ICON Växjö project by Peikko, Sweden

About the ICON project

ICON Växjö is a modern and very attractive building, with challenging technical solutions and fast delivery time. It is a part of the fast-growing Arenastaden area which has become a hub in the expansion of the whole city.

With new arenas for ice hockey, football, floorball, gymnastics and athletics, associations, property developers and other subjects work together to increase the opportunities for sports and the region's attractiveness.

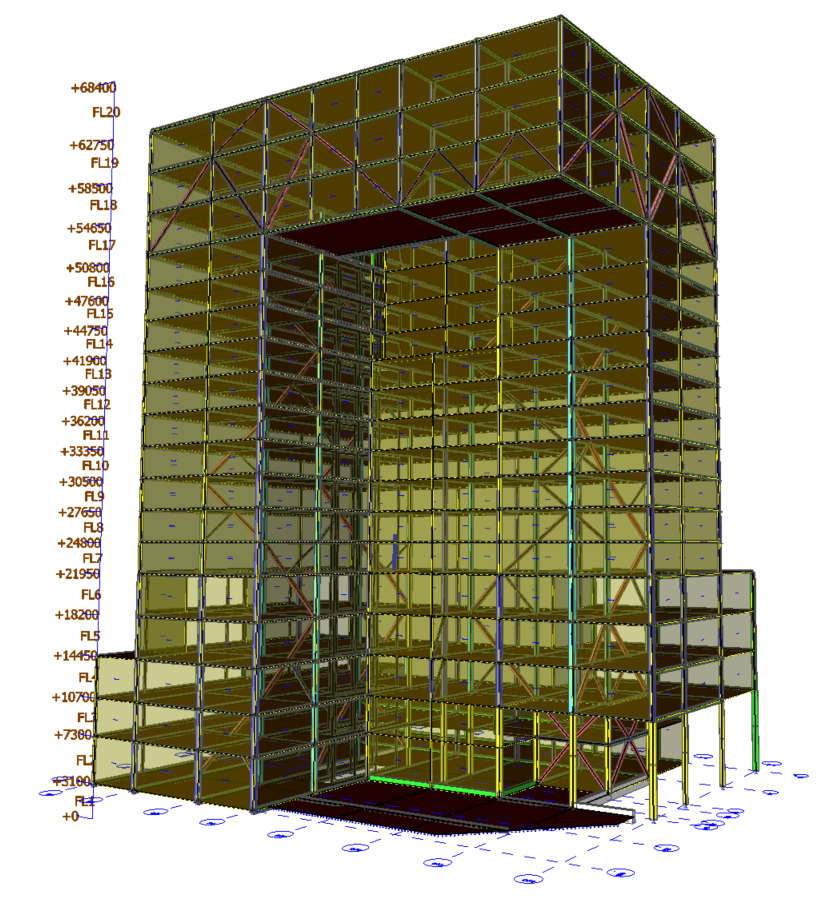

In the middle of this pulsating location, ICON Växjö has emerged and become Arenastaden's obvious eye-catcher and center property. On 20 floors, it provides a floor area of 37.000 sq.m., containing 280 flats, 4.500 sq.m. of offices, 1.600 sq.m. co-working premises and a high school for 500 students. There is also a restaurant, spa and a gym.

ICON Växjö was created by architect Magnus Månsson, Semrén & Månsson's architectural office in Gothenburg. Magnus was born and raised in Växjö and his goal has been to create a house gathering people and living for most of the day.

One of the IDEA StatiCa customers, Peikko, was responsible for a number of construction tasks. The building became one of Peikko's largest projects in Sweden. The project's main engineer was Artūras Vitkus from Peikko Lithuania. Peikko delivered the main steel frame and other steel assemblies for this project and is responsible for overall building stability design.

About Peikko

Peikko is a family-owned company founded in 1965. It is headquartered in Lahti, Finland. It has a net of sales offices in over 30 countries in Asia-Pacific, Europe, Africa, the Middle East, and North America, with manufacturing operations in twelve countries.

Peikko Group Corporation is a leading global supplier of slim floor structures, wind energy applications and connection technology for precast and cast-in-situ construction in a wide variety of applications. Peikko’s innovative solutions make the construction process faster, safer, and more effective.

The structure challenges

Main frame

Peikko delivered the DELTABEAM® Frame for this project and is responsible for overall building stability.

By using the DELTABEAM® Frame solution extremely high speed of assembly was achieved. And despite wintertime, it took only 9 months to assemble the frame.

