Coupling Beams and IDEA StatiCa

Coupling beams are typically added to a structure to improve its lateral force resistance. They bridge two separate, independent items together (like shear walls) to add stiffness to the overall system. They are usually short and thick, similar to deep beams. In concrete buildings, in particular, they take the form of concrete beams, which are often one of the most critical elements.

Figure 1. Fisher, Andrew W., et al. "Response of Heavily Reinforced High-Strength Concrete Coupling Beams." ACI Structural Journal, vol. 114, no. 6, Nov.-Dec. 2017, pp. 1483+. Gale Academic OneFile, link.gale.com/apps/doc/A558752923/AONE?u=anon~dff1dbd&sid=googleScholar&xid=6f6988a6. Accessed 1 Nov. 2022.

Coupling beams have two roles in most buildings. Firstly, the beam couples two shear walls to increase the moment of resistance. If you have two uncoupled shear walls, the force exerted from the side of one wall would not influence the second wall because they are not connected by beams with a typical rectangular cross section. This means that the force exerted will affect only one wall, which might cause movement to occur independently of the other one. This significantly decreases the structural integrity of the building. By contrast, by coupling the two, you reduce the stress each wall attracts by distributing the forces from one wall to the other through the beam system. Coupling beams also distribute the lateral force across the length of the second wall, which further spreads the tension along the element and enhances the overall resistance of the structural elements.

Figure 2. Yang Liu, Hai Chen, Zi-Xiong Guo & Hong-Song Hu (2020) Seismic performance of subassemblies with composite wall and replaceable steel coupling beam, Journal of Asian Architecture and Building Engineering, 19:2, 123-137, DOI: 10.1080/13467581.2020.1718679

The second role of a coupling beam is to act as a source of energy dissipation during extreme stress. For example, if there is an earthquake, a building has to be resilient against pressure. To be resilient, a structure cannot be too rigid. Otherwise, if there were an earthquake (for example), that building would break at the wall pier and collapse. By contrast, a slight amount of flexibility under extraordinary pressure means that the structure is much more able to maintain essential structural integrity under pressure.

A coupling beam then both strengthens the design of a building as a whole and is designed to yield first to preserve more vital parts of a building if it experiences extreme stress. By accommodating a building’s motion in beam design, structural engineers make more stable and safe structures.

