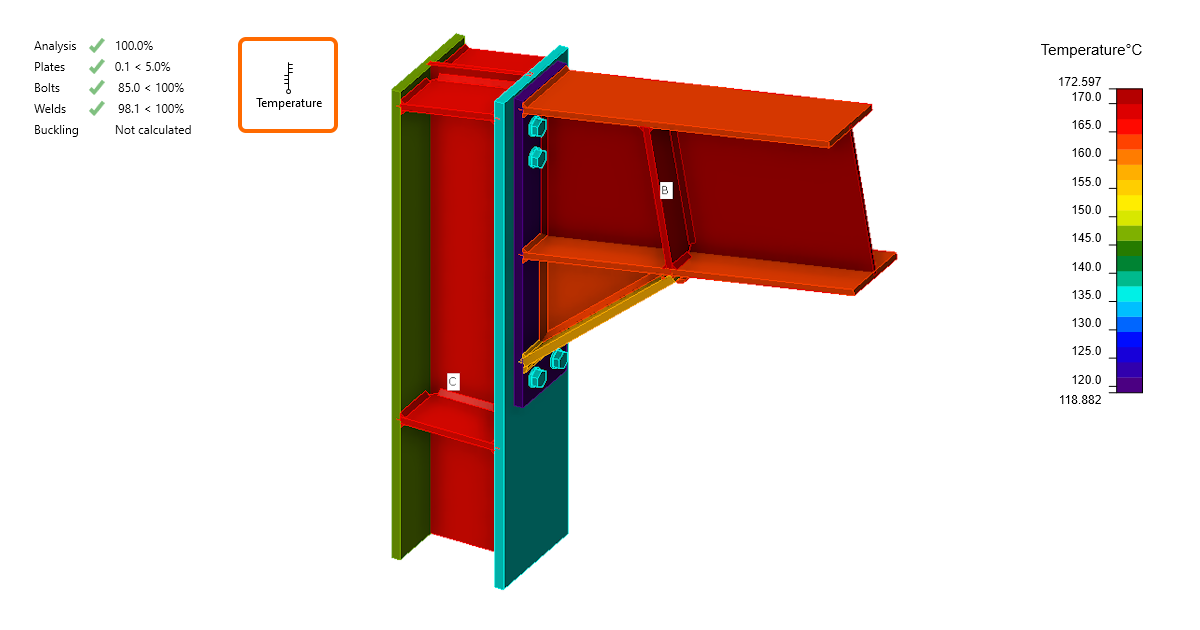

Temperature

In IDEA StatiCa Member, the user sets a temperature for the whole model. All entities in the model have a set temperature.

In IDEA StatiCa Connection, the user may set the temperature for each member or plate separately. The temperature of connecting elements - bolts and welds - is assumed to be according to the hottest connecting plate.

The temperature of members and plates in connections may be determined according to EN 1993-1-2 – Cl. 4.2.5 Steel temperature development and D.3 Temperature of joints in fire. The thermal properties of steel components are taken from EN 1993-1-2:

- Specific heat – Cl. 3.4.1.2

- Thermal conductivity – Cl. 3.4.1.3

Note that thermal elongation is not used in IDEA StatiCa Steel, because it would add forces that are greatly dependent on boundary conditions. Users are encouraged to add forces from the thermal expansion into the load effects themselves.

Material degradation

Material degradation of steel plates is available according to three codes:

- EN 1993-1-2 – Table 3.1

- AISC 360-16 – Table A-4.2.1

- CSA S16-14 – Table K.1

The multilinear material diagram is used for steel plates with six points according to EN 1993-1-2 – Figure 3.1. An example is shown for steel grade S355, material degradation according to EN 1993-1-2 – Table 3.1, and temperature \(\theta = 560^{\circ}\textrm{C}\). The slope of plastic branch past the yield strength \(f_y\) is \(E_{a,\theta}/1000\). The reduction factors for modulus of elasticity \(k_{E,\theta}\), for proportionality limit \(k_{p,\theta}\), and yield strength \(k_{y,\theta}\) are 0.426, 0.252, and 0.594, respectively. The plastic strain is assumed to build up since the proportionality limit.

| Strain | Plastic strain | Stress | |

| \(\varepsilon\) [%] | \(\varepsilon_{pl}\) [%] | \(\sigma\) [MPa] | |

| 0 | 0.00 | 0.00 | 0.0 |

| 1 | 0.10 | 0.00 | 89.5 |

| 2 | 0.25 | 0.15 | 131.4 |

| 3 | 0.50 | 0.40 | 160.5 |

| 4 | 1.00 | 0.90 | 191.3 |

| 5 | 2.00 | 1.90 | 210.9 |

| 6 | 15.00 | 14.90 | 222.5 |

Material degradation of bolts is available according to three codes:

- EN 1993-1-2 – Table D.1

- AISC 360-16 – Table A-4.2.3

- CSA S16-14 – Table K.3

Material degradation of welds is available according to one code:

- EN 1993-1-2 – Table D.1

Only the resistance of bolts and welds is reduced. Their stiffness remains the same as at ambient temperature.

Thermal expansion is neglected and not assumed in any models. If necessary, the effects of thermal expansion should be simulated by added loads.

Checks

Steel plates are checked for plastic strain 5% by default.

In Eurocode, a dedicated partial safety factor for Fire design, \(\gamma_{M,fi}\) is used for checks of bolts and welds. In all other codes, the standard resistance or safety factors are used. The load-deformation curves and checks of bolts and welds are reduced by factors \(k_b\) and \(k_f\) based on set temperature.

Preloaded bolts are assumed to slip and are checked as regular snug-tight bolts.

The temperature of the concrete block and anchors is unknown and corresponding components are not checked in Fire design.

Stiffness

Stiffness analysis is not available for Fire design at the moment. It is recommended to use stiffness analysis for ambient temperature and multiply the stiffness by reduction factor for modulus of elasticity \(k_{E,\theta}\).