Detailing of bolts and welds (AISC)

Bolts

The minimum spacing between bolts and distance to the bolt centre to an edge of a connected part are checked. The minimum spacing 2.66 times (editable in Code setup) the nominal bolt diameter between centres of bolts is checked according to AISC 360-16 – J.3.3. The minimum distance to the bolt centre to an edge of a connected part is checked according to AISC 360-16 – J.3.4; the values are in Table J3.4 and J3.4M.

Welds

The minimal and maximal weld size and the sufficient length of the weld are checked.

The maximal weld size is checked according to AISC 360-16 – J2.2b for a plate parallel to the welded plate with an edge-to-surface fillet weld.

- For plate thickness smaller than 1/4 in, the weld size should be no bigger than plate thickness.

- For plate thickness equal to or higher than 1/4 in, the weld size should be no bigger than the plate thickness −1/16 in.

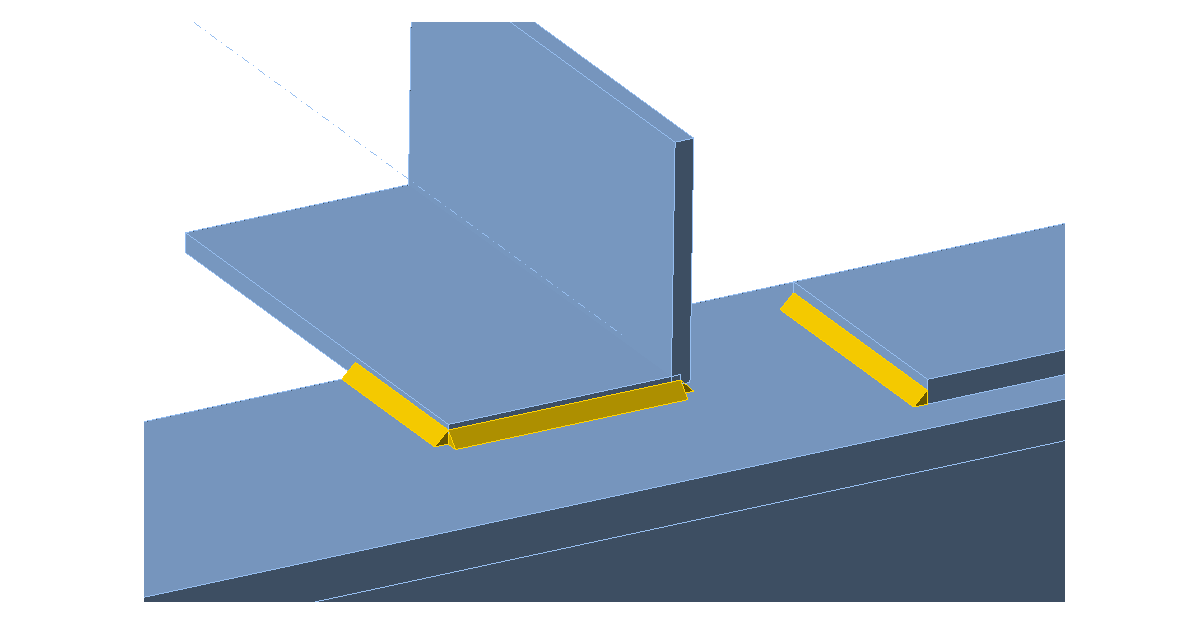

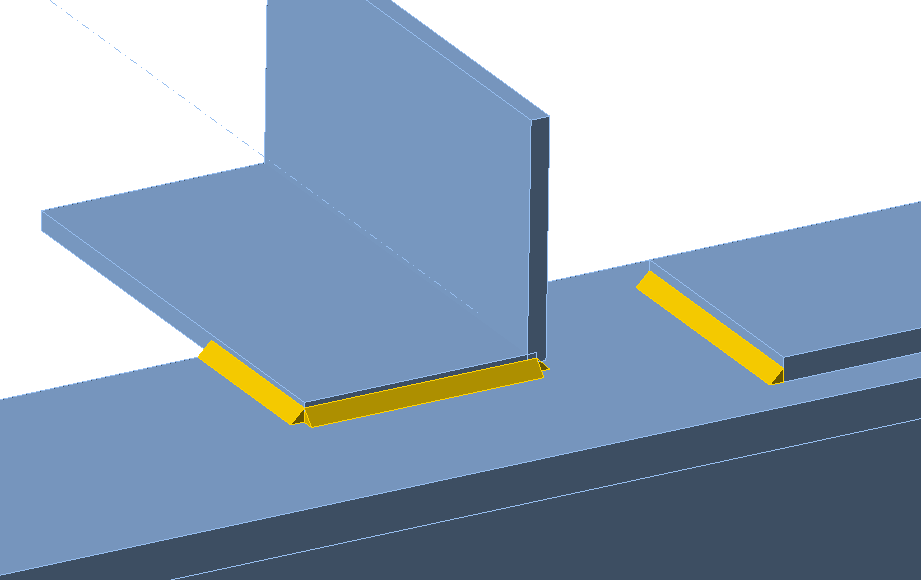

Examples for welds where maximum thickness is checked are in the following figure.

The minimal weld size of fillet weld is checked according to Table J2.4:

- For \(t_p \le 1/4\,\textrm{in}\) the weld size should be higher than or equal to 1/8 in.

- For \(1/4\,\textrm{in}< t_p \le 1/2\,\textrm{in}\) the weld size should be higher than or equal to 3/16 in.

- For \(1/2\,\textrm{in}< t_p \le 3/4\,\textrm{in}\) the weld size should be higher than or equal to 1/4 in.

- For \(3/4\,\textrm{in}< t_p\) the weld size should be higher than or equal to 5/16 in.

where \(t_p\) is the thickness of the thinner plate.

The minimum length of fillet welds should not be less than four times the weld size according to J2.2b (c).

The minimal effective throat of PJP groove weld is determined according to AISC 360-22 – Table J2.3:

| Thickness of thinner part joint [in.] | Minimum effective throat [in.] |

| \(t_p \le 0.25\) | 0.1250 |

| \(0.25 < t_p \le 0.50\) | 0.1875 |

| \(0.50 < t_p \le 0.75\) | 0.2500 |

| \(0.75 < t_p \le 1.50\) | 0.3125 |

| \(1.50 < t_p \le 2.25\) | 0.3750 |

| \(2.25 < t_p \le 6\) | 0.5000 |

| \(6.00 < t_p\) | 0.6250 |

Anchors

The spacing between anchors should be greater than four times anchor diameter according to ACI 318-14 – 17.7.1.

Minimum plate edge distance follows rules for bolts.