Bridge over the River Esinante

About the project

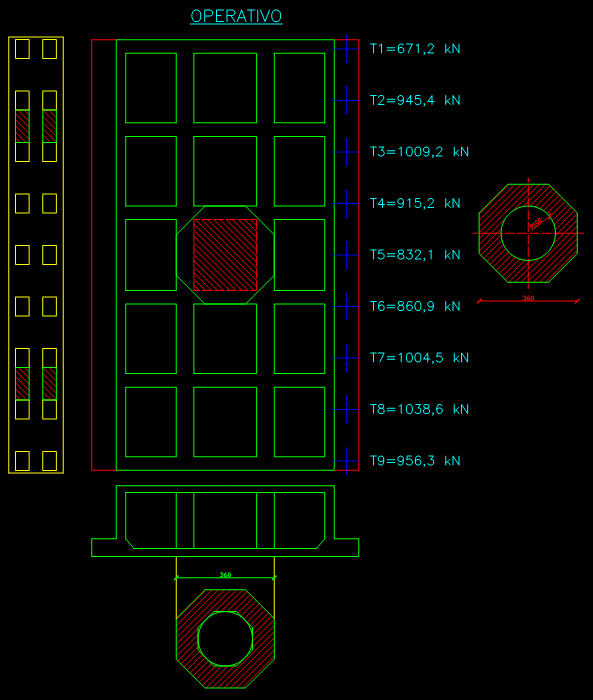

The bridge consists of nine prestressed concrete beams, each reaching spans of up to 34 m, supported by Gerber saddles embedded in the central pier. Each Gerber saddle is formed by a five-by-three section and features a centrally positioned octagonal concrete pillar, which together create a robust discontinuity region for transferring shear and bearing forces. These saddles channel the loads from the beams into the pier substructure, making them indispensable components in the overall load path.

\[ \textsf{\textit{\footnotesize{Layout of the Gerber saddle}}}\]

The applied loads, derived from the deck model, range from 671 kN to 1039 kN, with an equivalent concentrated load of 550 kN used in the analysis. The saddle has a thickness of 50 cm and is aligned with the transverse rib of the pier cap. The structure is made of reinforced concrete and was assessed using advanced FEM with nonlinear finite element modeling together with the CSFM (Continuous Stress Field Method) for discontinuity regions.

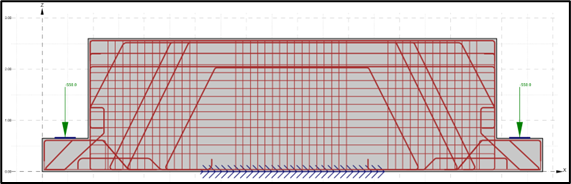

\[ \textsf{\textit{\footnotesize{Section of the gerber saddle}}}\]

Engineering challenges

The main challenge was to assess the structural capacity of Gerber saddles under both intact and degraded conditions. These elements present complex stress distributions due to discontinuities and concentrated loads, and conventional design codes offer limited guidance for such cases. This required advanced numerical approaches to capture the real behavior of the structure.