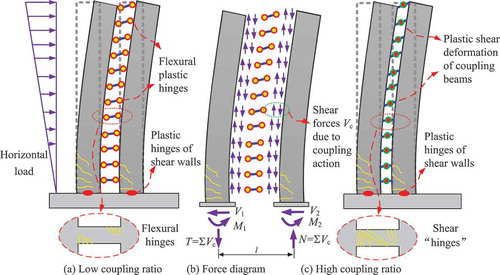

Coupling beam models

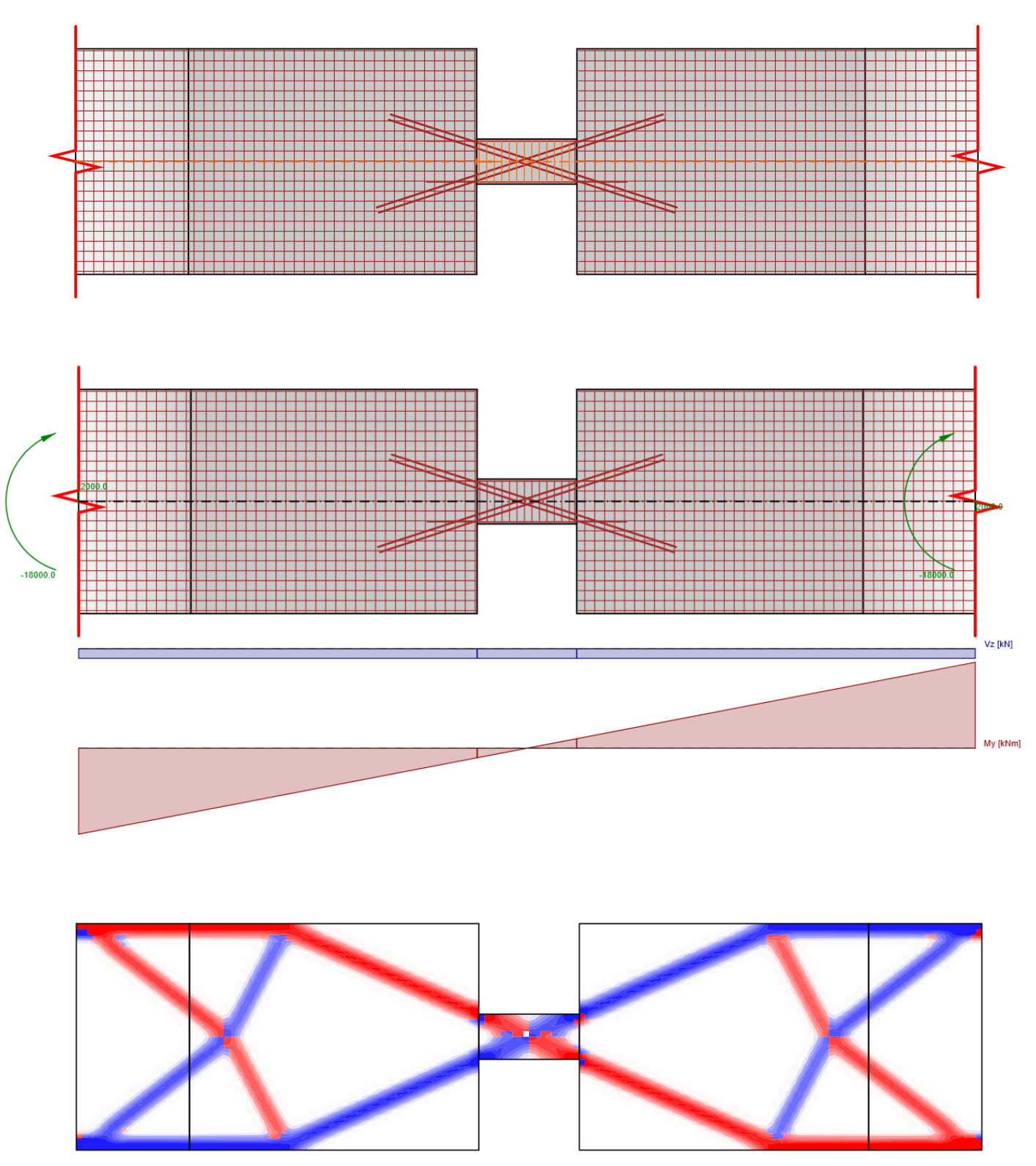

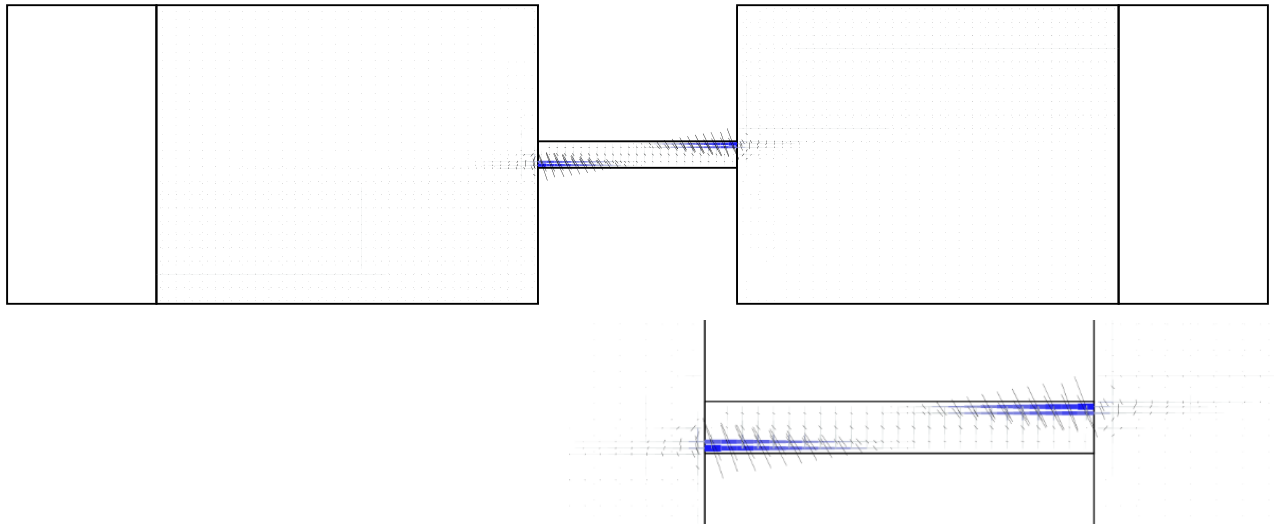

The model can be split according to the energy dissipation mechanism on the low/high coupling ratio. Due to the reinforcement ratio and mainly length/height ratio, the mechanism of plastic hinges will be developed on the coupling beams. Model 1 below has a low coupling ratio and l/h >4 and can be designed according to beam theory, and the plastic hinges will appear at the end of the beam. Models 2 and 3 below have a high coupling ratio with l/h<2 and this leads to different mechanisms of plastic hinges caused by the shear force. The models have been modeled and code-checked in IDEA StatiCa Detail and IDEA StatiCa Member.

Figure 3. Types of coupling beam according to the coupling ratio and plastic hinge development

