Steel frame design in a thermally demanding production facility

About the Project

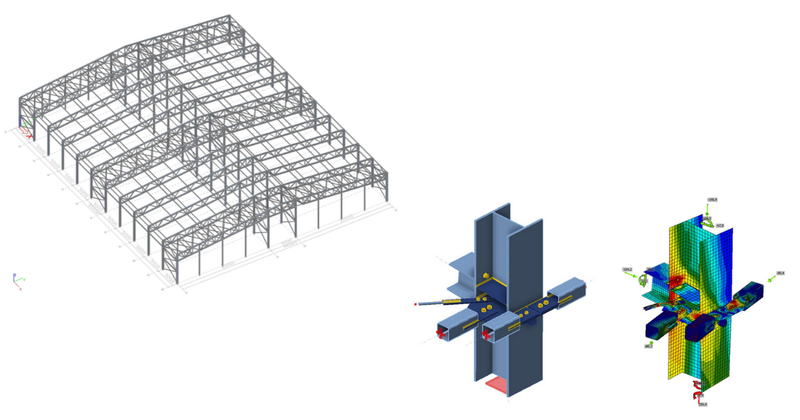

The facility comprises a steel hall with a double-pitched roof sloping at 6°, enclosing a rectangular floor plan of 56.36 x 47.50 meters. Standing 9.48 meters tall at the ridge, the hall is framed by 12 steel portals spaced at 5-meter intervals. Each frame features a four-column configuration, HEA300 profiles on the edges and HEA260 profiles at the interior axes, supporting truss beams with HEA200 top and bottom chords and SHS diagonals.

