Check of steel connection components (IS 800)

Design check of plates according to Indian standard

The resulting equivalent stress (HMH, von Mises) and plastic strain are calculated on plates. When the design yield strength, \( f_y / \gamma_{m0} \) (IS:800, Cl. 5.4.1), on the bilinear material diagram is reached, the check of the equivalent plastic strain is performed. The limit value of 5 % is suggested in Eurocode (EN 1993-1-5 App. C, Par. C8, Note 1). This value can be modified in Code setup, but verification studies were made for this recommended value.

Plate element is divided into 5 layers, and elastic/plastic behavior is investigated in each of them. The program shows the worst result of all of them.

Stress may be a little bit higher than the design yield strength. The reason is the slight inclination of the plastic branch of the stress-strain diagram, which is used in the analysis to improve the stability of the calculation.

Code-check of welds according to Indian standards

Butt welds

The verification of full penetration butt welds is not carried out, as it is assumed to have the same resistance as that of profile, as long as the parent material for the butt weld is superior to that of the profile (IS 800:2007, 10.5.7.1.2).

Fillet welds

Fillet welds are checked according to IS 800, Cl. 10.5.10.1.1:

\[ f_e = \sqrt{f_a^2 + 3q^2} \le f_{wd} = \frac{f_u}{\sqrt{3} \gamma_{mw}} \]

where:

- \( f_e \) – equivalent stress in weld

- \( f_a \) – normal stresses, compression or tension, due to axial force or bending moment

- \( q \) – shear stress due to shear force or tension

- \( f_{wd} \) – design strength of a fillet weld

- \( f_u \) – smaller of the ultimate stress of the weld or of the parent metal; the ultimate strength of the weld electrode is assumed better than of the parent metal

- \( \gamma_{mw} \) – partial safety factor for welds – IS 800, Table 5; editable in Code setup

The weld diagrams show stress according to the following formula:

\[ \sigma = \sqrt{\sigma_{\perp}^2 + \tau_{\perp}^2 + 3 \tau_{\parallel}^2 } \]

Code-check of bolts according to Indian standard

Shear capacity of bolts

The design strength of the bolt, \(V_{dsb}\), as governed shear strength is given by IS 800, Cl. 10.3.3:

\[ V_{sb} \le V_{dsb} \]

where:

- \(V_{dsb} = V_{nsb}/\gamma_{mb}\) – design shear capacity of a bolt

- \(V_{nsb} = \frac{f_{ub}}{\sqrt{3}} A_e\) – nominal shear capacity of a bolt

- \(f_{ub}\) – ultimate tensile strength of a bolt;

- \(A_e\) – area for resisting shear; \(A_e = A_n\) for shear plane intercepted by the threads, \(A_e = A_s\) for the case where threads do not occur in shear plane

- \(A_n\) – net tensile stress area of the bolt

- \(A_s\) – cross-section area at the shank

- \(\gamma_{mb} = 1.25\) – partial safety factor for bolts – bearing type – IS 800, Table 5; editable in Code setup

When the grip length of bolts \(l_g\) (equal to the total thickness of the connected plates) is higher than \(5d\), the design shear capacity \(V_{dsb}\) is reduced by a factor \(\beta_{lg}\) – IS 800, Cl. 10.3.3.2:

\[ \beta_{lg} = \frac{8}{3+l_g/d} \]

According to IS 800, Cl. 10.3.3.3, the design shear capacity of bolts carrying shear through a packing plate with the thickness \(t_{pk} \ge 6\) mm shall be decreased by a factor:

\[ \beta_{pk} = (1-0.0125 t_{pk}) \]

Each shear plane is checked separately, and the worst result is shown.

Bearing capacity of bolts

The design bearing strength of a bolt on any plate, as governed by bearing is given by IS 800, Cl. 10.3.4:

\[ V_{sb} \le V_{dpb} \]

where:

- \(V_{dpb} = V_{npb} / \gamma_{mb}\) – design bearing strength of a bolt

- \(V_{npb} = 2.5 k_b d t f_u\) – nominal bearing strength of a bolt

- \(k_b = \min \left \{ \frac{e}{3d_0}, \, \frac{p}{3d_0}-0.25, \, \frac{f_{ub}}{f_u}, \, 1.0 \right \}\) – factor for joint geometry and material strength

- \(e\) – end distance of the fastener along bearing direction

- \(p\) – pitch distance of the fastener along bearing direction

- \(f_{ub}\) – ultimate tensile strength of the bolt

- \(f_u\) – ultimate tensile strength of the plate

- \(d\) – nominal diameter of the bolt

- \(d_0\) – diameter of bolt hole

- \(t\) – plate thickness

- \(\gamma_{mb} = 1.25\) – partial safety factor for bolts – bearing type – IS 800, Table 5; editable in Code setup

Bearing on each plate is checked separately and the worst result is shown.