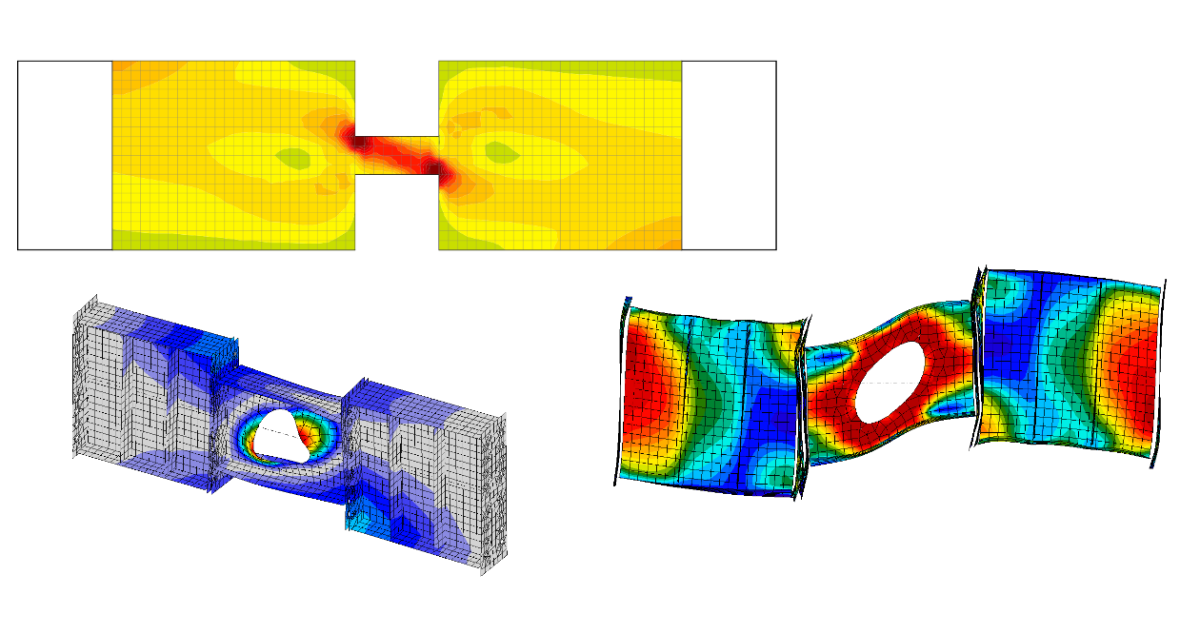

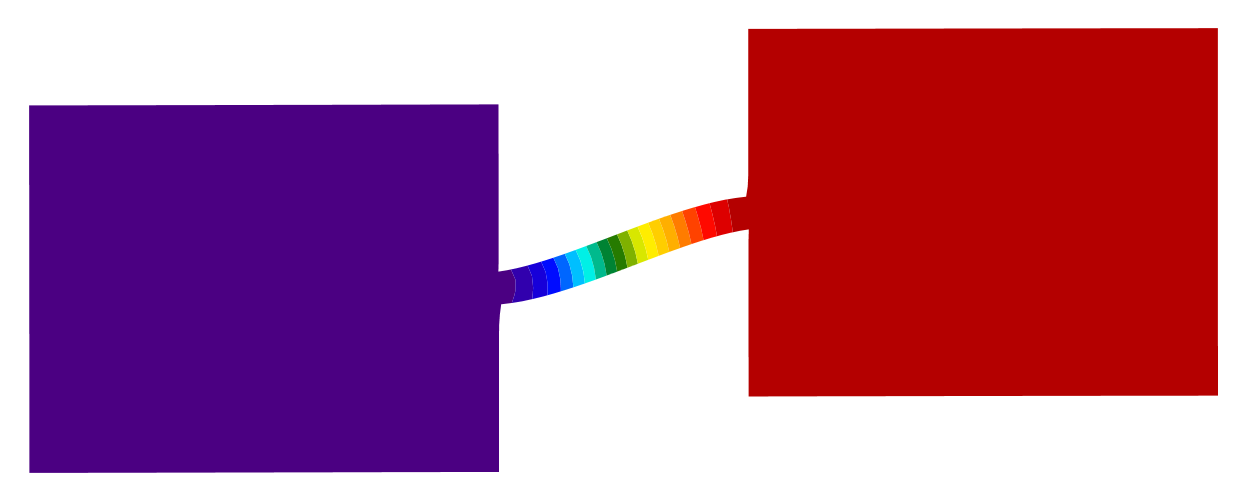

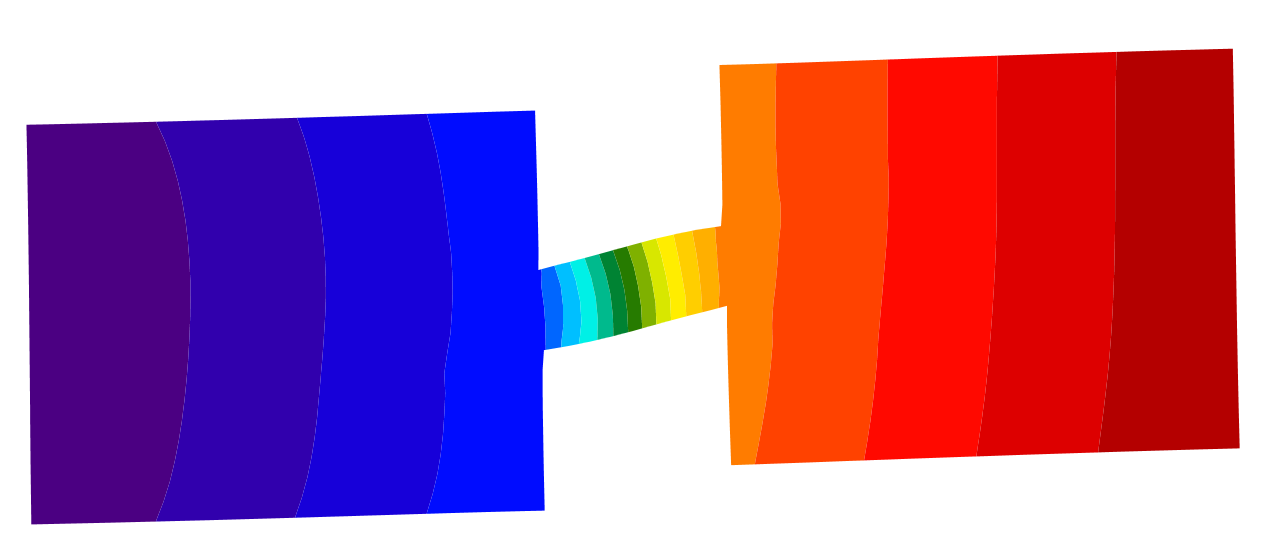

Loads and topology optimization

Shear walls can serve as an effective structural system to resist lateral loads, such as earthquakes or wind, in high-rise buildings. Coupling beams that connect these walls, which behave independently on each floor, can improve the building’s lateral resistance capacity and dissipate energy. The internal forces induced by these dynamic loads are mainly in-plane forces. The principal stresses reveal the most demanding areas of the structure and help us understand the correct reinforcement layout. Topology optimization uses the strut and tie method, which is familiar to structural engineers.

