When we add a member to the model, its length is calculated automatically by the software based on the height of the cross-section. The calculation algorithm is part of the CBFEM method and is calibrated after numerical and experimental results.

The calculated member length ensures that proper stress diffusion will take place in accordance with the CBFEM methodology.

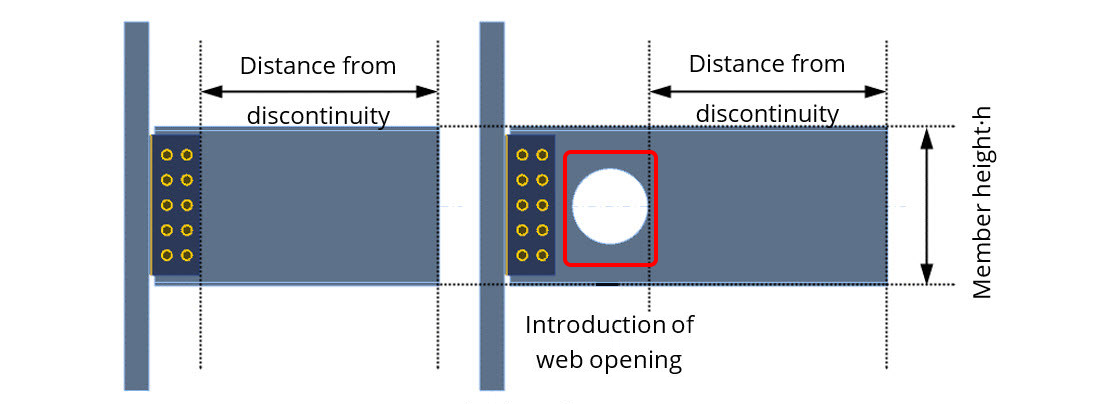

In case an element or a modification (bolt holes, notches, openings, etc) is added to this member the software will adjust the overall length accordingly in order to maintain a distance from the discontinuity.

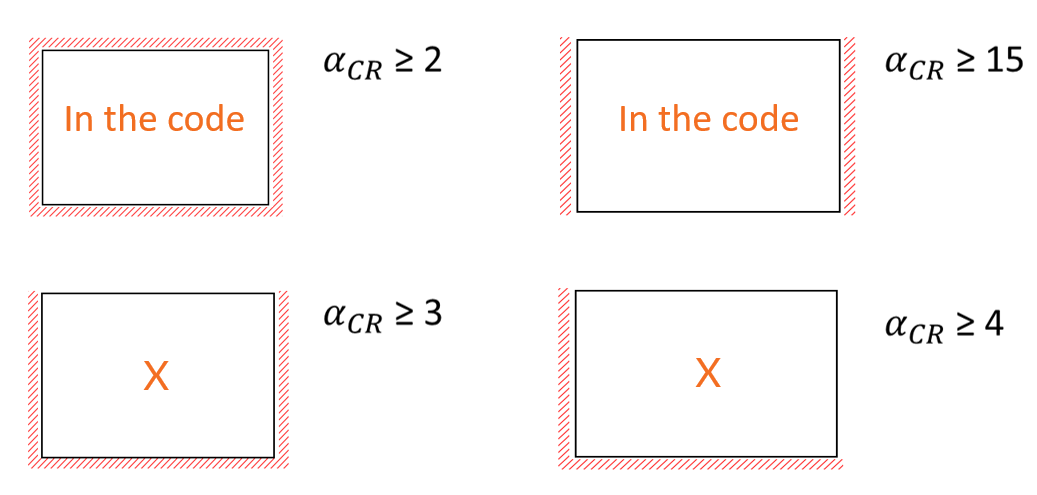

However, the software allows the change of the default factor for the member length calculation, through the “Code setup” settings, which then influences the overall length. Users are strongly advised to leave this value as default, as such changes can influence the results significantly. All our verifications were performed with the default settings.

