Removing critical blockers in anchoring and connections for Air Arabia Hangar

United Arab Emirates

The challenge

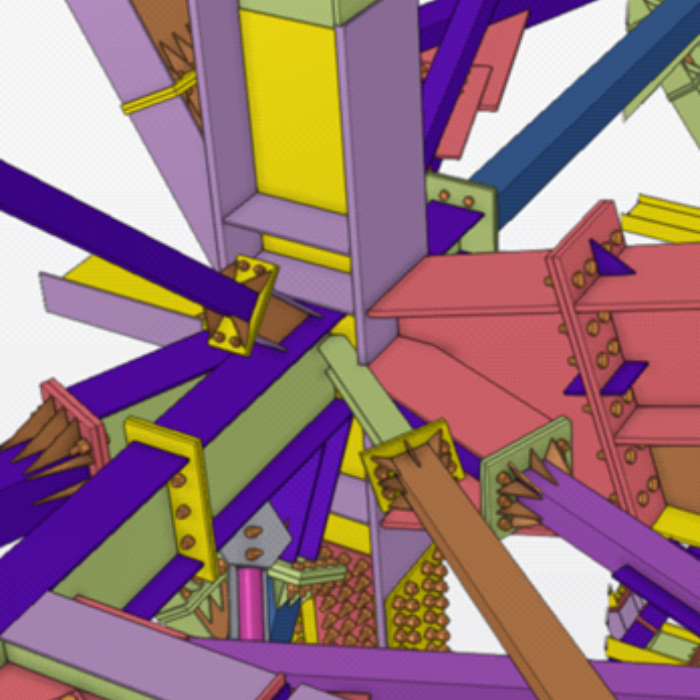

The project required a pinned connection for the base detail to form a perfect hinge. The connection is formed by a central steel rod (the pin) with its axis perpendicular to the applied loads and several plates with circular holes through which the pin is inserted.

Designing such complex details required a finite analysis supported by standard code equations. The consultant has restricted the connection design by requiring the use of a connection software that is able to define all the parameters and tolerance for pin holes after fabrication. “IDEA Statica software enabled us to do this,” states Dr. Seham.

Moreover, the project required verifying a node where 13 members converged into a single joint at irregular angles. Apart from many complex connections, solving 150+ similar connections and transferring data among teams would take a lot of time if only standard tools were used.

Fortunately, thanks to their experience and professionalism, Kirby's team found solutions for all of the project's challenges.

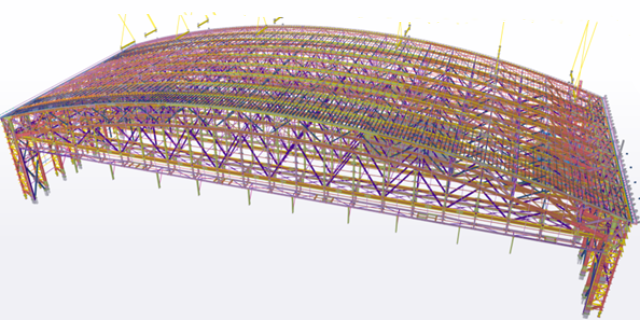

About the Project

The Air Arabia Hangar is a large-span steel truss structure designed for aircraft maintenance operations at Sharjah International Airport. The hangar’s external dimensions are 136 m wide × 57 m deep, with a minimum clear span of 129.5 m and a crane hook height of 15 m. It accommodates three overhead cranes (6T capacity), mezzanines, skylights, fall arrest systems, and specialized hangar doors.

Protection of steel was ensured using shop primer compatible with intumescent fireproofing. Kirby’s scope included the design and supply of the steel structure, preparation of design drawings and calculations, consultant approval, shop and fabrication drawings, fabrication and supply of pre-engineered sections, and provision of erection methodology.

Solving a pinned base connection – a challenge to the job’s progress

The consultant required a pinned base connection detail that was rarely used in practice. The challenge escalated when they required a connection software that could perform this type of detail.

United Arab Emirates

Fortunately, Kirby’s team prepared for this situation. Using IDEA StatiCa’s component-based finite element method (CBFEM), they designed the pinned base connection with the actual fabricated conditions. The software evaluated the stress distribution and interaction under realistic loading, demonstrating that the connection remained safe and within acceptable performance limits.

The validated outputs, supported by third-party verification, gave the consultant confidence to approve the connection.

How 13-member joints stopped being a challenge

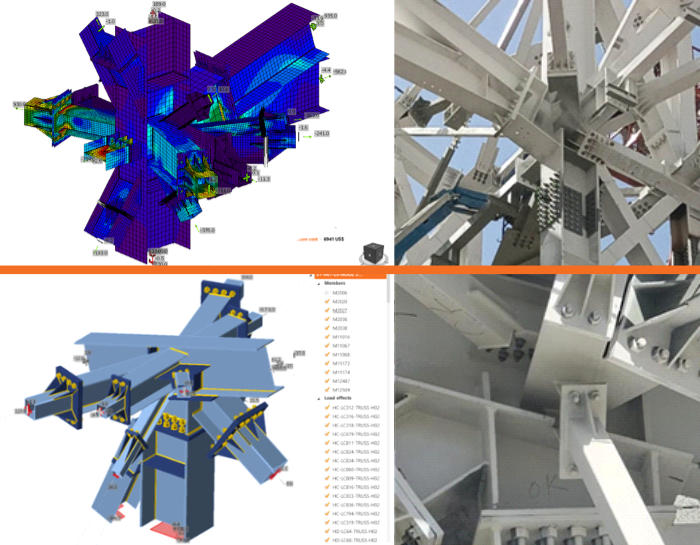

One of the most demanding tasks in the hangar project was verifying a node where 13 members converged into a single joint at irregular angles. This was exceptionally challenging because it required consideration of axial, shear, and bending interactions simultaneously in a highly unsymmetrical 3D geometry. Manually rebuilding the geometry and calculating stress interactions branch by branch would have been excessively time-consuming and prone to error.