Figure 4.1. Internal forces and topology optimization for low coupling ratio

Figure 4.2. Internal forces and topology optimization for high coupling ratio

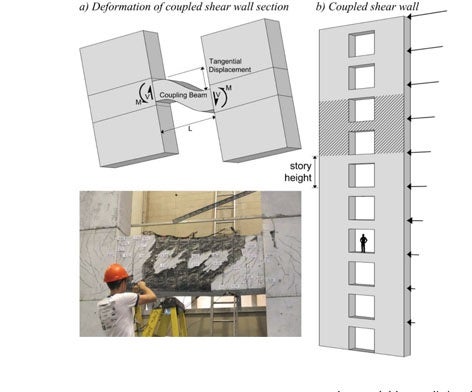

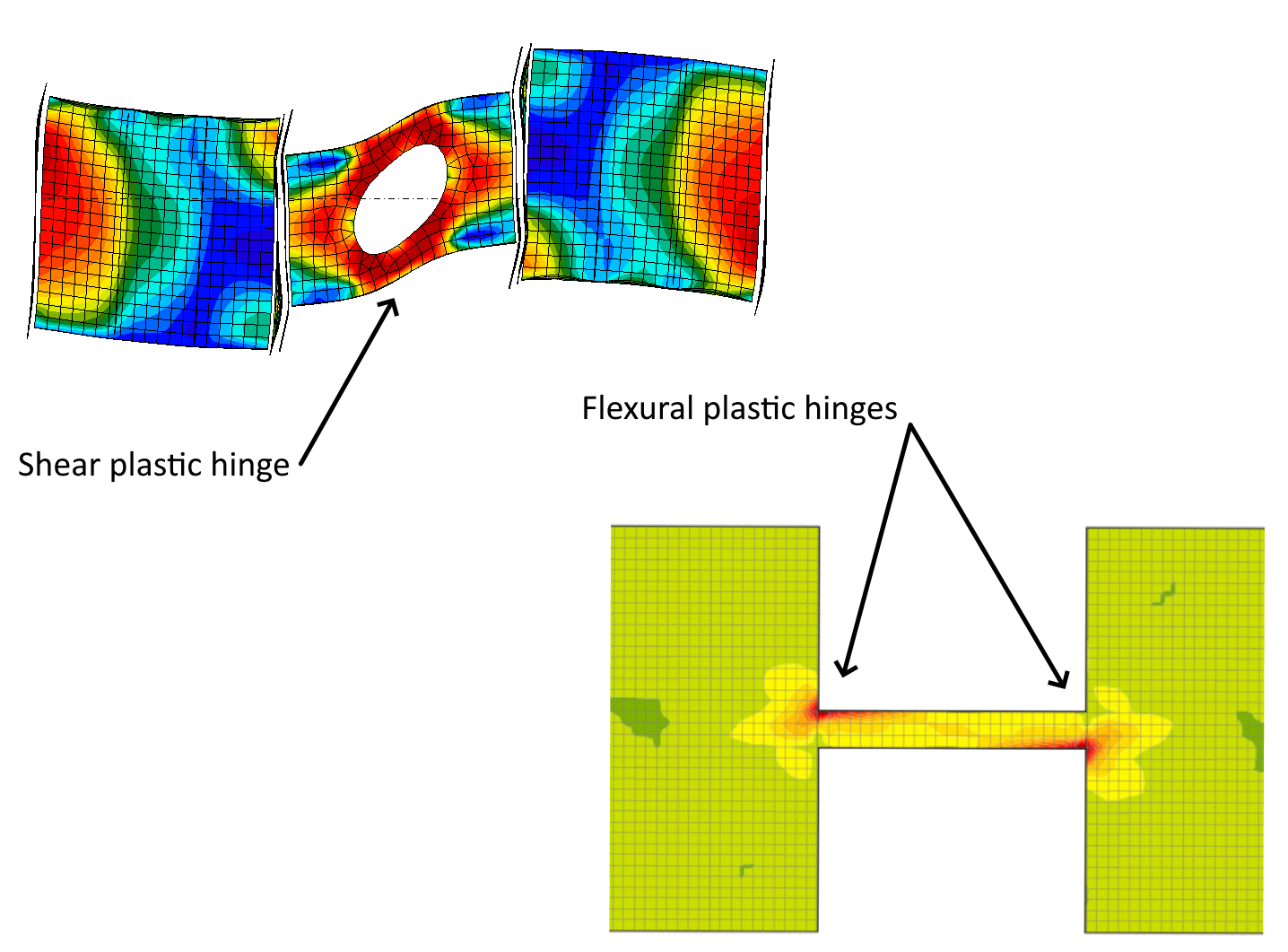

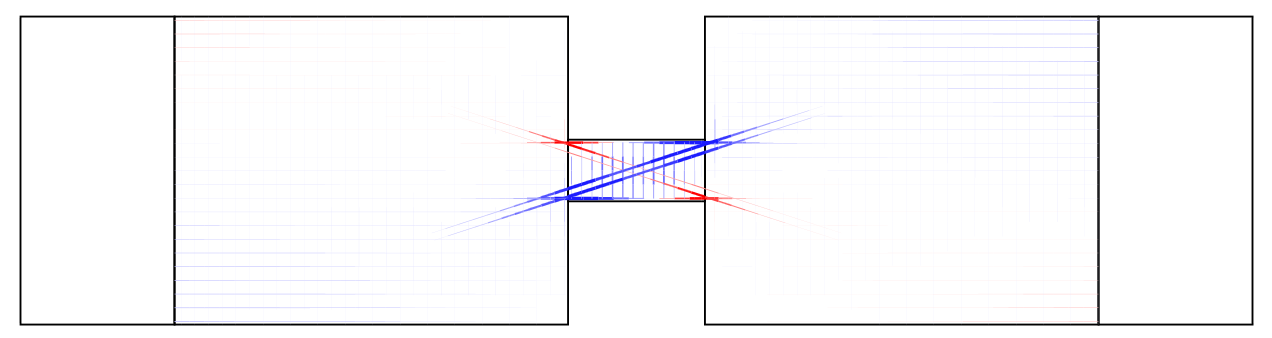

Plastic hinges mechanism

Plastic hinges are developed based on the coupling ratio. Deep coupling beams with a high coupling ratio develop shear plastic hinges located in the middle of the beam. On the other hand, a beam with a low coupling ratio leverages the low bending stiffness of the beams to create the plastic hinges at the ends of the coupling beams.

