Capacity design according to Australian standards

Capacity design is a part of seismic check and ensures that the joint has sufficient deformation capacity.

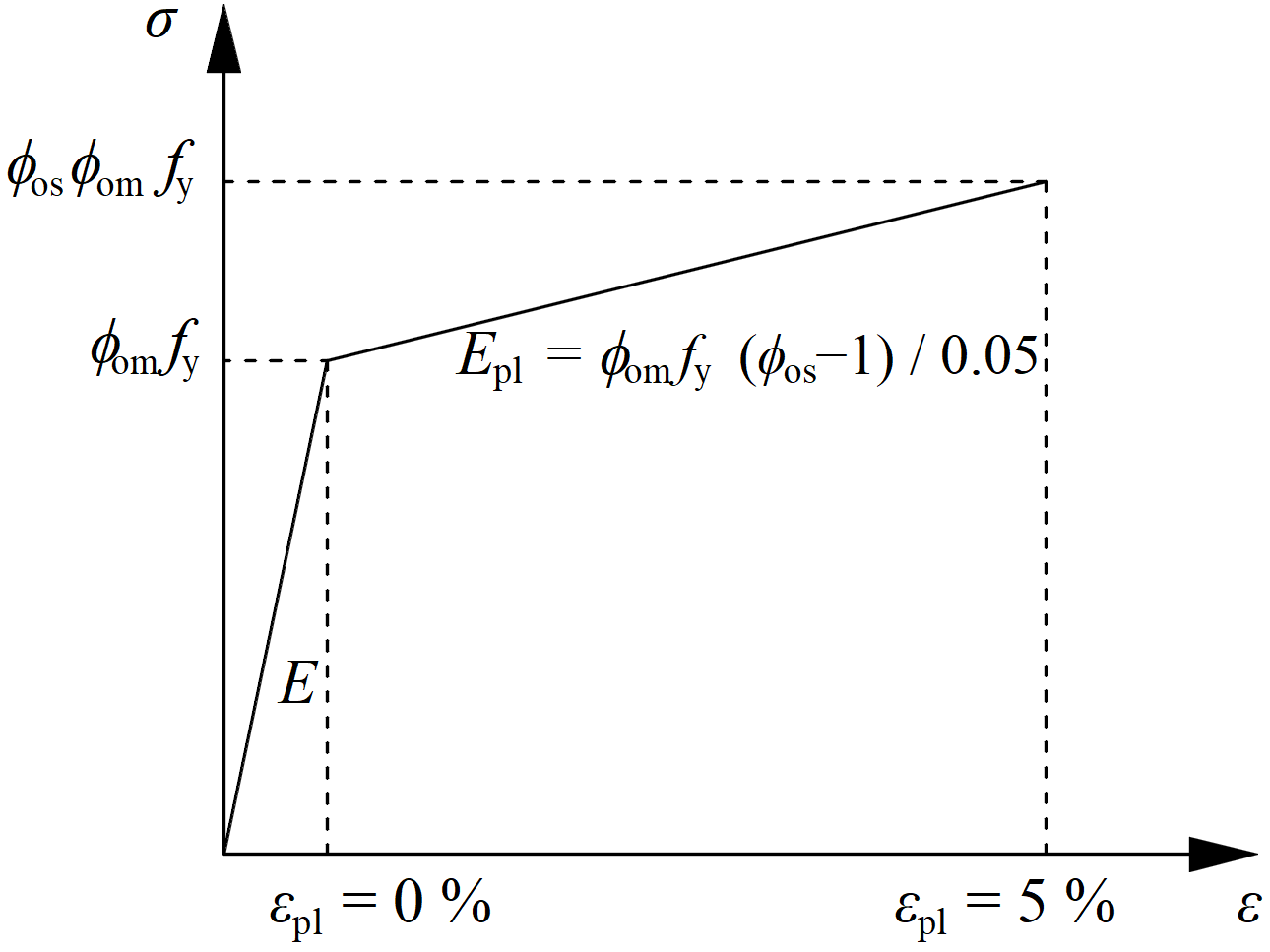

The objective of capacity design is to confirm a building undergoes controlled ductile behavior in order to avoid collapse in a design-level earthquake. Capacity design is missing in Australian standard so New Zealand standard is used instead. Plastic hinge is expected to appear in dissipative item and all non-dissipative items of the joint must be able to safely transfer forces due to the yielding in the dissipative item. The dissipative item is usually a beam in moment resisting frame but it may also be e.g. an end plate. The safety factor is not used for dissipative items. The yield strength of the dissipative item is calculated as Fy,max = 0.9 ϕos ϕomfy, where:

- ϕos – strain-hardening factor; the recommended values are ϕos = 1.15 for beam in moment resisting frame, γsh = 1.0 otherwise; editable in operation

- ϕom – overstrength factor – EN 1998-1, Cl. 6.2; the recommended value is ϕom = 1.3; editable in materials

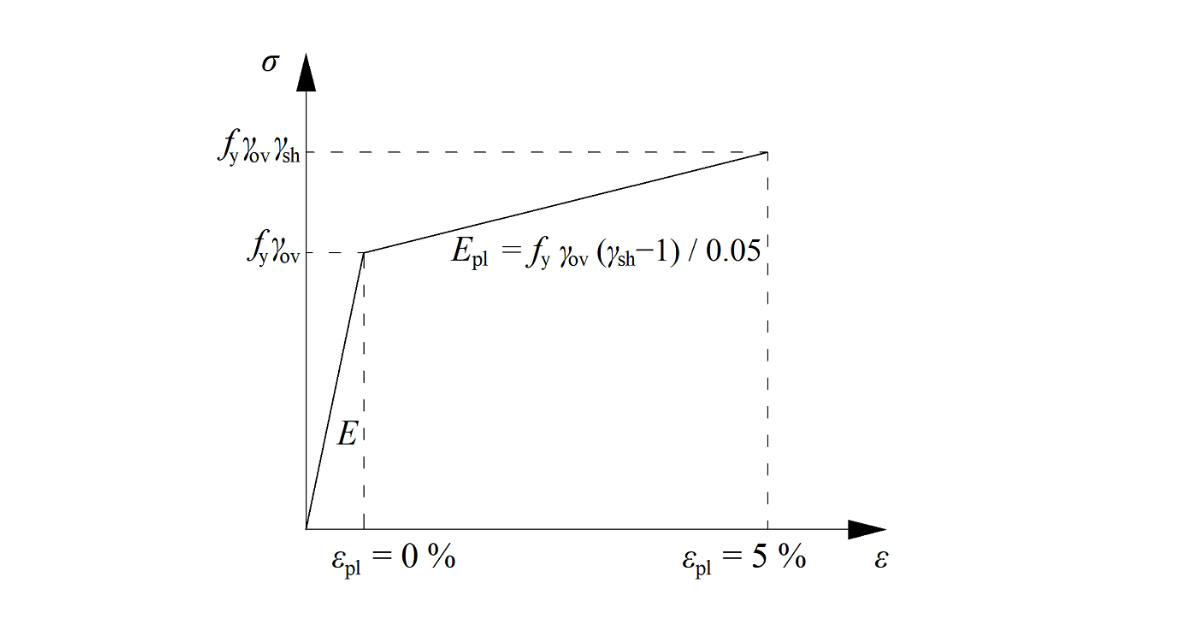

The material diagram is modified according to the following figure:

The increased strength of the dissipative item allows for the input of loads that cause the plastic hinge to appear in dissipative item. In the case of moment resisting frame and beam as the dissipative item, the beam should be loaded by My = fy,maxWpl,y and corresponding shear forceVz = –2 My / Lh, where:

- fy – characteristic yield strength

- Wpl,y – plastic section modulus

- Lh – distance between plastic hinges on the beam

In case of asymmetric joint, the beam should be loaded by both sagging and hogging bending moments and their corresponding shear forces.

The plates of dissipative items are excluded from check.