Delegated Connection Design in Industrial Steel Pipe Rack Structures

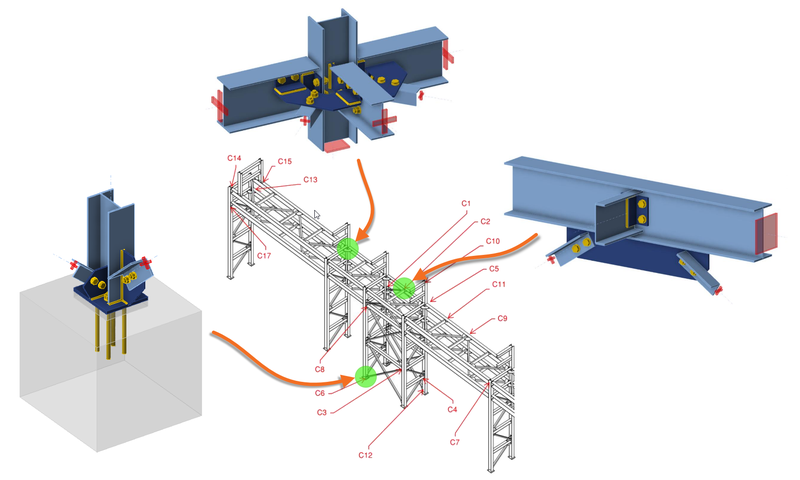

Weldment Design, founded by Corbin Collier in 2019, was contracted by St. George Steel to perform delegated connection analysis for the steel pipe rack system serving the USA Rare Earth Magnet Manufacturing Project. The industrial rack system spanned nearly 800 linear feet, rising 28 feet tall, and was designed by Hatch (EOR) with detailing by Cronus Steel Detailing.

The goal of Weldment Design was to verify that all structural reinforcement connections met AISC code requirements and were structurally adequate using a reliable and transparent validation method.

Structure and Design

- Total length: ~800 linear feet

- Height: ~28 feet

- Frame type: Typical industrial pipe rack consisting of moment frames, braced frames, and multi-bay modules

- Members: Wide-flange beams and columns supporting pipe trays and process lines

- Connection types: Predominantly shear connections, extended shear plates, stiffened plates, and re-pad configurations