The bearing resistance is reduced for oversized and slotted holes by a factor:

- 0.7 – for oversized and short slotted holes

- 0.5 – for long slotted holes

Sizes of oversized, short slotted, and long slotted holes are determined according to IS 800, Table 19.

Tension capacity of bolts

A bolt subjected to a factored tensile force is checked according to IS 800, Cl. 10.3.5:

\[ T_b \le T_{db} \]

where:

- \(T_{db} = T_{nb} / \gamma_{mb}\) – design tensile capacity of the bolt

- \(T_{nb} = \min \{ 0.9 f_{ub} A_n, \, f_{yb} A_s (\gamma_{mb} / \gamma_{m0}) \}\) – nominal tensile capacity of the bolt

- \(f_{ub}\) – ultimate tensile strength of the bolt

- \(f_{yb}\) – yield strength of the bolt

- \(A_n\) – net tensile stress area of the bolt

- \(A_s\) – cross-section area at the shank

- \(\gamma_{mb} = 1.25\) – partial safety factor for bolts – bearing type – IS 800, Table 5; editable in Code setup

- \(\gamma_{m0} = 1.1\) – partial safety factor for resistance governed by yielding – IS 800, Table 5; editable in Code setup

Bolt subjected to combined shear and tension

A bolt required to resist both design shear force and design tensile force at the same time shall according to IS 800, Cl. 10.3.6 satisfy:

\[ \left( \frac{V_{sb}}{V_{db}} \right)^2 + \left( \frac{T_{b}}{T_{db}} \right)^2 \le 1.0 \]

where:

- \(V_{sb}\) – factored shear force

- \(V_{db} = \min \{ V_{dsb}, \, V_{dpb} \}\) – design shear resistance of the bolt – IS 800, Cl. 10.3.2

- \(V_{dsb}\) – design shear resistance

- \(V_{dpb}\) – design bearing resistance

- \(T_b\) – factored tensile force

- \(T_{db}\) – design tensile capacity of the bolt

Code-check of preloaded bolts according to Indian standards

Slip resistance

Slip resistance of preloaded bolt is checked according to IS 800, Cl. 10.4.3:

\[ V_{sf} \le V_{dsf} \]

where:

- \(V_{dsf} = V_{nsf} / \gamma_{mf}\) – design shear capacity of a bolt as governed by slip for friction type connection

- \(V_{nsf} = \mu_f n_e K_h F_0\) – nominal shear capacity of a bolt as governed by slip for friction type connection

- \(\mu_f\) – coefficient of friction (slip factor) as specified in IS 800, Table 20; editable in Code setup

- \(n_e = 1\) – number of effective interfaces offering frictional resistance to slip; each shear plane is checked separately

- \(K_h\) – factor for bolt holes; \(K_h = 1.0\) for fasteners in standard holes, \(K_h = 0.85\) for fasteners in oversized and short slotted holes, \(K_h = 0.7\) for fasteners in long slotted holes

- \(\gamma_{mf}\) – partial safety factor for bolts – friction type – IS 800, Table 5, \(\gamma_{mf}=1.10\) if slip resistance is designed at service load, \(\gamma_{mf}= 1.25\) if slip resistance is designed at ultimate load; editable in Code setup

- \(F_0 = A_n f_0\) – minimum bolt tension (proof load) at installation

- \(A_n\) – net tensile stress area of the bolt

- \(f_0 = 0.7 f_{ub}\) – proof stress

Capacity after slipping (IS 800, Cl. 10.4.4) should be checked by switching bolt type from friction to bearing – tension/shear interaction for design capacity at ultimate load.

