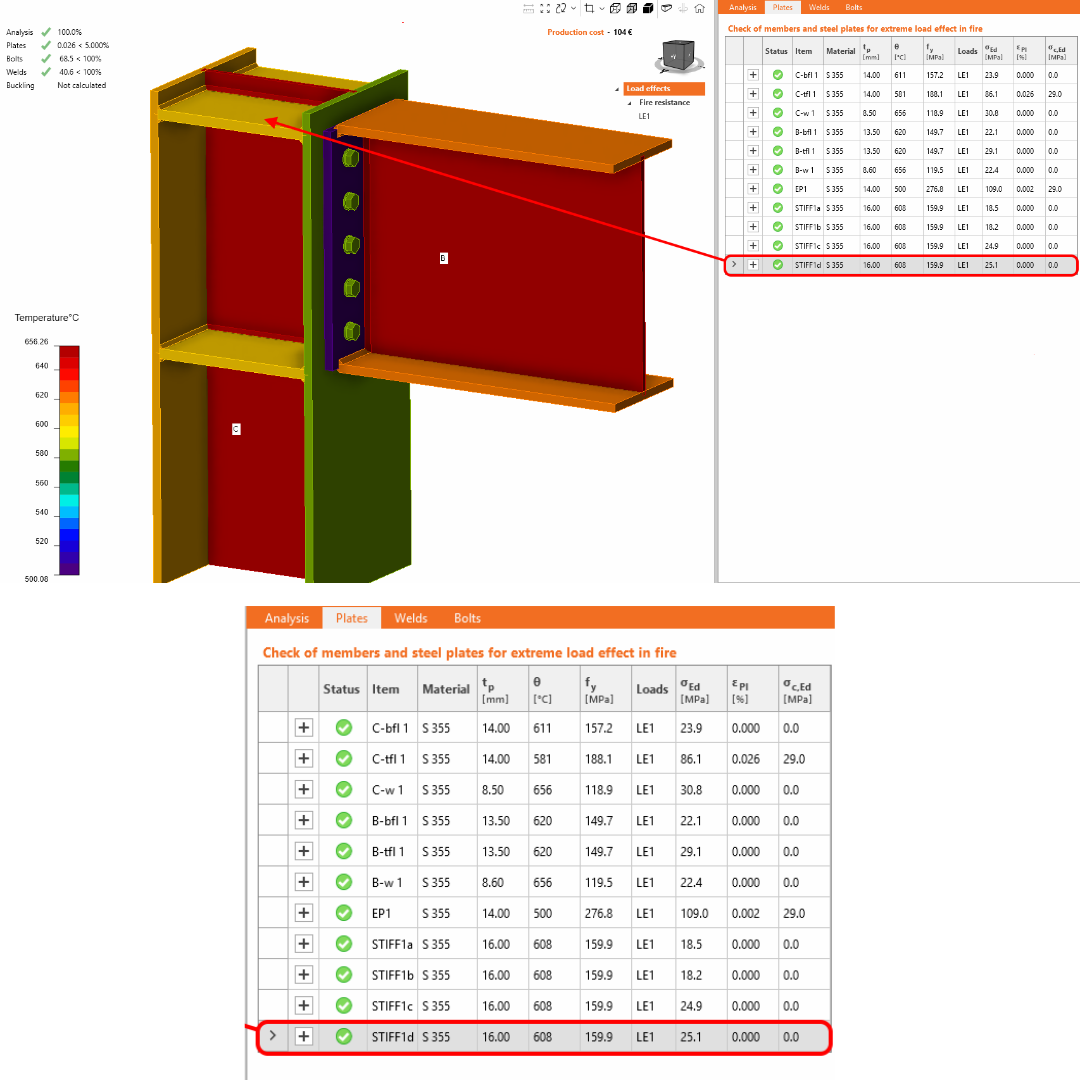

Fire temperature verification of a stiffening plate

Introduction

Fire analysis is not a routine task for a structural engineer. This article showcases the solution behind IDEA StatiCa, which automatically calculates the temperature for plates in the connection model under fire exposure.

