Shear connection – get the best of it!

Generally speaking, the shear connection is a joint that doesn't allow the transfer of a bending moment between two structural members or from the structure to the foundation. The aim is to ensure free rotation in the node. Such connections do not provide rigidity in comparison to the moment connections. In the global analysis model, the node is declared as a pin.

Shear connections can be found in almost every structure, but their typical use is in braced frames, floor, and roof beams.

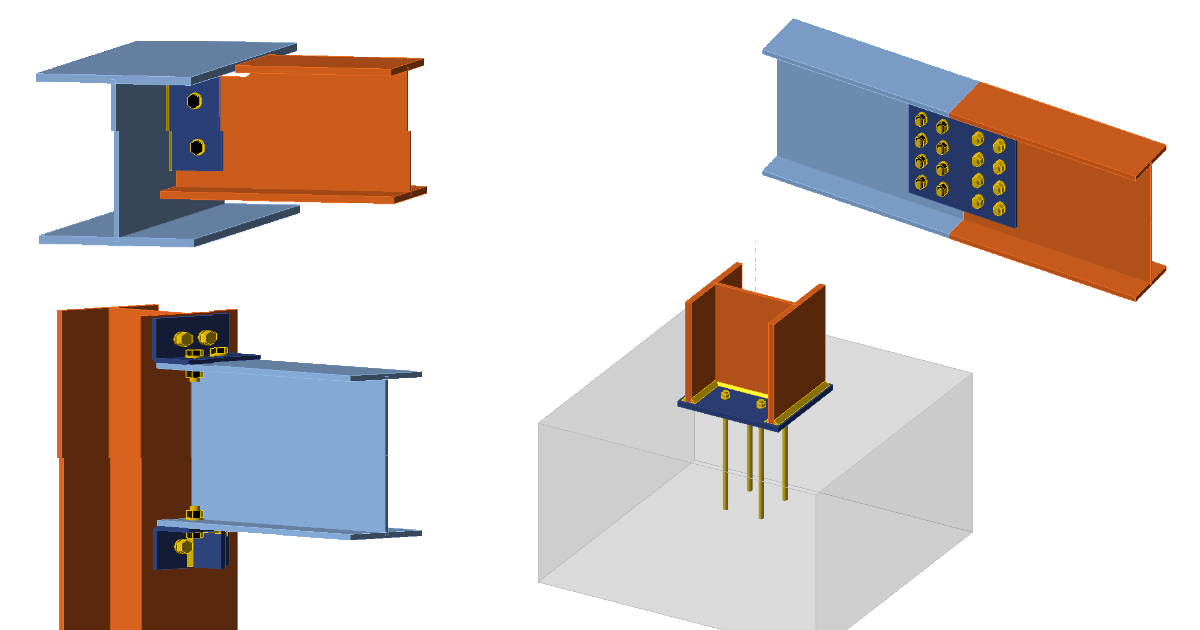

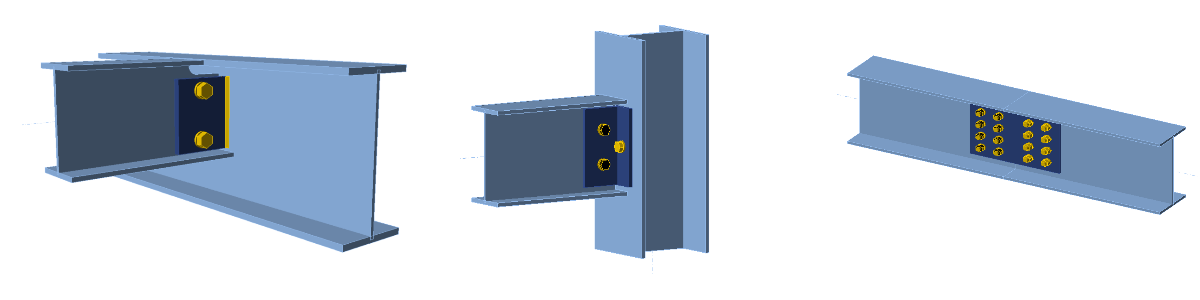

The most common shear connection (not only in North America) is a single plate connection consisting of a plate fillet welded to a supporting column or girder and bolted to the web of a simply supported beam.

When comparing to the moment connections, shear connections are simple to fabricate, simple to erect, and are significantly cheaper.

