How many connections are not simple?

When you talk about connection design with engineers, academics and industry players across the United States, Germany, or Singapore, you might get different answers for very basic questions. That is why we decided to invest quite a bit of effort to an objective (we believe) market research into the matter.

This blog post shares the first insights from this research.

Data research

We hired a professional data research agency that conducted telephone research (approx. 13 minutes questionnaires). The data was collected between May 19 and July 19, 2021, primarily from the eastern half of the United States. In total, we spoke to representatives of 498 engineering companies and completed 244 questionnaires.

The results

First, let’s check the basics. How many engineers are doing connection design? 87% of them told us they do it as a part of their services, which means they are designing steel connections in their projects.

Pretty clear so far.

And then we got to the heart of the matter by asking the question on the connection complexity engineers were dealing with most often.

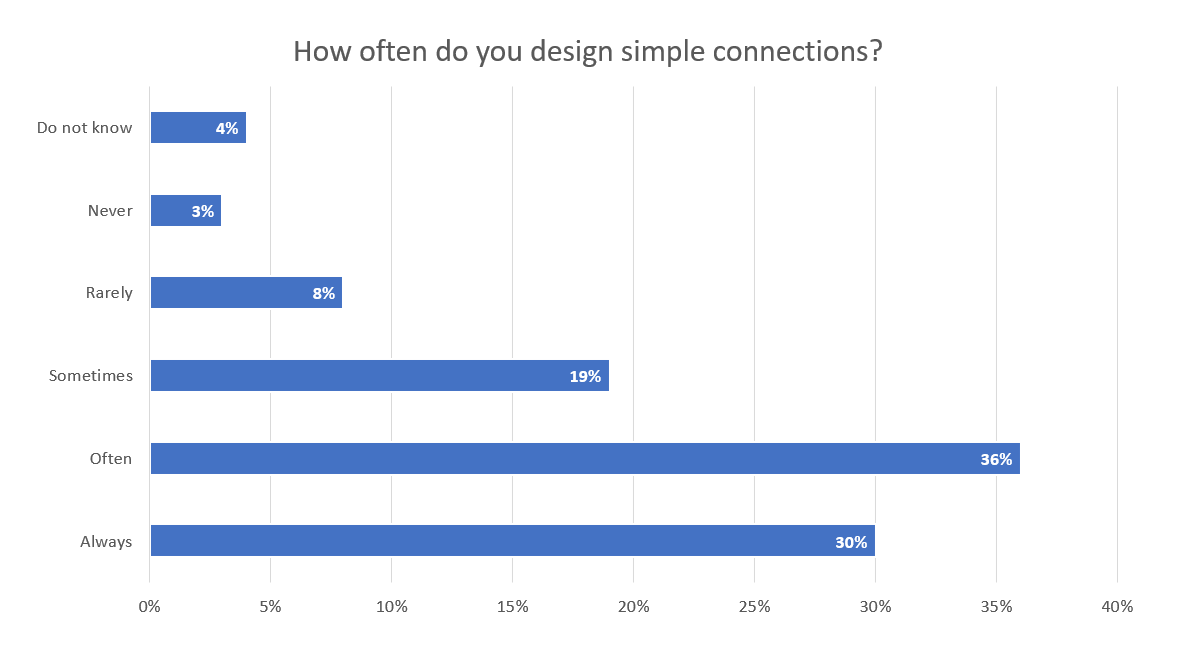

- How often do you deal with simple connections?

