Why bother with connection stiffness

During the analysis of every structural model, an Engineer has to define the type of each connection between members. As the model should represent the real behavior of the structure, an engineer has to predict what type of connection suits best.

A good approximation of the model to the real structure is important, especially in the field of steel structures, where linear members are used most often. Steel structures are widely used for their effectiveness.

To obtain the best outputs, designers are often forced to optimize not only member cross-sections but also the design of connections.

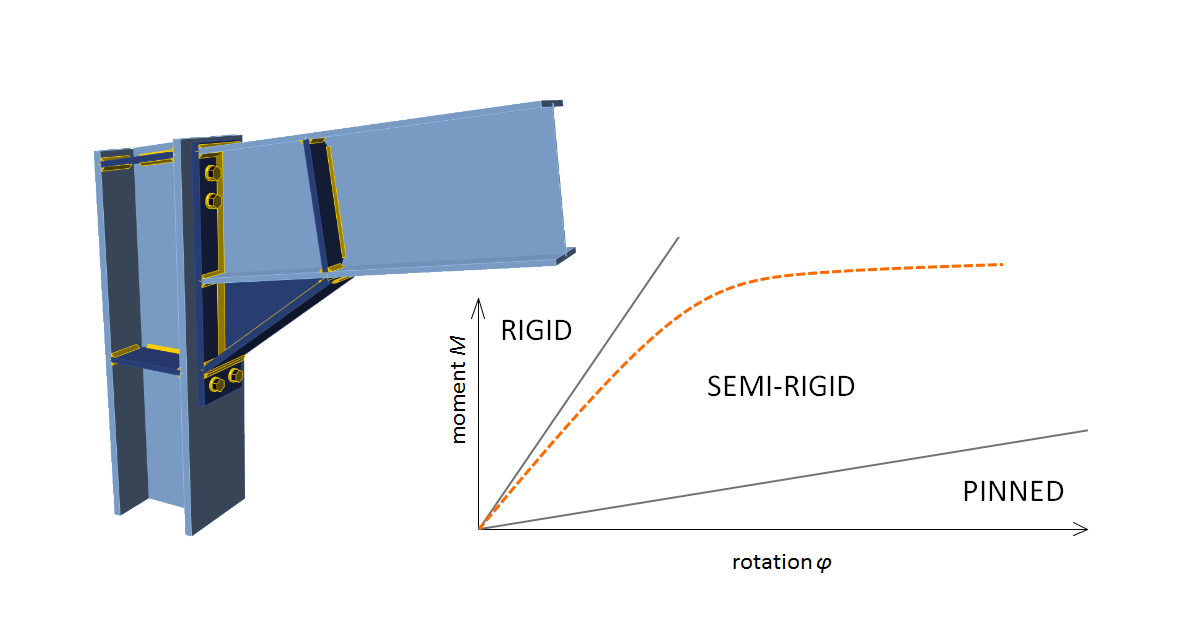

In general, the Structural engineer has to choose from 3 basic types of connections classified according to joint stiffness:

- Pinned – joints that do not develop bending moments.

- Rigid – joints with an insignificant change of original angles between members

- and an infinite number of values in between

In the global structural analysis model, the first two options are mostly used. Contradictory, most of the real steel structure connections belong to the third group.

This classification is supported by Eurocode as well as in AISC standards. Although the nomenclature is different, the meaning is the same.

| Eurocode: | AISC: |

| (EN 1993-1-8 sec. 5.2.2) | (AISC 360-16 Cl. B3.4) |

- Rigid - Pinned - Semi-rigid | Moment Connections: - Fully Restrained - Partially Restrained Simple Connections |

For both codes, there is a bunch of requirements for a particular classification. If you want to know the details, you can simply follow the theoretical backgrounds either for Eurocode or for AISC standards. Before jumping right into assessments, some basic and advanced theory could be found very useful.

Two main problematic situations

- Joints considered pinned in the global analysis model behave semi-rigid in construction reality (transmit bending moments into connected member).

- Joints that are considered rigid are not rigid enough.

Mainly because of manufacturing and assembly reasons, the first situation occurs more often.

Some could say that this inaccuracy is on the safe side and, therefore, it doesn't cause any problem. And yeah, the bending moments in the span are in real structure reduced by connection moments at the edges.

But it is necessary to go further: It isn't dangerous for the beam itself, but for the member to which the beam is connected!

