Hollow structural section (HSS) connections – what makes them so special?

Steel is a great material for creating bearing structures. No doubt about that. Even better if the author of the design manages to keep it visible. I remember a simple statement of my university professor and a respected engineer: 'A good structure is supposed to be true'. Whatever it means, in my ears it sounds like the bearing principle should be clear and not only to an expert but to every observer.

And it can be a tough task for an architect or a designer. If they succeed in the exposure of such construction, the details are crucial. No surprise, that the public spaces want to look different than an industrial area.

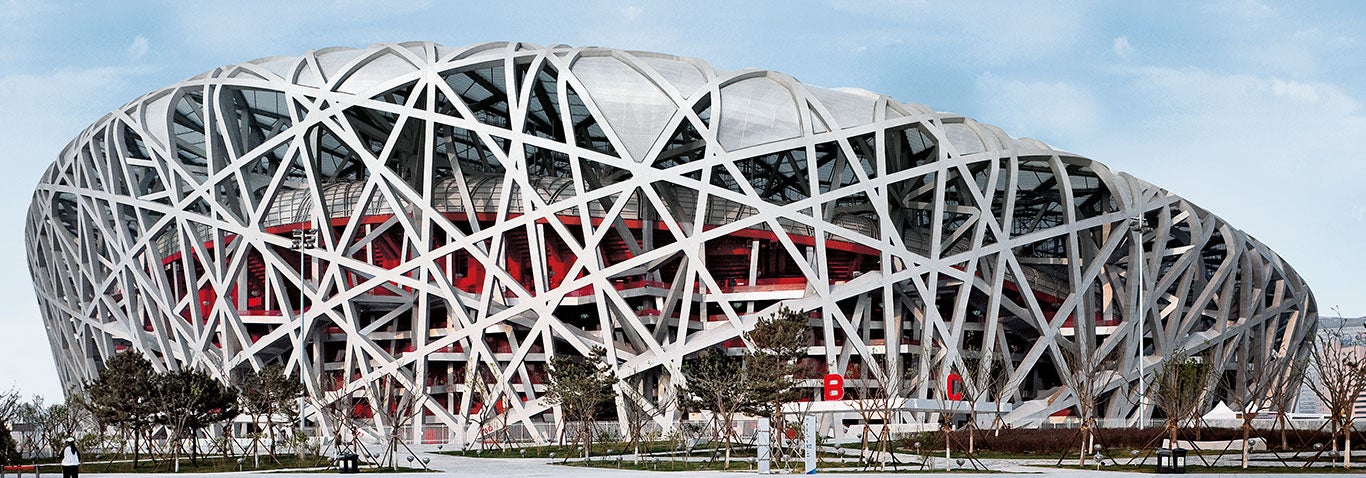

Birds nest - Beijing National Stadium steel structure is a nice example with the use of HSS members in an iconic architectural masterpiece. The applied cross-section type completely influenced the overall impression of the structure volume.

When dealing with the exposed bearing structure, hollow structural sections (HSS) are desired more than open sections. The fewer connections visible the better. If the connection is needed then the welded one is desired more than the bolted one. And if the bolted connection is inevitable then the fewer bolts the better. And so on...

What is the wanted goal for the author of a clean simple-looking structure, can be really unwanted for the structural engineer and even less appreciated by the manufacturer and erector.

But whatever the situation is right now, the well-trained, open-minded, and passionate structural engineer isn't here to find the way to avoid the tough situations but to solve them.

Let's take a closer look at what is behind the whole area of HSS structures. Which sections are HSS? All the types that are not open (that was quite easy, right?).

Standard HSS shapes

What tube arsenal is available for a structural engineer's design?

- RHS - rectangular hollow section

- SHS - square hollow sections

- CHS - circular hollow sections

- Exceptionally even elliptical

Use of HSS members

We can use HSS members everywhere, but the most common applications are:

- Columns

- Braces

- Trusses

- Curved beams

How are the tubes made

It's quite a typical question - how are all the tubes actually made? The tubular members are manufactured in two different ways:

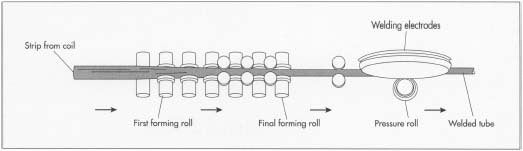

- Cold-formed / rolled + welded

(the tubes are created by bending sheet metal into the required shape and then welded into the closed section)

- Continuous milling

(the basic material is heated to white-hot and molded into a cylinder and then a bullet-shaped piercer point is pushed through)

Advantages of HSS members

- Aesthetics - clearer look than the open sections

- Economical

- weigh less, so in general, they should be cheaper per meter

- less surface area with lower finishing costs - Great static parameters

- torsional resistance up to 200 times greater than the open sections (I, C, L, and T shapes)

- also higher compression capacity for the same unbraced length - Usable as a jacket for the concrete column (for increased axial capacity)

- Wide range of standard sizes

Speaking of a wide range of standard sizes - what are the maximum standard sizes available these days? An answer could be found in the new world's largest continuous ERW mill just recently built in Chicago as the pride of US steel pipe and tube manufacturer Zekelman Industries. Until now, the maximum HSS size provided in the US was 16"x16"x5/8" (406x406x16 mm) In this new mill, they increased the maximum tube sizes up to: SHS - 22"x1" (559x25 mm) RHS - 34"x10"x1" (864x254x25 mm) CHS - 28"x1" (711x25 mm) |

Disadvantages of HSS members

- Not ideal as flexural (bending moment-resisting) members due to more steel usage compared to an equivalent I-shape section

- Bolted connections are difficult to install since the section is closed

How to deal with the hollow section connections?

