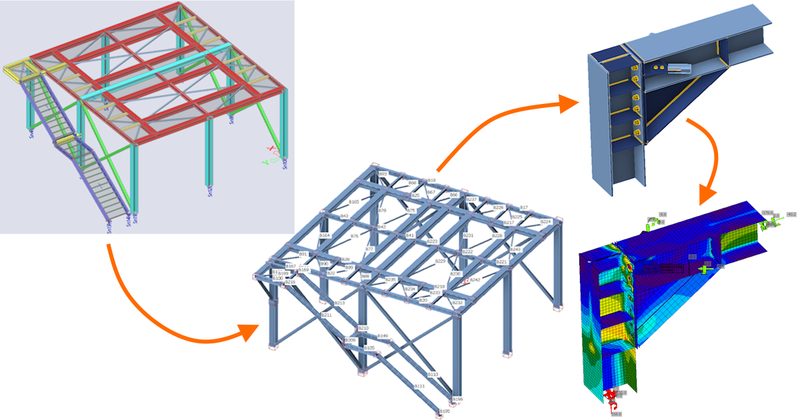

Seismic-resistant steel support for generators in Bucharest

About the Project

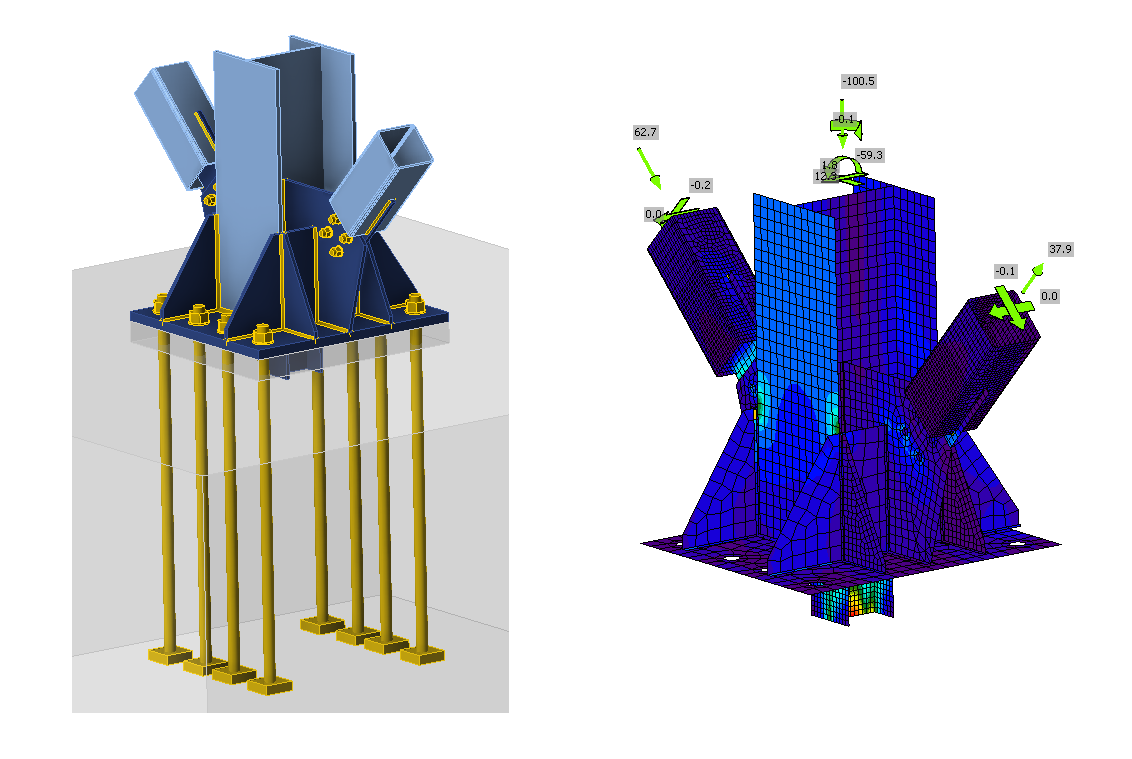

With a clear functional focus, emergency power support, the Bucharest platform is built with a structural height of 4.2 meters, two bays of 4.3 meters, and spans of 4.05 meters. A steel-grating access corridor wraps around the generator units, providing safe maintenance access. Vertical access is via a cantilevered steel staircase, anchored directly to the platform’s columns, reducing interference with the generator footprint. Lateral load resistance was delivered through a combination of moment-resisting frames in one direction and concentrically braced frames in the other, ensuring resilience under both wind and seismic actions.