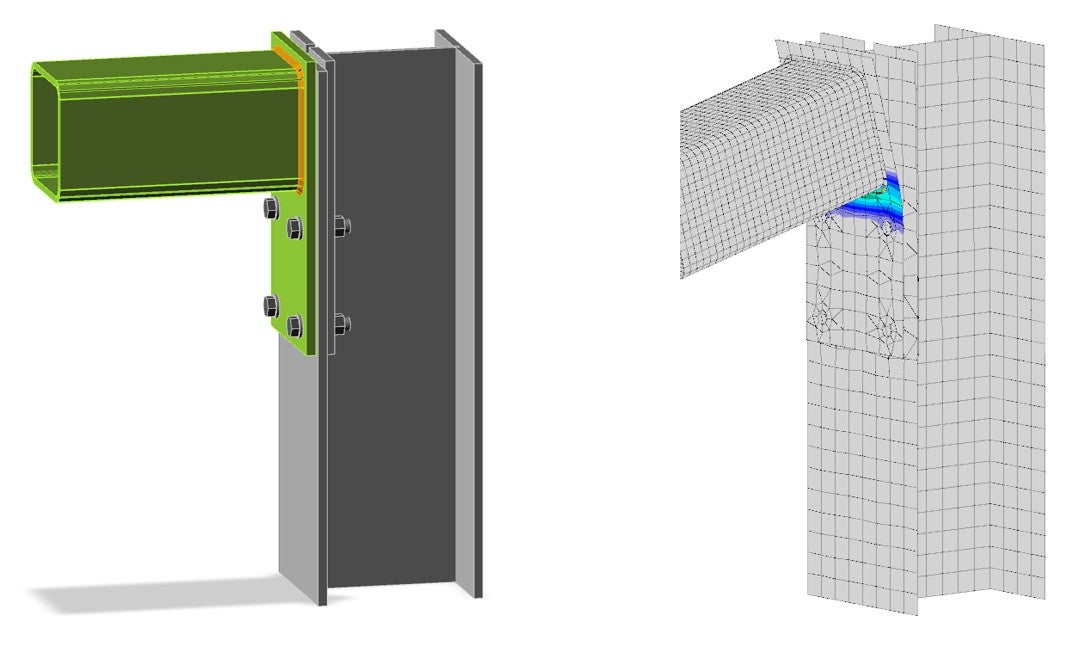

In rare cases, the default values of this setting may lead to a failure that would not otherwise occur. Examples of rare scenarios might be 1. overly deep beams (e.g. 1.5+ m.) leading to excessive distance from the nearest discontinuity or, 2. high localized shear force applied on a short-length section (e.g. a short console holding crane runway girder), which IDEA StatiCa would, by default, model longer than in reality. Both cases would result in high bending at the loaded end.

It is for this reason that this setting is available, to provide experienced users some flexibility when dealing with these rare cases where a reduced length might be necessary.