Tension capacity of bolts

A bolt subjected to a factored tensile force is checked according to IS 800, Cl. 10.3.5:

\[ T_f \le T_{df} \]

where:

- \(T_{df} = T_{nf} / \gamma_{mf}\) – design tensile capacity of the friction bolt

- \(T_{nf} = \min \{ 0.9 f_{ub} A_n, \, f_{yb} A_s (\gamma_{mf} / \gamma_{m0}) \}\) – nominal tensile capacity of the friction bolt

- \(f_{ub}\) – ultimate tensile strength of the bolt

- \(f_{yb}\) – yield strength of the bolt

- \(A_n\) – net tensile stress area of the bolt

- \(A_s\) – cross-section area at the shank

- \(\gamma_{mf}\) – partial safety factor for bolts – friction type – IS 800, Table 5, \(\gamma_{mf}=1.10\) if slip resistance is designed at service load, \(\gamma_{mf}= 1.25\) if slip resistance is designed at ultimate load; editable in Code setup

- \(\gamma_{m0} = 1.1\) – partial safety factor for resistance governed by yielding – IS 800, Table 5; editable in Code setup

Prying forces are determined by finite element analysis and are included in the tensile force.

Friction bolt subjected to combined shear and tension

A bolt required to resist both design shear force and design tensile force at the same time shall according to IS 800, Cl. 10.3.6 satisfy:

\[ \left( \frac{V_{sf}}{V_{df}} \right)^2 + \left( \frac{T_{f}}{T_{df}} \right)^2 \le 1.0 \]

where:

- \(V_{sf}\) – applied factored shear at design load

- \(V_{df}\) – design shear strength

- \(T_f\) – externally applied factored tension at design load

- \(T_{df}\) – design tension strength

Code-check of concrete block according to Indian standards

Concrete in bearing

Two options for checking of concrete in bearing are available:

- According to IS 800, Cl. 7.4

- According to IS 456, Cl. 34.4

Concrete in bearing checked according to IS 800, Cl. 7.4

The maximum bearing pressure should not exceed the bearing strength equal to \(0.6 f_{ck}\), where \(f_{ck}\) is the characteristic cube strength of concrete. The strength of grout is assumed to be higher than that of concrete foundation. Cl. 7.4.3.1 provides the formula for the minimum thickness of column bases:

\[ t_s = \sqrt{2.5 w c^2 \gamma_{m0} / f_y} > t_f \]

where:

- \(w\) – uniform pressure from below on the slab base under the factored load axial compression

- \(c\) – overlap of the column base over the column

- \(f_y\) – yield strength of the column base

- \(t_f\) – column flange thickness

- \(\gamma_{m0} = 1.1\) – partial safety factor for resistance governed by yielding – IS 800, Table 5; editable in Code setup

The formula can be rewritten to determine the overlap with the assumption that \(w = 0.6 f_{ck}\):

\[ c = t_s \sqrt{\frac{f_y}{1.5 f_{ck} \gamma_{m0}}} \]

The area \(A_{c,eff}\) is determined by offsetting the column (with stiffeners) cross-sectional area intersecting the base plate by overlap \(c\). Another area, \(A_{FEM,eff}\) determining the area in contact between the base plate and concrete foundation (grout) by finite element analysis. The area resisting the compressive forces, \(A_{eff}\) is intersection of these two areas, \(A_{c,eff}\) and \(A_{FEM,eff}\). Bearing strength \(0.6 f_{ck}\) on this area \(A_{eff}\) is assumed at the ultimate limit state.

The check of concrete in the bearing is performed in a form of stresses:

\[ \sigma_c \le w \]

where:

- \(\sigma_c = \frac{N_c}{A_{eff}}\) – average bearing stress below the base plate

- \(N_c\) – compressive force

- \(w = 0.6 f_{ck}\) – bearing resistance of the concrete

Concrete in bearing checked according to IS 456, Cl. 34.4.