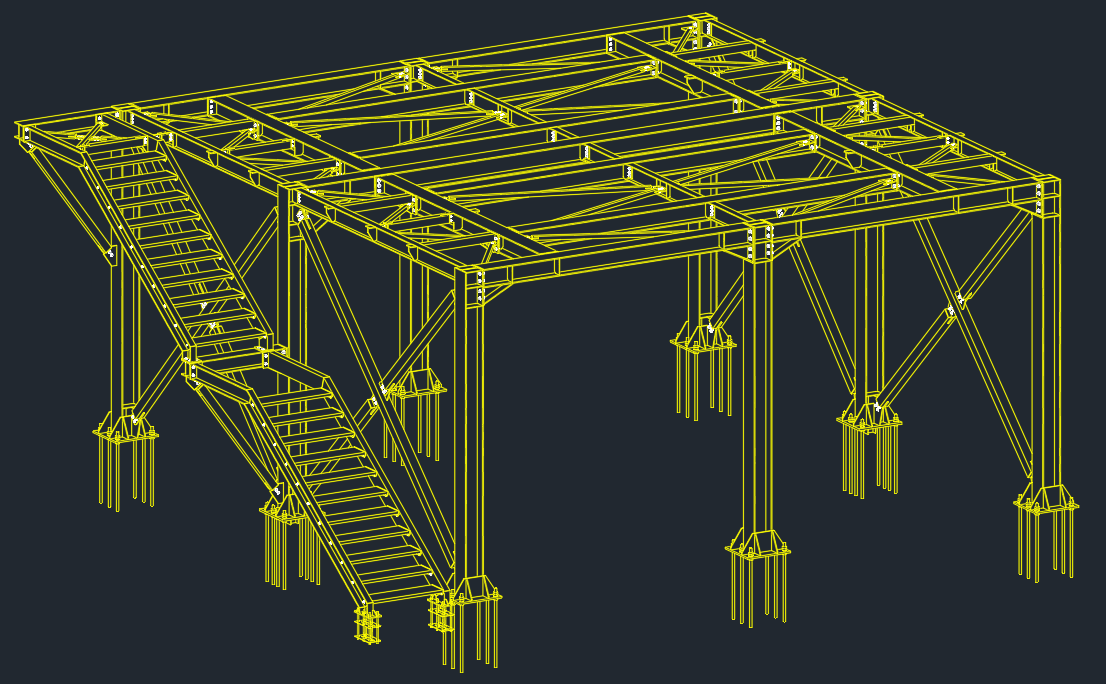

\[ \textsf{\textit{\footnotesize{CAD model of the structure}}}\]

The margin for error was low, support failure could compromise the entire emergency power system. The primary challenge was connection design under seismic and dynamic loads, and the solution demanded not just engineering precision, but speed and traceability. With IDEA StatiCa Connection and its BIM link with SCIA Engineer, SC Selfconsulting delivered a compliant, optimized platform while saving valuable hours on design iteration.

