Fatigue of steel due to cyclic loading

Some facts about fatigue

- The first article published on fatigue is from 1837

- Fatigue causes irreversible damage; the material cannot recover

- Steel has a theoretical fatigue limit; continuous loading under this limit does not lead to failure due to fatigue

- Tensile stresses mainly cause fatigue, but even compressive loads can be the reason

- A more comprehensive stress range leads to a shorter life of the structure

- Temperature, surface roughness, residual stresses, and other factors influence the fatigue life

Fatigue stages

Generally, there are three stages we distinguish:

- Stage one – Crack initiation

Micro-cracks start to form around stress-concentrating geometric formations such as edges. When the width of a rupture exceeds 10 μm, we can speak about the crack.

- Stage two – An increase of cracks

The crack increase depends on the range of cyclic loading, mean stress, but also on overloads and underloads. Crack growth may even stop if the loads are smaller than a certain threshold.

- Stage three – Crack propagation

Cracks propagation occurs when the micro-cracks and related stresses reach a certain size. When the stress exceeds the value called fracture toughness (a quantitative way of expressing a material's resistance to brittle fracture when a crack is present), the unsustainable fracture will occur.

How to prevent fatigue

Fatigue can be lessened or entirely avoided with proper engineering considerations. For steel structures, there are two main ways to prevent fatigue failures.

1. keep stress below the threshold of fatigue limit (infinite lifetime concept)

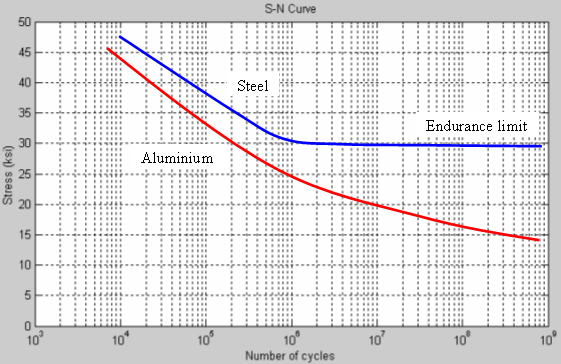

Fatigue life Nf is the number of stress cycles of a specified character that a structure sustains before failure occurs. For steel, there is a theoretical value for stress amplitude below which the material will not fail for any number of cycles. This value is called a fatigue limit or endurance limit.

By AndrewDressel at English Wikipedia, CC BY-SA 3.0, https://commons.wikimedia.org/w/index.php?curid=6319461

2. running a software fatigue analysis on structure designs

The software analysis could reveal areas where fatigue is an issue. It can help to redesign the structure, for example, focus the stresses to preferable places on the structure, change dimensions and positions of holes, etc.

Our solution

The first step of this extensive task has been done in the IDEA StatiCa V21. Check this article, where the analysis according to EN 1993-1-9 is described.

The analysis can be found next to the other types below the upper ribbon.

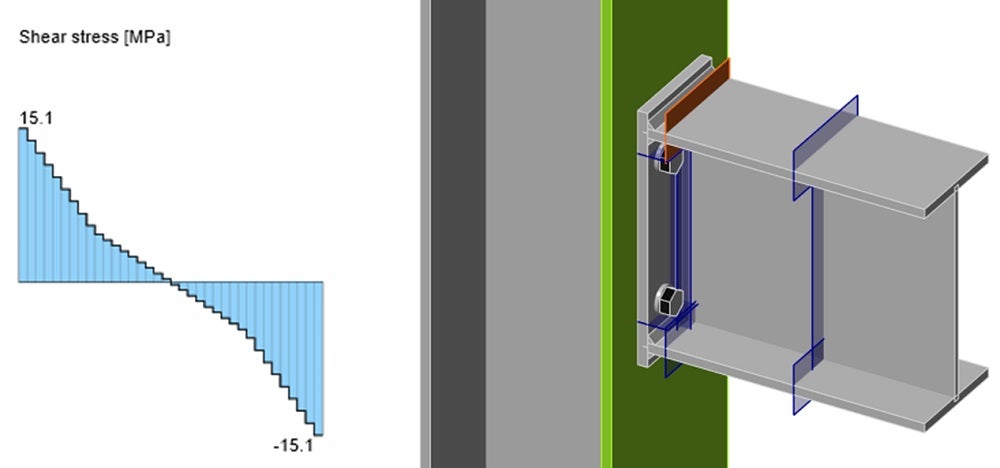

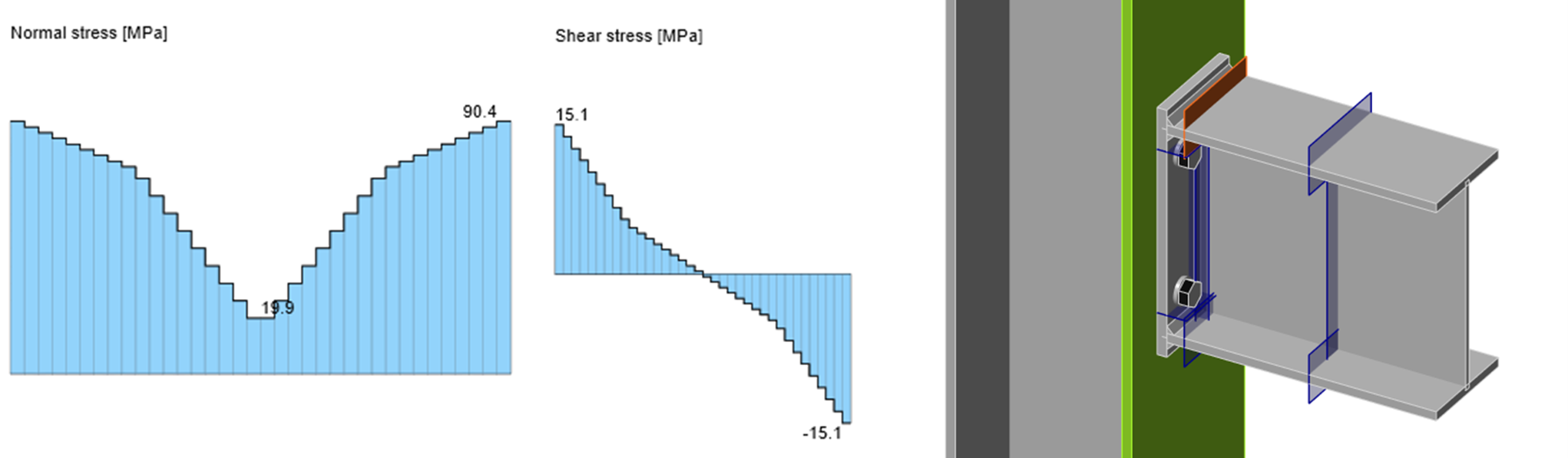

Fatigue analysis type serves to determine the normal and shear stress range between two load cases. The stresses correspond to nominal stresses and must be further evaluated using code design methods. It is assumed to be used for the design of high-cycle fatigue details, where no yielding is expected.

The fatigue analysis type does not provide any final resistance or number of cycles the detail can take. It just provides inputs for further calculations according to the codes.

The nominal stress can be calculated for:

- Bolts – in tension and shear

- Welds – automatically generated in a plate section next to the weld

- Plates – in user-defined sections

The nominal stress is determined by subtracting the stresses of the reference load case from another load case.

To take a closer look at this type of analysis, please visit our Support Center:

Theoretical Background: Fatigue analysis type

Fatigue analysis – Butt welds of I section

This type of analysis is available for our users in Enhanced edition.