolt)

else:

print ('Iteration %i for rows failed' % row)

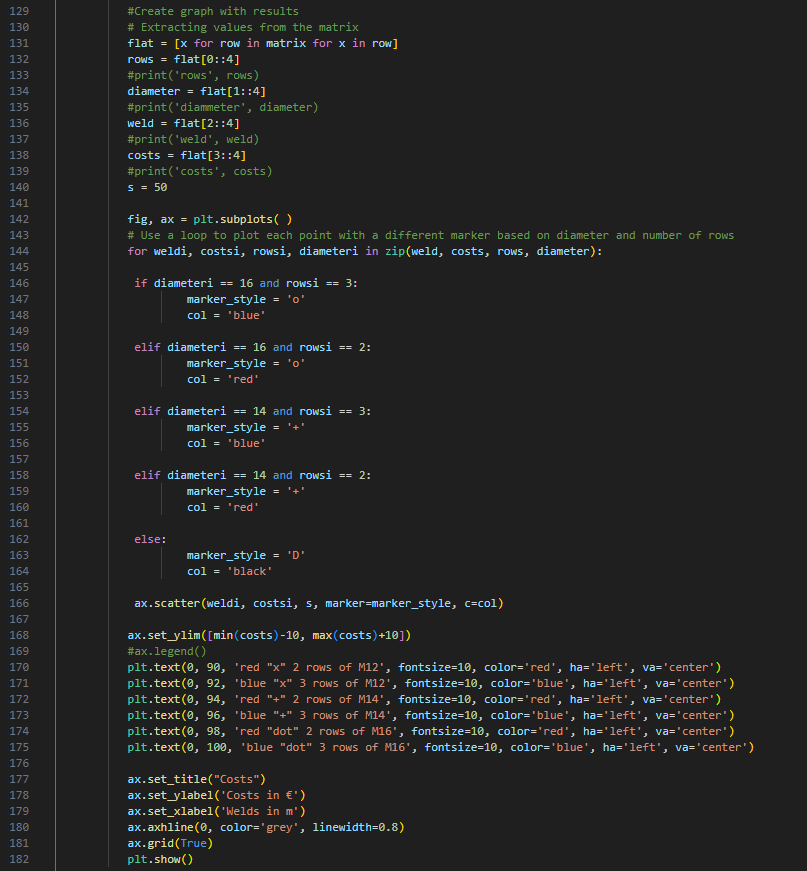

- The last part is about creating a graph with our results.

#Create graph with results

# Extracting values from the matrix

flat = [x for row in matrix for x in row]

rows = flat[0::4]

#print('rows', rows)

diameter = flat[1::4]

#print('diammeter', diameter)

weld = flat[2::4]

#print('weld', weld)

costs = flat[3::4]

#print('costs', costs)

s = 50

fig, ax = plt.subplots( )

# Use a loop to plot each point with a different marker based on diameter and number of rows

for weldi, costsi, rowsi, diameteri in zip(weld, costs, rows, diameter):

if diameteri == 16 and rowsi == 3:

marker_style = 'o'

col = 'blue'

elif diameteri == 16 and rowsi == 2:

marker_style = 'o'

col = 'red'

elif diameteri == 14 and rowsi == 3:

marker_style = '+'

col = 'blue'

elif diameteri == 14 and rowsi == 2:

marker_style = '+'

col = 'red'

else:

marker_style = 'D'

col = 'black'

ax.scatter(weldi, costsi, s, marker=marker_style, c=col)

ax.set_ylim([min(costs)-10, max(costs)+10])

#ax.legend()

plt.text(0, 90, 'red "x" 2 rows of M12', fontsize=10, color='red', ha='left', va='center')

plt.text(0, 92, 'blue "x" 3 rows of M12', fontsize=10, color='blue', ha='left', va='center')

plt.text(0, 94, 'red "+" 2 rows of M14', fontsize=10, color='red', ha='left', va='center')

plt.text(0, 96, 'blue "+" 3 rows of M14', fontsize=10, color='blue', ha='left', va='center')

plt.text(0, 98, 'red "dot" 2 rows of M16', fontsize=10, color='red', ha='left', va='center')

plt.text(0, 100, 'blue "dot" 3 rows of M16', fontsize=10, color='blue', ha='left', va='center')

ax.set_title("Costs")

ax.set_ylabel('Costs in €')

ax.set_xlabel('Welds in m')

ax.axhline(0, color='grey', linewidth=0.8)

ax.grid(True)

plt.show()

As you can see, in this particular case, the most economical joint is that with a 6 mm weld and three rows of M14 bolts.

Download allegati

- tutorial 04 - 3 optimize bolts and welds.py (PY, 9 kB)

- tutorial 03 with template-new.ideaCon (IDEACON, 59 kB)