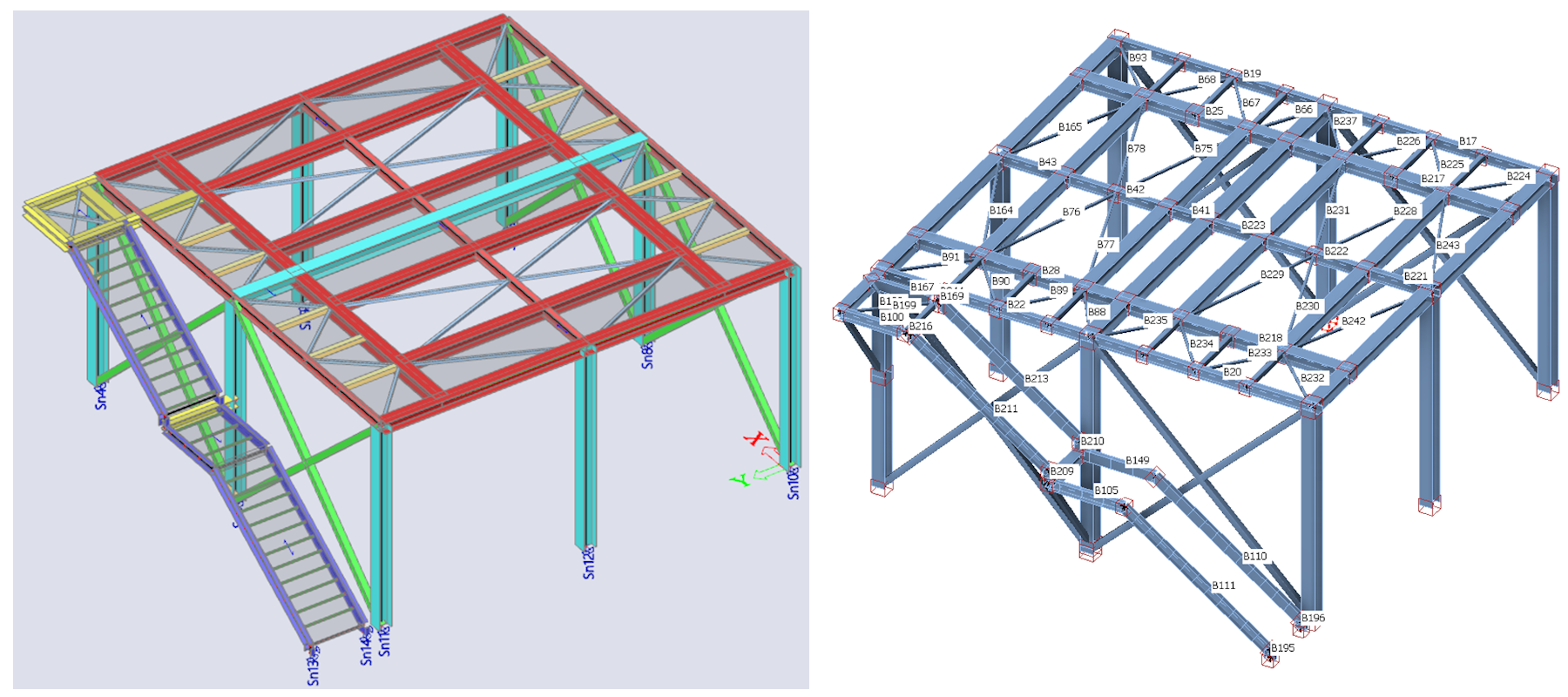

\[ \textsf{\textit{\footnotesize{Model of the structure in SCIA Engineer (left) and IDEA StatiCa Checkbot (right)}}}\]