Shear connection types and classifications

Acc. to the usage:

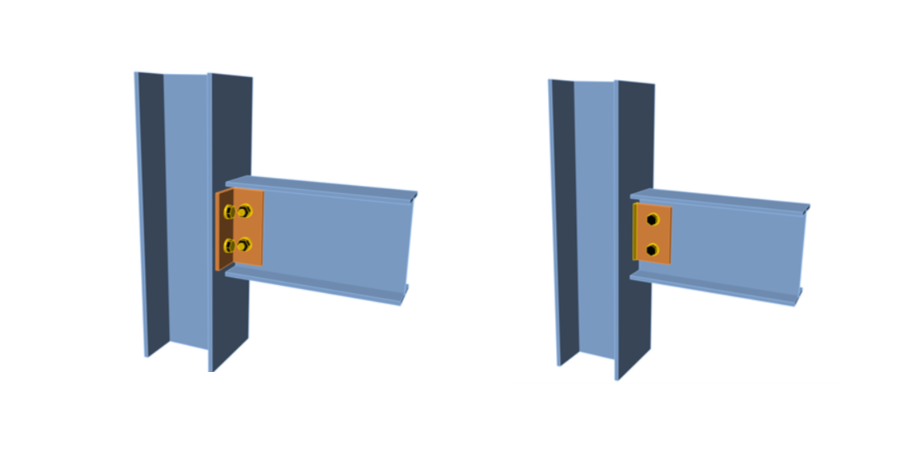

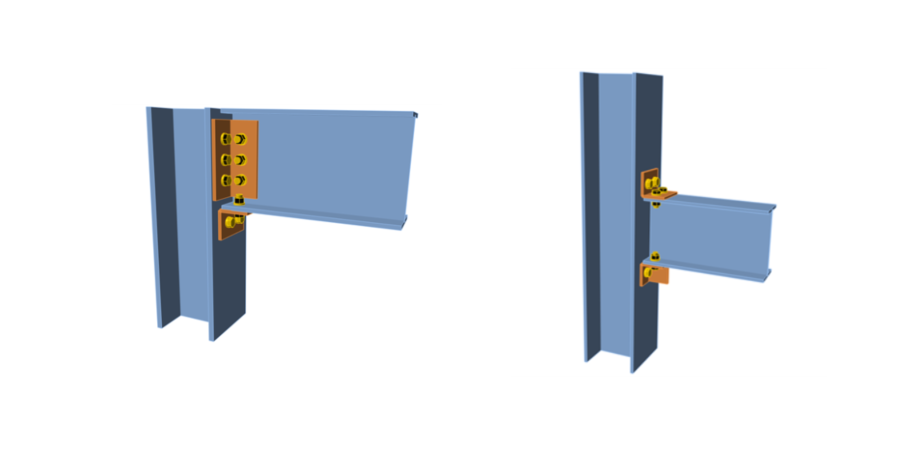

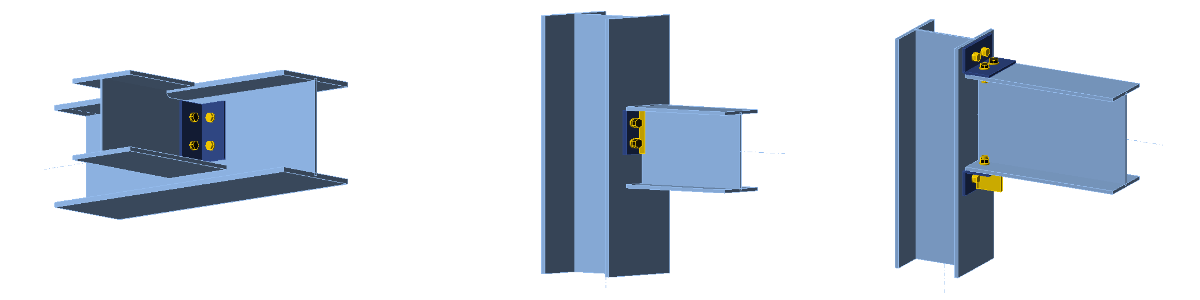

- Framed – connecting beams, web-to-web, directly

- Seated - beam is seated on a column indirectly

Acc. to the connection elements:

- Bolted (only)

- Welded (only)

- Combined

Acc. to the typology:

- double and single clip angle

- shear end-plate connections

- seat connections

- single shear plate connections

- T-connections (or T-joints)

- shear splice connections

IDEA StatiCa Connection has pre-prepared templates for all mentioned connection types and offers the possibility to create user-defined templates just according to your needs. Thanks to this, you can save a lot of time when designing such connections from scratch.

Position of the loads

For a correct analysis of the joint, where a shear connection is used, you have to consider the following.

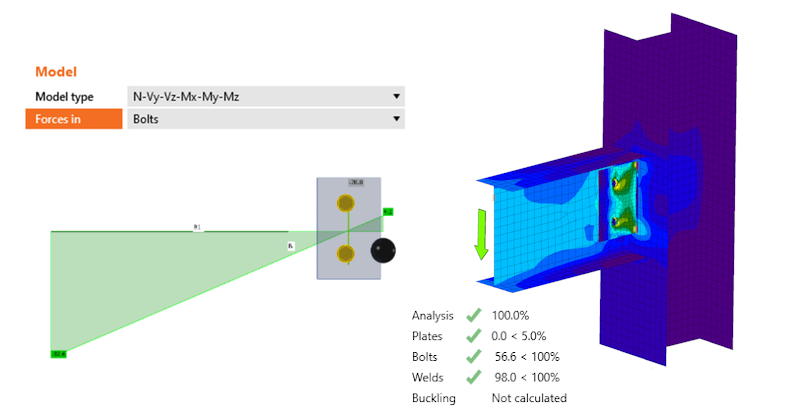

In the analytical model, a shear connection is declared as a pin and its position is at the intersection of the beam axes. However, the shear loads from the beam are actually transferred via the connector. So in reality, the shear forces are acting in bolts.