The maximum bearing pressure should not exceed the bearing strength equal to \(0.45 f_{ck} \cdot \min \left \{ \sqrt{\frac{A_1}{A_2}}, \, 2 \right \} \), where:

- \(f_{ck}\) – characteristic cube strength of concrete; strength of grout is assumed higher than that of concrete foundation

- \(A_1\) – supporting area taken as the area of the lower base of the largest frustum of a pyramid or cone contained wholly within the footing and having for its upper base, the area actually loaded and having side slope of one vertical to two horizontal

- \(A_2\) – bearing area determined by finite element analysis (equal to \(A_{FEM,eff}\))

The check of concrete in the bearing is performed in a form of stresses:

\[ \sigma_c \le w \]

where:

- \(\sigma_c = \frac{N_c}{A_{2}}\) – average bearing stress below the base plate

- \(N_c\) – compressive force

- \(w = 0.45 f_{ck} \cdot \min \left \{ \sqrt{\frac{A_1}{A_2}}, \, 2 \right \}\) – bearing resistance of the concrete

Transfer of shear

The shear action at the base plate is assumed to be transferred from the column to the concrete foundation by:

- Friction between base plate and concrete/grout

- Shear lug

- Anchor bolts

Anchors

The tensile forces in anchors include prying forces and are determined by finite element analysis.

Anchors are not checked in the software.

Detailing of bolts and welds according to Indian Standard

Bolts

Bolt minimum spacing is according to IS 800, Cl. 10.2.2: Centre to centre of the bolt should be larger than \(2.5 \cdot d\), where \(d\) is nominal bolt diameter.

Minimum end and edge distances measured from the centreline of the bolt are taken according to IS 800, Cl. 10.2.4 as \(1.5 \cdot d_0\), where \(d_0\) is the standard hole diameter according to IS 800, Table 19.

The grip length of bolts should be limited to \(8d\) according to IS 800, Cl. 10.3.3.2.

Welds

Minimal size of welds is checked according to IS 800, Table 21:

| Thickness of thicker part [mm] | Minimal weld size [mm] |

| \(t \le 10 \) | 3 |

| \( 10 < t \le 20 \) | 5 |

| \( 20 < t \le 32 \) | 6 |

| \( 32 < t \) | 10 |

Note that weld size is assumed as throat thickness multiplied by \(\sqrt{2}\).

Column base

Column base thickness should be larger than the thickness of column flange according to IS 800, Cl. 7.4.3.1.