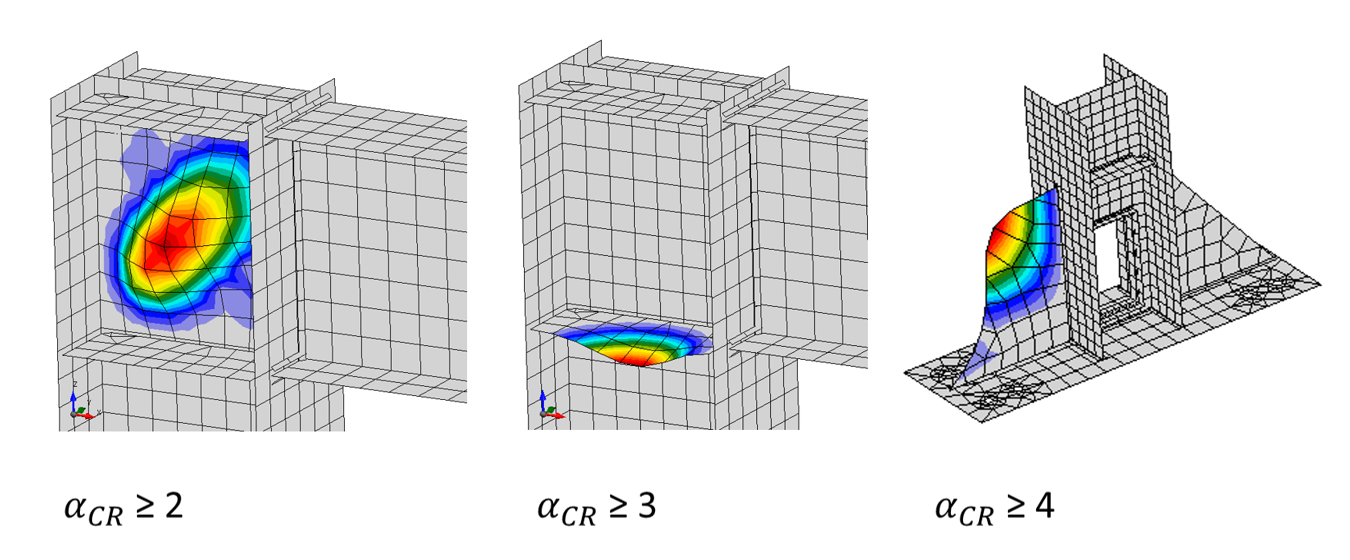

In such cases, where it is absolutely clear that the issue is due to the member length alone, the user would need to conduct a study to examine the impact of any reduction in the member depth/length ratio on the model behavior (stress/strain fields and forces in the various components). Should the output match, a reduction in the parameter may be possible, though this may need to be done in conjunction with the mesh settings in some models.

In other words, if the user decides to modify this setting, they must be able to adequately justify this by referring to output from an associated study demonstrating that the reduction has not influenced the output in the joint components.

For this reason, we recommend getting in touch with our support team before modifying any of these critical parameters.