Quick demonstration

Let's show the importance of choosing the right connection for the right purpose. (And also the consequences of inappropriate connection for the global analysis)

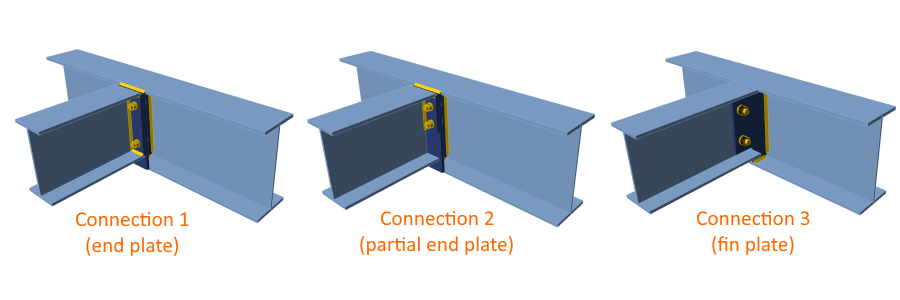

If you solve the standard connection of the ceiling girder to the main beam, you'll have many connection alternatives. I chose three very common ones.

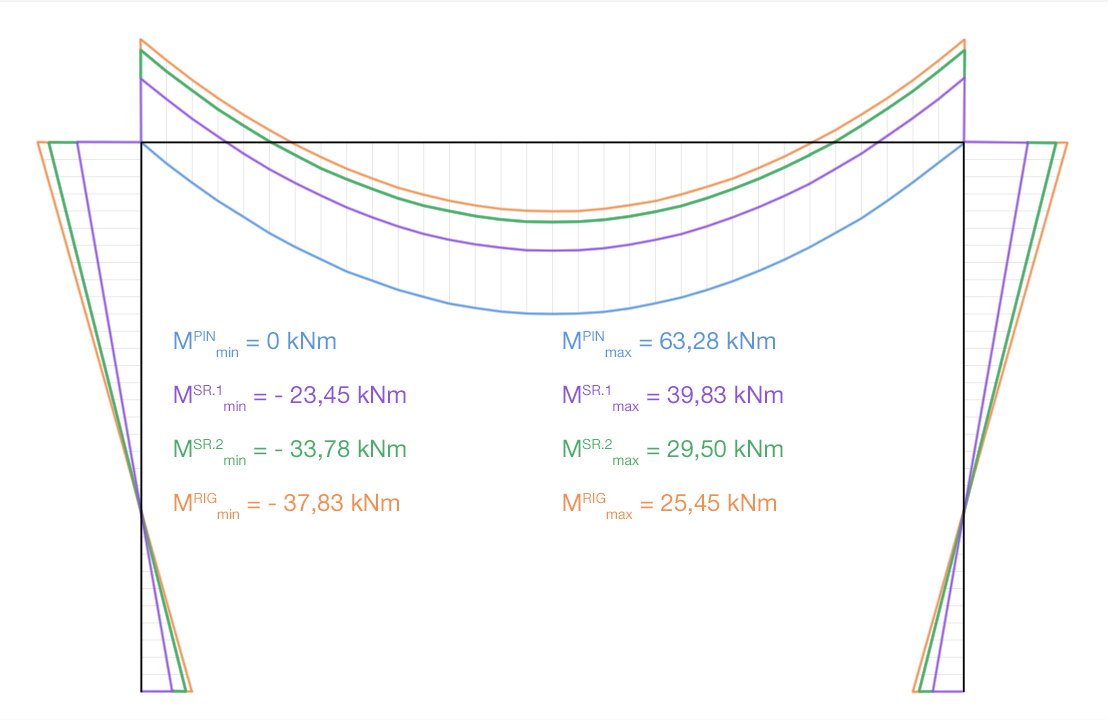

With IDEA StatiCa Connection, you're able to calculate connection rigidity in a few seconds. For better comparison, I added extreme cases with Rigid and Pinned joints:

- Rigid connection

- Connection 1 (Sj,ini = 6.7 MNm/rad)

- Connection 2 (Sj,ini = 1.3 MNm/rad)

- Connection 3 (Sj,ini = 0.5 MNm/rad)