Figure 5. Shear and flexural plastic hinges

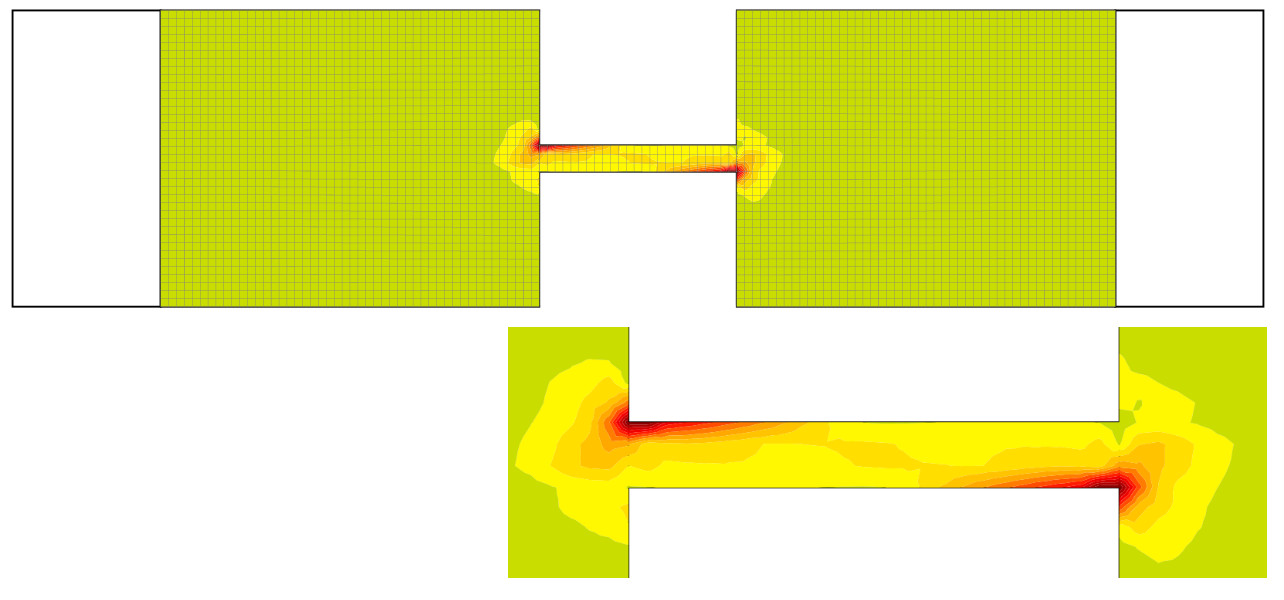

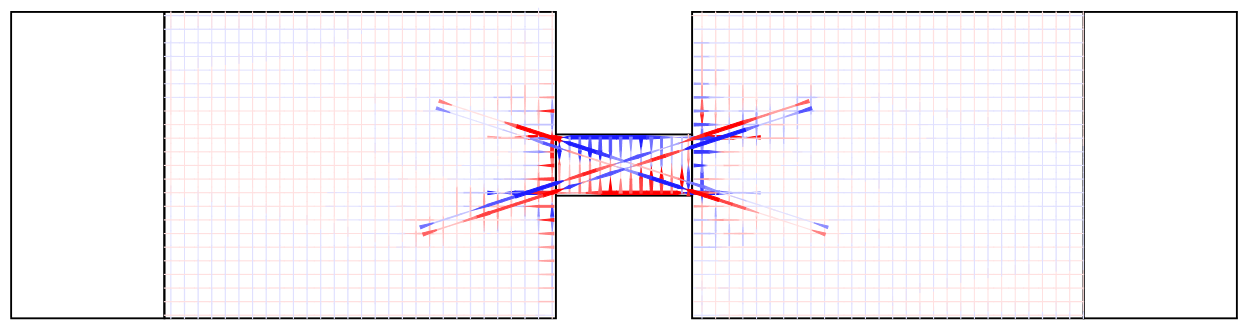

Singularities vs. stress

The sharp corner created at the junction of the coupling beam and shear wall creates a local stress peak which skews the model results. This peak is caused by the singularities at the point of the sharp re-entrant corner. The question is how to deal with these peaks in the models themselves. Find out more here.

Coupling beams code-check

A code check, according to the code, is the main part of the analysis procedure. Let's investigate what we can get from the results for concrete and hybrid coupling beams by using IDEA StatiCa Detail and IDEA StatiCa Member.

Coupling beams – low coupling ratio

Due to its relatively simple detailing and ease of construction, the conventional RC coupling beam is the most extensively used coupling beam type in building design. In low seismic risk areas, conventional RC coupling beams are sometimes sized wider than the connecting shear walls in flat-slab buildings. However, the conventional RC coupling beam does not provide good energy dissipation capacities under high cyclic shear stresses, and significant 'pinching' phenomena are present in its hysteresis response. Diagonal shear failure and sliding shear failure are not avoidable in this type of coupling beam, even with closely spaced transverse reinforcing detailing.