The weld and bolt components take the temperature of the connected plate with the highest temperature. More about assumptions: https://www.ideastatica.com/support-center/general-theoretical-background#Fire-design

Model & assumptions

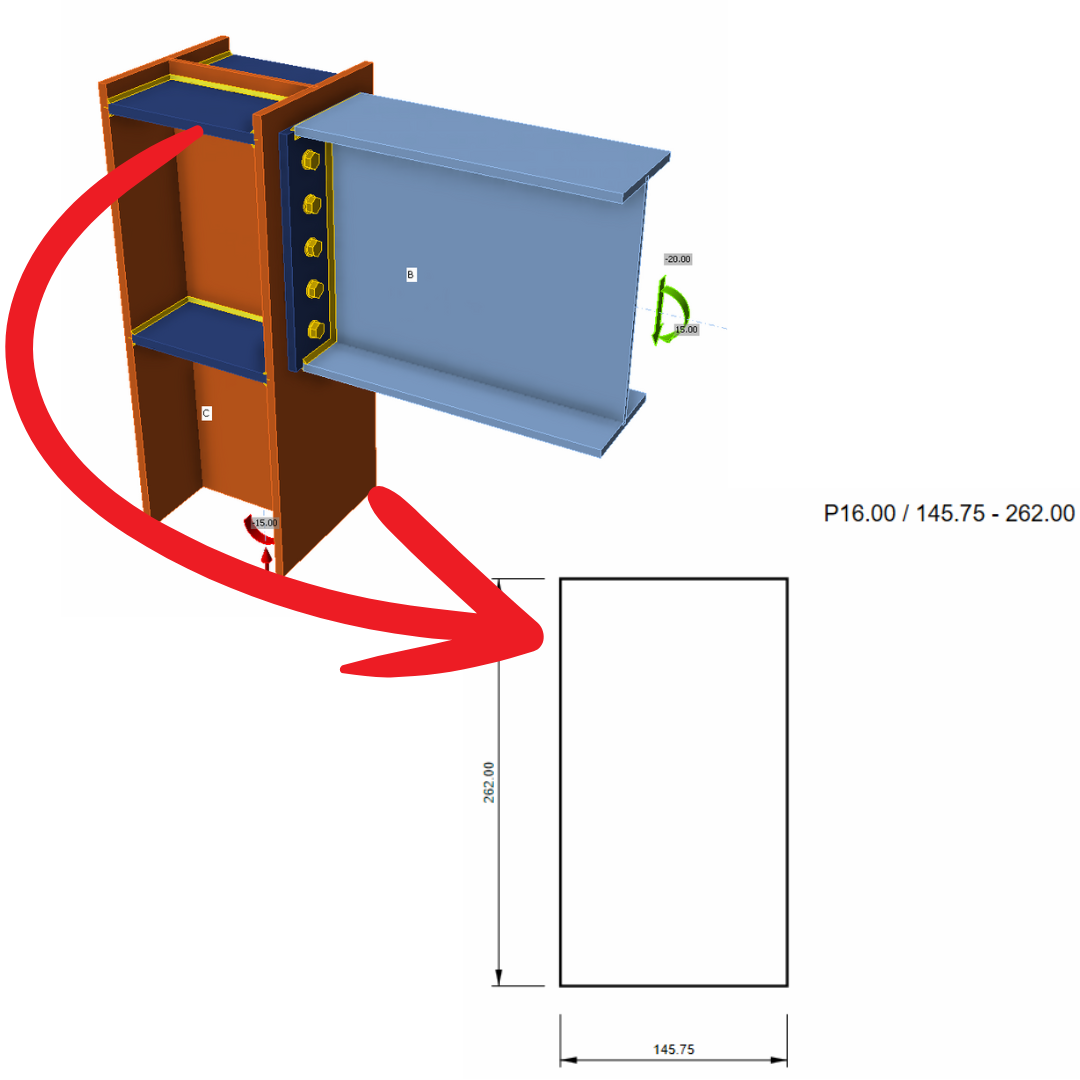

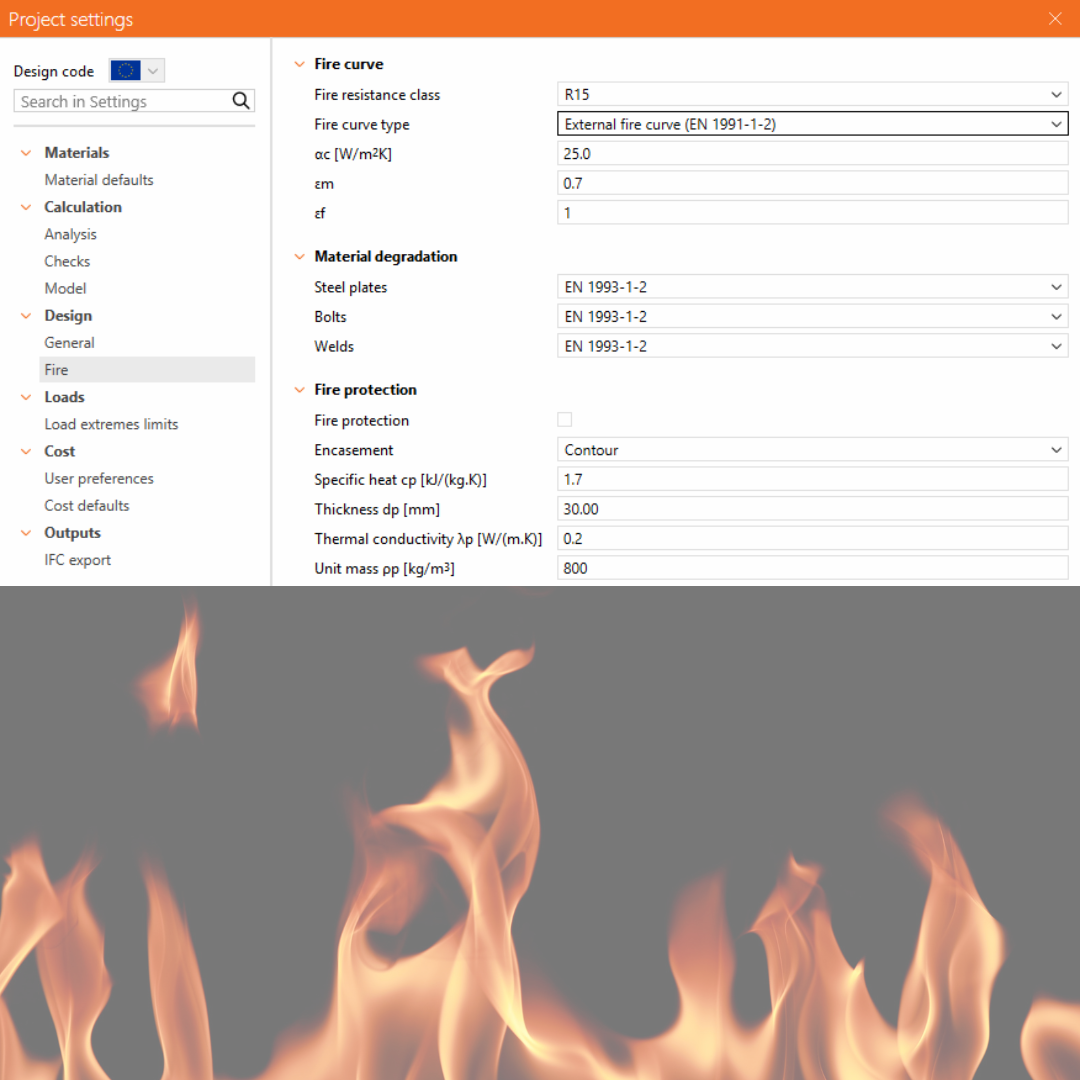

The temperature of the stiffener at this connection point will be checked. The connection will be exposed to fire and must withstand at least 15 minutes R15. The fire curve used for simulation is "External fire curve (EN 1993-1-2)." There is an important notice that the fire protection has not been applied.