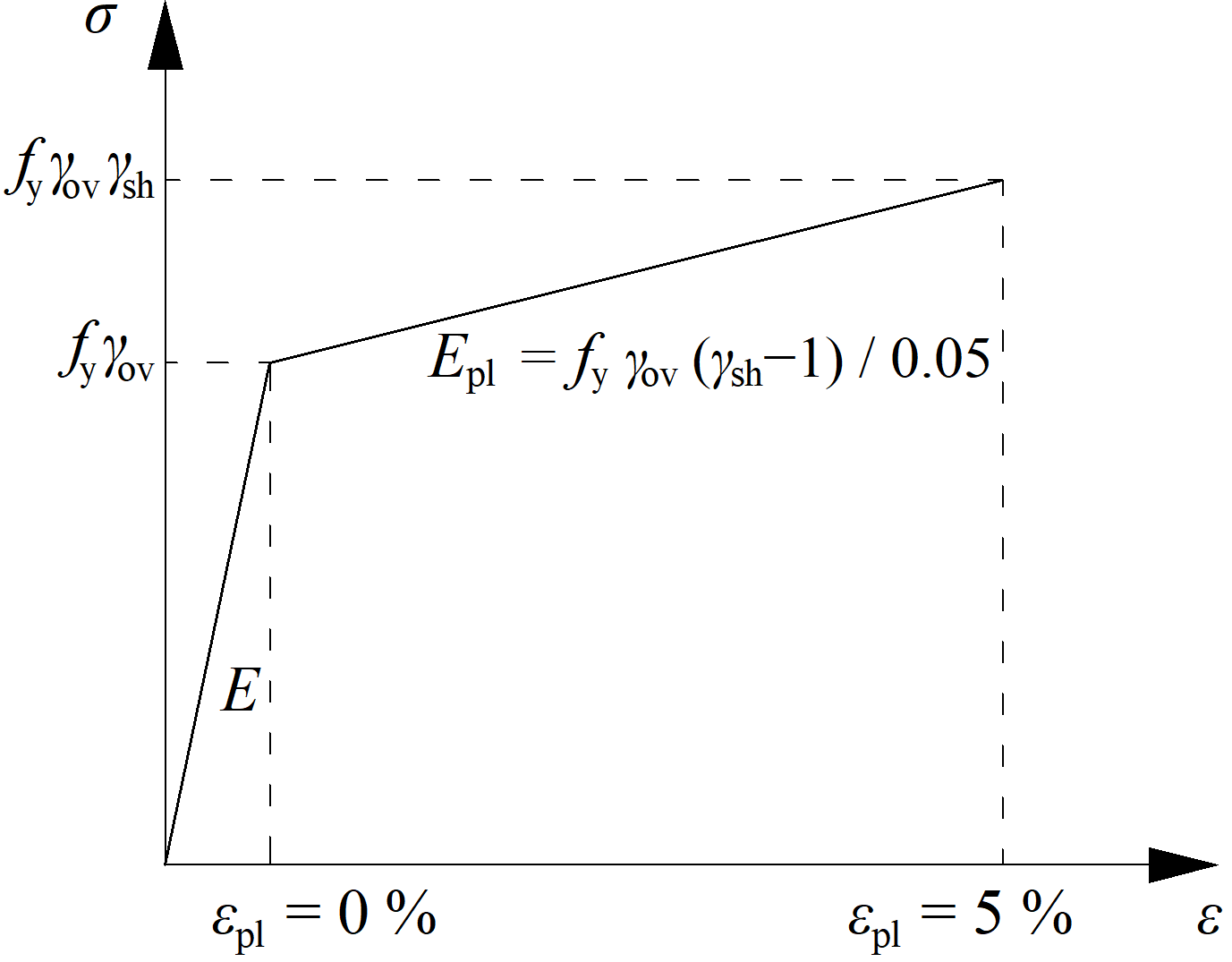

Capacity design according to Indian Standard

Plastic hinge is expected to appear in dissipative item and all non-dissipative items of the joint must be able to safely transfer forces due to the yielding in the dissipative item. The dissipative item is usually a beam in moment resisting frame. The safety factor is not used for dissipative items:

Two factors are assigned to the dissipative item:

- \(\gamma_{ov}\) – overstrength factor – IS 800, Cl. 12; the recommended value is \(\gamma_{ov} = 1.2\); editable in materials

- \(\gamma_{sh}\) – strain-hardening factor; the recommended value is \(\gamma_{sh} = 1.0\); editable in operation

The increased strength of the dissipative item allows for the input of loads that cause the plastic hinge to appear in the dissipative item. In the case of moment resisting frame and beam as the dissipative item, the beam should be loaded by \(M_{y,Ed} = \gamma_{ov} \gamma_{sh} f_y W_{pl,y}\) and corresponding shear force \(V_{z,Ed} = -2 M_{y,Ed} / L_h\), where:

- \(f_y\) – characteristic yield strength

- \(W_{pl,y}\) – plastic section modulus

- \(L_h\) – distance between plastic hinges on the beam

In the case of an asymmetric joint, the beam should be loaded by both sagging and hogging bending moments and their corresponding shear forces.

The plates of dissipative items are excluded from the check.

Classification according to stiffness for Indian standard

Joints are classified according to joint stiffness to:

- Rigid – joints with insignificant change of original angles between members,

- Semirigid – joints which are assumed to have the capacity to furnish a dependable and known degree of flexural restraint,

- Pinned – joints that do not develop bending moments.

Joints are classified according to the EN 1993-1-8 – Cl. 5.2.2.

- Rigid – \( \frac{S_{j,ini} L_b}{E I_b} \ge k_b \)

- Semirigid – \( 0.5 < \frac{S_{j,ini} L_b}{E I_b} < k_b \)

- Pinned – \( \frac{S_{j,ini} L_b}{E I_b} \le 0.5 \)

where:

- Sj,ini – initial stiffness of the joint; the joint stiffness is assumed linear up to the 2/3 of Mj,Rd

- Lb – theoretical length of the analyzed member; set in member properties

- E – Young's modulus of elasticity

- Ib – moment of inertia of the analyzed member

- kb = 8 for frames where the bracing system reduces the horizontal displacement by at least 80 %; kb = 25 for other frames, provided that in every storey Kb/Kc ≥ 0.1. The value of kb = 25 is used unless the user sets "braced system" in Code setup.

- Mj,Rd – joint design moment resistance

- Kb = Ib / Lb

- Kc = Ic / Lc