Innovations in structural design – unlocking the future

Why even bother changing anything in what we do on an everyday basis? Isn't it already great enough in the current state of our engineering offices? The amount of work is big enough, new structures are being built every day, and it probably won't change soon. The digital tools of today's engineers are already extremely powerful with speeds unthinkable of several years ago. The force pushing for any kind of change always arises from a need. So what is the current "need" of civil engineering offices?

It appears that there are several...

- there are fewer and fewer people willing to do the job every day

- the amount of work to do is getting bigger every year thanks to economic growth in many regions

- the pace of development in other engineering fields related to civil engineering is much higher

- the complexity of the projects is increasing monumentally with a focus on 'green' solutions, energy consumption, and CO2 impact

Let's try and take a sneak peek into the near future of our field.

What will it be like to be a structural engineer?

Is the job of a structural engineer one of these endangered by the emergence of AI? Not so much, at least, not so soon. The number of variables coming into every assignment is simply too high to be covered by algorithms. And not because of the necessary computational power, but because of non-synchronized and not cooperating databases from different fields, and because of the human common sense needed to make sense out of all the data mess.

On the other hand, will the everyday job of a structural engineer look the same as it does today? Paper drawings, hand remarks, hundreds of DWGs and PDFs, neverending spreadsheets, structural models of different granularity (not willing to communicate with each other), hundreds of emails and chat messages about the projects, due dates, budgets, long hours spent in offices full of files, books, design codes, manuals, and structural magazines?

Hopefully not.

But what can we improve to get from today's reality to a much more hospitable environment in the future? If we want to work smart instead of hard, we should use the opportunities available. And, if they are not visible now, we could take a look in some neighboring fields such as mechanical engineering where expressions like machine learning, big data processing, or topology optimization have already been in use for some time.

What is quite obvious already, even though the job title structural engineer will survive, the need for new skills and abilities is unavoidable. Having a knowledge of mathematics, physics, structural mechanics, materials, and design code requirements will no longer be enough. A brand new set of digital skills will be required – working with data, building data links between different tools, usage of parametric design, understanding machine learning, knowledge in efficient prompt creation, etc.

One very important side not covered so far in this post, but still crucial in the designing process, is governments, design codes, and checking agencies. These can't be left out because, without acceptance and cooperation in this part, the progress of technologies would be dramatically quicker than the response of the engineering community could be.

Topology optimization

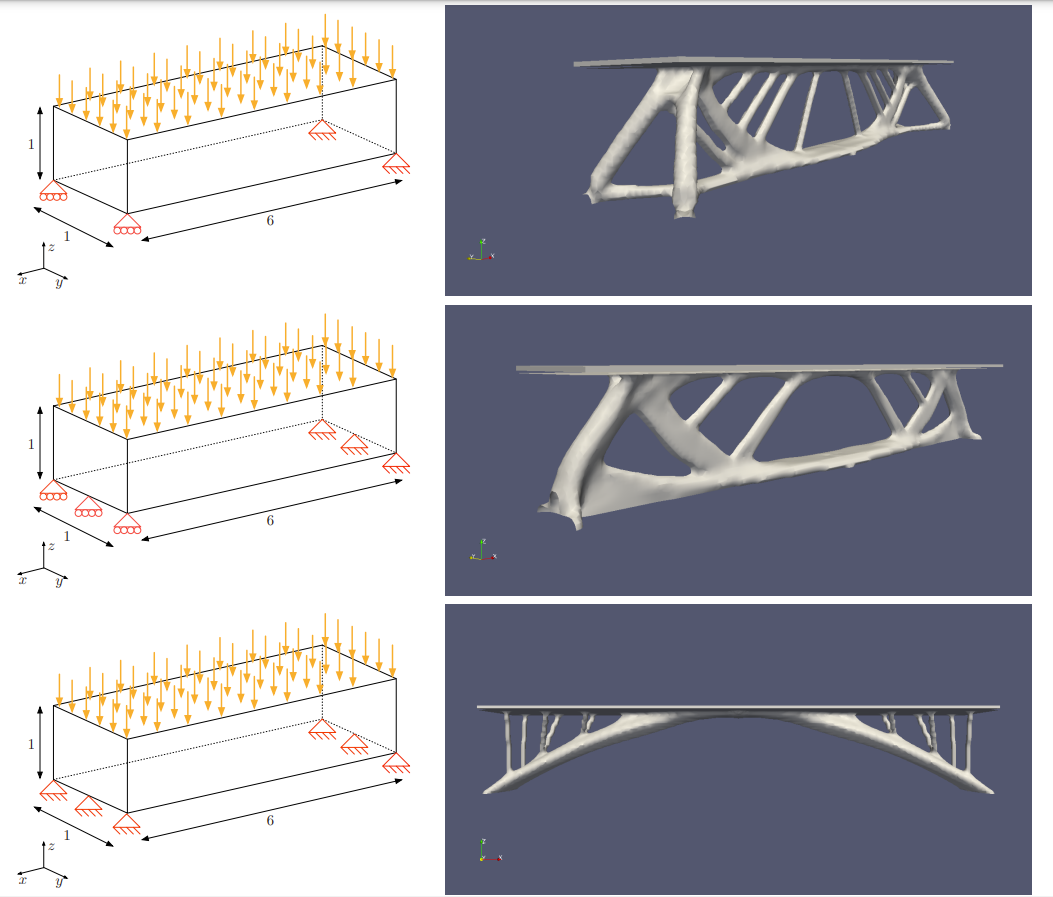

What is it all about? To put it simply, it's like solving a difficult task where you have a specific amount of building blocks to create a structure. And you want it to be strong enough to hold up under specific loading, but you also want to use as few building blocks as possible.