United Arab Emirates

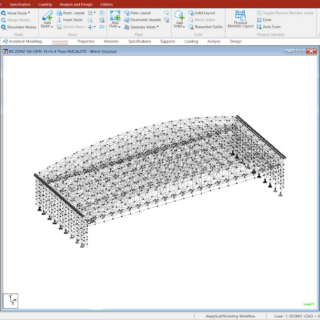

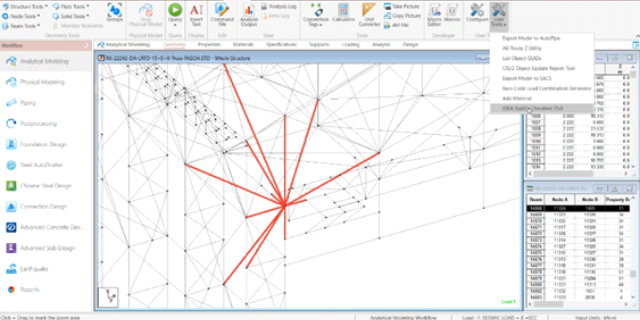

Kirby’s team did stand up to the challenge and managed to overcome it with flying colours. Using BIM Links through IDEA StatiCa’s app Checkbot, Kirby integrated IDEA StatiCa directly with STAAD.Pro. The joint topology, cross-sections, inclinations, and multi-plane rotations, along with all the load cases, were automatically extracted and transferred into IDEA StatiCa. This eliminated the need for manual reconstruction and provided an immediate, validated starting point.

“It was very important that we could export the data from STAAD.pro directly to IDEA StatiCa Checkbot, which significantly reduced the risk of error,” states Dr. Seham.

Instead of envelope load cases, the team analysed directly corresponding load effects, resulting in a more economical design. IDEA StatiCa captured the full stress interactions across the node and verified the connection with comprehensive code-based checks, completing in hours what would have otherwise required extensive engineering effort.

Saving 20% of repetitive work with each of +150 similar connections

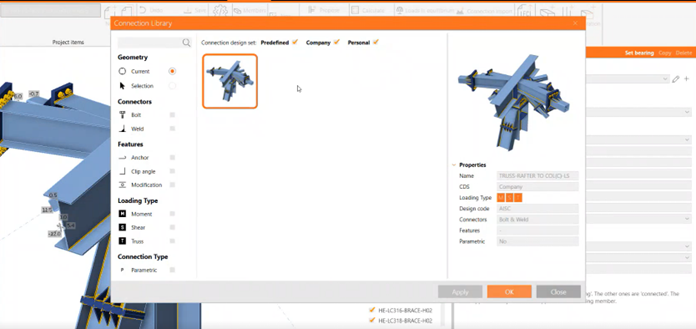

Slight geometric variations across the hangar meant that many nodes were similar but not identical. Engineers would have to re-model and re-check each connection separately, which would be repetitive, time-consuming, and risking inconsistency.

Kirby found a way to trim the process considerably so that they could focus on the challenging work where their skill matters the most. They used the Propose & Publish functionality, modelling a connection once in IDEA StatiCa and publishing it to their internal template library, to be reused wherever a similar node occurs.

By simply proposing the saved template into the new location, they avoided starting from scratch. This significantly reduced engineering time and ensured uniform quality across all grid lines.

United Arab Emirates

Cutting down the time to share connection designs with the detailing team

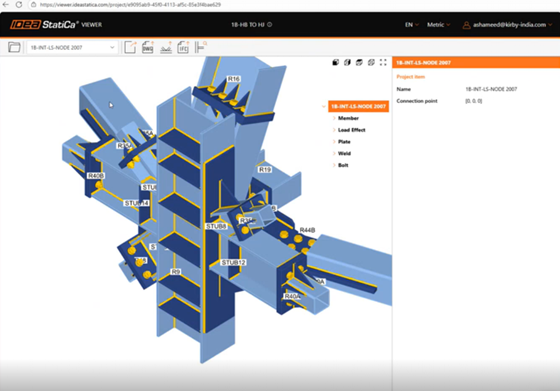

Conventionally, engineers would prepare detailed sketches for each connection and send them to the detailing team, leading to long cycles of back-and-forth validation and a high risk of misinterpretation when moving designs into Tekla.

As usual, Kirby’s engineers found a way to solve this issue: they shared direct IDEA StatiCa Viewer links with their detailing team. This allowed detailers to open the connection models online, inspect every plate, weld, and bolt, and then directly model the details in Tekla. This eliminated the need for sketch preparation, reduced review loops, and streamlined communication between engineering and detailing teams.

United Arab Emirates

Meet Kirby’s Engineers

Dr. Seham Ahmed El Saeed has 20 years of experience in steel structures as a designer, scientist, researcher and active publisher. She is currently responsible engineering technical manager for training and development of Kirby across MEA engineering offices.

Shahul Hameed is a Civil Engineer and Drafting Manager at Kirby Building Systems & Structures, India Pvt Ltd. He has more than 25 years of experience, and he specializes in structural steel and pre-engineered building systems.

Try IDEA StatiCa for free