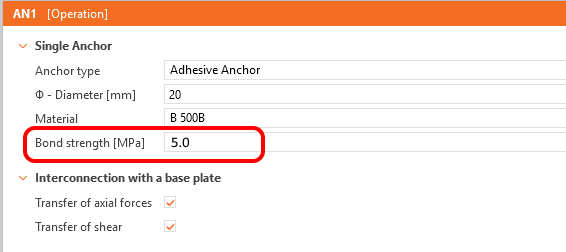

Bond strength for anchors in Detail 3D

Bond strength property of a Single anchor in Detail 3D is the design value of bond resistance of Adhesive (post-installed) anchor. It is a crucial parameter for anchoring design in Detail 3D.

In terms of EN 1992-4, we can define design bond resistence as τRd = τRk /γMp

γMp is partial safety factor defined by table 4.1 in EN 1992-4

γMp = γMc = γc ⋅ γinst

γc = 1.5

γinst - factor accounting for the sensitivity to installation of post-installed fasteners. Can be found in relevant European Technical Product Specification for the specific product.

τRk - is characteristic bond resistance of a post-installed bonded fastener. Depending on concrete strength class, and state of the concrete – cracked vs. uncracked. It can be found in certificate for injection mortar, for example ETA – European Technical Assesment.

Eurocode Example

Lets have post-installed bonded anchor made from M12 threaded bar and mortar Hilti HIT-HY 200-A V3. The hole is hammer-drilled. The anchor is installed in dry conditions into cracked C20/25 concrete. Design life is 50 years.

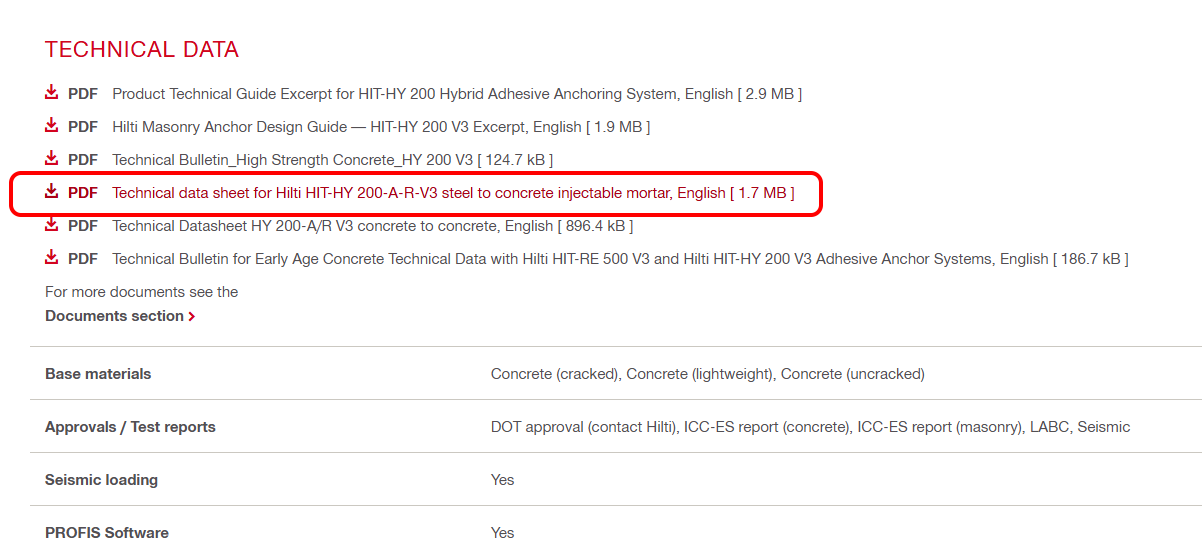

At first we need to go to HIT-HY 200-A product web page here. We are looking for ETA document. Go to Technical data section of the page and open PDF document Technical data sheet for Hilti HIT-HY 200-A-R-V3 steel to concrete injectable mortar, English.