In topology optimization, calculation algorithms are used to help us figure out the best way to place our blocks. The program plays around with different designs, trying hundreds of variations of where to put the blocks to make the structure as strong as possible while using as few blocks as necessary. It's like the computer is testing out all sorts of bridge designs to see which one can hold the most weight without falling down, but also at the same time not wasting any blocks.

This method helps engineers and designers come up with very efficient, and sometimes unusual-looking, structures that do their job using the least amount of material possible. It's a smart way to design things because it saves materials, reduces weight, and often leads to innovative designs that we might not think of on our own.

In the image above, you can see three optimized designs of a three-dimensional bridge associated with different sets of fixations [K. Bando, R. Din, M. Fouquerand, L. Gilbert, A. Moissenot, and M. Nicolas, Optimisation d’une structure et application architecturale, PSC MEC07, Ecole Polytechnique (X), 2016].

What's available already

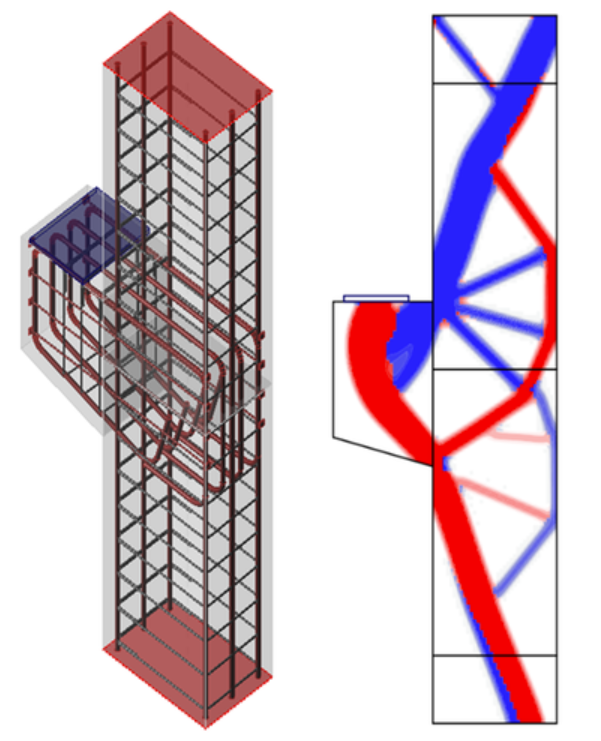

Maybe the most advanced design tool for structural reinforced concrete available these days, IDEA StatiCa Detail, is capable of showing the user topology optimization based on stress flows in the assigned geometry. This tool very clearly and visually shows the designer what the positions and directions most efficient for reinforcing bars are. You can browse through our blog article dedicated to topology optimization.

Even these powerful and advanced models are just the beginning of what could be possible when handled seriously. We already know hundreds of designs where the geometry is based on organic shapes and looks much more like an image from a biology book than a typical truss shape. We can find several already-built or under-construction projects with organic-shaped inspiration. One nice example is the current project of the Metro station in Riyadh by Zaha Hadid Architects.

With some imagination, these organic shapes could appear in architecture not only because of their beauty but also as a geometry of the bearing structures thanks to topology optimization and new construction processes.

What kind of structures and projects are being solved thanks to today's designing tools? Let's take a look into our library of Case studies.