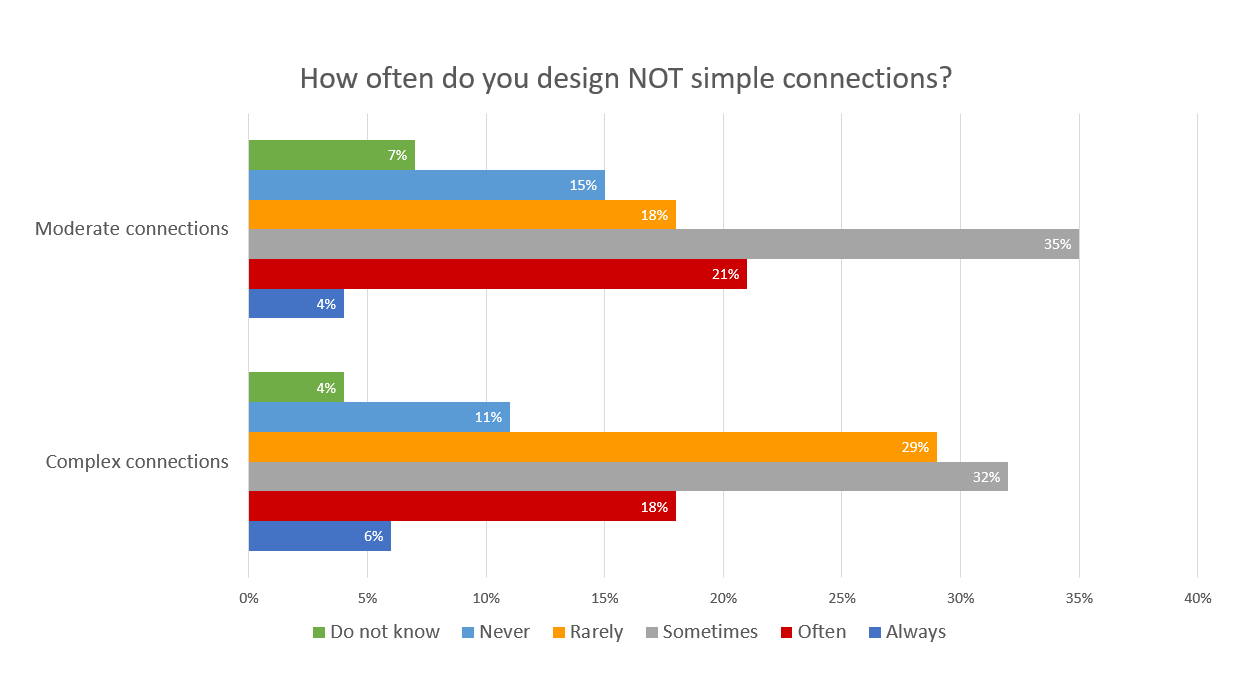

- How often do you deal with non-standard connections? (By non-standard connections are meant those not explicitly covered by the codes. Designing these connections requires assumptions and engineering judgment.)

- And we also offered a category of "something in between". (for the purpose of this article let's call them "moderate")

The possible answers were "Always", "Often", "Sometimes", "Rarely", "Never" to each question.

Answers to the first question were pretty expectable. Everybody deals with simple connections, right? No surprise, 68% of engineers do them either Always or Often. These represent the connections that are well documented in the design guides or excel spreadsheet templates. These are the repetitive parts of connection design.

It gets more interesting once the engineers need to step out of this limited set of known and simplified connection designs:

Over 60% of engineers indicated that they do connections which are “something in between” ("moderate") either Always, Often or Sometimes. That means they regularly must deal with steel connections which are not exactly prescribed in the code but still not “too crazy”. Those might be connections templates we know but, for example, the engineer needs to add an opening in the beam or rotate it by 20 degrees.

Here, it gets more interesting. 49% of engineers indicated they deal with very complex steel connections either Always, Often or Sometimes on their projects. That means connections not defined in the design guides, usually multi-beam nodes, loaded in all planes and welded/bolted in a specific way.

Where are the complex steel connections coming from?

You might ask here, why are there so many complex connections today?

One of the main factors is the advancement in modeling and design software over the last 25 years. This no longer affects just the large skyscraper projects. Everyday buildings are becoming more complex, and building owners are looking for every possible efficiency during design, construction and operation. This has pushed architects to use BIM to develop their designs and be more creative while understanding if their designs are constructible.

Nowadays engineers can take that BIM model and use it via direct import or as a template for the structural analysis model. Virtually every structural engineer around the globe has some type of finite element software to be able to analyze and design all the skews, curves, etc. that are part of projects today. When was the last time you saw a project that was perfectly rectilinear?

These more complex designs lead to the need for more complex connections. There is no going back now, projects are going to continue to get more complex.

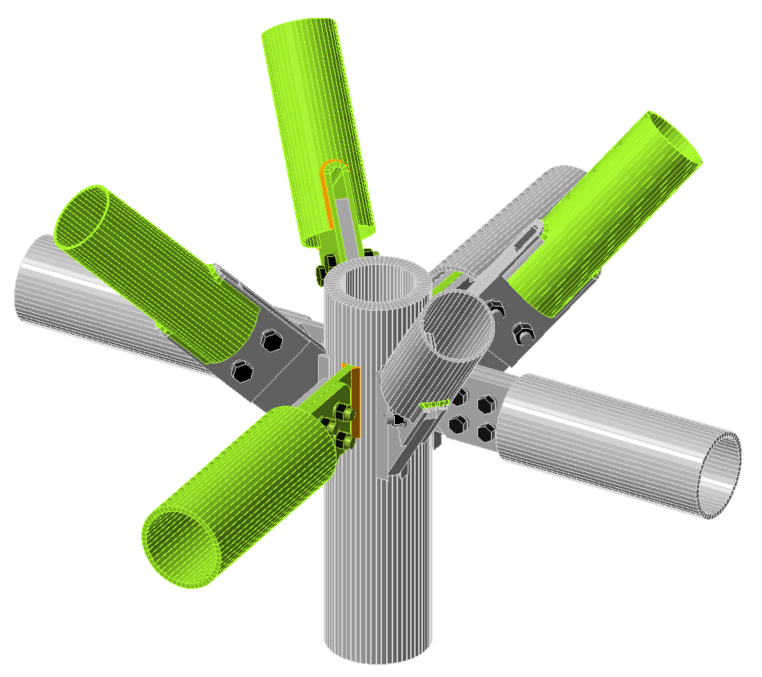

The design of steel connections that are “not simple” has become a reality – embrace it! Make it one of the key competencies of your team and use it to increase the value of your work. Which is going to sell your work better – an endless excel spreadsheet of a connection or a complete connection design report with to-the-point pictures like this?

Structural engineers have been using finite element analysis for several decades for the overall structural design. So, why not use that same technology for the most problematic parts of the steel structure – the connections?

It is hard not to have this key competence in-house. Many engineering companies are already doing it to some degree and are looking to expand it to most of their projects.

Are you or your boss not sure this is needed at your firm? We put together the “Steel connection design value calculator” – just enter your data and let it calculate what value will it bring if your organization level up its connection design capabilities with IDEA StatiCa.

If you are interested in the full research we have conducted, drop us an email.

And stay tuned for vol. 2 of this research ;)

Thanks for reading this and as always - Calculate yesterday’s estimates!