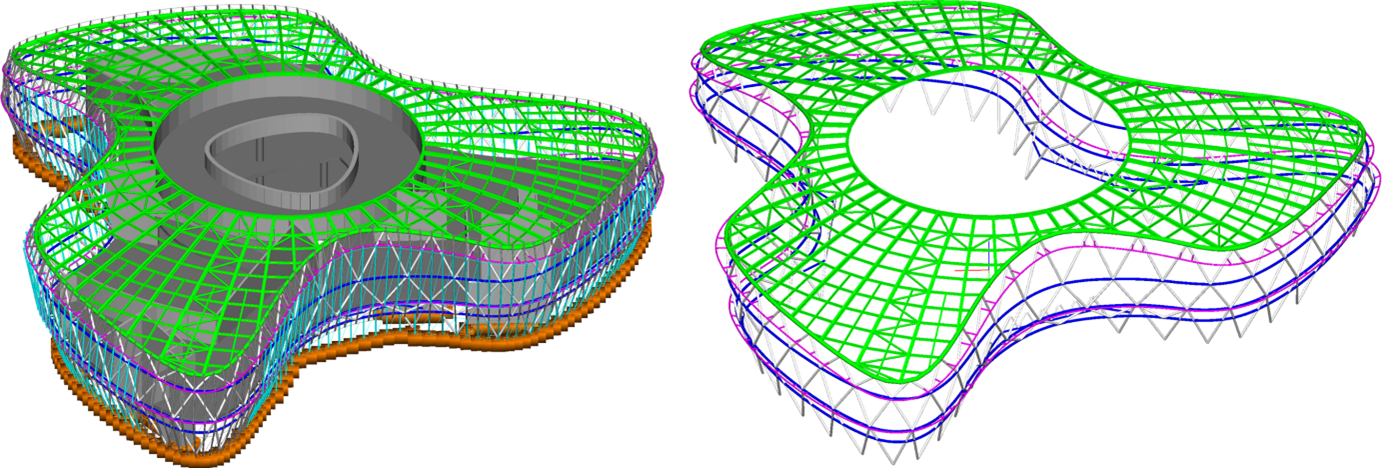

A masterpiece in using hollow sections for the roof structure, even with relation to the BIM interconnection between several design tools, is HUNGEXPO project provided by KÉSZ Romania. It's a success story where demanding architectural concept, engineering skills, and modern design tools met accordingly.

Design workflow with software links:

Rhinoceros/Grasshopper -> Pangolin plugin -> ConSteel -> IDEA StatiCa Connection -> Tekla Structures

Of course, such structures are not a daily bread for the majority of structural engineers. More often some standard connections prepared in accordance with the design manuals are on the table.

Design codes and manuals dealing with HSS connection design

If you would like to get familiar with some regional guidelines, there are the main ones shortlisted:

- AISC 360 - Chapter K

- AISC Design Guide #24: Hollow Structural Section Connections

- CISC Design Guide (Hollow Structural Section - Connections and Trusses 1997)

- EN 1993-1-8 - Chapter 7

- CIDECT Design Guides (International Committee for the Development and Study of Tubular Structures)

- HSS Design manual, Volume 3: CONNECTIONS AT HSS MEMBERS (Steel Tube Institute)

- etc.

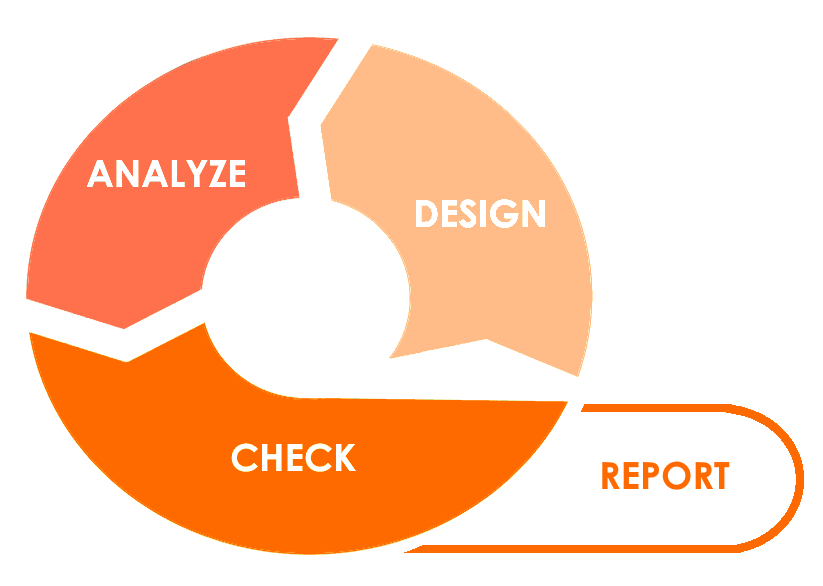

It doesn't really matter whether you're following some design manual, company connection set or you create a new connection type from the scratch. You always need to go through the same basic steps:

And in case the check is not OK in the first round, you need to iterate until you are there.