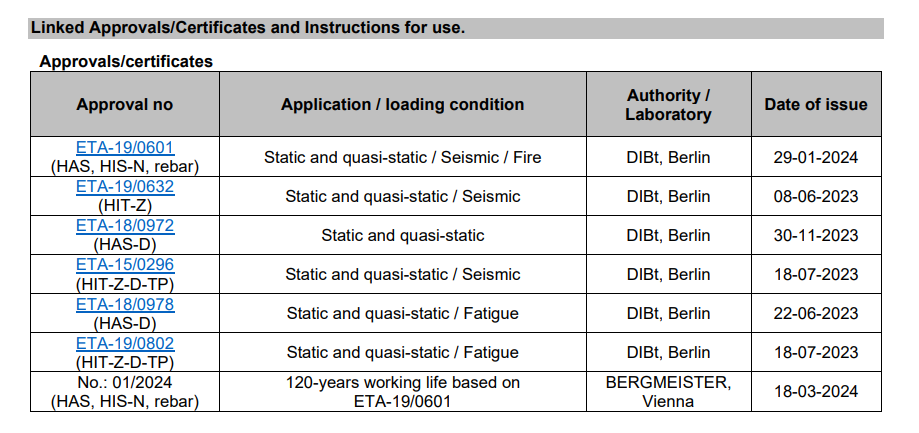

On page 3 of the document, you can find links to relevant ETA documents.

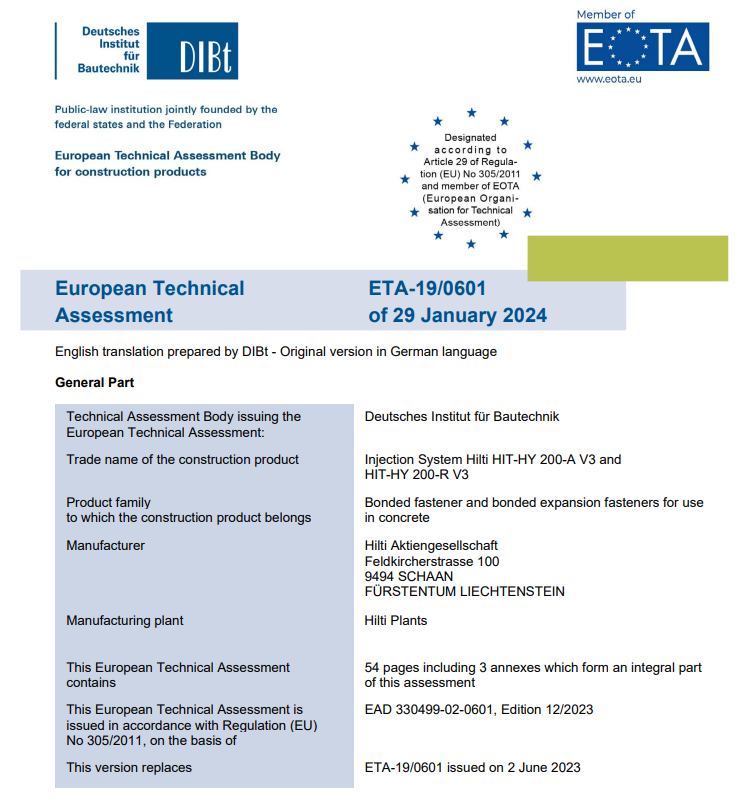

Open ETA-19/0601 linked in the first row of the table, which is relevant for us.

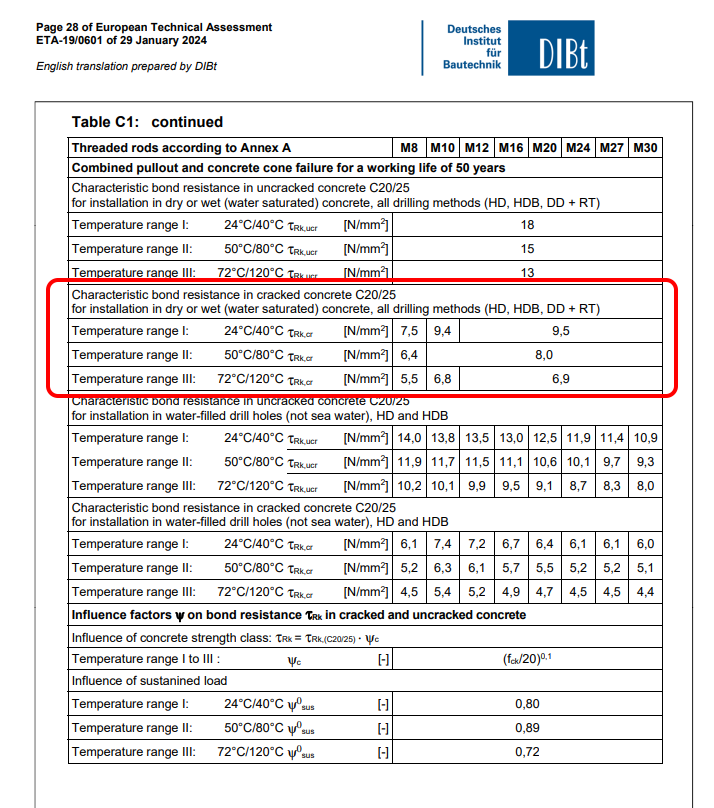

In table C1 of this document, you can find data for τRk - characteristic bond resistance. Conservatively for temperature range II, in our case τRk = 8.0 MPa.