Code formulas

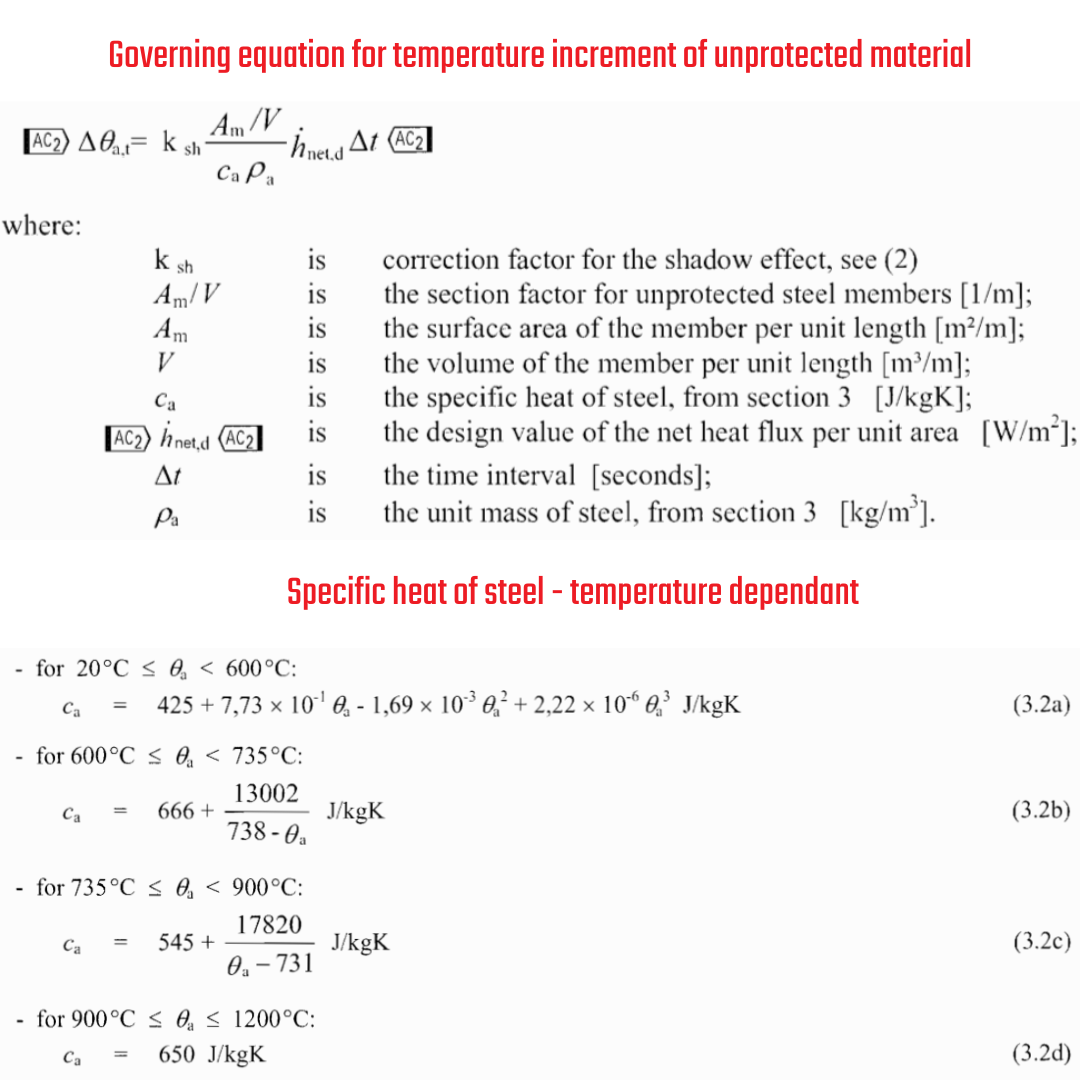

The assumptions are based on EN 1993-1-2 for unprotected steel materials. Because no protective insulation exists, the material is directly exposed to heat from convection and radiation from the flames, causing it to heat up much more quickly.