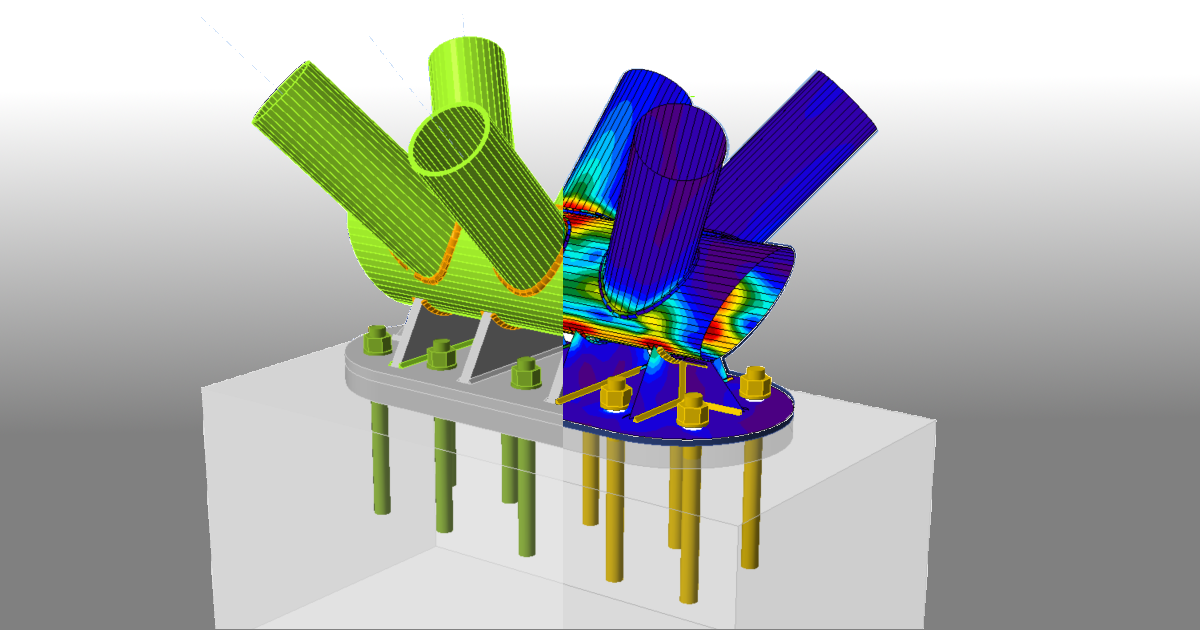

Advantages of HSS connection solved in IDEA StatiCa

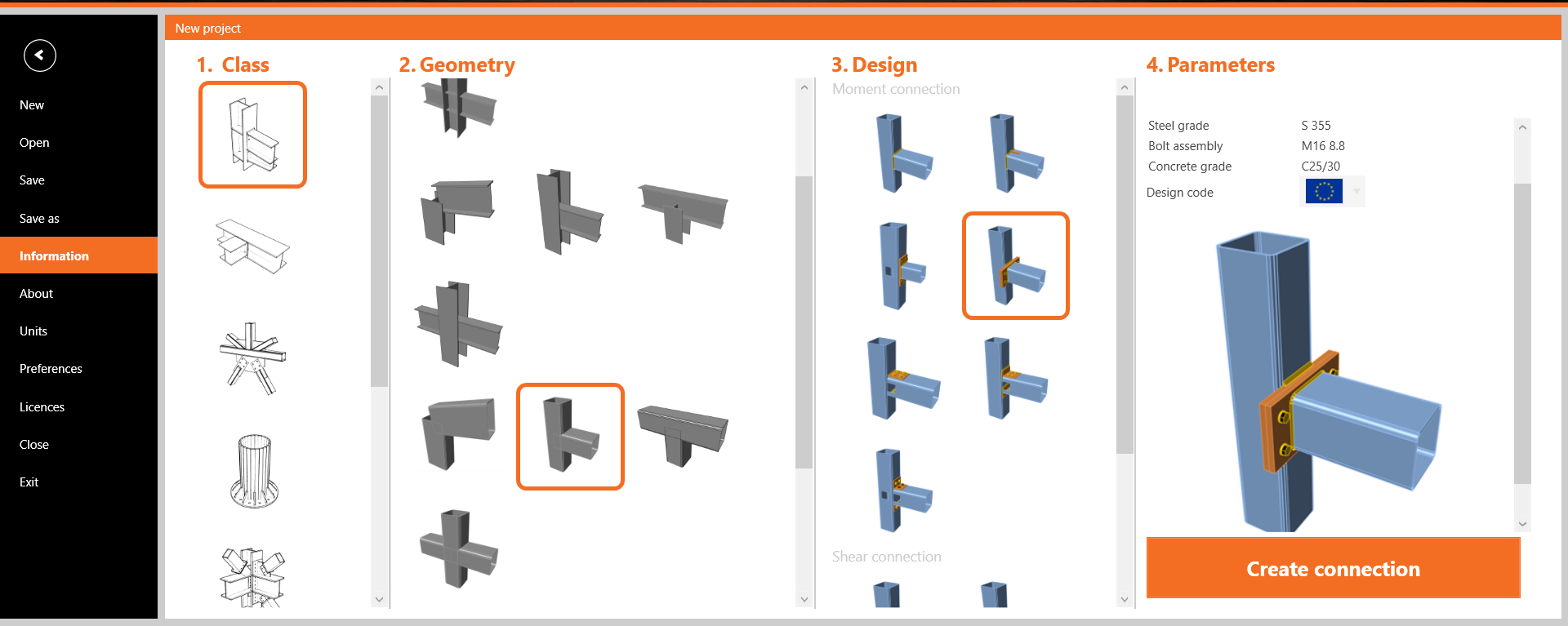

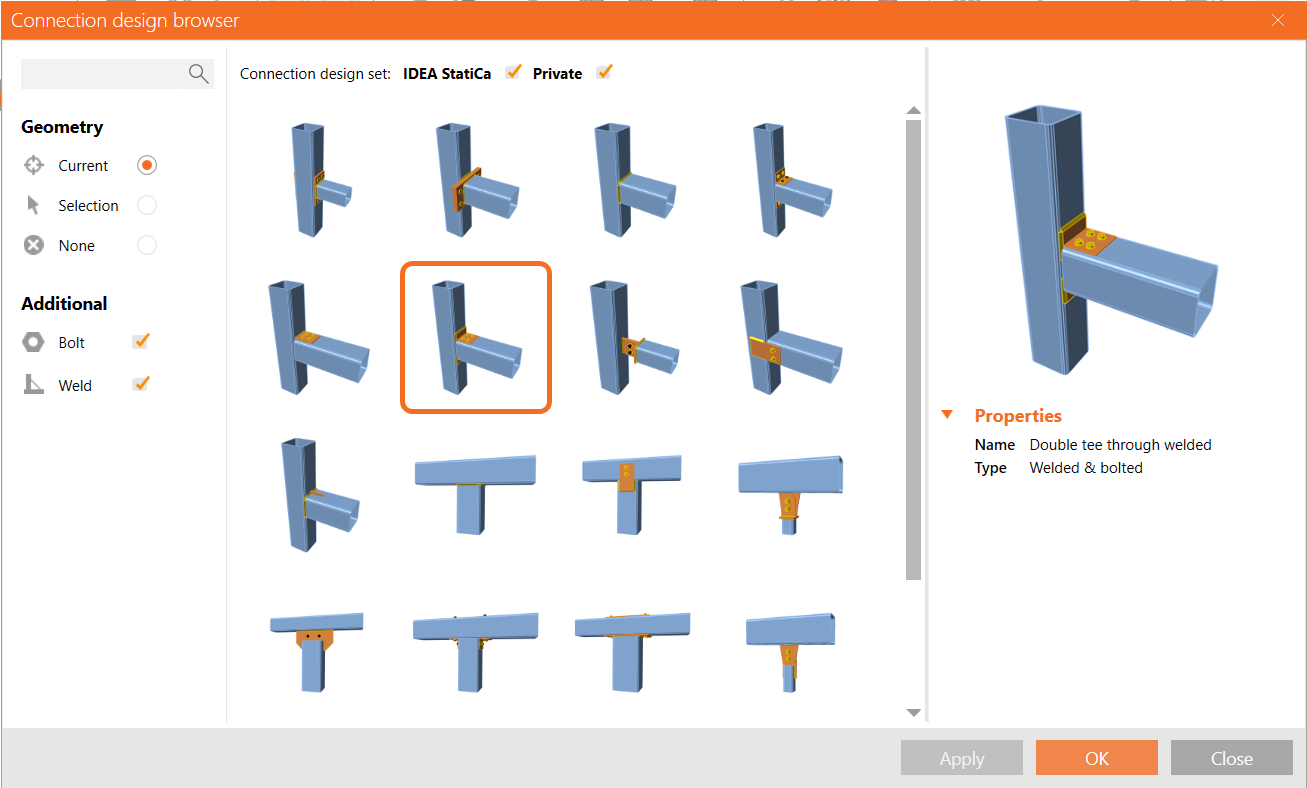

What can save a lot of time spent by straddling at the beginning, is the set of initial design templates embedded in the IDEA StatiCa Connection app. There are dozens of prepared templates in the Starting Wizard, ready for the Engineer's or Detailer's final touch.

In case, the first idea won't become the best solution, by simple right-click with the 'Connect to' feature, other dozens of designs pop up in the Connection browser window. Here, not only the default sets but also the user's designs are stored and the suitable ones for the specific geometry are displayed in seconds.