- Loading: Gravity, lateral, pipe loads, and concentrated loads at tray levels

- Design basis: AISC 360 and relevant industrial design standards

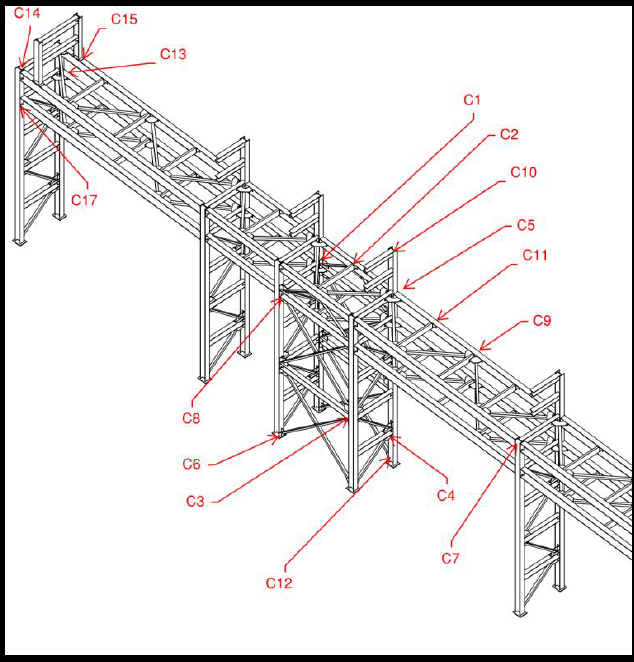

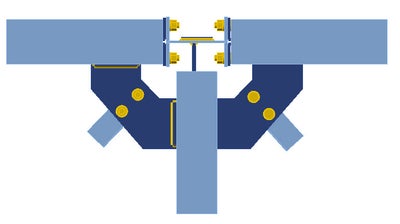

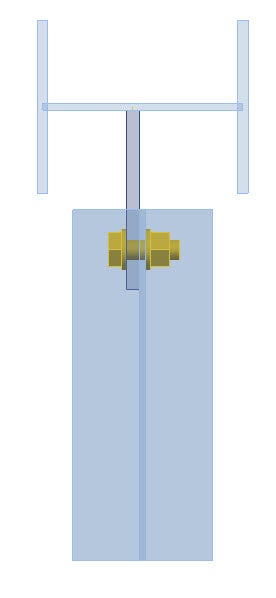

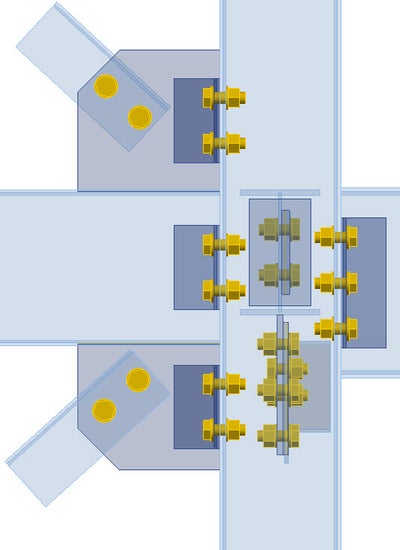

Figure 1. Connection Location (C1 to C15, C17)

Using IDEA StatiCa on the project

Weldment Design used IDEA StatiCa with the CBFEM method to perform a comprehensive connection design and verification across project phases. Corbin and his team modeled the connections using the standalone version of the software. A total of 20 different connections were designed using IDEA StatiCa's operation tools that enable modeling both standard and custom connections.

The main steel connection types were:

Geometry & Model Setup

- IFC models from the detailer enabled exact reconstruction of member geometry and connection interfaces.

- Detailed modeling captured tight clearances common in pipe racks, where trays, braces, and secondary steel converge.

- Grouped connection families were used to quickly analyze repeating details across multiple bays.