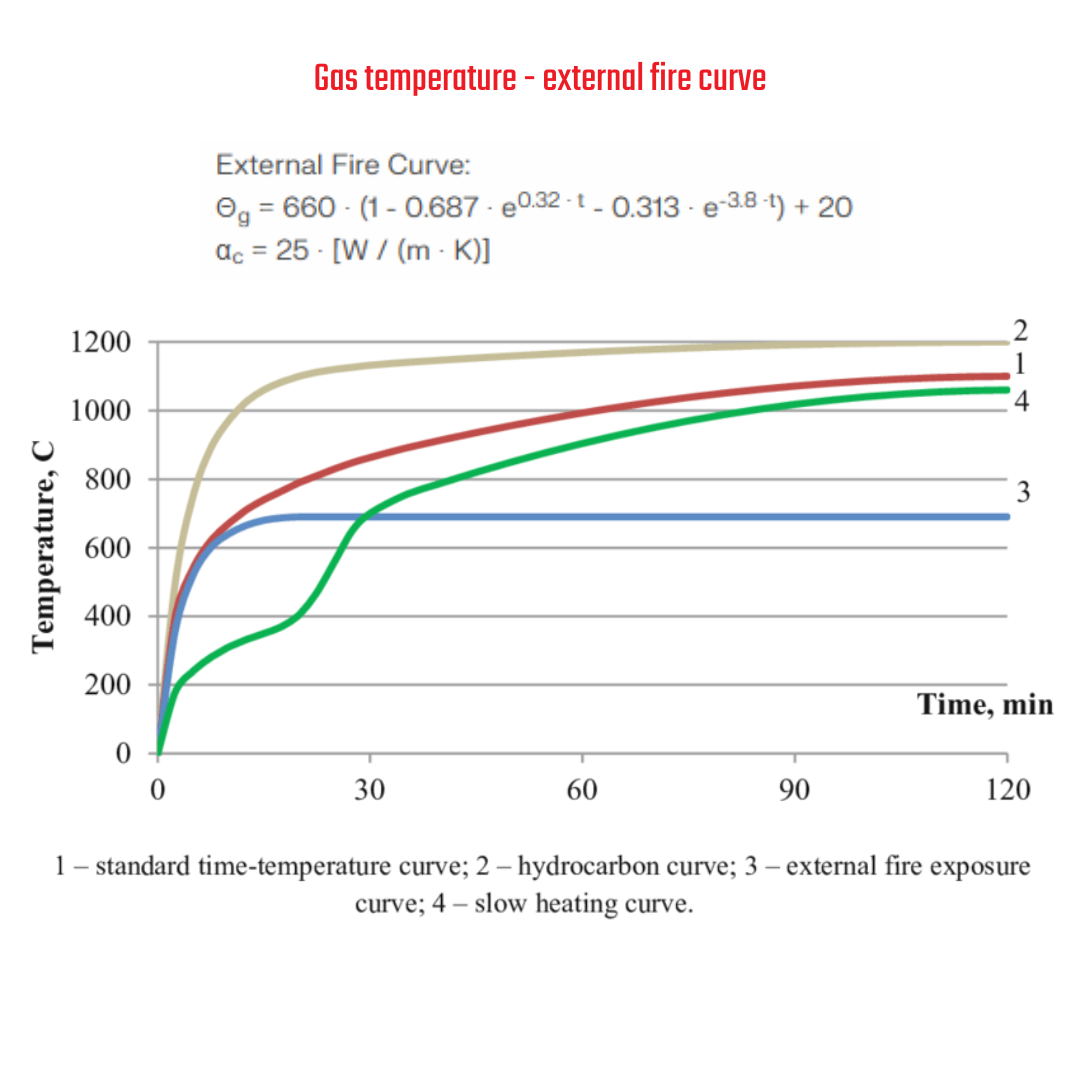

Eurocode defines several nominal temperature–time fire curves used in structural fire design:

- Standard Fire Curve (ISO 834 / EN 1991-1-2, Eq. 3.1)

- Represents a conventional, severe compartment fire.

- Use: For standard fire resistance classification (R30, R60, R90, …). Typically applied in prescriptive design and laboratory testing.

- Hydrocarbon Fire Curve

- Rapid temperature rise, reaching ~1100 °C within 5 minutes.

- Use: For fires involving hydrocarbons (oil, gas, fuel storage, petrochemical industry, tunnels with heavy traffic).

- External Fire Curve

- Lower temperature rise compared to the standard curve, max ~680 °C.

- Use: For façade and external wall exposure to fire.

- Parametric Fire Curves (not included in IDEA StatiCa)

- Based on compartment size, ventilation, and fire load density.

- Show heating and cooling phases.

- Use: For performance-based design of real building compartments where fire load and ventilation are known.

How engineers should select the fire curve

Code compliance/resistance rating required: → Use Standard Fire Curve.

Petrochemical, tunnels, storage of flammable liquids: → Use Hydrocarbon Fire Curve.

Façades, external members exposed to outdoor fire: → Use External Fire Curve.

Realistic fire scenario (performance-based design): → Use Parametric Fire Curve (if sufficient input data is available).