- Pinned connection

Impact of rigidity on bending moments

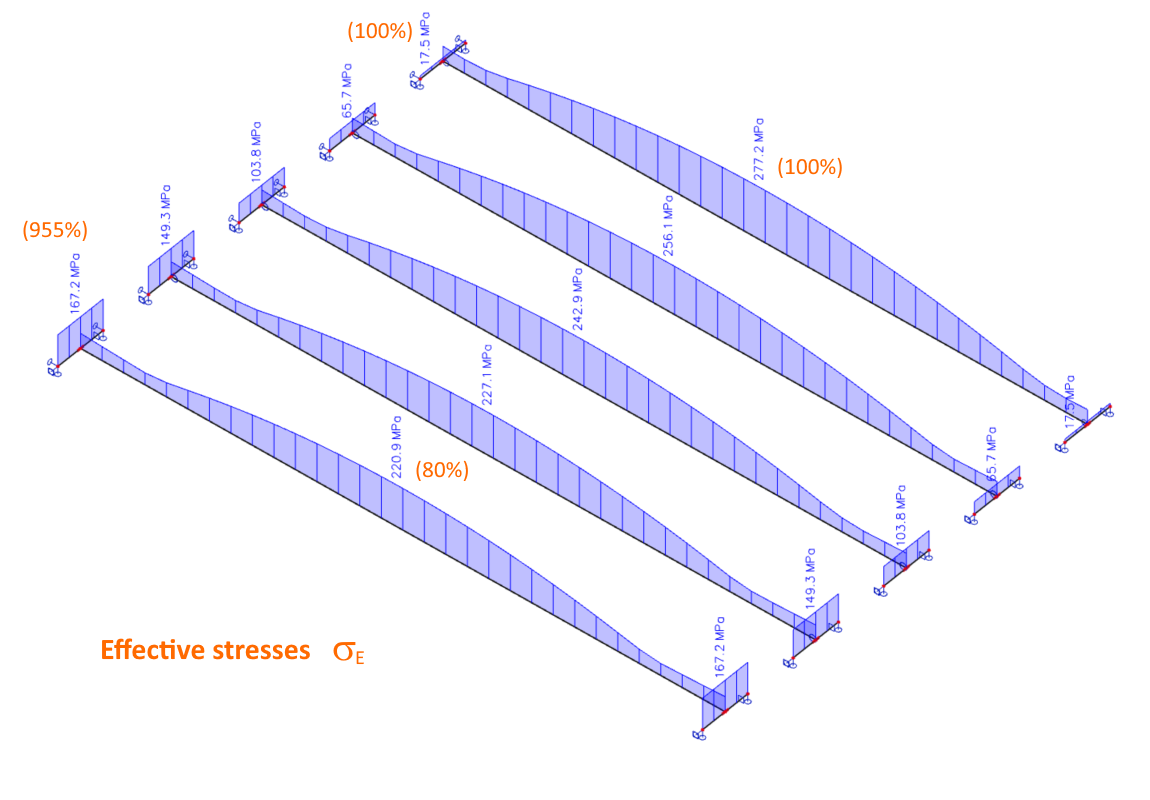

Impact of rigidity on effective (von Mises) stresses

As you can see, while the girder is used less with the connection rigidity increase, the main beam can be easily overloaded in some cases.

The common way to do it

When the structural engineer decides that the real stiffness of the connection should be taken into account (what should be quite often), there are several options for calculation.

- manual

- in a prepared spreadsheet template

- calculation by dedicated software

Sample analysis

- you solve a simple structure with 100 linear steel members,

- it means 200 ends to connect.

- such structure can contain 20 types of different connection types,

- you have 10 load cases and 100 generated load combinations.

It would become a nightmare to solve all connections for each decisive load combination. That’s why you calculate only the important ones. Still, it can be 10 critical connections with 2 - 6 members included and your workflow could look as follows:

1 ) Although incredibly time-consuming, connection models and calculations of their rigidity could be feasible. At least for the first run.

2 ) After the Stiffness analysis is done, you can set the rotational stiffness in joints of the global analysis model. You can import it

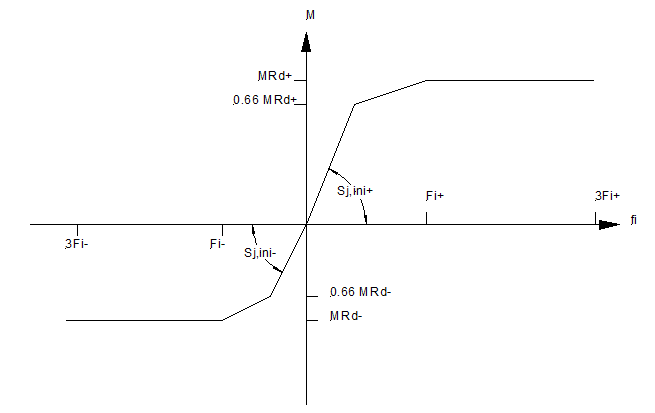

as a single value:

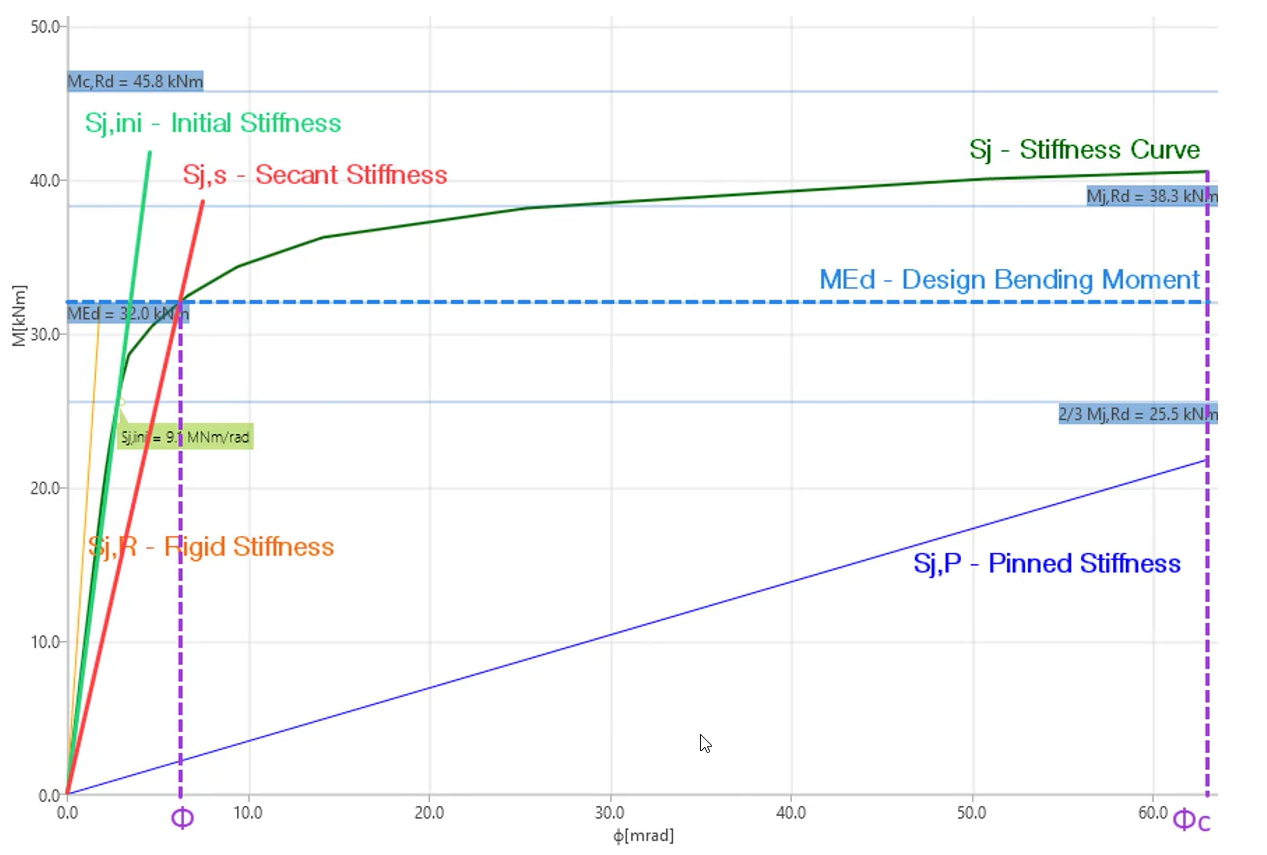

- if MEd is lower than 2/3 Mj,Rd you can directly use Initial Stiffness of connection

- if MEd is higher than 2/3 Mj,Rd - iteration process

or as a non-linear function:

3 ) With updated stiffness parameters you can run the global analysis, where of course new internal forces will be calculated. The influence of the new setting can be minor but also huge in some cases. We have already solved some cases in the past, so you can check our knowledge base article about this topic.

4 ) Now you need to check and revise your cross-section and the connection design. If everything suits you fine, you're lucky and can proceed to the next step of designing. More probably some changes in the original design will be needed, so you have to come back to point 1 ) and repeat the iteration process until all design components satisfy all the requirements.

The smart way to do it

The best tool for connection stiffness calculation nowadays is the IDEA StatiCa Connection application. For maximum workflow simplification and saving a lot of precious time, you can use a BIM link to export your connection design from your CAD application to IDEA StatiCa Connection.

Then you set the analysis type to Stiffness analysis and in a few seconds, you obtain your rigidity parameters. To be as effective as possible, some useful tips for stiffness analysis could be found in our Support center.