You can find more about it in our Theoretical background.

The location of the load effect has a big influence on the correct design of the connection. When modeling hinged connections, it is necessary to change the position of the acting load into the place where the hinge is assumed (where the zero bending moment is). To avoid all misunderstandings, we allow the user to select from three options – Node / Bolts / Position.

Find more helpful articles to get a better understanding of the correct load position issue.

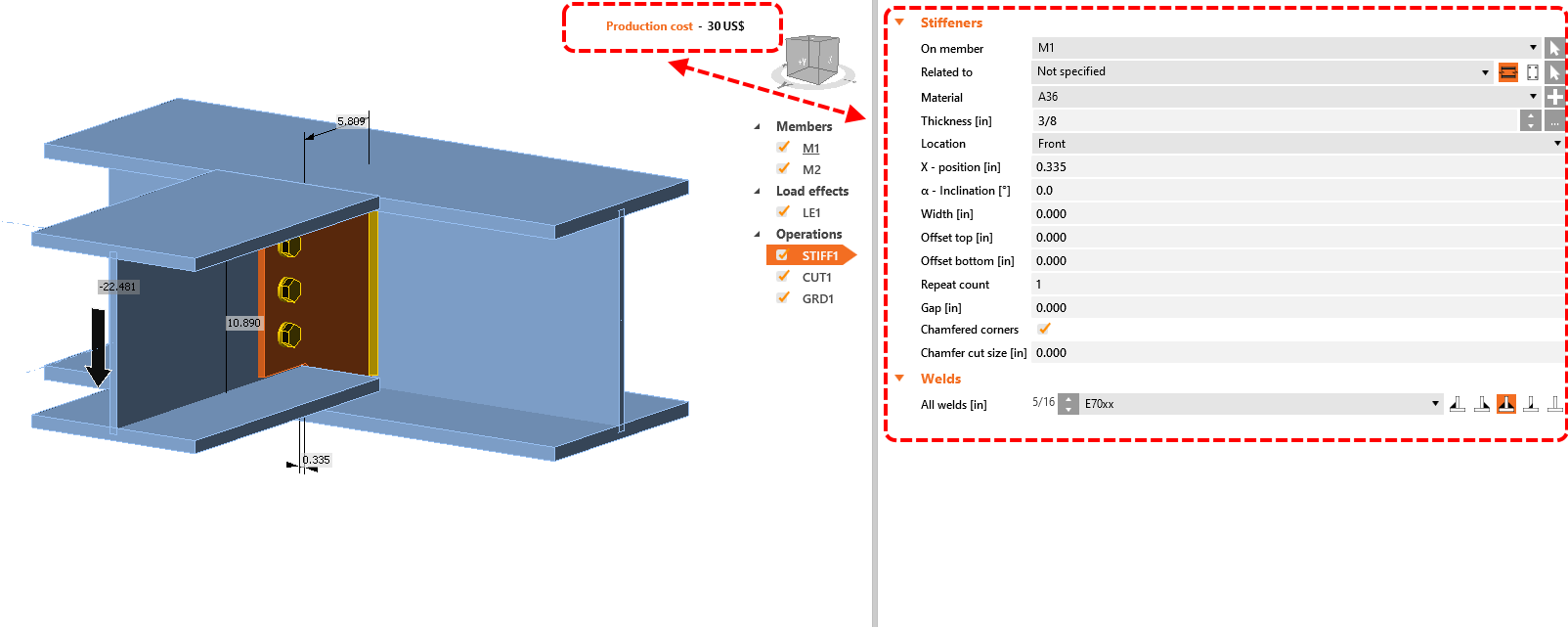

Cost optimization

There is always a huge number of possibilities of how to design a particular connection, but the experience helps us to choose the correct one. One great feature that can help you with the choice of the most appropriate and effective design is the Production cost calculator built-in in the app, which shows you immediately how the design changes influence the price.

Calculation and assessment

There are many ways and tools for the calculation and assessment of the specific shear connection type. You can find many applications which provide code-checks for particular connection arrangements. But if you want to assess literally any of them, the list of your options narrows. If your connection isn’t part of separated members only and is embedded in spatial structure with other members connected, you have only two options left:

1) The first one is to model the whole connection set as a shell non-linear model in some advanced FEA applications without the possibility of code-check according to a specific standard.

2) The second option is to use the IDEA StatiCa Connection application. In this case, you have no limitations in modeling and analyses. In a few minutes, you prepare the bolt, weld, and stress-strain checks right according to the selected design code.

Just select your template, edit it, optimize according to the results and assess all checks needed in few minutes.

No reason to wait anymore. Try it for free now on your own.