Precision pipe connections for landmark pergola in Vienna

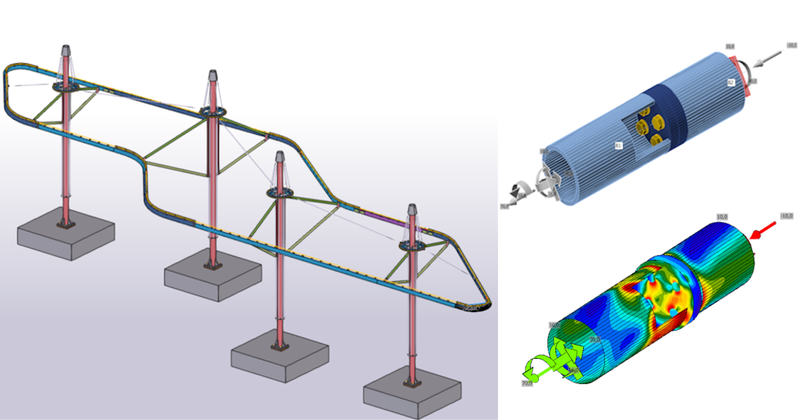

\[ \textsf{\textit{\footnotesize{Vertical section of the pergola}}}\]

About the Project

The pergola, located in Austria's capital, is a visually striking canopy supported by four 7-meter-high cantilevered columns made of CHS 193.7×14.2 hollow steel sections. These columns are moment-connected to concrete foundations and form the core vertical elements of the structure. Curved ring beams, both inner and outer, are pretensioned between the columns and stabilized with membrane shells. Additional compression diagonals link the ring beams to the columns to enhance overall stiffness and spatial stability.

The ring beams themselves are fabricated from CHS 139.7×14.2 and CHS 76.1×4 tubes in S355J0 steel. The design team was responsible for all critical joint connections between these curved and inclined elements, ensuring that structural integrity, aesthetic constraints, and installation feasibility were all carefully balanced.