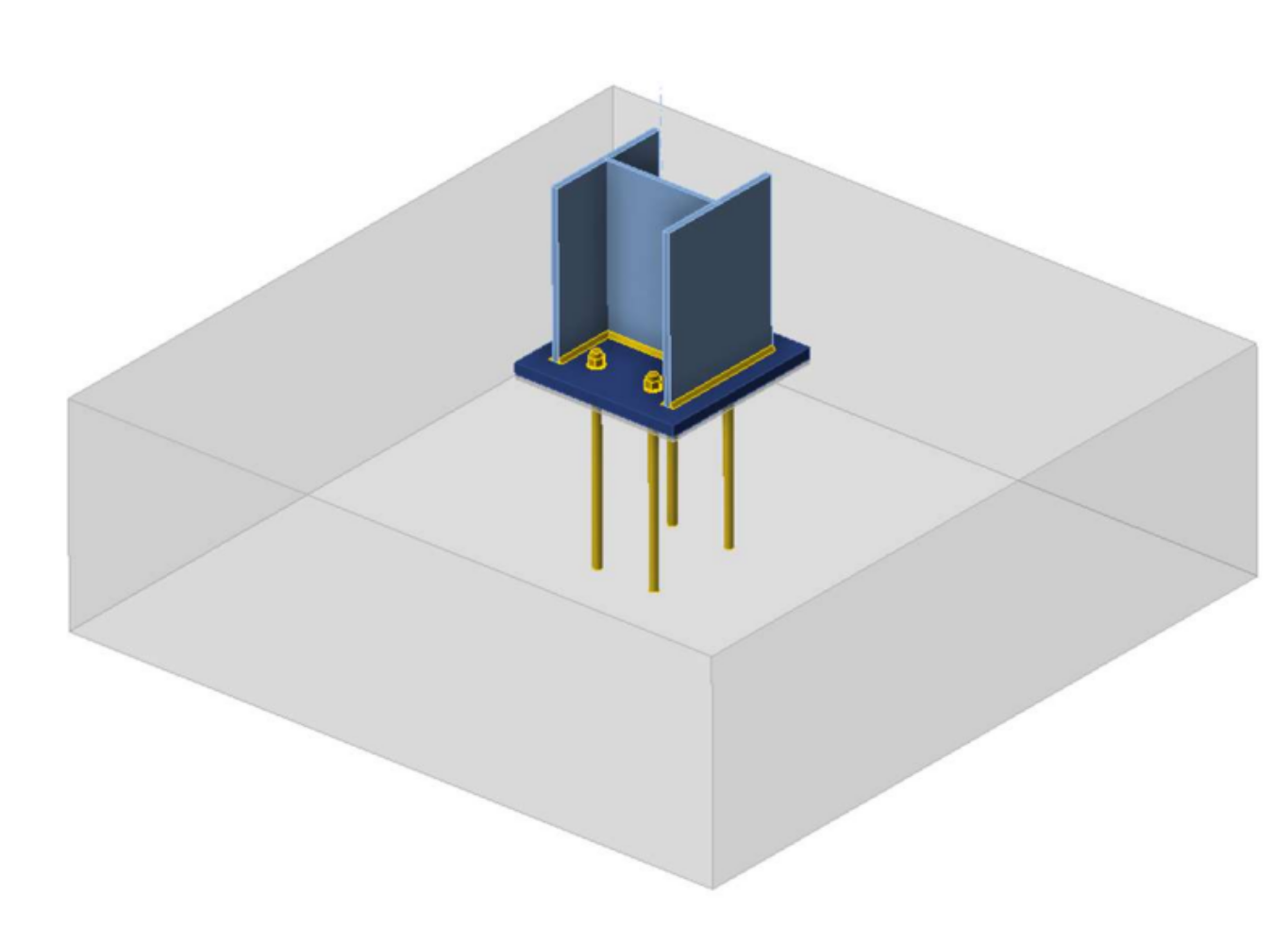

Lateral stability is ensured through a combination of horizontal and vertical bracing systems in the longitudinal direction, while frame stiffness alone provides transverse stability. The structural grid accommodates three key vertical bracing zones: one centrally located and two adjacent to the gable ends. Foundations consist of RC pad footings linked by strap beams, with pinned connections between the steel columns and their foundations via pre-installed anchors. Purlins and side rails will be cold-formed Z and C sections respectively, completing the roof and façade systems.

\[ \textsf{\textit{\footnotesize{3D structural model in SCIA Engineer}}}\]

Croatia

Engineering Challenges

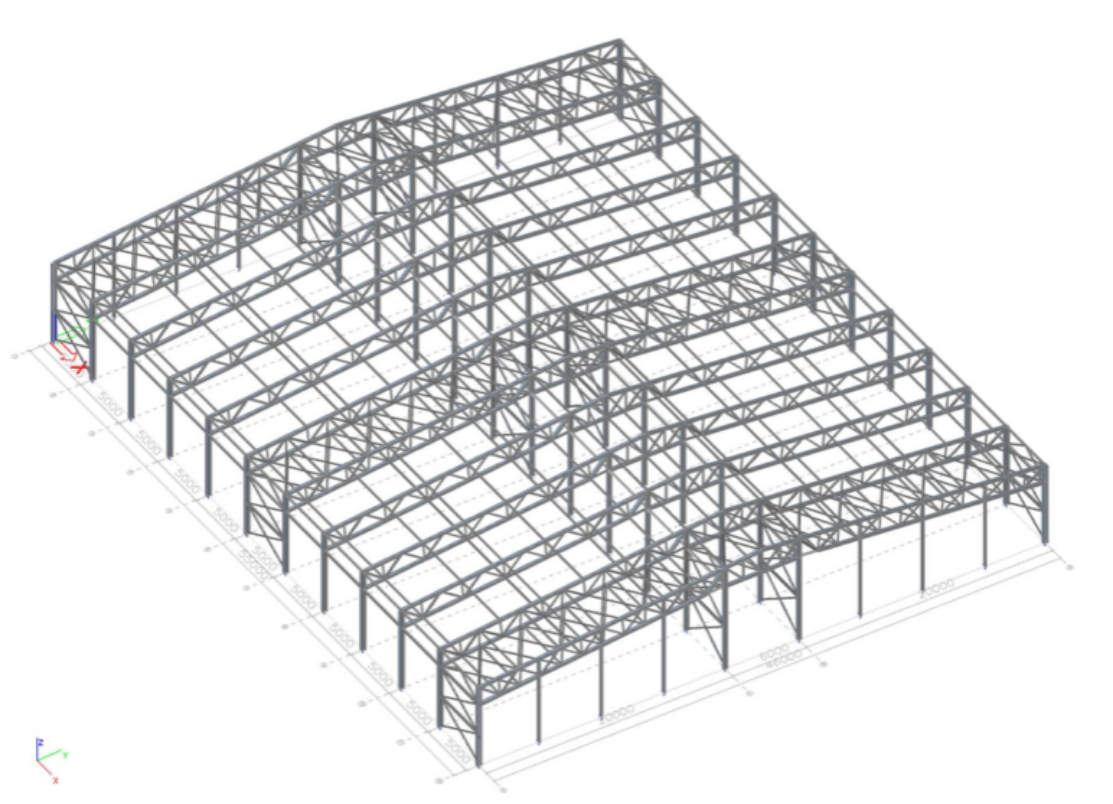

The production process demanded high indoor humidity levels, compelling the designer to protect the steelwork from internal moisture. Thermal insulation was therefore positioned on the interior face of the columns and trusses, a design decision that left large portions of the steel frame exposed to severe outdoor conditions. According to Eurocode 1 (EC1), these include both extreme summer heat and harsh winter cold, making thermal actions a major structural concern.