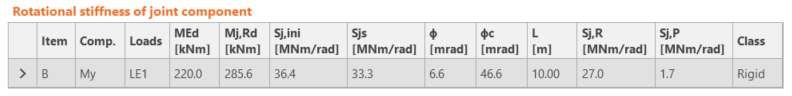

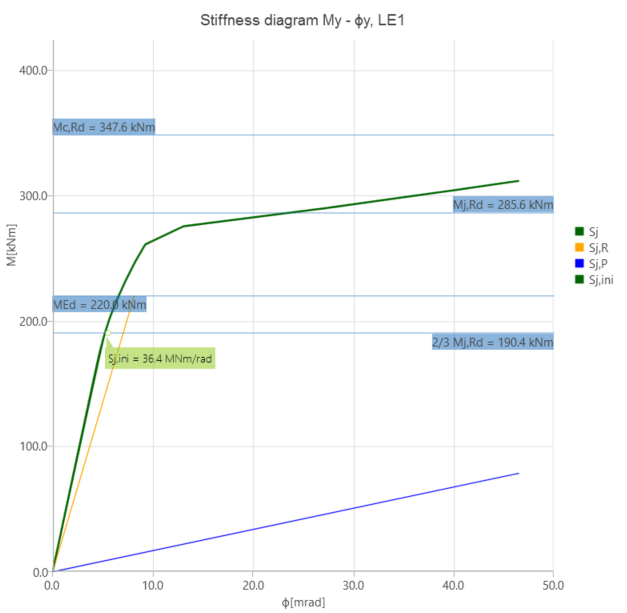

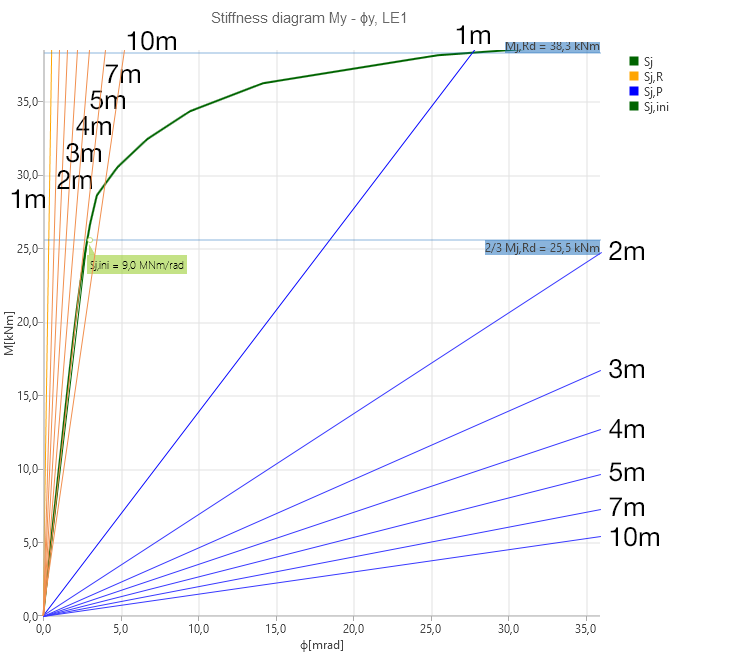

Each rigidity analysis provides immediately these precious outputs:

All the important values in one table

Graphic visualization of calculated values

Do you want to calculate the connection stiffness on your own with IDEA StatiCa Connection? Just follow the prepared tutorial for EN or for AISC standard.

The verification process of the new application had finished and the studies were published together with university teams. You can go through several verification examples.

Important facts

- It’s worth remembering, that the same connection can be categorized differently depending on the length of the member

- Initial stiffness (Sj,ini) isn't influenced by Design bending moment (MEd), while it has an impact only on Secant stiffness (Sj,s)

- Changes of joints' stiffness parameters always affect the internal forces calculated in the global analysis model

- In the Eurocode approach, you have to distinguish between Braced and Unbraced structural systems as the same connection could be classified as Rigid or Semi-rigid depending on bracing

- If the Sj,ini and Sj,s show infinite stiffness, this means the stiffness curve is so steep that its actually 90° in the diagram so that the tangent results in infinity. This always means a rigid connection far from the border of semi-rigid class so the exact values are not important.

Try IDEA StatiCa for free

Interested in the abilities of IDEA StatiCa in analyzing connection stiffness? There is no better time to give a try to IDEA statiCa than now!

Start your trial today and enjoy 14-days of full access and services free of charge.