More prestressing does not always mean more resistance!

As you probably know, the Ultimate Limit State check indicates how much load a structure can handle before failure. It is valid that the load effects are resisted by a pair of internal forces on a lever arm.

It doesn't matter whether it is prestressed concrete or reinforced. With the same amount of steel with the same yield strength, the prestressed and the reinforced structures withstand the same load before reaching the bearing capacity. The additional compressive stress in prestressed concrete does not help the structure to resist for a longer period. So what's all the hype about?

Let's take a closer look

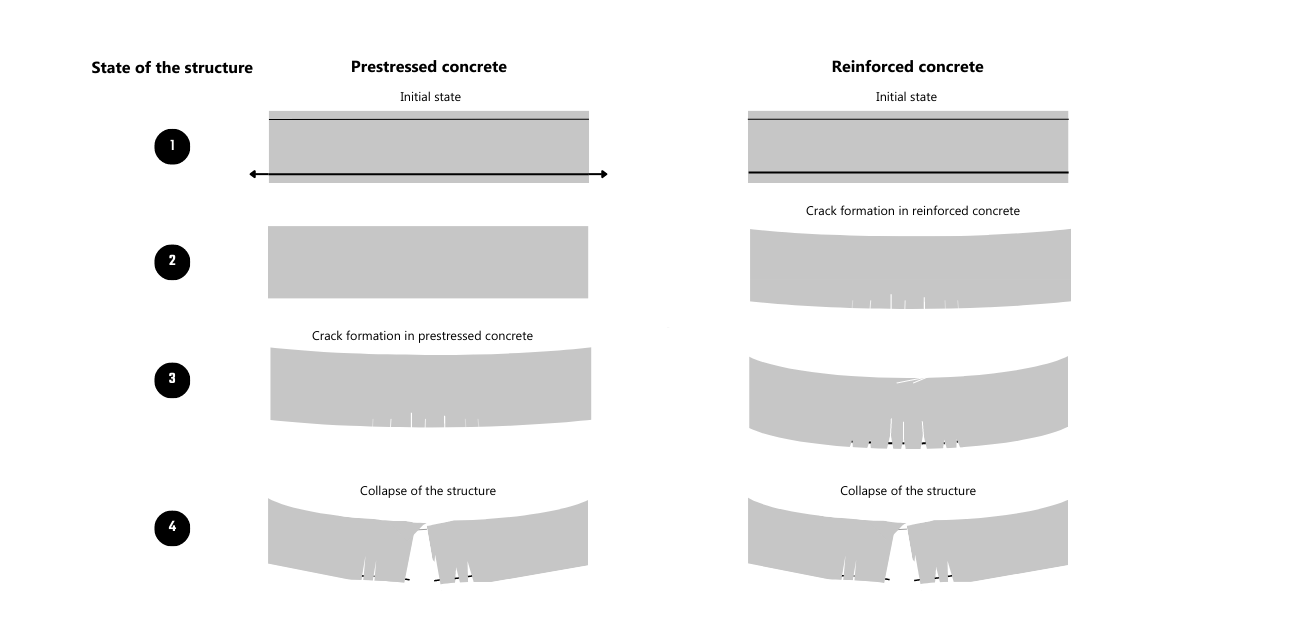

By prestressing, we add compressive stress to the concrete, significantly changing the material's behavior. Crack formation is delayed as the stress reserve resists the first load. With other load increments, concrete reaches a state of decompression. Later, the concrete resists tension until the tensile strength is exceeded.

Crack formation, therefore, occurs much later compared to reinforced concrete. Also, crack development is slower for the same load and with smaller crack widths in prestressed concrete. This is important because of the corrosion of the reinforcement. But it is also related to the structure's stiffness. Higher stiffness of prestressed structures leads to smaller deformations.