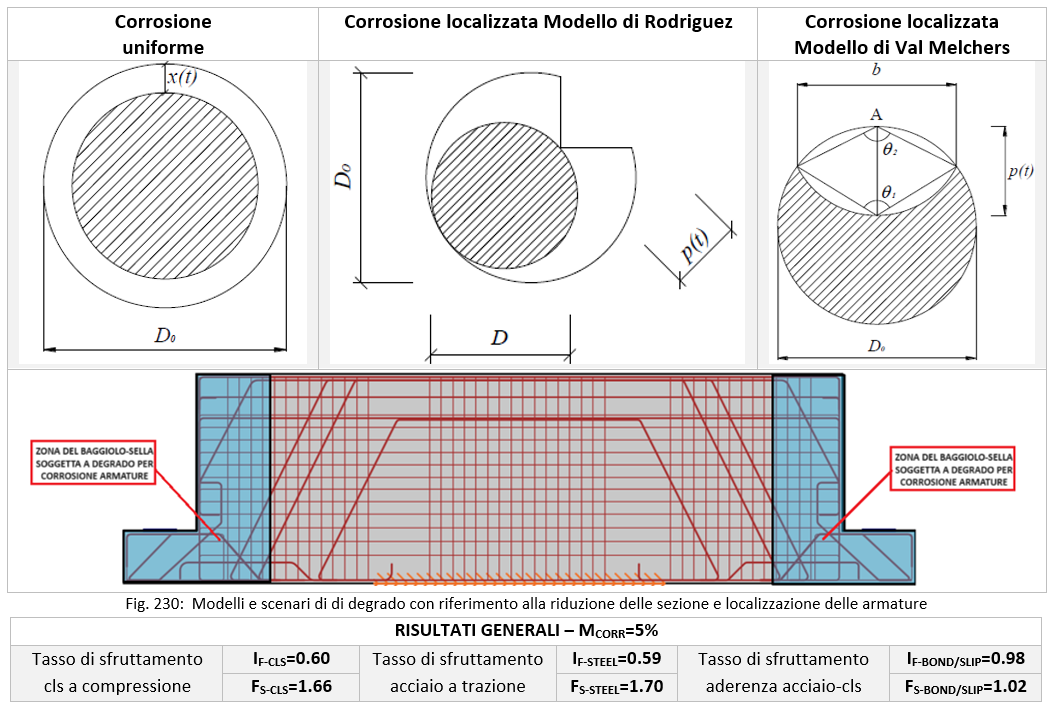

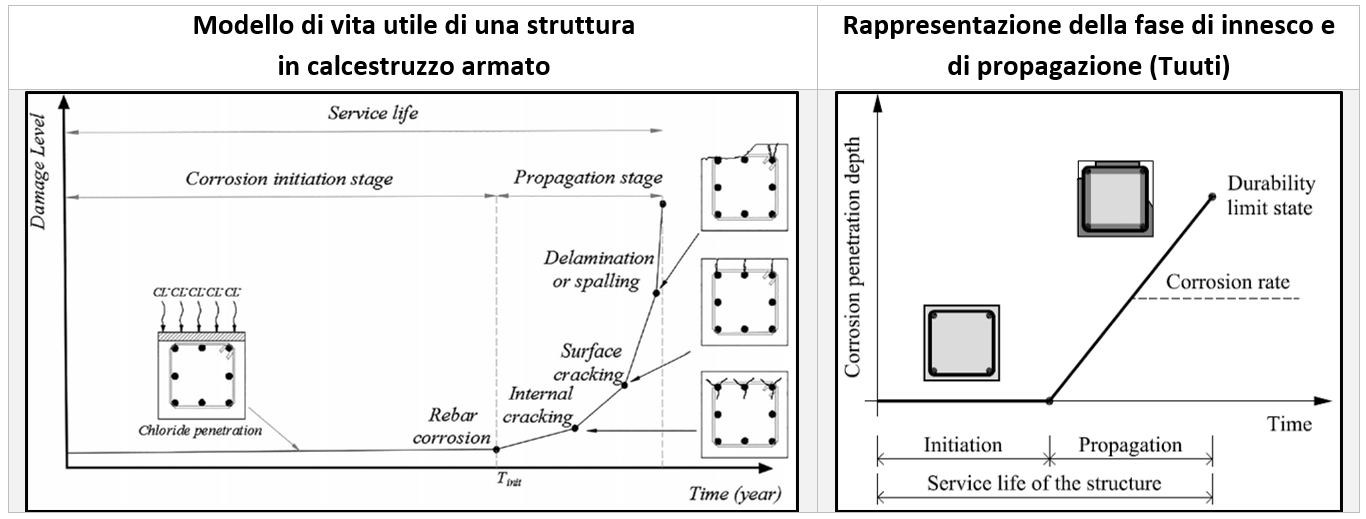

Another critical issue was the presence of corrosion-induced degradation, promoted by chloride contamination from de-icing salts. Corrosion affects reinforcement cross-sections, bond strength, and concrete integrity, reducing the structure’s resistance and ductility over time. Predicting the long-term safety margin under progressive deterioration scenarios without direct field data on corrosion rates added further complexity to the analysis.

Solutions and results

To overcome these challenges, the engineer adopted a multi-phase approach. In the first phase, a detailed non-linear FEM model was developed to capture the saddle’s behavior under operational loads.