Section factor Am/V

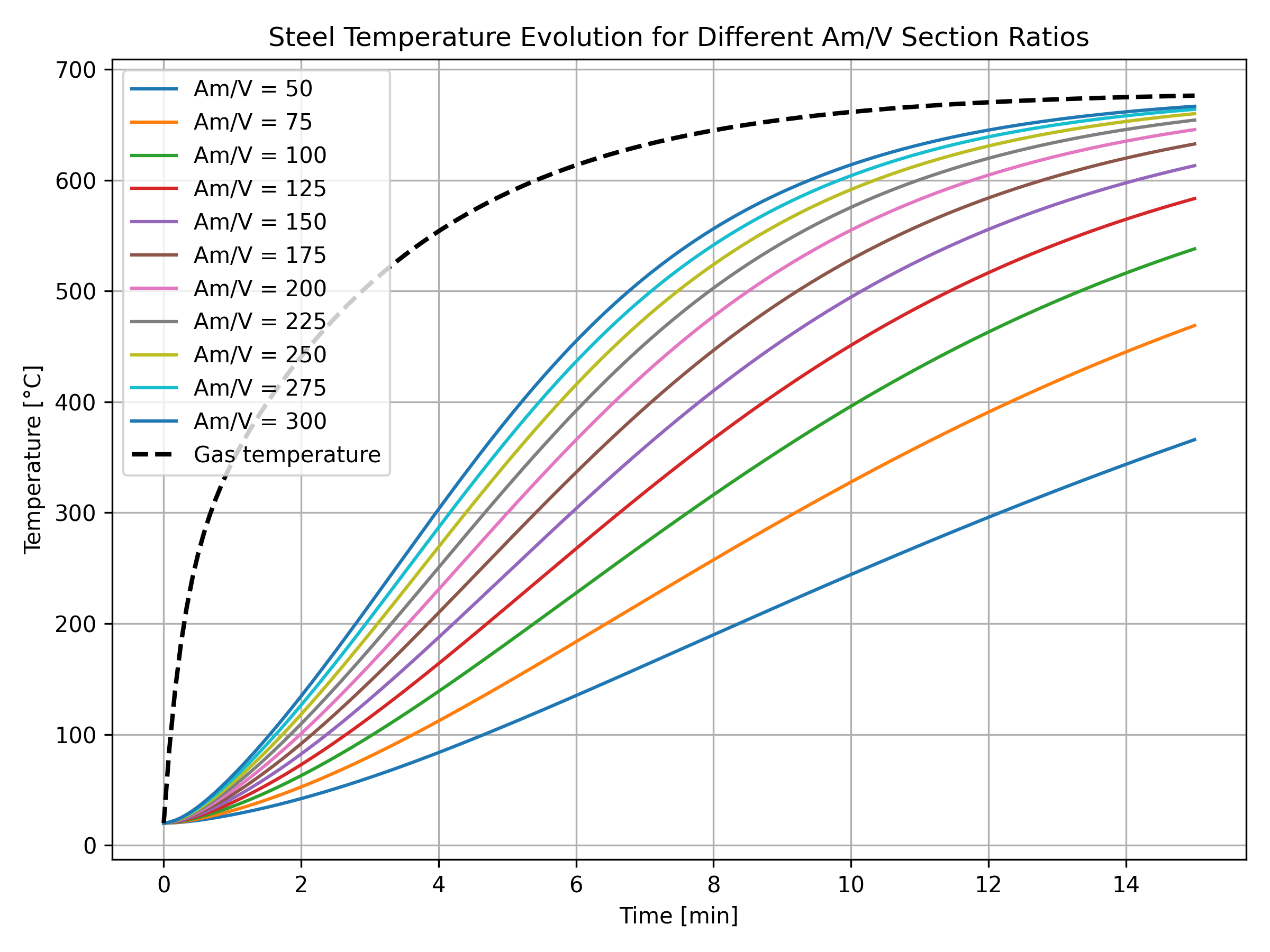

General sensitivity

The section factor (Am/V) is a significant constant for each plate. In the governing equation, it appears as a numerator, indicating that increasing the temperature increment influences the temperature at the conclusion of the simulation. Let's observe the factor's sensitivity in the range [50,300] after incrementing by 25.