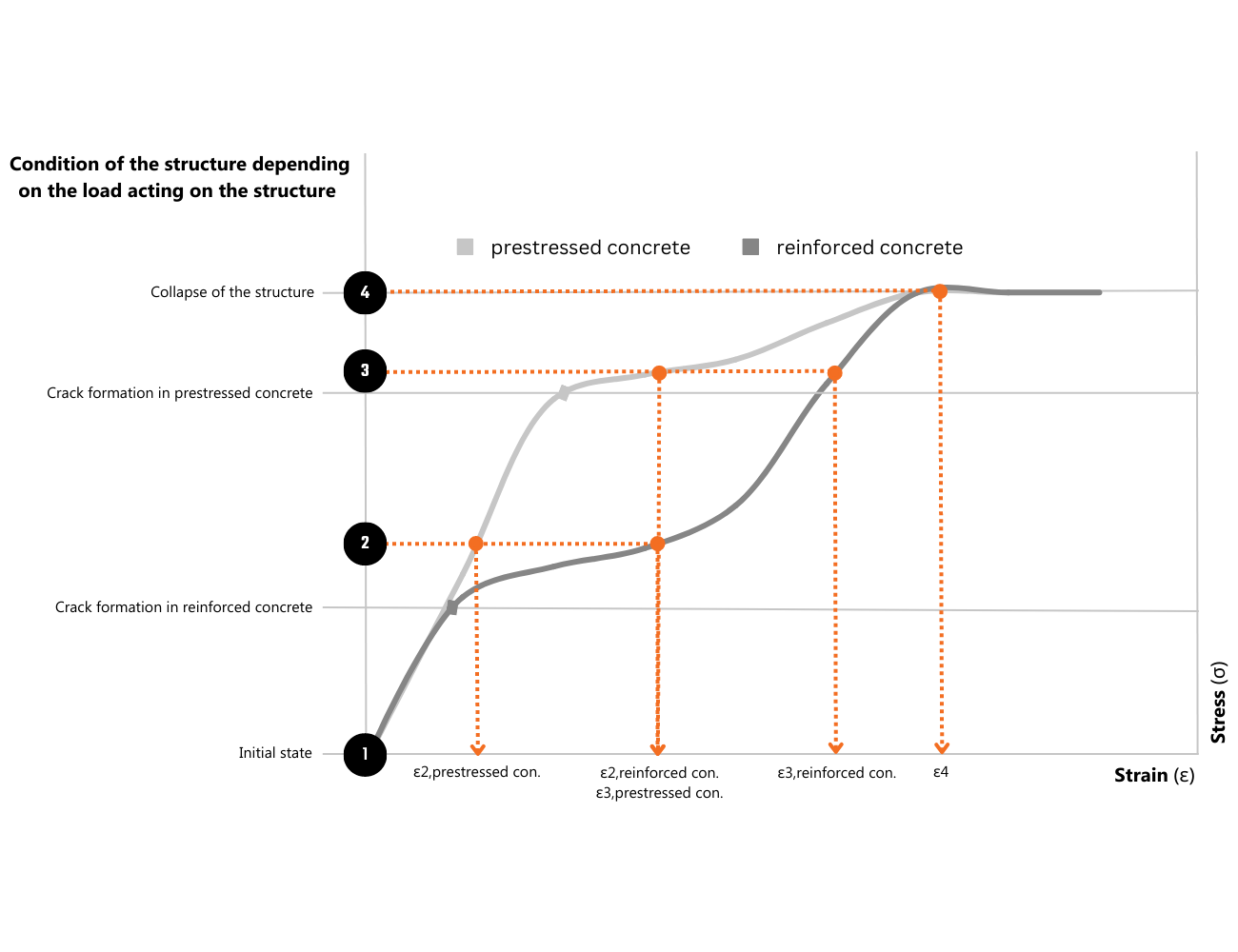

In the figure below, you can see a theoretical comparison of the prestressed and reinforced elements loaded by an external axial tension force. Assume the steel strands and reinforcement are of the same steel with the same yield strength. The amount also corresponds to each other. The only difference is that the strands are tensioned.

- State 1 - First load increment is applied. The prestressed concrete uses a stress reserve. The reinforced concrete also resists until the tensile strength is exceeded.

- State 2 - Once the tensile strength in the reinforced concrete is exceeded, cracks occur. At that point, the utilization of reinforcement increases, along with the strain. Whereas in the prestressed concrete, the stress reserve still counteracts the effects.

- State 3 - Once the tensile strength in prestressed concrete is exceeded, cracks occur. At that point, the utilization of reinforcement increases, along with the strain, as with the reinforced concrete.

- State 4 - The yield strength of steel is exceeded.

This implies we would theoretically get the collapses simultaneously for both structures. In other words, the additional compressive stress does not affect the ULS checks.

In contrast, significant cracks and strain would occur much earlier with the same load in the reinforced structure compared to the prestressed one. And thus, the design would not satisfy the Serviceability Limit State checks.

It is also fair to mention that in addition to the above advantages of prestressed concrete, we can influence the distribution of internal forces by the position of the prestressed elements. It is widely used in the case of post-tensioned structures.