Figure 6. Principal stress in compression

Figure 7. Stress in reinforcement bars

Figure 8. Anchorage bond stress in the reinforcement

Figure 9. Crack development and direction

Figure 10. Nonlinear deflection

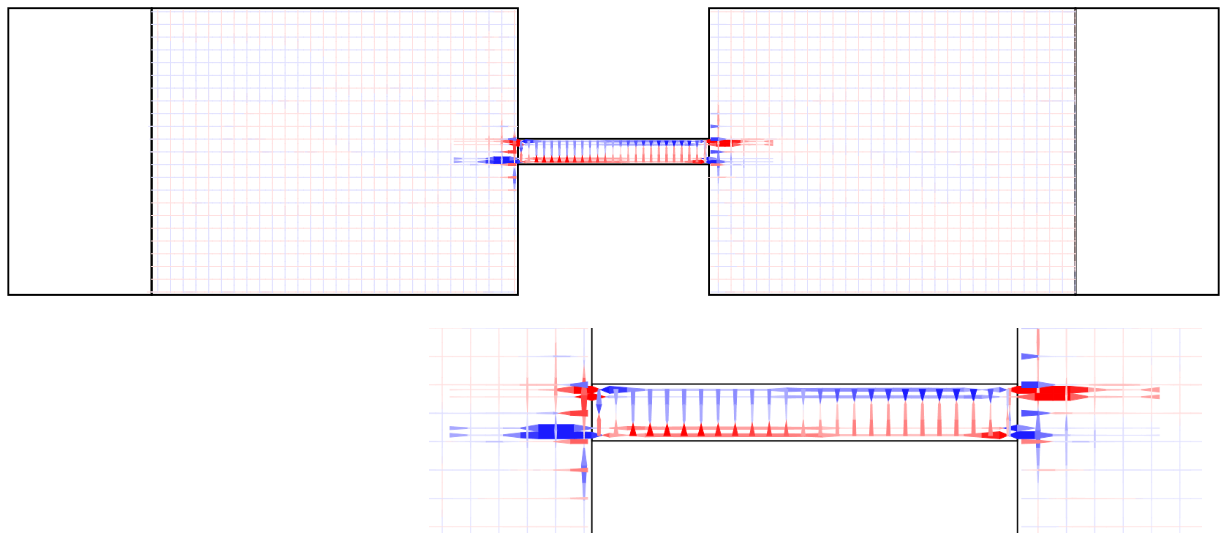

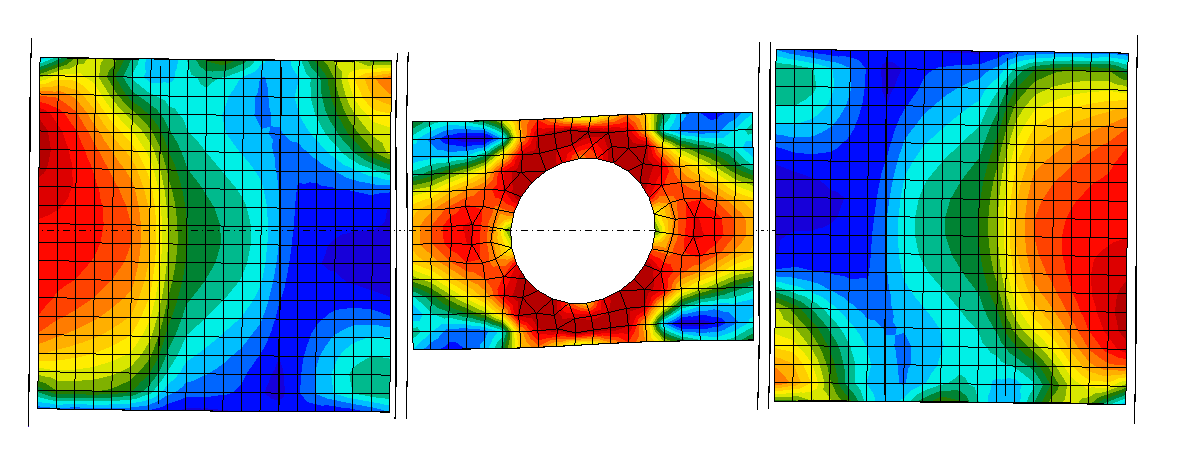

Coupling beams – high-coupling ratio

Diagonally reinforced concrete coupling beams are recognized as the most effective type of reinforcing beam for providing ductile performance with an excellent energy dissipation capacity, especially when the span/depth ratio is less than two. Although diagonally reinforced coupling beams exhibit excellent stiffness and highly ductile energy dissipation capacities, some constructability issues limit their application.