If you are interested and want to try some completely finished sample projects, you can easily download any of them on our IDEA StatiCa Support Centre.

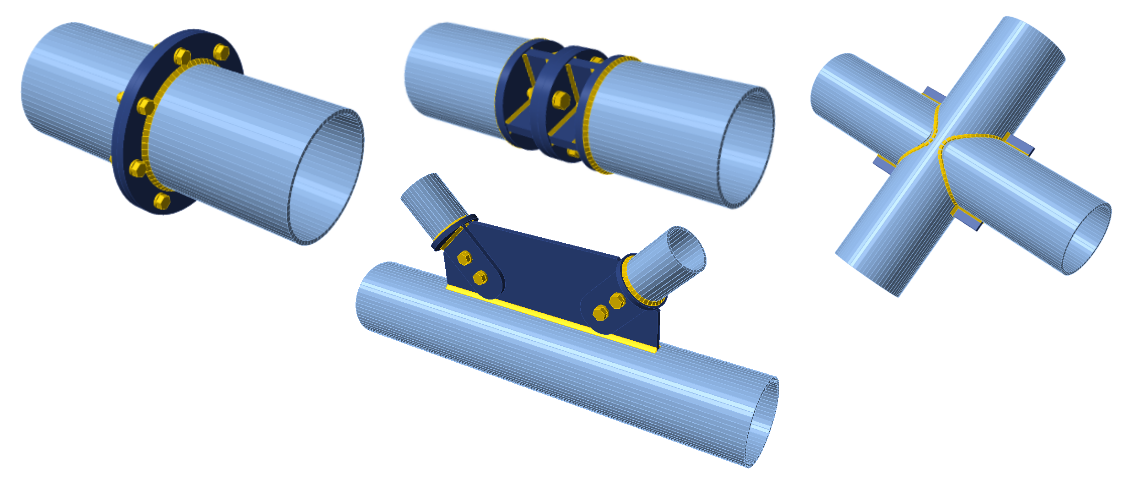

The options of the bolted connections for the hollow sections:

As a first option for how to make an HSS connection mountable, you can think about some simple solutions. These simple answers can also bring some obstacles.

| Simple solution | Possible obstacle |

| 1) Use of through bolts | These can deform the hollow section shape while tightening |

| 2) Cut the thread in the wall of the HSS member | Cut threads don't have to be tension resistant enough |

| 3) Weld a nut from the inner side of the HSS member | Welded nuts are additional costs on welding and are not always feasible in narrow spaces |

Well, fortunately, we're not the first ones to invent this wheel. There are a few other options on the market ready to help with bolt connecting directly to the hollow sections.