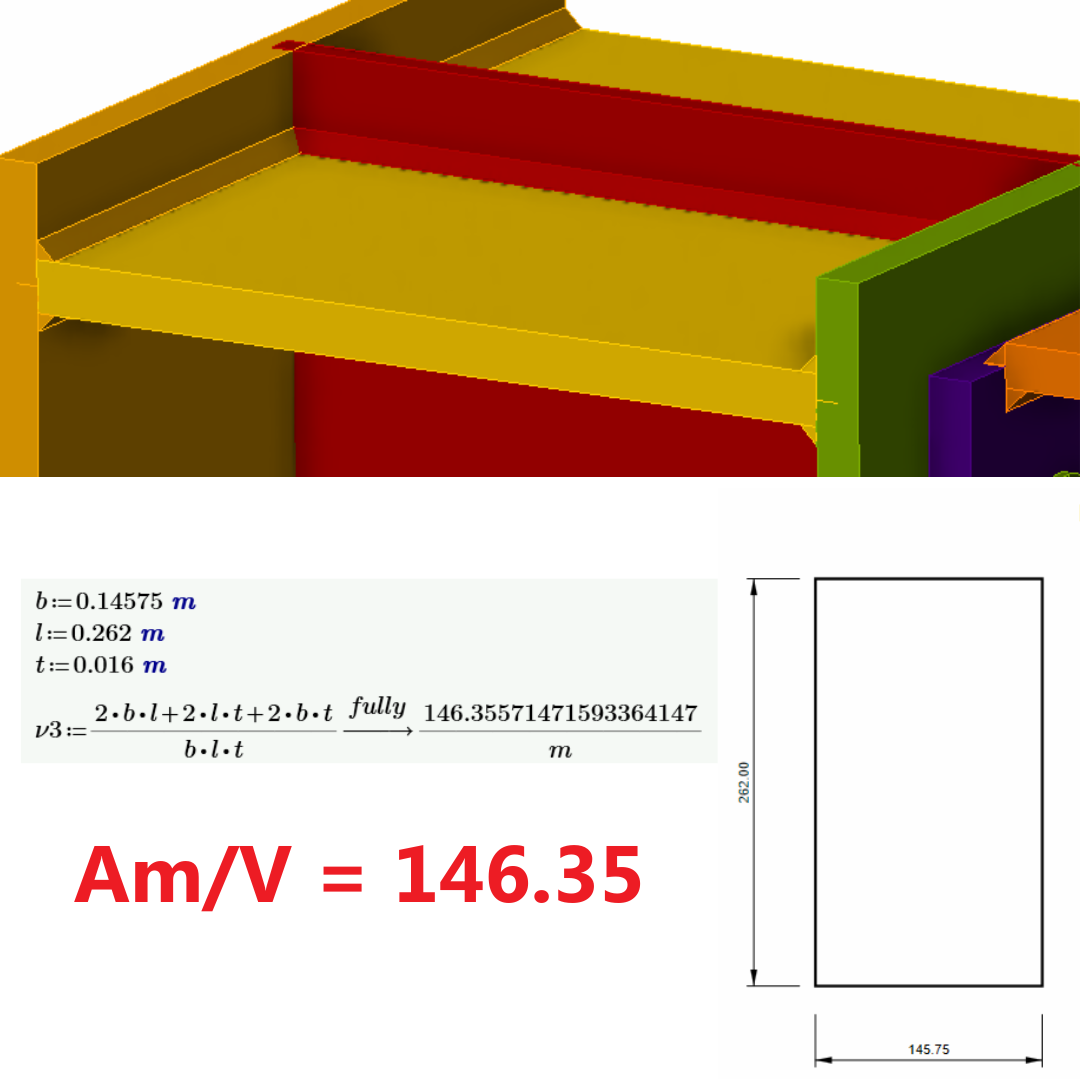

How to calculate the value for the stiffener

The section factor calculation for referring stiffeners should clarify the methodology for calculating the stiffeners. If a face not aligned with the edge of the plate is covered by another plate, the covered area must be excluded from the section factor calculation. Ignorance of this aspect can result in misleading outcomes compared to manual verification.