Theory in practice

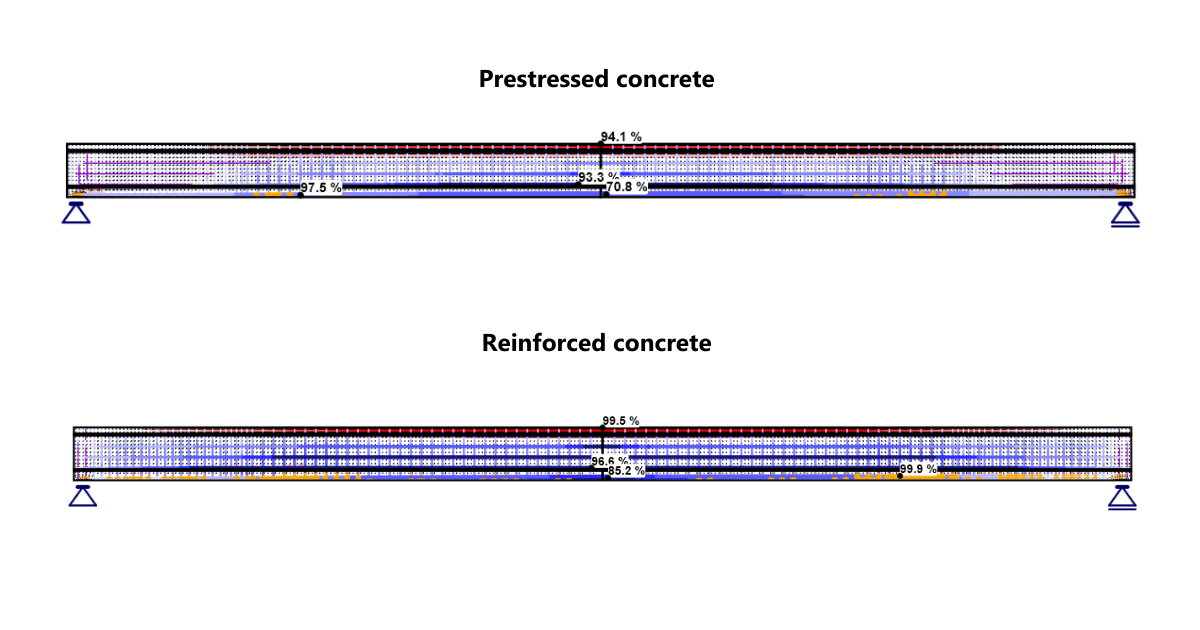

Let's check how the logic corresponds with the results in the IDEA StatiCa application. We will observe two examples in IDEA StatiCa Detail. The first example is the pre-tensioned beam, and the second one is identical except for the prestressing.

In contrast to the theoretical case, the element is now also loaded with a bending moment. We would experience a much larger deformation just before the collapse. Otherwise, the principle should remain the same.

IDEA StatiCa Detail

The figure below shows the utilization of concrete, reinforcement, and strands. Both structures can transfer the applied load. As we expected, the ULS checks, even for the reinforced beam, were passed with a similar utilization.