Engineering Challenges

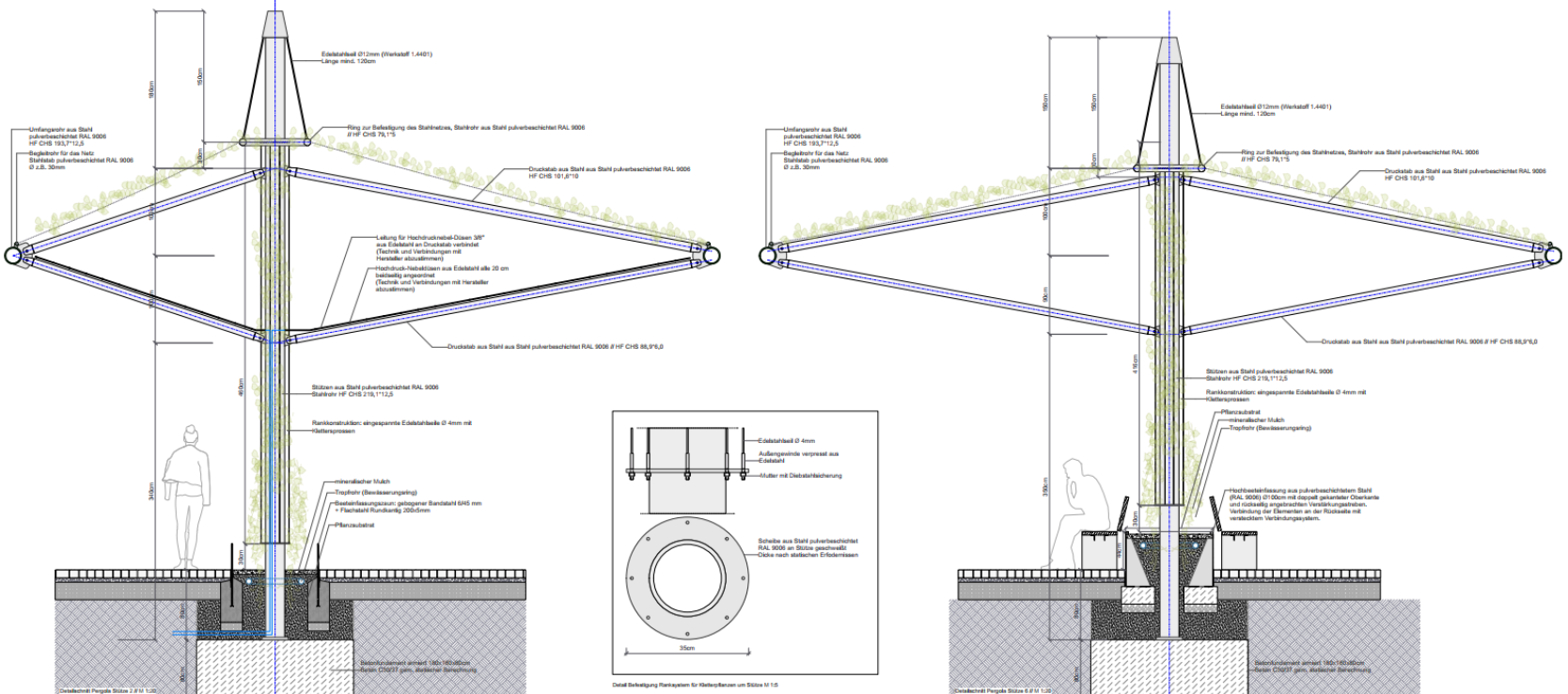

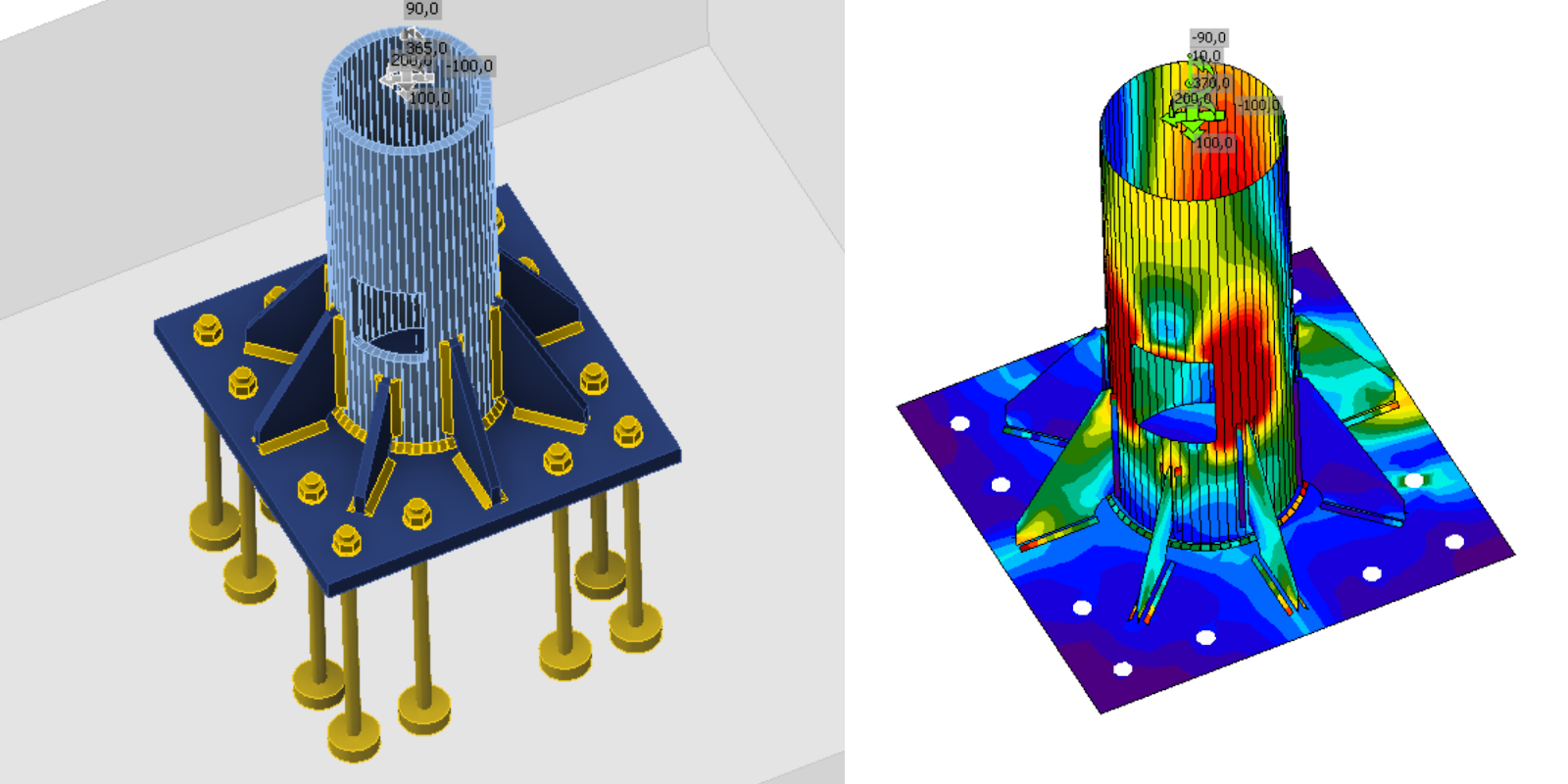

The defining challenge of the project lay in the geometry and force conditions at the connections of the tubular steel sections. Each joint had to carry a full suite of internal forces, including significant torsion, weak-axis bending, axial load, and shear, all within a visually minimal and architecturally acceptable envelope. Bolt locations had to be concealed or embedded where possible, and the use of cut-outs and openings to achieve this further complicated the load path and local plate behavior.