Analysis Approach

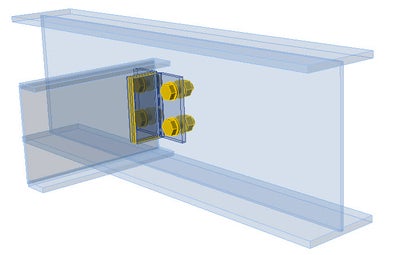

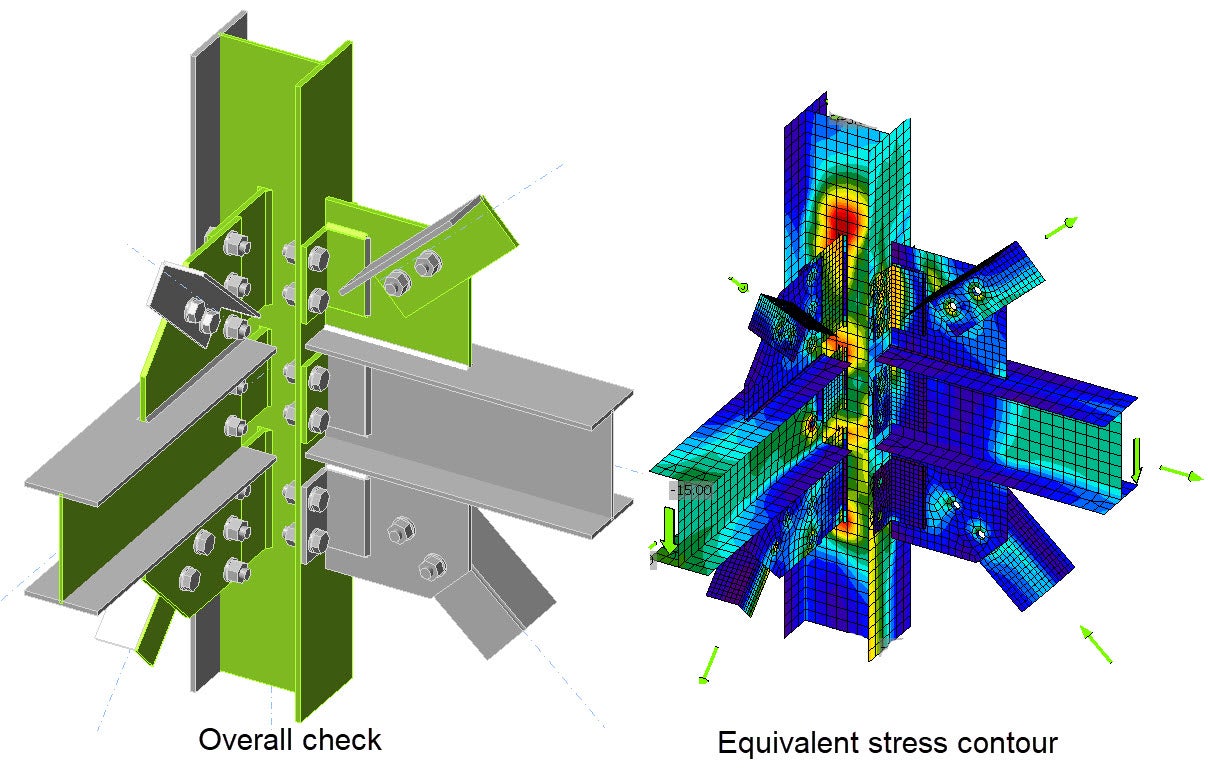

- Component-Based Finite Element Modeling (CBFEM) allowed Weldment Design to simulate real load paths in complex joints—something difficult using traditional formulas.

- Steel connection limit states were verified by IDEA StatiCa, as they are explicitly modeled while running FEA:

- Shear, bearing, and weld strength

- Block shear, net section rupture

- Column web crippling/web yielding

- Plate buckling and stiffener performance

- Load distribution through bolts, plates, and welds

Figure 2. Bi-directional vertical bracing connection. Overall check view and equivalent stresses contour in IDEA StatiCa

Design Refinement & Coordination

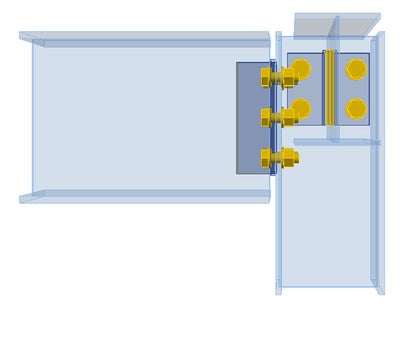

- IDEA StatiCa was used to compare extended shear plates vs. standard shear tabs, highlighting where added length or re-pads were required to meet capacity.

- The team preserved fabricator-preferred details wherever possible by iterating plate sizes, welds, and bolt patterns directly in the 3D model.

- IDEA StatiCa Viewer files were shared with the EOR and fabricator, enabling clear visual communication without needing proprietary software.

Figure 3. IDEA StatiCa online viewer showing one connection from the project

Conclusion

All connections across the ~800-ft rack were confirmed to meet AISC requirements.

Critical limit states were identified and addressed early using visual, transparent CBFEM outputs.

The entire multi-phase delegated design scope was completed in about three weeks—madepossible by:

- IFC shared files

- Connection grouping

- Visual model-based coordination

Because the analysis clearly showed where fabricator details were acceptable and where modifications were required, rework was limited and shop changes were minimal.

CBFEM visuals, force flow diagrams, and annotated 3D models helped eliminate ambiguity that typically slows industrial projects.

Result: the EOR accepted the package on first submission with no comments.

The project demonstrated how advanced modeling tools like IDEA StatiCa support efficient verification of:

- Multi-bay, repeating structures

- Heavy industrial loads

- Connections with constrained geometry

- Fast-turnaround delegated design scopes

Essayez IDEA StatiCa gratuitement

Related content