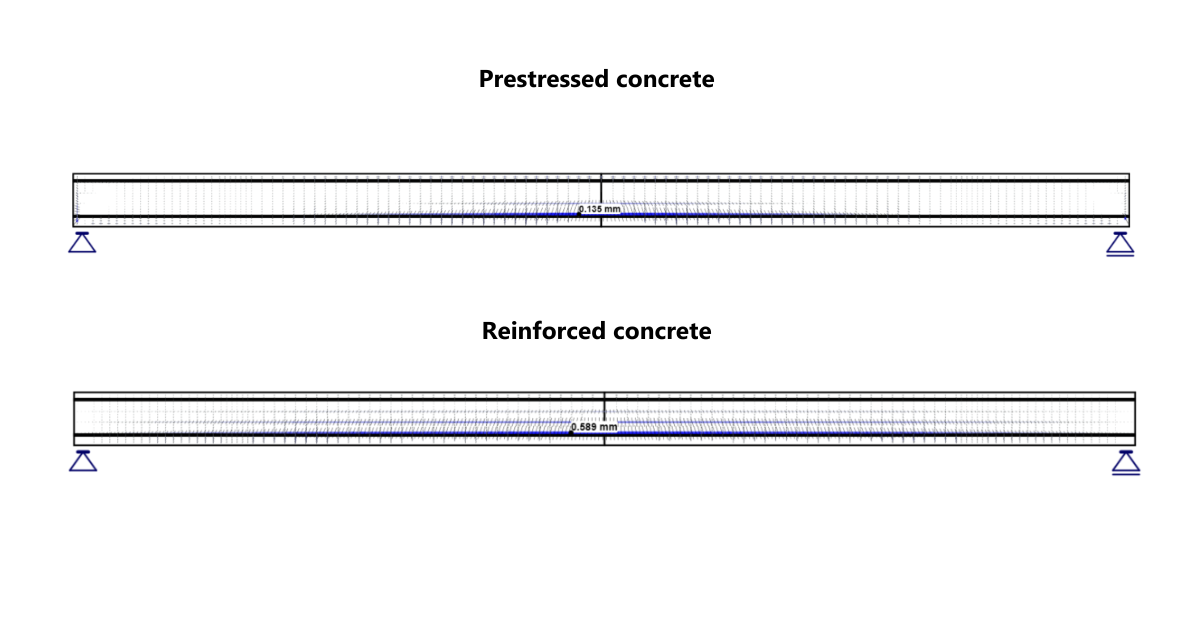

A significant difference occurs with SLS checks.

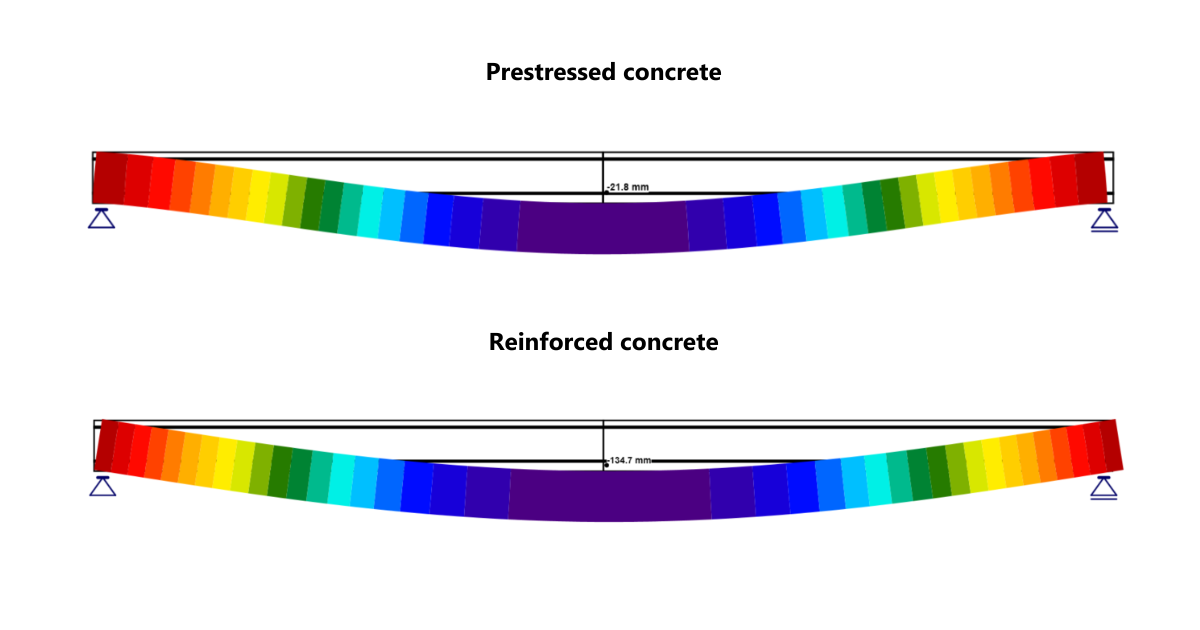

Cracks are more developed in reinforced concrete, and, as stated earlier, it affects the stiffness of the structures and, thus, the deformation.

Why do I need to know?

It is essential to mention that this is a theoretical example. In practical use, we could not reinforce the element with reinforcement of the same properties. Also, it wouldn't have worked due to the Serviceability criteria. So why is it important?

A proper understanding of the behavior of prestressed concrete simplifies its utilization. It is crucial to be able to decide if it is better to add prestressing force or more prestressed strands/post-tensioning tendons. Or modify the design.

With the right knowledge, prestressing serves us in overcoming greater distances using less material and with more elegant shapes. Whether in civil engineering, in the case of bridges (mostly post-tension concrete designs), or in structural engineering, in the case of pre-stressed beams and post-tension slabs.

Which application is suitable for the design of prestressing?

To design general prestressed elements (pre- or post-tensioned), you can use the IDEA StatiCa Beam application. It provides the solution, including the construction phases and loss calculation.

We recommend using the IDEA StatiCa Detail application and not only for discontinuity regions.