\[ \textsf{\textit{\footnotesize{Outer ring endplate splice with cut-out}}}\]

Hungary

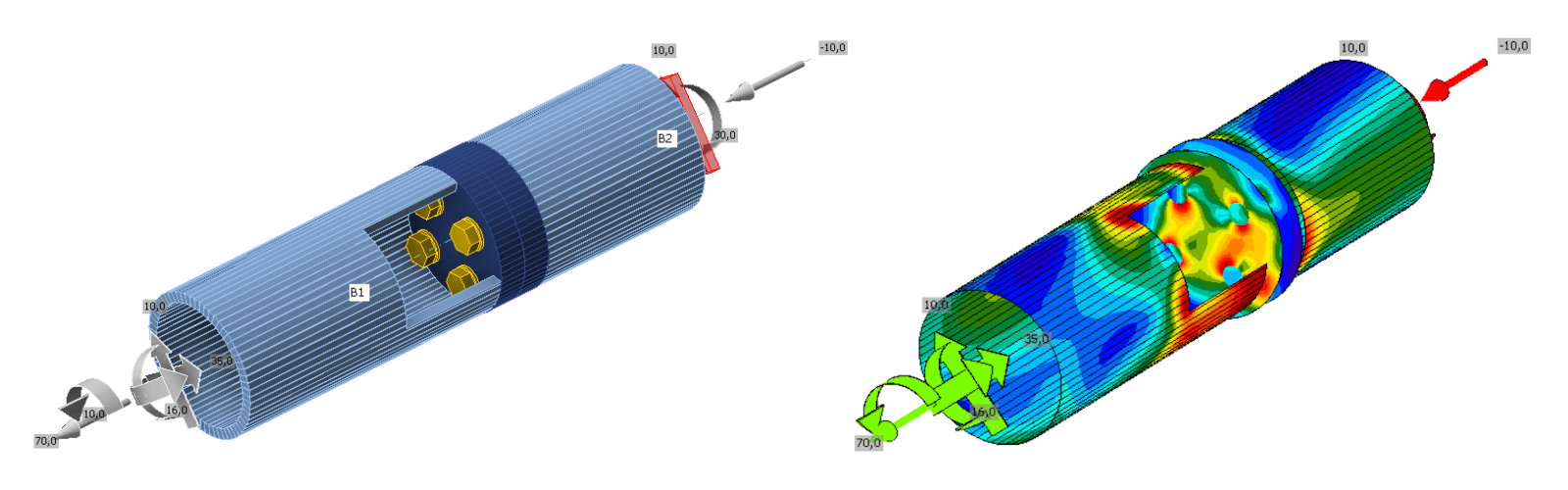

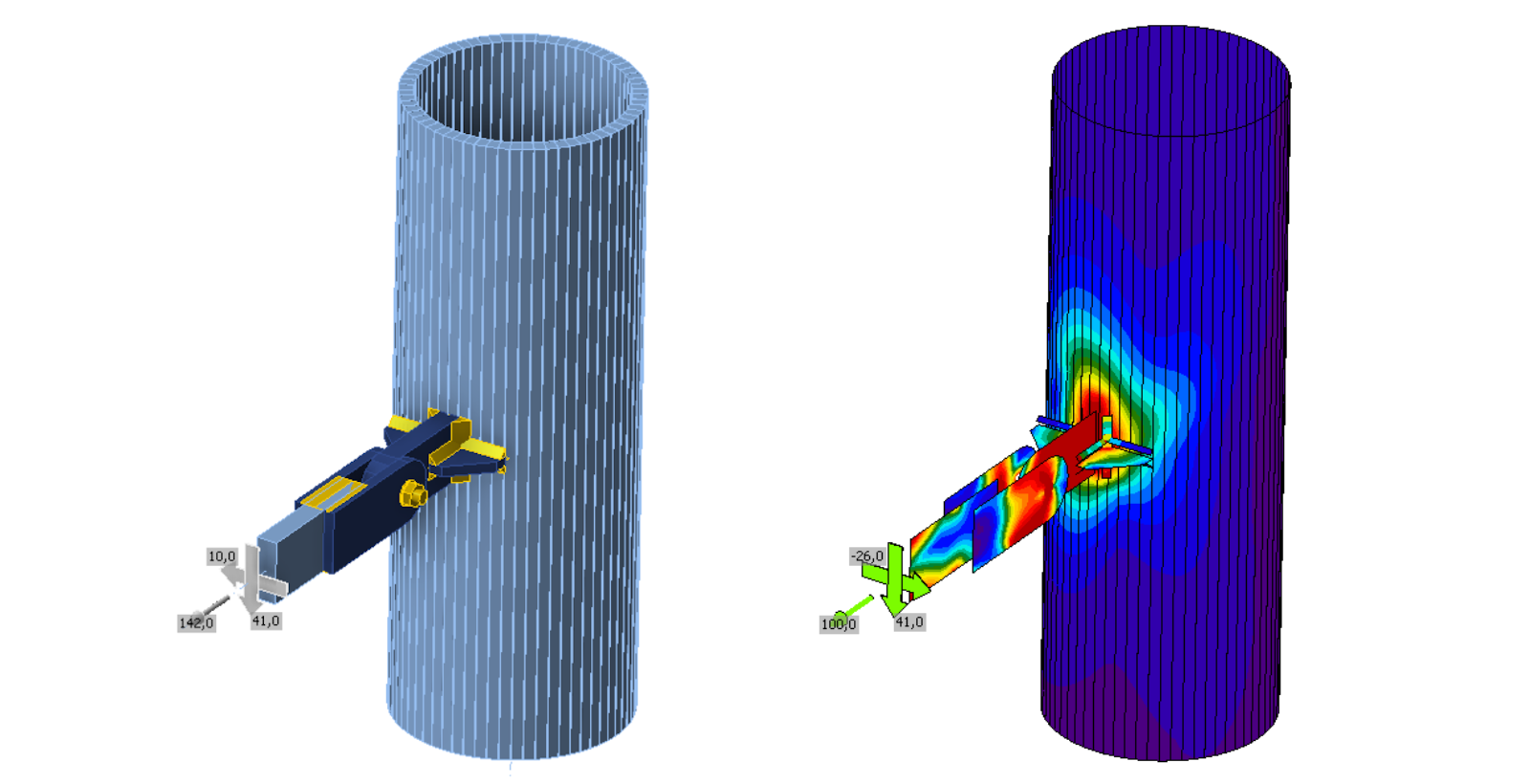

The moment-resisting base plates required detailed engineering with IDEA StatiCa Connection to manage stress concentrations from the tall cantilevered columns, especially under lateral load conditions. These base connections featured large cut-outs for concealed fixings, making traditional hand-calculation or simplified joint models impractical. The same applied to tension rod interfaces and curved ring beam splices, where eccentricity, buckling, and local stability had to be evaluated simultaneously.

\[ \textsf{\textit{\footnotesize{Base plate connection with cut-out}}}\]

Hungary

Given the number of connections and the high variability in geometry, a manual FEA approach would have been time-consuming, error-prone, and difficult to document. In addition, the client required tight turnaround times and compact, efficient joint designs, increasing pressure on the engineering team to deliver accurate and compliant solutions quickly.

Solutions and Results

IDEA StatiCa Connection enabled E-STEEL Ltd. to model each complex connection scenario, whether base plates, diagonal rods, or curved ring splices, with full fidelity. The software's ability to handle all six internal force components, including torsion and out-of-plane bending, was crucial in this project. Thanks to the component-based finite element method (CBFEM), the engineers could visualize force flow, evaluate plastic strain zones, and check local plate buckling, all within a unified environment.

Hungary