\[ \textsf{\textit{\footnotesize{Position of thermal insulation panels}}}\]

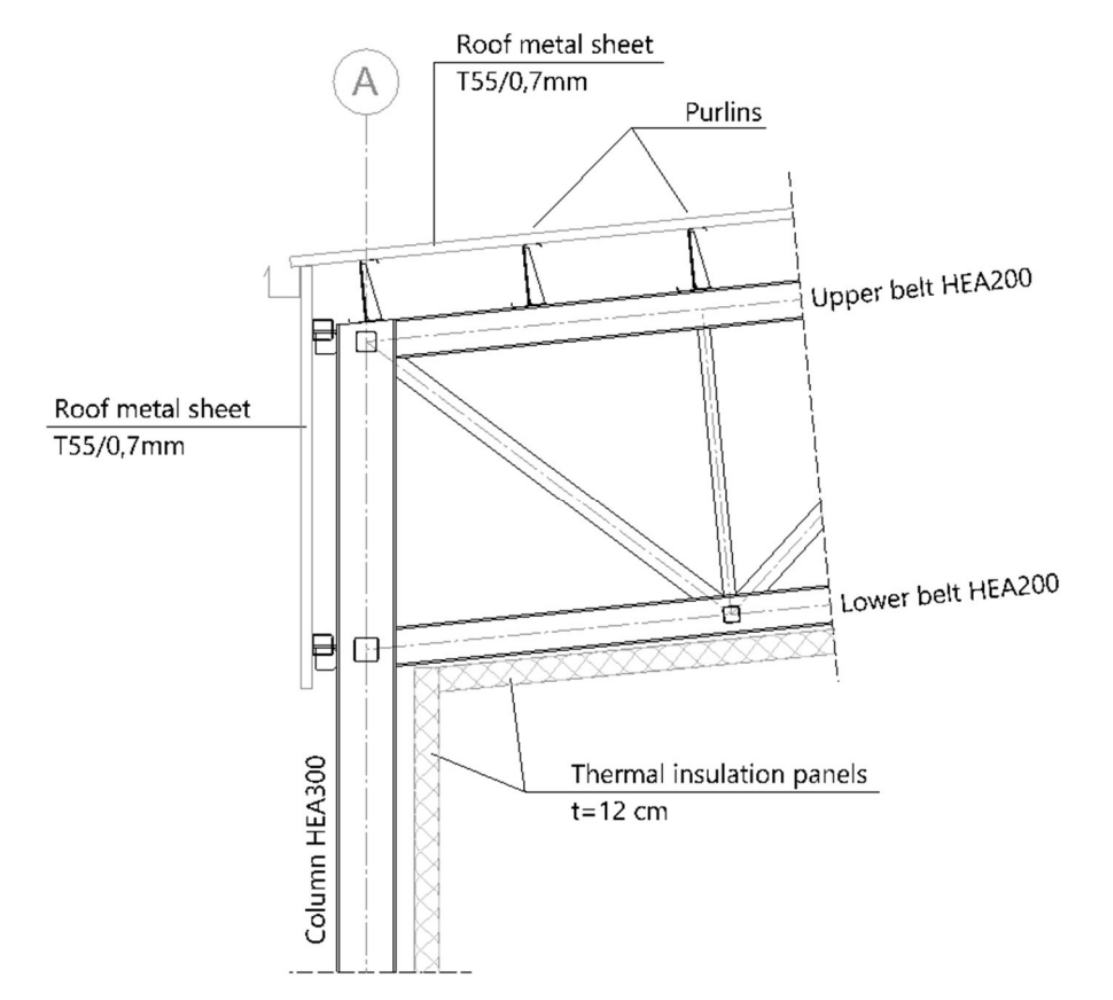

With most steel members experiencing unshielded thermal fluctuations, significant normal forces developed within longitudinal elements and vertical bracing. The UG1 beams, supporting façade sheet metal, were particularly affected. These beams were not aligned with the horizontal members of the vertical bracing system (HUS2), introducing pronounced eccentricities and complex load paths that had to be addressed at the connection level.