a) Blind bolts

b) Hollo bolts

c) SHURIKEN - structural nut keeper

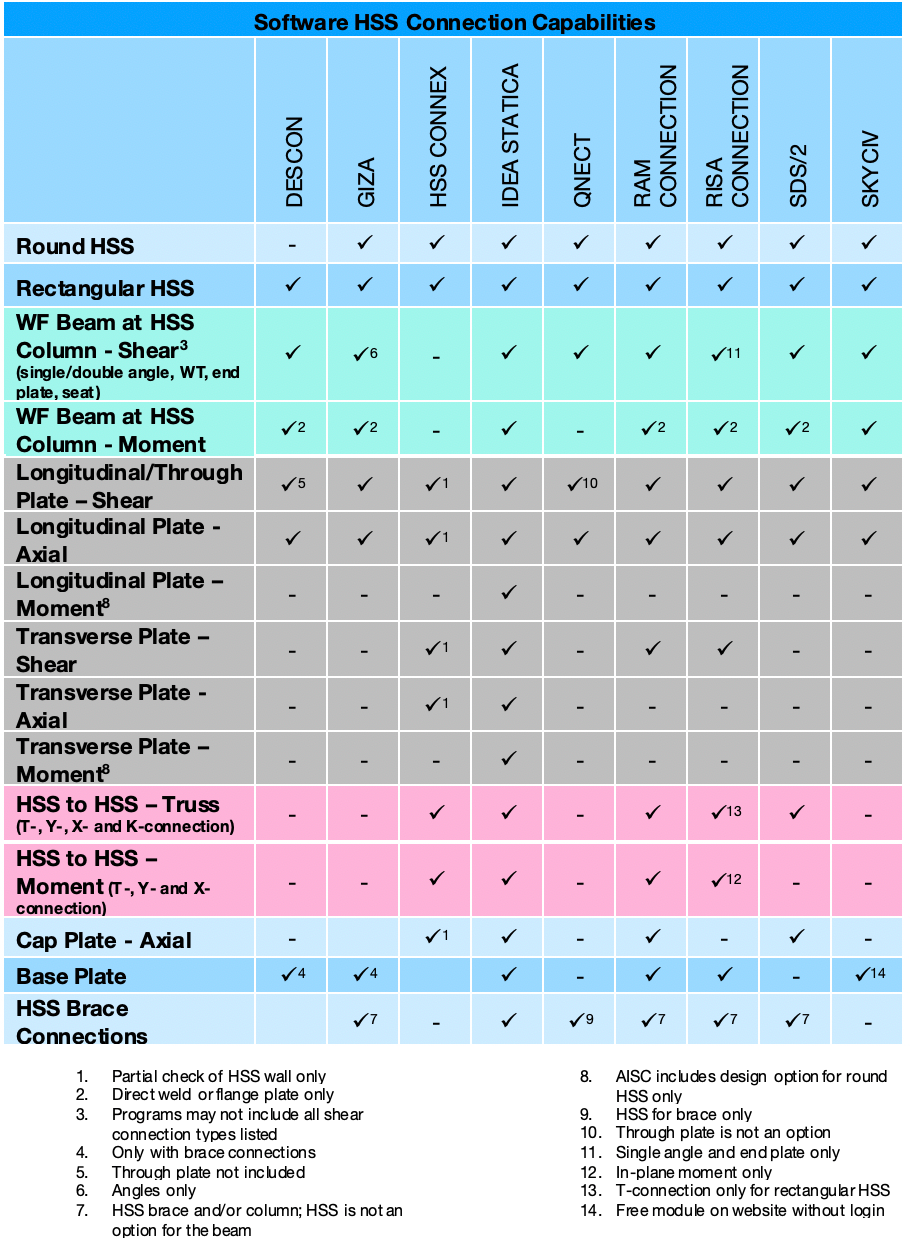

What tools can be used for HSS connection design

There is a whole bunch of connection design applications on the market. A very nice overview of capabilities was elaborated by the Steel Tube Institute in its recent article dedicated to today's software tools for HSS connections. IDEA StatiCa Connection app placed very well as the only tool based on the FEA method and therefore capable of modeling any connection topology. From this overview, IDEA StatiCa also came as the only tool fulfilling all the evaluated parameters.