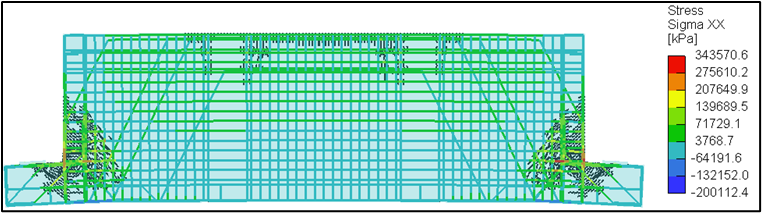

\[ \textsf{\textit{\footnotesize{Results of the FEM analysis}}}\]

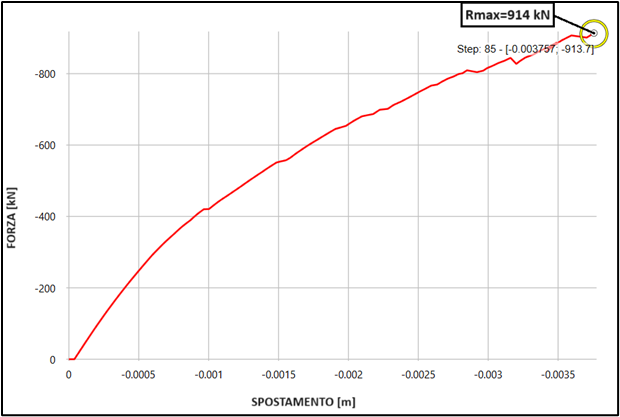

The analysis provided a capacity curve indicating a maximum resistance of 914 kN, yielding a global safety factor of 1.66, well above the required threshold. The failure mechanism involved widespread cracking, concrete crushing, and local instability of reinforcement bars near the cantilever root.

\[ \textsf{\textit{\footnotesize{Capacity curve derived from the FEM analysis}}}\]

In the second phase, corrosion scenario modeling was performed using validated degradation models from scientific literature. Simulations considered mass loss rates ranging from 5% to 30%. Up to 15% corrosion, safety factors remained acceptable, with steel at 1.28 and concrete at 1.63. Beyond this threshold, significant reductions in ductility and bond strength led to premature brittle failures, particularly in the saddle region.

\[ \textsf{\textit{\footnotesize{Corosion scenario used for advanced analysis}}}\]

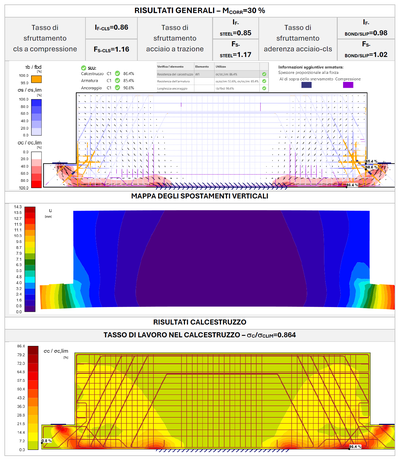

At 30% corrosion, deformation rates in steel increased dramatically, indicating severe structural vulnerability. The Continuous Stress Field Method (CSFM) in IDEA StatiCa Detail was applied for discontinuity regions, confirming FEM results and highlighting the importance of considering bond-slip effects under corrosion.

\[ \textsf{\textit{\footnotesize{Results of the CSFM analysis in IDEA StatiCa Detail - ULS and SLS, crack width}}}\]

Conclusions

The study concluded that while the bridge currently exhibits satisfactory safety margins, its long-term performance depends on controlling corrosion and implementing timely interventions. Recommendations included periodic monitoring and preventive maintenance to limit corrosion progression below critical thresholds.

Itálie

The analysis demonstrated that advanced non-linear modeling is indispensable for evaluating complex structural elements like Gerber saddles, especially under degradation scenarios. This case underscores the need for integrating durability models into structural assessments to ensure resilience against environmental aggressors.

About ing. Francesco Oliveto

Francesco Oliveto is a consulting expert and firm for advanced numerical modeling and analysis in the structural and geotechnical fields.

The company provides advanced structural and geotechnical analysis services, with strong expertise in seismic assessment of existing buildings, even those affected by damage or deterioration. Its work covers soil-structure interaction, deep foundation design, top-down and bottom-up excavation techniques, and local seismic response, using cutting-edge numerical modeling (FEM, CSFM).