The power of data in engineering

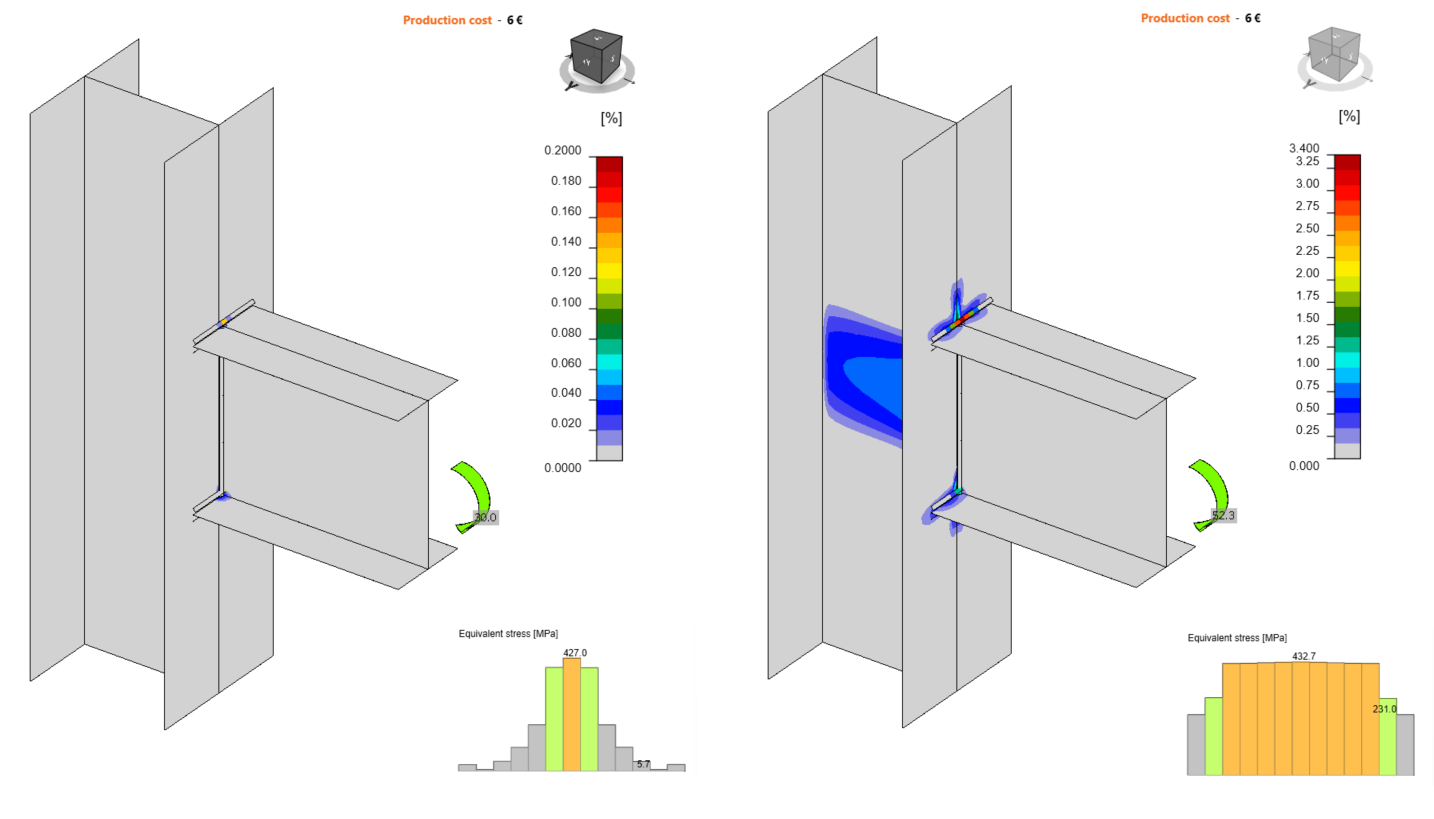

The researchers of IDEA StatiCa presented at one recent steel structural conference the new methods used for automated prediction of weld utilization in the Connection app. This revolutionary approach solves one simple question with a very complex solution. What is the real capacity of a weld when plastification of material is allowed?

The innovative method described in the document employs advanced artificial intelligence, specifically convolutional neural networks, to significantly improve the accuracy of predicting weld utilization rates in steel structures. This novel approach is groundbreaking for structural engineers as it goes beyond traditional methods by intricately analyzing stress distribution and strain history along weld lines. Such a detailed analysis allows for more precise estimations, catering to various weld configurations and loading scenarios. This advancement not only enhances the safety and efficiency of structural designs but also exemplifies the potential of integrating machine learning with conventional engineering practices, paving the way for smarter, data-driven solutions in structural engineering. For more about how to use this improvement here.

Because it's not that easy to calculate hundreds of load increments in seconds, the algorithm uses a huge set of data from previous analyses performed in the past and is able to find the closest weld size values to the wanted solution in real-time.

Dictionary tips for new structural engineers:

Machine learning (ML) is a branch of artificial intelligence that enables computers to learn from and make decisions based on data. In structural design and analysis, ML can be used to predict material behavior, assess structural integrity, and optimize design processes. By analyzing vast datasets, ML algorithms can identify patterns and insights that might be missed by traditional methods. This can lead to more efficient, safer, and cost-effective structural designs. ML can also assist in the real-time monitoring and maintenance planning of structures, further enhancing their lifespan and safety.

Convolutional neural networks (CNNs) are a type of artificial intelligence widely used for processing data with grid-like topology, such as images. They excel in tasks like image recognition and classification. A CNN learns to recognize patterns and features in input data through layers that perform convolutions – mathematical operations that filter and compress data. This structure allows CNNs to identify intricate patterns, making them powerful tools in various engineering applications, from structural analysis to automated design processes. Their ability to process complex datasets efficiently makes them a valuable asset in modern engineering problem-solving.

Summary

As you've just seen, the future is closer than you would think. Not the one from AI-generated pictures, but the first principles of automation and smart optimization are already being embedded in structural analysis tools.

The tools won't do the revolution by themselves. What is needed to unleash these new possibilities is a major mind-shift of the parties involved in the design process. It's up to engineers how they will adapt to the opportunities available and how they will incorporate them into their everyday workflows.