One standout application was the base plate design, which featured cut-outs and hidden bolts. With IDEA StatiCa, the engineers could explicitly model the complex contact interactions, validate bearing pressure, and determine optimal weld size and positioning, all without oversizing the connection. For the diagonal tension rods, IDEA StatiCa provided clear visualization of stress in cleats and gussets, allowing refined sizing and geometry tweaks.

\[ \textsf{\textit{\footnotesize{Tension rod connection}}}\]

The ability to iteratively adjust geometry and welds, and immediately rerun code checks, saved hours on each joint type. Weld sizes were optimized for fabrication economy, with no need for conservative overdesign. Each connection passed Eurocode compliance with full documentation, reducing risk during review and enabling the team to meet tight submission deadlines.

Measured Impact

Using IDEA StatiCa, E-STEEL Ltd. reduced connection detailing time by approximately 50% compared to their conventional FEA-based workflow. More importantly, they were able to deliver architecturally compact joints that didn’t compromise structural safety or code requirements. With at least six distinct connection types and dozens of load combinations involved, the ability to rapidly input, analyze, and document each scenario made IDEA StatiCa a core enabler of the project’s success.

Hungary

About E-STEEL Ltd

E-STEEL Ltd provides structural engineering services across all phases of design, from concept to detailed execution, for clients in Hungary and abroad. While their main focus is on industrial steel structures, they also work on reinforced concrete buildings, cladding structures, silos, mechanical supports, and residential developments.

Încercați IDEA StatiCa gratuit

OTHER CASE STUDIES