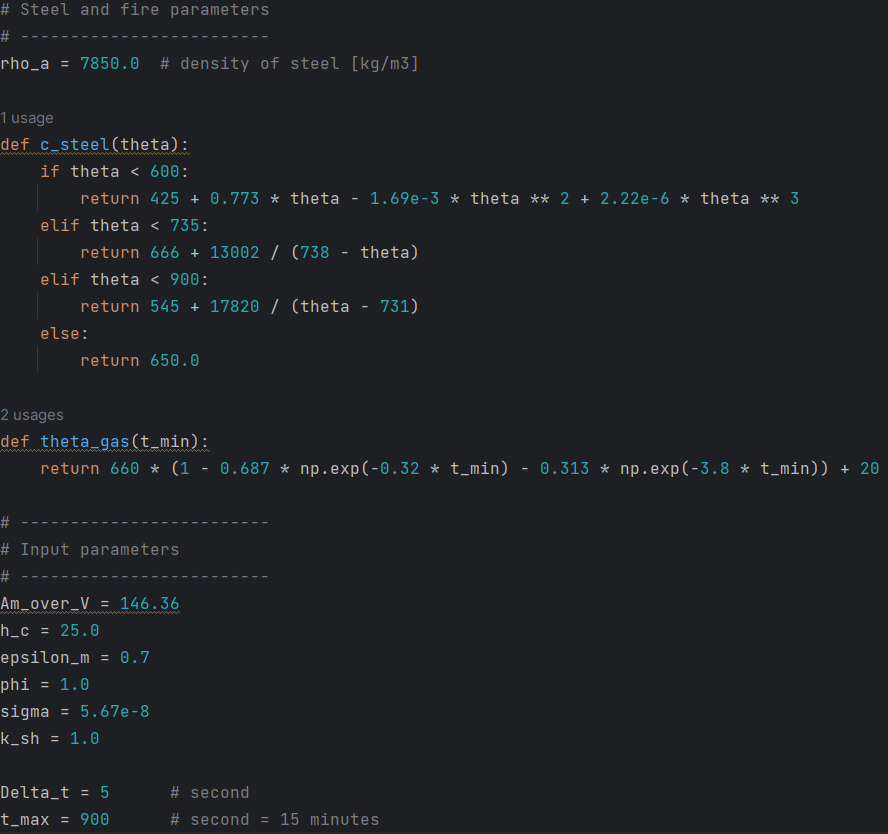

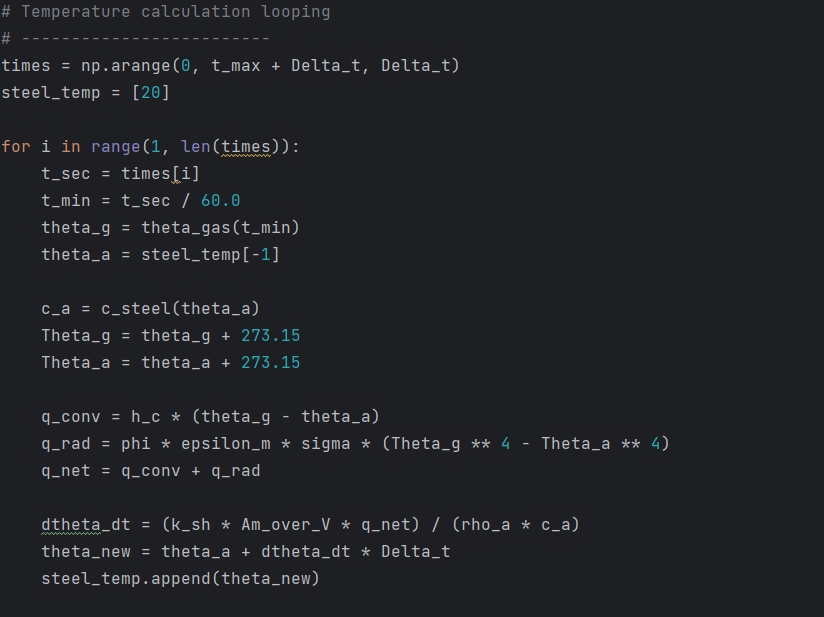

Calculation procedure step by step

The outlined procedure describes the workflow of temperature increase over time for the External fire curve.

Comparison of IDEA StatiCa vs hand calculation

The temperature calculated by IDEA StatiCa reached 608 degrees Celsius.

Using the manual step-by-step procedure, the temperature reached 609 degrees Celsius.

Conclusion

The objective was to introduce more transparency into the fire design workflow and to encourage structural engineers to confidently use IDEA StatiCa for the fire design and code-checking of steel connections and members compared to hand calculations.

In fire design, temperature becomes a critical state variable. It directly influences the stiffness and strength of materials through temperature-dependent properties defined in EN 1993-1-2.