Engineering Challenges

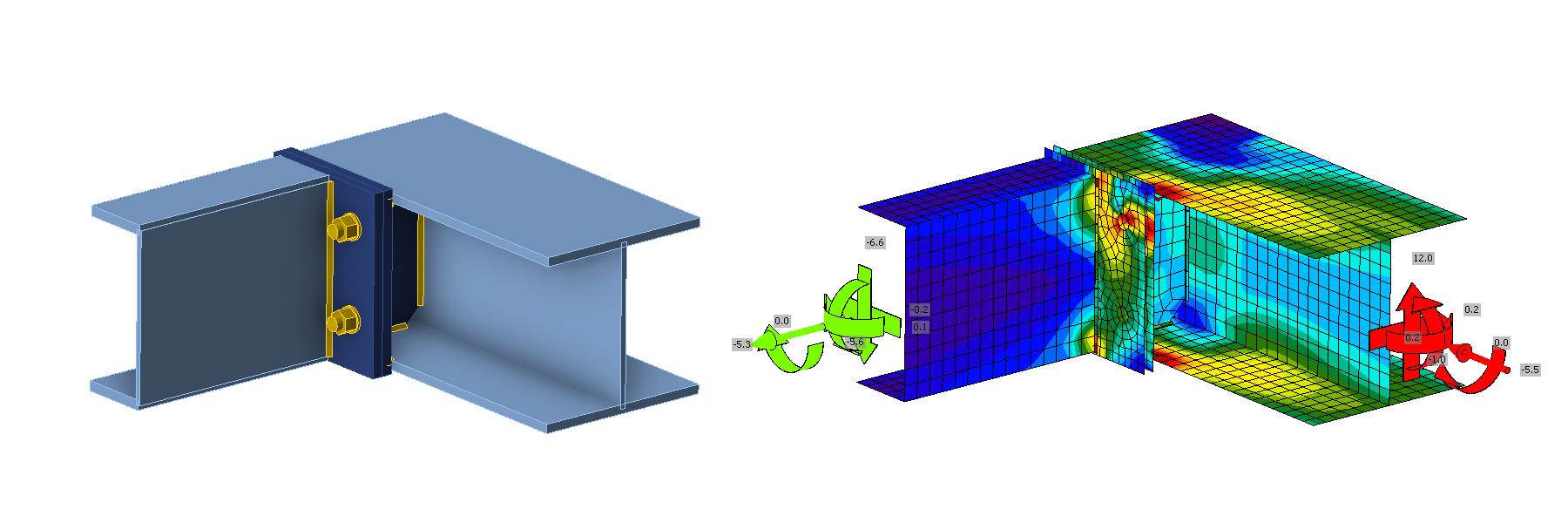

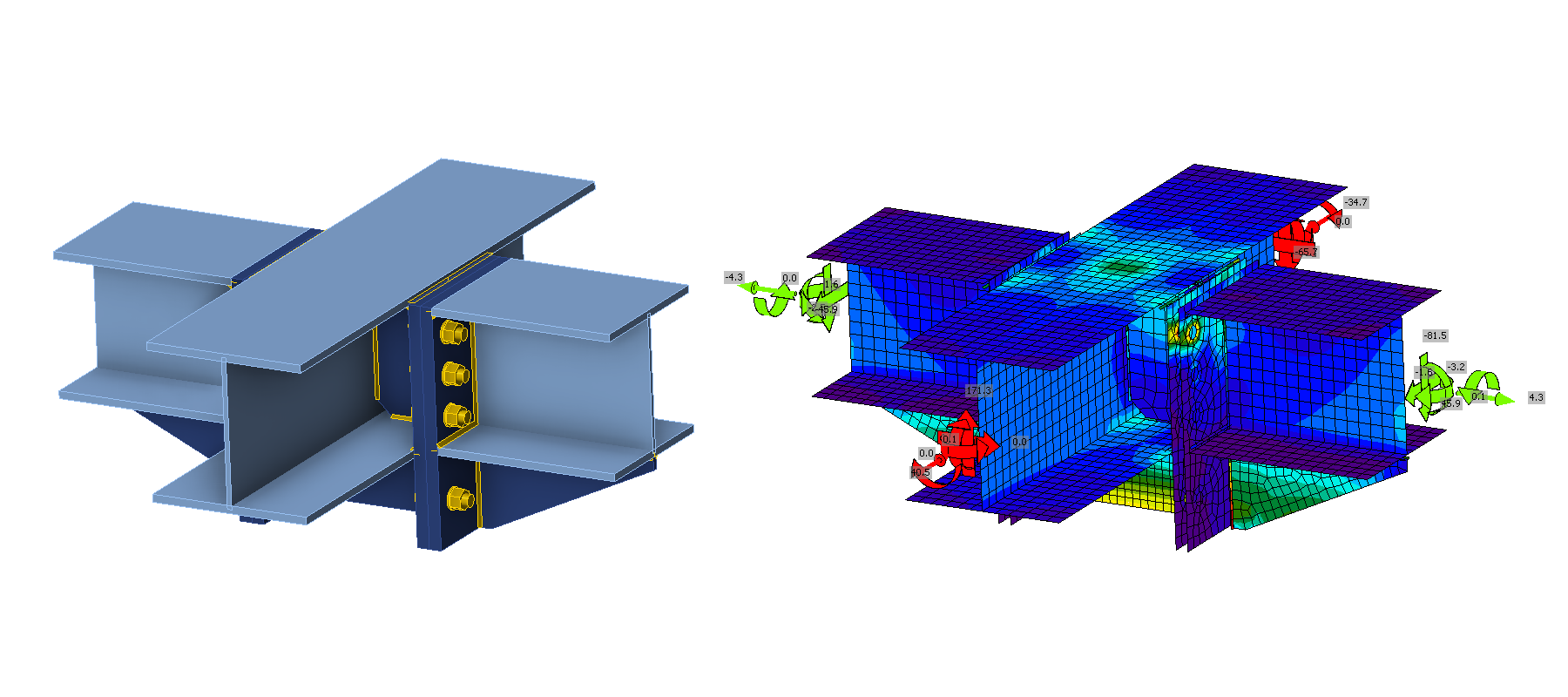

At the heart of the engineering complexity were the connection details. The jointing between secondary and primary beams required special consideration, not only due to load transfer but also to account for practical bolt access and fabrication tolerances. These connections had to balance stiffness and ductility, particularly in areas subjected to both gravity and lateral forces.

The column bases presented another layer of difficulty. Due to design constraints, oversized holes were required for anchor bolts, necessitating welded washers to ensure plate integrity without compromising anchorage performance. This called for careful modeling of bolt pretension, contact surfaces, and local yielding behavior. IDEA StatiCa’s component-based finite element method was instrumental in making these localized checks transparent and accurate.

Romania

The loading scenario was a further challenge. Each generator exerted a concentrated vertical load of 7233 kg, supported over a narrow footprint. Distributed live loads from maintenance activity (1.5 kN/m²) and the steel grating itself (0.5 kN/m²) had to be superimposed. The seismic design posed particular complexity: the non-structural CNS forces added 11.7 kN/m of horizontal load, requiring the team to validate that all critical connections could accommodate seismic drift and amplification effects without failure.

While fabrication challenges were minimal, the diversity and volume of unique joints required smart management. Connection reuse and fast iteration became essential to maintain schedule and avoid bottlenecks in detailing. Traditional manual calculation would have delayed the delivery significantly and increased the risk of inconsistencies.

Solutions and Results

To overcome these technical and process challenges, the SC Selfconsulting team deployed IDEA StatiCa Connection in combination with SCIA Engineer via the Checkbot link. This allowed all connection forces to be automatically imported from the global model, eliminating manual transfer errors and reducing coordination time between global analysis and connection checks. With Checkbot, each connection was evaluated under real load cases using a non-linear FEM-based approach, giving clear insight into load paths, plastic strain limits, bolt slippage, and weld stress concentrations.