What kind of obstacles can appear during the design

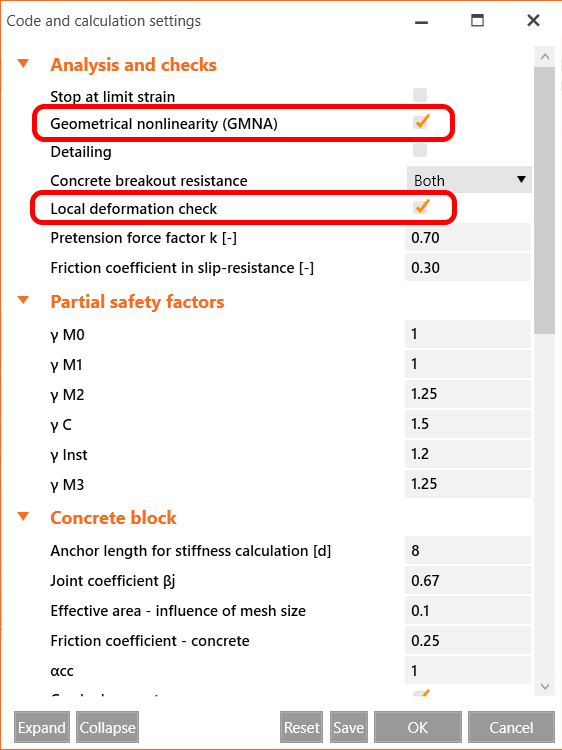

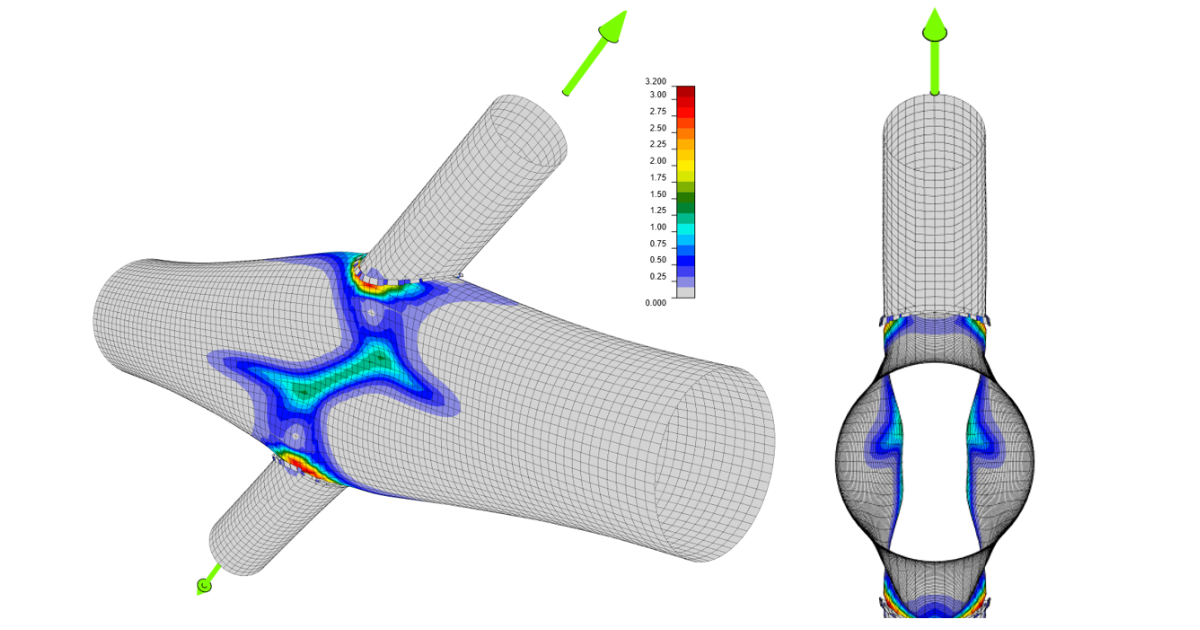

Quite often overlooked mistakes or imperfections in design could be caused by missing checks for hollow member local buckling failure. For users of IDEA StatiCa Connection, this is an easy task since there is a simple check box embedded in the setup dialog. With this feature turned on, the local deformation check is contained by the connection analysis.

The specialties related to HSS connections were also specified in our Theoretical background dedicated to joints of hollow section cross-section members.

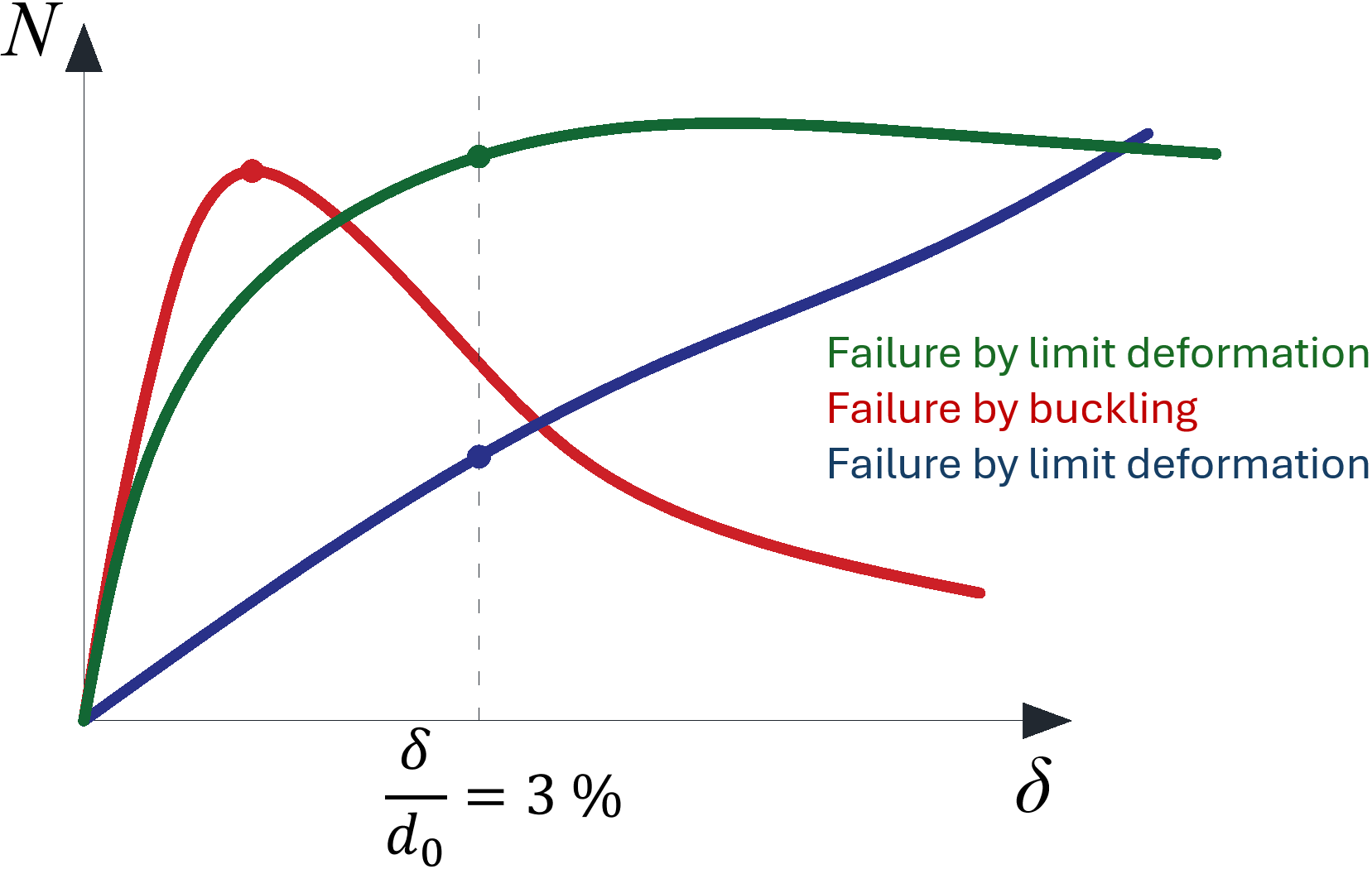

Besides the local deformation issue, we can find there an important difference between failure modes of thin-walled and standard hollow section members:

(red line - thin-walled members, green line - standard members in compression, blue line - standard members in tension)

Other resources to hollow section connections

The HSS connection design and analysis couldn't be precise enough without the GMNA (geometrically and materially nonlinear analysis). What was it developed for and when to use it? All the necessary information are summed up in one of the previous blog posts dedicated to this topic.