Figure 11. Principal stress in compression

Figure 12. Stress in reinforcement bars

Figure 13. Anchorage bond stress in the reinforcement

Figure 14. Crack development and direction

Figure 15. Nonlinear deflection

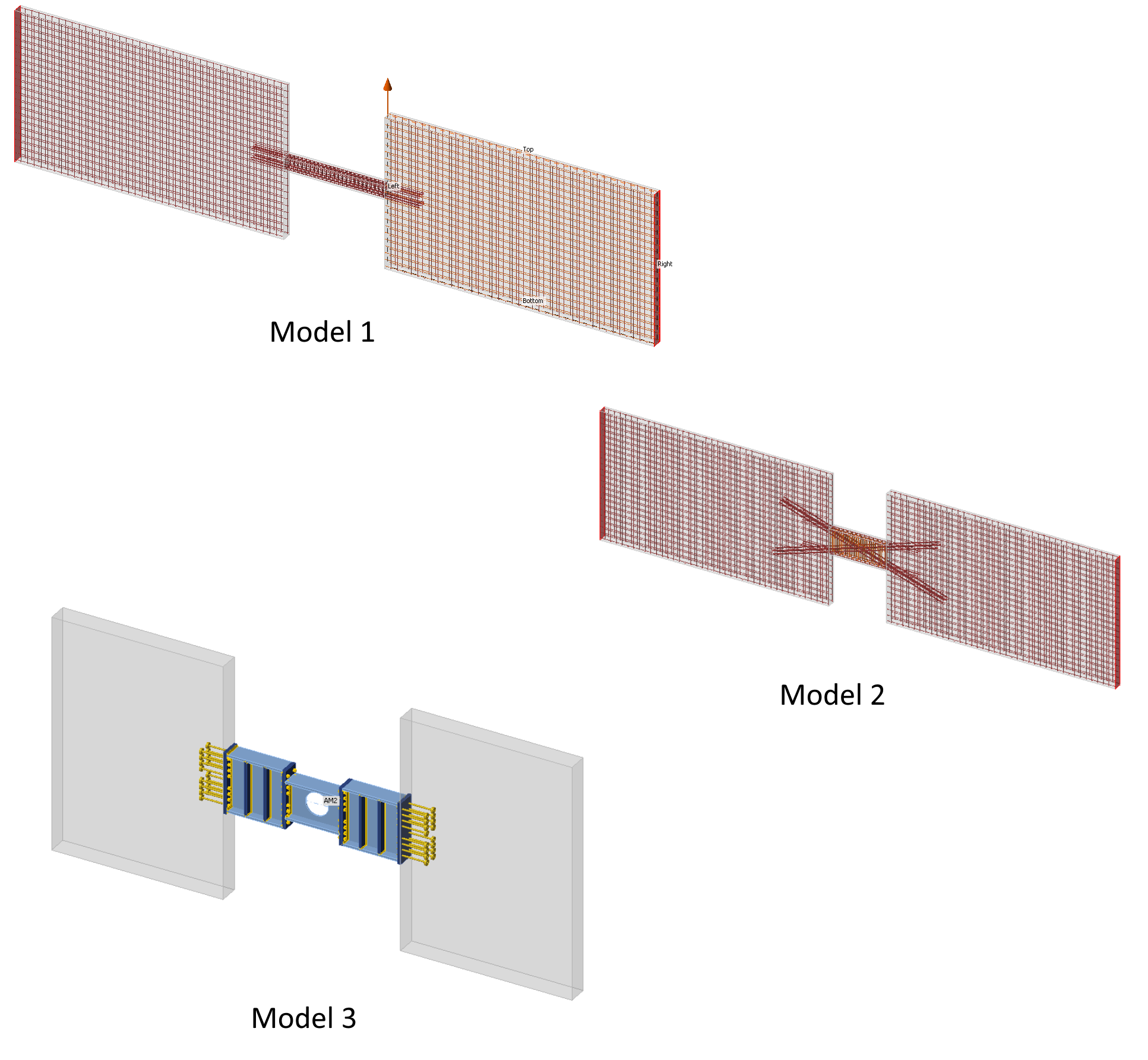

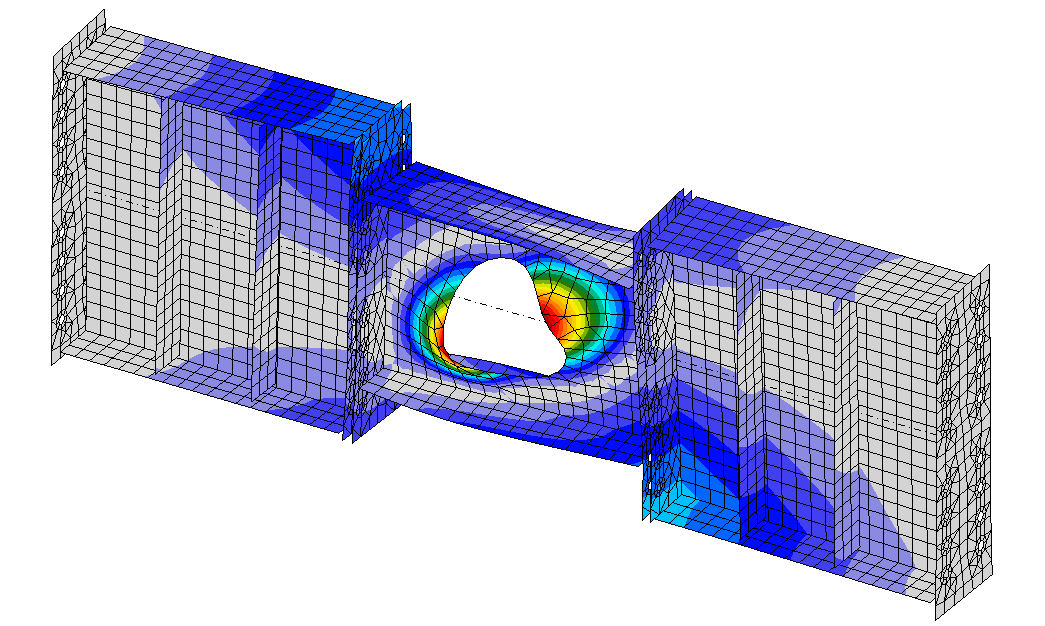

The hybrid coupling beam

Coupling beams are difficult and time-consuming to repair once damaged after an earthquake. Recently, several researchers developed various types of replaceable coupling beams that can be repaired post-earthquake. One primary concern for the replaceable coupling beam is to improve its self-centering capacity to reduce the residual drift of structures.