Stability and bracing

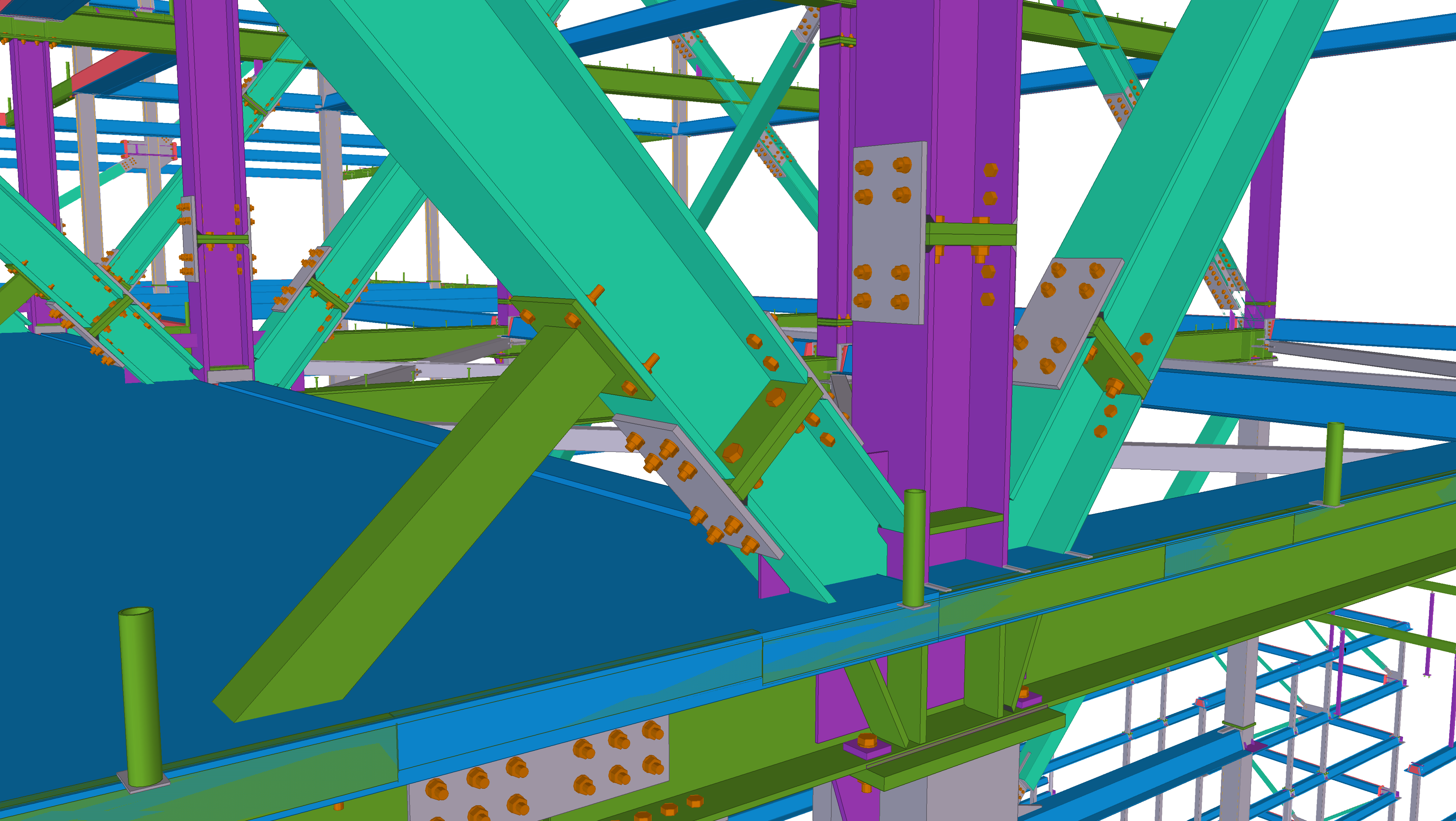

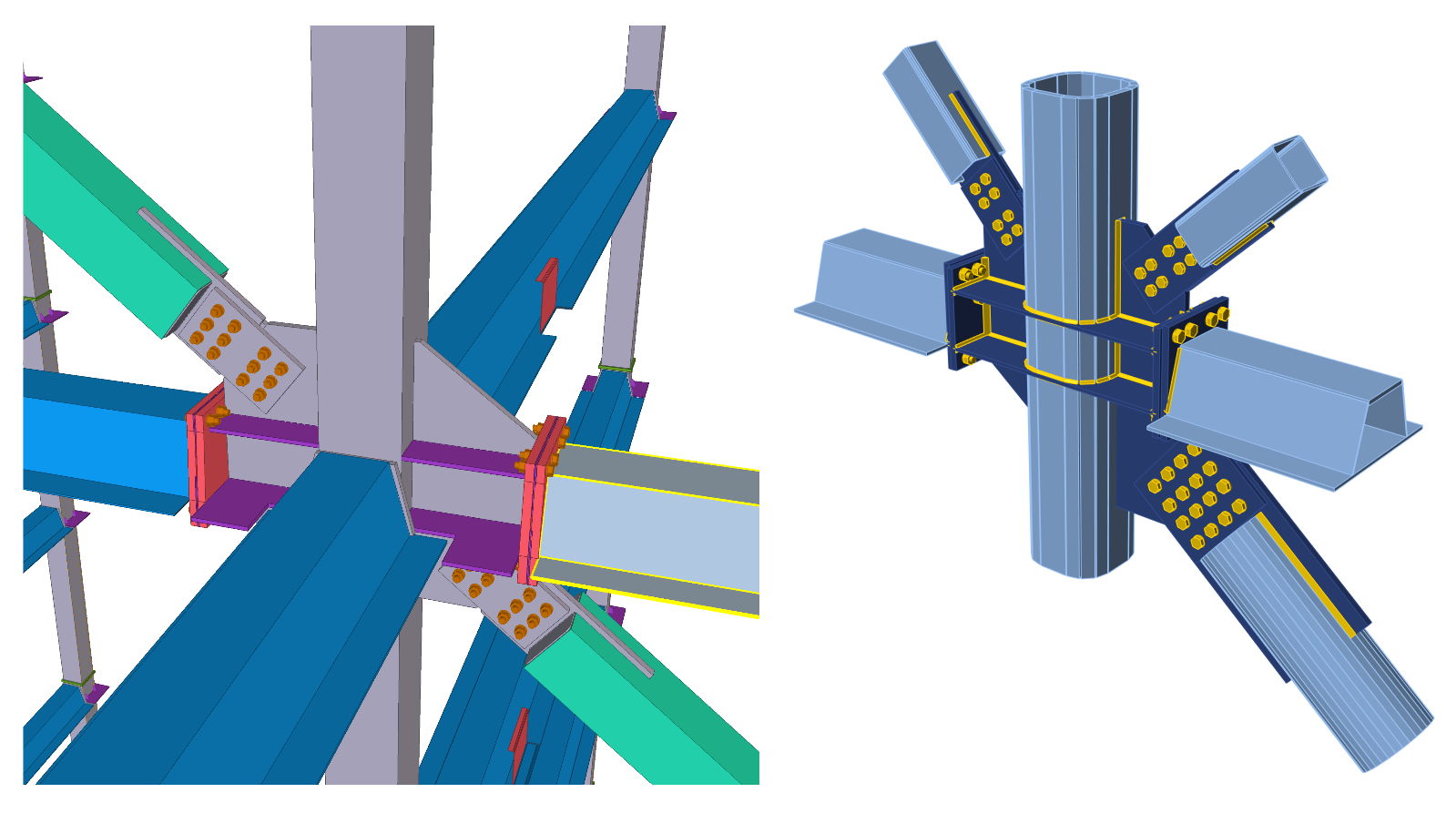

For a project of such size and height, stability is crucial for safe design. The shape of the structure with the cantilever part above 50 m brings another challenge to the appropriate design of steel bracing members and its connections.

In the visualization below, you can see the complexity of the solution.

Bracing structural members

Thanks to Peikko's design of the whole steel structure under one roof, it was possible to successfully combine the standard bracing members with atypical hollow sections of the composite slim floor beams.

Prefabrication of the whole main frame made it possible to assemble the structure within admirable 9 months.