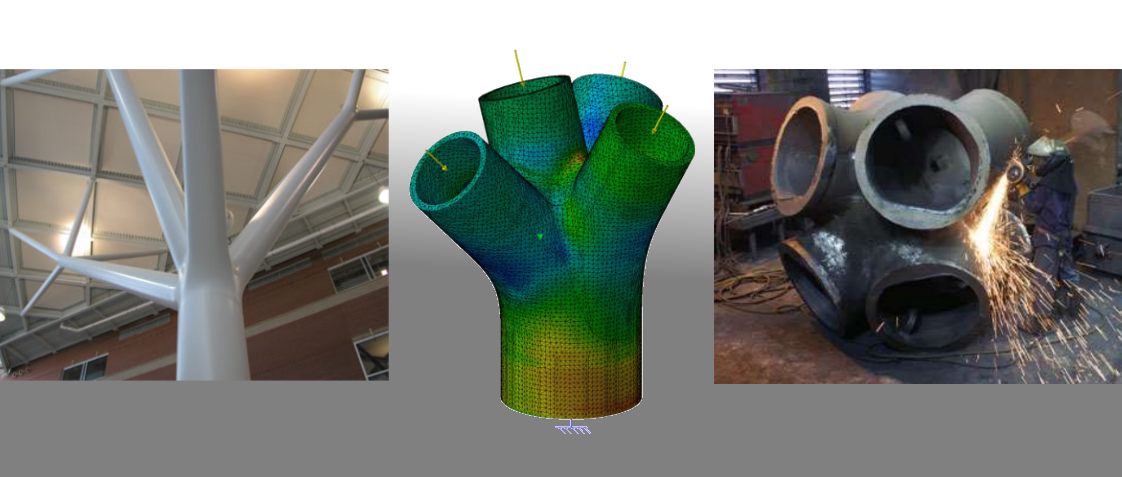

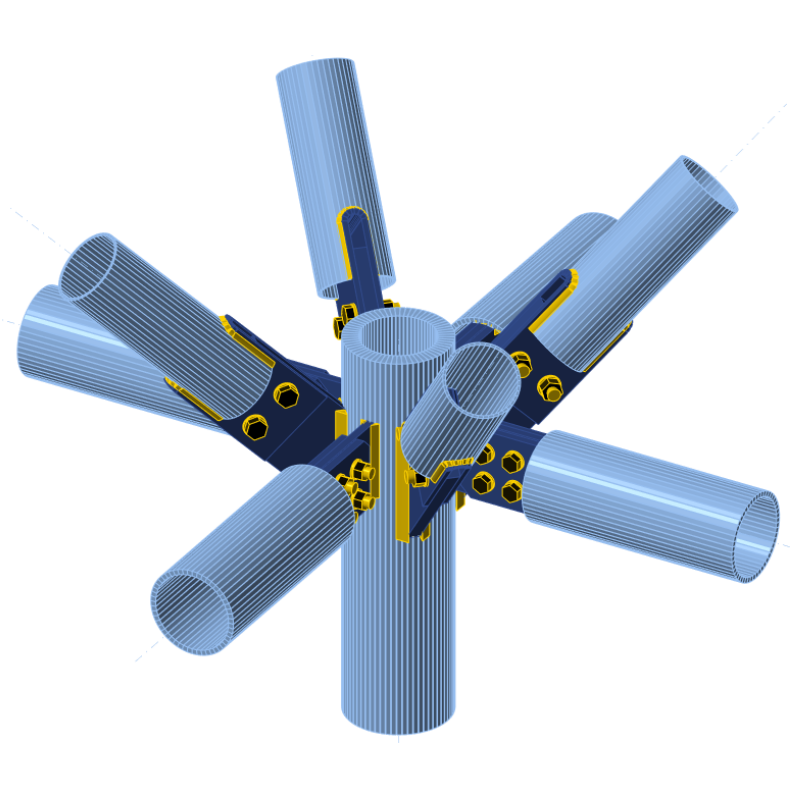

If you're looking for some inspiration for circular hollow sections, you could be interested in these webinars dedicated to CHS bracing member connection and to 3D multimember connection combining CHS and SHS profiles.

Ultimate message

The challenge for today's engineers was nicely recognized by Jason McCool in his interview for Steel Tube Institute. He's stated that a good approach for dealing with the complexity of today's structural connection requirements is out of box thinking based, or at least supported by looking at approved solutions from different regions.

In our global world with no informational borders, it can be quite enriching to sneak into the kitchens of Engineers from different parts of the world. Although there is no perfect connection for every structure, we can always improve our designs by sharing our best practices.

image and data resources: http://architectuul.com, http://madehow.com, https://steeltubeinstitute.org/

Try IDEA StatiCa for free

Interested in the abilities of IDEA StatiCa in designing HSS connections? There is no better time to give a try to IDEA statiCa than now!

Start your trial today and enjoy 14-days of full access and services free of charge.