Croatia

Solutions and Results

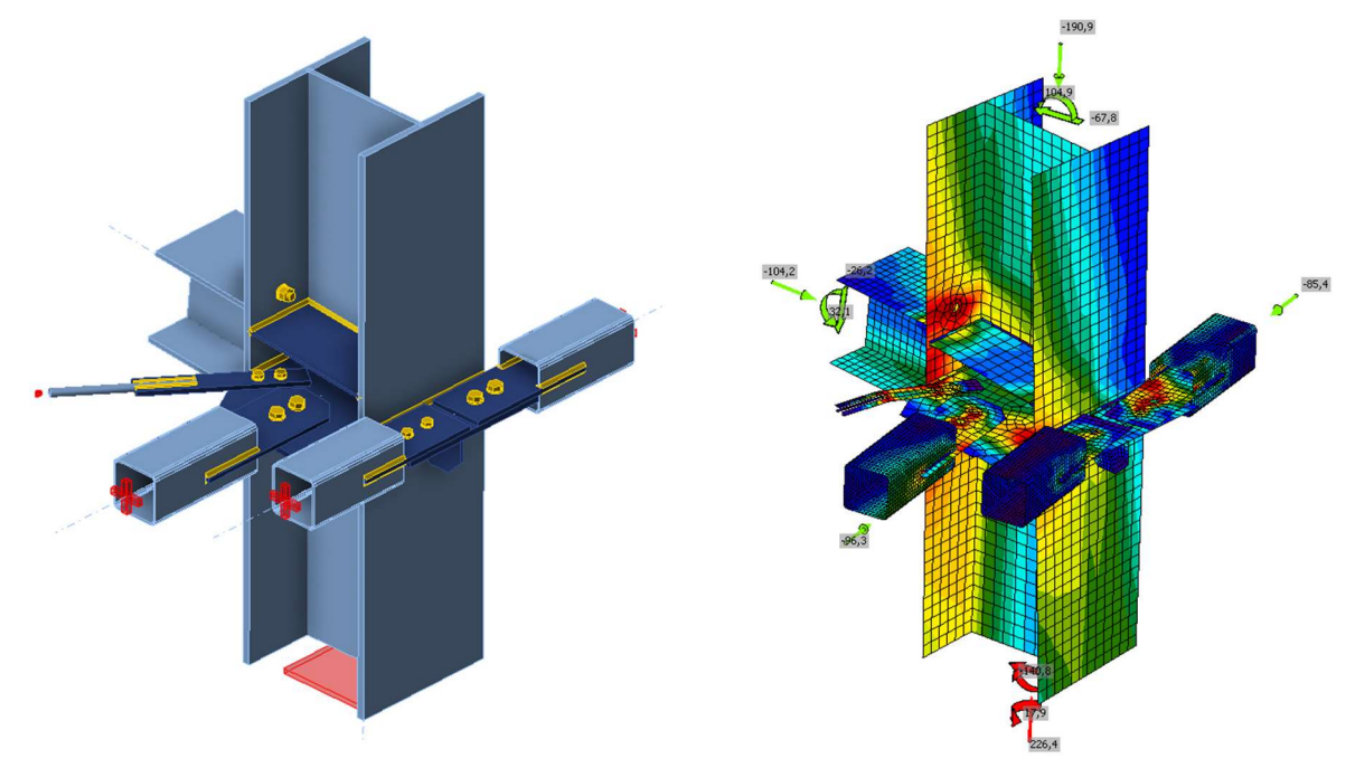

A global structural model was developed in SCIA Engineer 20.0, encompassing all primary steel components except the secondary purlins and side rails. For joint design, IDEA StatiCa Connection was employed. Its quick setup and clear visualization of joint behavior under load made it an indispensable tool, especially for connections subjected to longitudinal eccentric forces.

\[ \textsf{\textit{\footnotesize{Steel joint with significant eccentricity of longitudinal forces in IDEA StatiCa Connection }}}\]

By lusing IDEA StatiCa, the engineering team could explore deformation patterns and stiffness characteristics of connections in near real-time. This capability significantly enhanced the global model's accuracy, particularly in predicting displacements and internal force redistribution.

Croatia

Another major advantage was the efficient design of steel baseplates and pre-installed anchors to EN 1992-4. The software’s dedicated anchorage module replaced what would traditionally be a laborious, manual process with a fast, code-compliant, and traceable solution, drastically improving the overall workflow.

\[ \textsf{\textit{\footnotesize{Connection of steel column and RC pad foundation in IDEA StatiCa Connection}}}\]

Croatia

About UOIG Nikola Patrk

UOIG Nikola Patrk is a small company founded in 2018 (currently operating as one-man-team) based in Zadar, Croatia. It specialises in design of reinforced concrete, masonry, steel and timber structures. Nikola Patrk is structural designer with more than 10 years of experience as associate designer and main designer on projects of various scale and purpose.