Romania

Critically, the Publish and Propose functions allowed the team to standardize connections and reuse validated designs across multiple similar joints. This avoided repetitive modeling and allowed a connection template library to emerge organically during the project. As a result, detailing time for recurring connections was reduced by over 60%. IDEA StatiCa’s automatic reporting also meant that documentation for code compliance, especially for seismic checks, was traceable and export-ready for review.

Romania

Baseplate checks were modeled including eccentric anchor arrangements and the influence of stiffeners and welded washers. Without IDEA StatiCa, such modeling would have required custom FEA setups and manual result interpretation, adding days of work per connection. Instead, the entire verification cycle per joint dropped to under 20 minutes, including analysis, adjustment, and documentation.

Measured Impact

The engineering team reported that connection reuse alone saved over 40 hours of detailing work across the platform. More importantly, the ability to validate and document every load-bearing connection, especially seismic-sensitive ones, meant no delays in review cycles. With over 15 unique connection types, and at least 30 load cases considered in the SCIA–IDEA StatiCa workflow, the project met all verification demands within the originally planned design schedule. The value wasn’t just in time saved, but in the confidence the team could design complex, compliant steel joints without compromise.

Romania

About SC Selfconsulting SRL

SC Selfconsulting SRL is a Romania-based firm delivering multidisciplinary design services in civil and industrial construction. Its growing team includes architects, structural engineers, and project managers, serving both public and private sector clients.

Prova IDEA StatiCa gratis