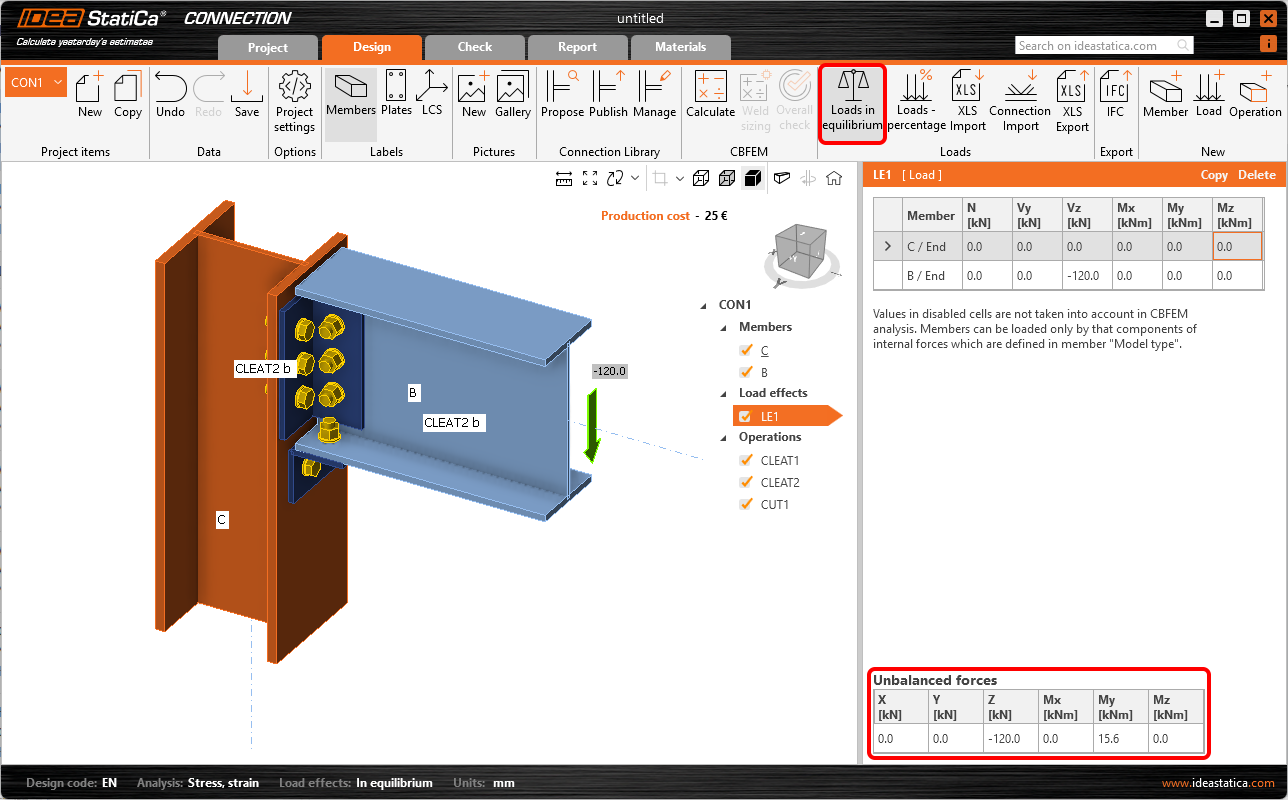

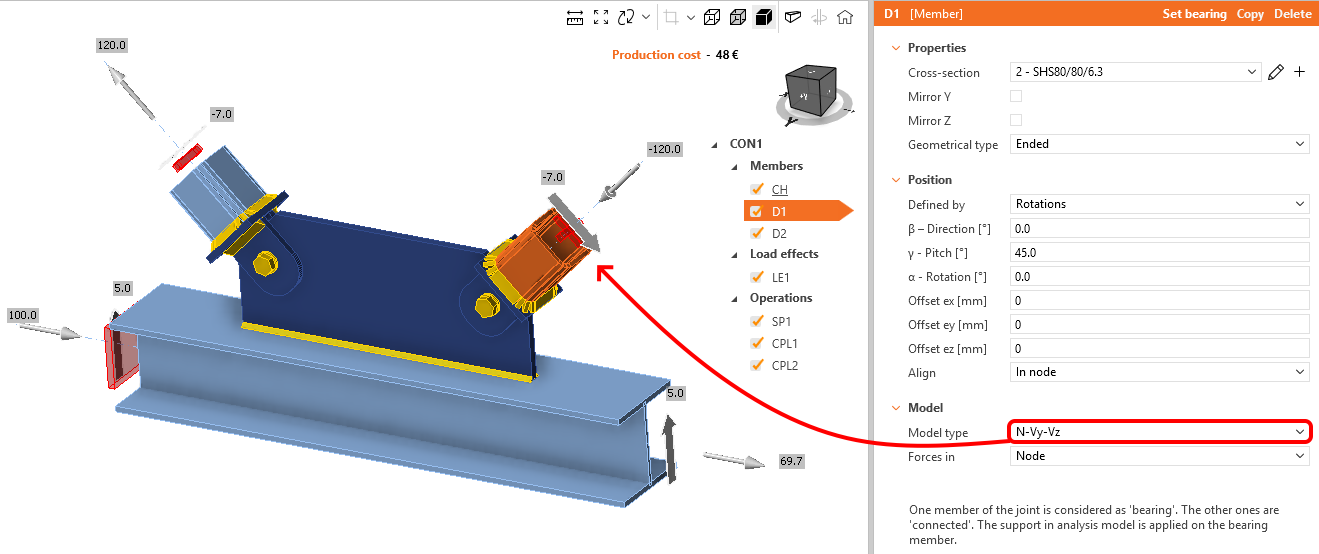

Example study demonstrating a reduction in member length/depth ratio without significant impact on stress field and component loading.