Solving the steel-to-concrete connection challenge

Currently, it is a common practice to use a number of different tools to complete the design of steel-to-concrete connections, including hand calculations, with each addressing a different element of the connection – anchor, baseplate, weld, stiffener – with the engineer following several technical guidelines.

White Paper “Designing Steel-to-concrete Connections” published by Hilti and the New Civil Engineer magazine looks at the creation of PROFIS Engineering software from Hilti, which has been developed to address these very issues.

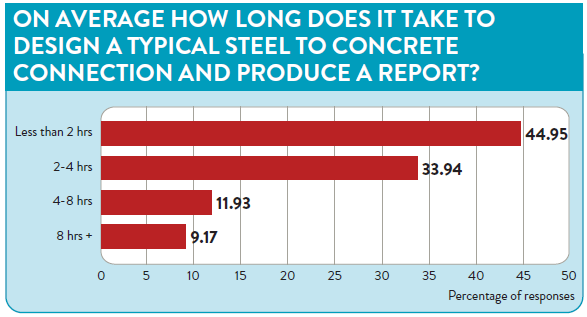

Based on Hilti’s research published in the article which explored the experience of more than 100 practicing civil engineers, 79% claim to spend up to 4 hours on designing a typical steel-to-concrete connection and produce a report.

According to the engineering experience, with the right selection of software tools, the design time taken for one individual connection is slashed by an average of 50% (give or take depending on the complexity of the calculation). And there are potential additional savings in material and operative time as well as health and safety benefits if you are drilling fewer holes, the benefits for everyone in the supply chain are clear.

As we have already mentioned, Hilti’s PROFIS Engineering software is powered by IDEA StatiCa’s unique CBFEM (Component-based Finite Element Method) solver.

Lubomir Šabatka, CEO of IDEA StatiCa, is pleased with the collaboration: “We believe that the new component-based finite element method is the right approach to break the limits of anchoring/footing topologies while keeping safety first. We put the CBFEM into the core of our product, Idea StatiCa Connection, and Hilti has integrated it in its new PROFIS Engineering Suite.”

Development of the new PROFIS Engineering software takes into consideration the challenges, explores the research that led to the solution, and demonstrates exactly how the software ensures all four key connection components can be designed in compliance with code requirements in a fraction of the time it currently takes to undertake the task.

Are you interested in more information about how CBFEM powers PROFIS Engineering?

Check our recording of the joint webinar on steel-to-concrete joints or watch the presentation from Autodesk University 2019, where challenges and limitations in the steel-to-concrete design process were addressed.