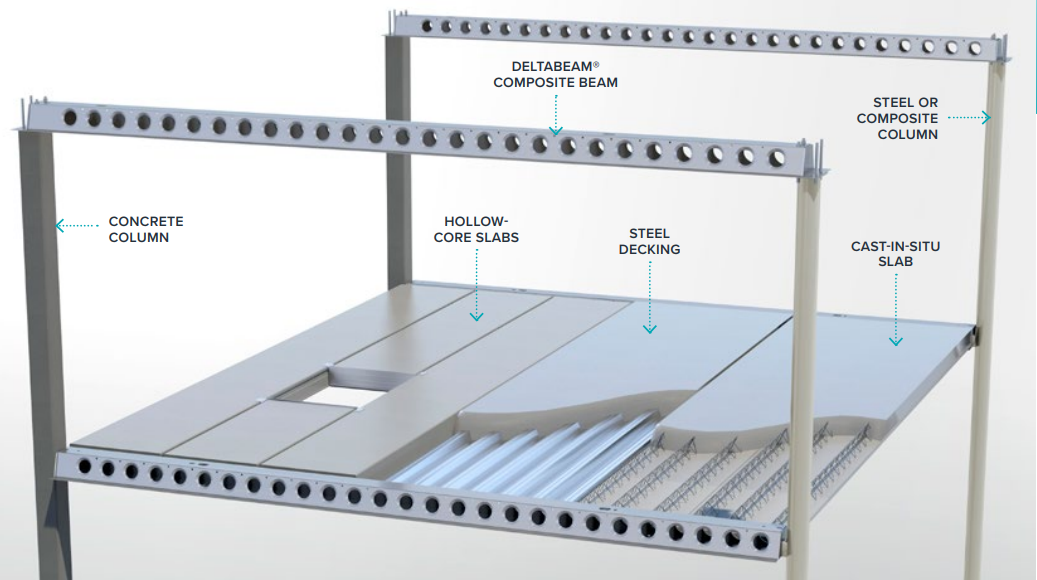

Peikko's original solution

Peikko’s DELTABEAM® Slim Floor Structure is a flexible solution always tailored to the customer’s needs. It enables slender and light structural solutions that provide savings in terms of volume and costs. The composite action between steel and concrete allows the construction of creative structures with large open spaces.

These composite beams have excellent fire resistance without any additional protection. Its shallow design decreases a building’s floor-to-floor height while eliminating conflicts with HVAC systems.

DELTABEAM® can be connected to concrete, steel, or composite columns by using Peikko’s innovative solutions, such as Hidden Corbels, Anchor Bolts, or Welding Plates.

DELTABEAM® Benefits

- Long spans

- Flexible open space

- Additional room height

- Easy and space-saving HVAC installations

- Lower heating and cooling costs

- Integrated fireproofing

- Suitable for all slab and column types

What's typical for the Peikko's original DELTABEAM solution, is the fact that they have no typical product range catalog of members, from which the Structural designer has to choose. On the contrary, their beams are designed and fabricated tailored to each project by their Structural design teams. This is a huge advantage for both sides - the developer and also the contractor. By this way of the design process, it is possible to dimension the cross-sections just right for the particular project and think thoroughly about all aspects of the reliable construction process.

Tekla BIM interconnection

Exchange of information, speedy modeling, and solution development were crucial in many phases of the project. In an early stage, the best structural shape of the stability system and column cross-sections was found in cooperation with the architect via IFC models. The model was also used to find clashes between the structural and architectural designs.

Since all the project parties are interdependent, BIM is the way to retain a link between them. For example in the detailing stage, the connections between precast, composite and steel structures had to be communicated between two parties throughout the project. Using BIM, the engineers were free to model custom connections with very little effort when presenting them to the other project participants.

Model information was utilized directly at the workshop when fabricating the structures. The NC1 and DXF files exported from Tekla Structures were transferred to the production unit easily and quickly. Utilizing data directly from the model, instead of drawings and material lists, reduced the human error probability. This allowed good control over materials and production planning.

BIM supported communications and work planning in the project. Presenting the big picture of the whole structure to the mounting team was easy in 3D. In this project, it was especially useful in the planning of the step-by-step erection sequence of the cantilever structure of a multistorey truss, for example.

In a project of this magnitude, the exchange of information and speed of modeling were important factors, as was the ability to make changes to the solutions on the fly. Without BIM, it wouldn’t have been possible.

Use of IDEA StatiCa

Structural engineers of Peikko used the advantages of IDEA StatiCa Connection in free topology and cross-sections assessment very effectively. The solution provided the ability to model any type of connection from the very simplest to the most complex ones. As well as Peikko's DELTABEAM steel members, the IDEA StatiCa Connection has no limitation in the structural design. The structural engineer can assess exactly the same detail arrangement in the CBFEM model as in the CAD model.

Connection analysis in IDEA StatiCa

Customer's experience

Matej Hrubý - Peikko Slovakia

We used IDEA StatiCa Connection for the design of DELTABEAM endplates, the design of stiffeners of complicated joints, and splicing connections of steel sections. Maybe the most important feature and also the reason why we purchased IDEA StatiCa Connection is the design of bolted endplates. With the CBFEM calculation method, we are able to optimize the thickness of plates. That is very useful for us because such an endplate is almost impossible to design based on EC design code. This method takes into account the real „behavior“ of the endplate, which means, e.g., increase of forces in bolts due to prying effects, which is a correct assumption.

Peikko Slovakia

Slovakia