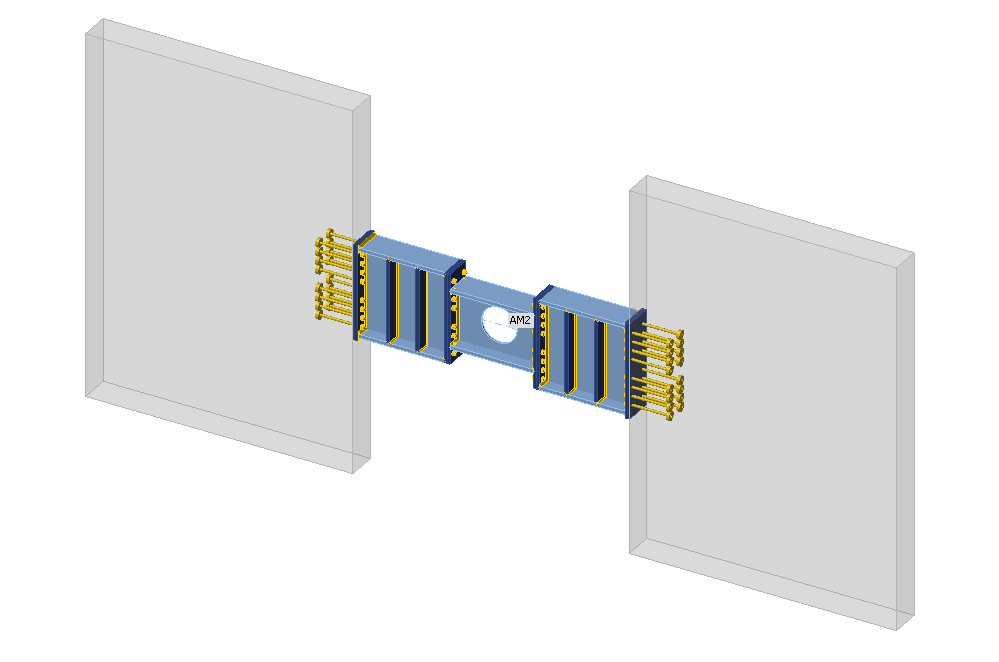

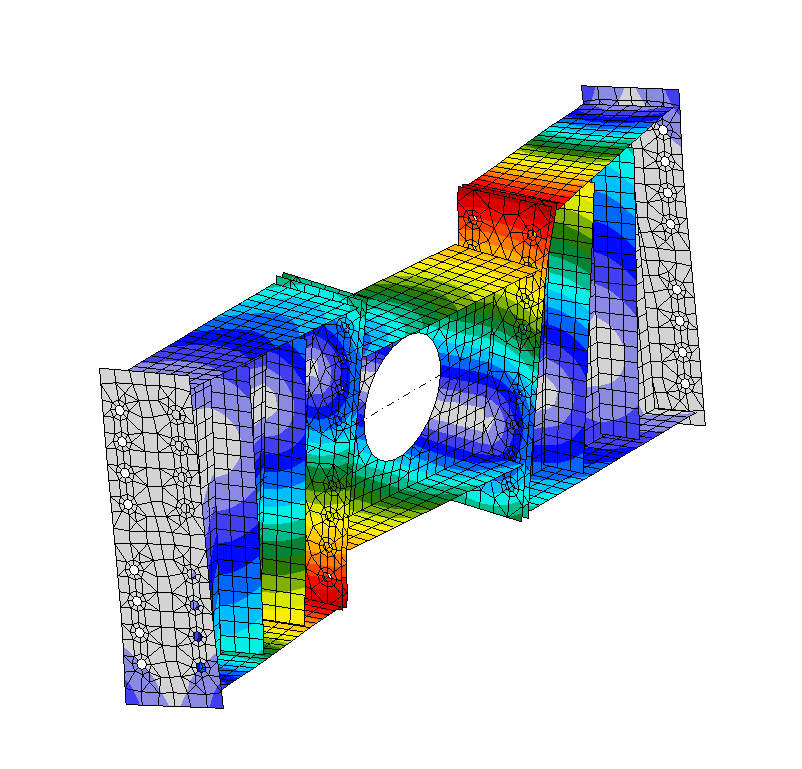

Figure 16. Model of hybrid coupling beams

Figure 17. Equivalent stress

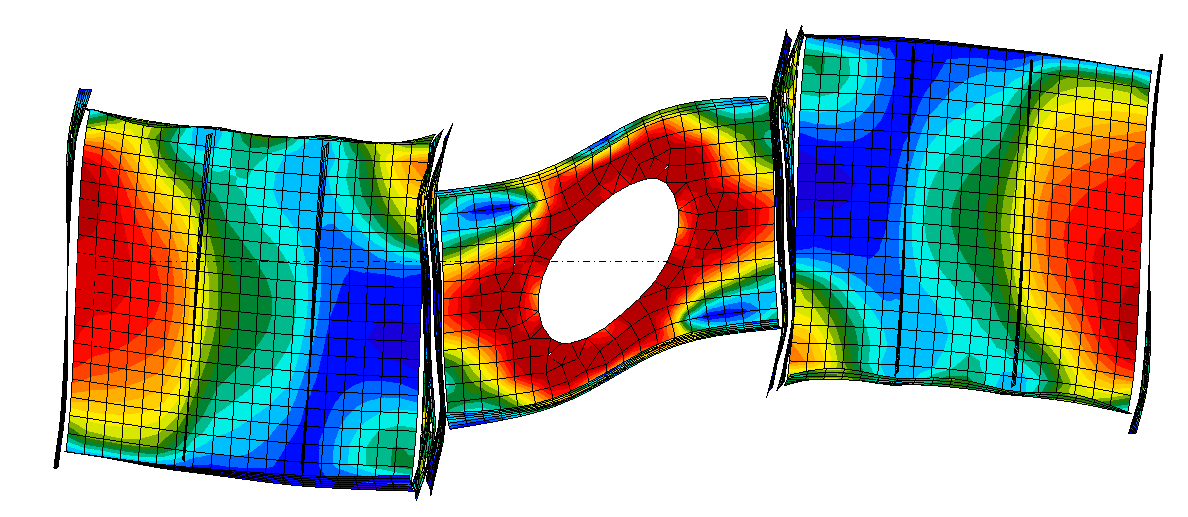

Figure 18. First linear buckling shape

Figure 19. Second linear buckling shape

Figure 20. GMNIA and deflect shape

Conclusion

Each coupling beam type adopted by the industry has its own benefits and limitations. Still, not one single type of coupling beam is applicable to all cases in building design. The conventional RC coupling beam is often the most feasible and economical coupling beam whenever the beam shear stress is low and the beam is controlled by flexure. When the coupling beam span-to-depth ratios are small, high shear stresses are expected. The limitations of these types of coupling beams and the associated anchorage requirement should be kept in mind when choosing an appropriate coupling beam type for specific projects. As always, the designer should consider the preferences of the construction team whenever possible, as many contractors will have varying opinions related to each methodology.