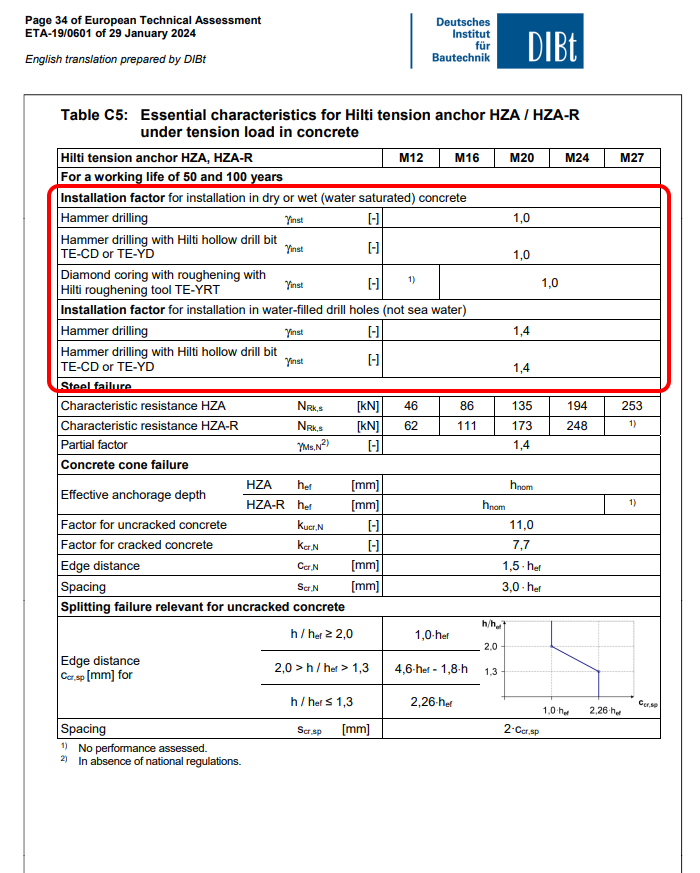

In table C1 of the document, you can also find relevant γinst values. In our case γinst = 1.0.

The final value of design bond strength is τRd = 8.0 /(1.5x1.0) = 5.3 MPa.

ACI EXAMPLE

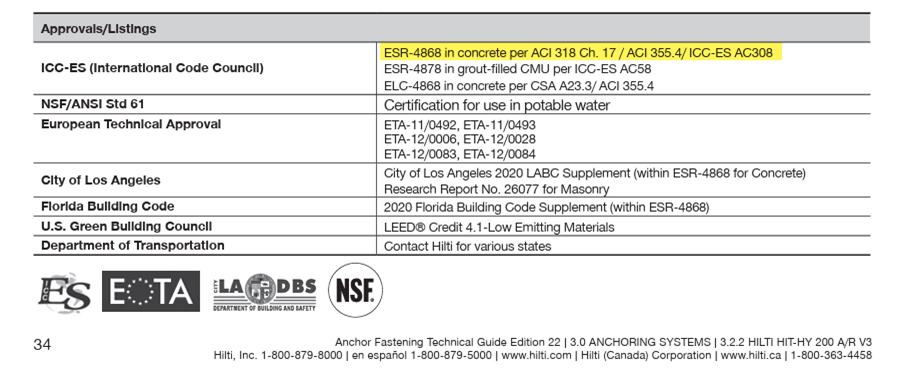

When using ACI, you can follow a similar process, for instance, Hilti HY200, go to their website. Find the product technical guide and open the PDF, The approvals are shown on the second page:

Then, we can open the selected ESR: https://icc-es.org/report-listing/esr-4868/

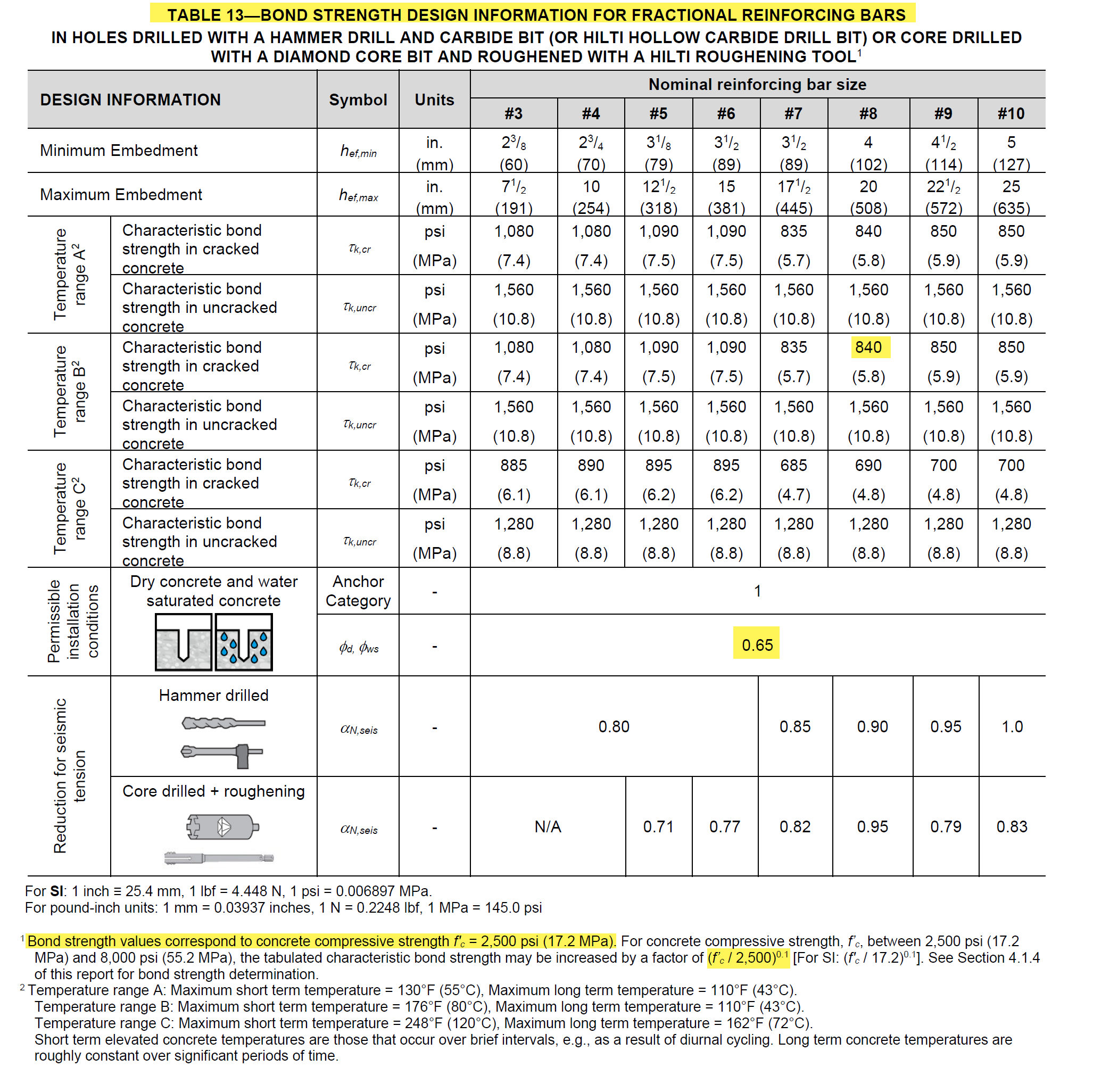

The bond strength tables are in the document. They are presented as a function of the concrete compressive strength, whether the concrete is cracked or uncracked, the concrete temperature range, and the installation conditions.

The resulting characteristic bond strength shall be multiplied by the associated strength reduction factor, and the bond strength may also be made for increased concrete compressive strength as noted in the footnotes to the bond strength tables.

Once you find the correct table, select the characteristic bond strength in cracked concrete, which is due to the principles of the Detail app, where the strength in tension is neglected.

- τRk=840 psi

- φd=0.65

- Concrete increase factor for a f'c=4000 psi= 1.0481

- IDEA StatiCa bond strength input = 0.65*1.0481*840psi= 572.26 psi

The bond strength should be input from technical data sheets; do not consider the values we have by default.